Abstract

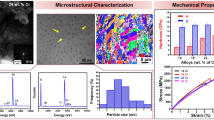

In this paper, 15Cr-ODS steels containing 0, 1 wt%, 2 wt% and 3 wt% Al element were fabricated by combining wet-milling and spark plasma sintering (SPS) methods. The microstructure and mechanical properties of ODS steel were investigated by XRD, SEM, TEM, EBSD and tensile tests. The results demonstrate that the Al addition significantly refines the particle precipitates in the Fe−Cr matrix, leading to the obvious refinement in grain size of matrix and the improvement of mechanical properties. The dispersion particles in ODS steels with Al addition are identified as Al2O3 and Y2Ti2O7 nanoparticles, which has a heterogeneous size distribution in the range of 5 nm to 300 nm. Increasing Al addition causes an obvious increase in tensile strength and a decline in elongation. The tensile strength and elongation of 15Cr-ODS steel containing 3 wt% Al are 775.3 MPa and 15.1%, respectively. The existence of Al element improves the corrosion resistance of materials. The ODS steel containing 2 wt% Al shows corrosion potential of 0.39 V and passivation current density of 2.61×10−3 A/cm2(1.37 V). This work shows that Al-doped ODS steels prepared by wet-milling and SPS methods have a potential application in structural parts for nuclear system.

摘要

本文利用湿磨和放电等离子烧结技术制备了Al 含量分别为 0, 1 wt%, 2 wt%和3 wt%的 15Cr-ODS 钢。通过XRD、 SEM、 TEM、 EBSD 和拉伸测试等对ODS 钢的显微组织结构与力学性能进行了 研究。研究结果表明, Al 元素的添加能够显著细化Fe−Cr 相基体中的析出相颗粒, 减小基体晶粒尺寸 并改善材料的力学性能。 Al 添加ODS 钢基体中尺寸为 5∼300 nm 的弥散颗粒可以被标定为 Al2O3 与 Y2Ti2O7 纳米粒子, 这些弥散颗粒的尺寸分布较为不均匀。随着 Al 元素添加量的增加, 材料的伸长率 降低, 但其抗拉强度显著的提升。 当 Al 元素添加量为3 wt%时, 15Cr3Al-ODS 钢抗拉强度与伸长率 分别为 775.3 MPa 和15.1%。 Al 元素的添加还可增强材料的耐腐蚀性能, Al 含量为 2 wt%ODS 钢的 腐蚀电位(Ecorr)与钝化电流密度(ipass)分别为0.39 V 和2.61×10−3 A/cm2 (1.37 V)。 因此, 本文使用湿磨和 放电等离子烧结方法制备的 Al 添加 ODS 钢在核能系统结构部件中能够具有良好的应用前景。

Similar content being viewed by others

References

ODETTE G R, ALINGER M J, WIRTH B D. Recent developments in irradiation-resistant steels [J]. Annual Review of Materials Research, 2008, 38(1): 471–503. DOI: https://doi.org/10.1146/annurev.matsci.38.060407.130315.

ZINKLE S J, SNEAD L L. Designing radiation resistance in materials for fusion energy [J]. Annual Review of Materials Research, 2014, 44(1): 241–267.

KIMURA A, KASADA R, IWATA N, KISHIMOTO H, ZHANG C H, ISSELIN J, DOU P, LEE J H, MUTHUKUMAR N, OKUDA T, INOUE M, UKAI S, OHNUKI S, FUJISAWA T, ABE T F. Development of Al added high-Cr ODS steels for fuel cladding of next generation nuclear systems [J]. Journal of Nuclear Materials, 2011, 417(1–3): 176–179. DOI: https://doi.org/10.1016/j.jnucmat.2010.12.300.

BISCHOFF J, MOTTA A T. Oxidation behavior of ferritic-martensitic and ODS steels in supercritical water [J]. Journal of Nuclear Materials, 2012, 424(1–3): 261–276.

DUBUISSON P, DE CARLAN Y, GARAT V, BLAT M. ODS ferritic/martensitic alloys for sodium fast reactor fuel pin cladding [J]. Journal of Nuclear Materials, 2012, 428(1–3): 6–12. DOI: https://doi.org/10.1016/j.jnucmat.2011.10.037.

ALLEN T R, CRAWFORD D C. Lead-cooled fast reactor systems and the fuels and materials challenges [J]. Science and Technology of Nuclear Installations, 2007: 097486. DOI: https://doi.org/10.1155/2007/97486.

TAKAYA S, FURUKAWA T, AOTO K, MUELLER G, WEISENBURGER A, HEINZEL A, INOUE M, OKUDA T, ABE F, OHNUKI S, FUJISAWA T, KIMURA A. Corrosion behavior of Al-alloying high Cr-ODS steels in lead-bismuth eutectic [J]. Journal of Nuclear Materials, 2009, 386–388: 507–510. DOI: https://doi.org/10.1016/j.jnucmat.2008.12.155.

ISSELIN J, KASADA R, KIMURA A. Corrosion behaviour of 16%Cr−4%Al and 16%Cr ODS ferritic steels under different metallurgical conditions in a supercritical water environment [J]. Corrosion Science, 2010, 52(10): 3266–3270. DOI: https://doi.org/10.1016/j.corsci.2010.05.043.

KLIMIANKOU M, LINDAU R, MÖSLANG A, SCHRÖDER J. TEM study of PM 2000 steel [J]. Powder Metallurgy, 2013, 48(3): 277–287. DOI: https://doi.org/10.1179/174329005x64171.

MEDRAJ M, HAMMOND R, PARVEZ M A, DREW R A L, THOMPSON W T. High temperature neutron diffraction study of the Al2O3−Y2O3 system [J]. Journal of the European Ceramic Society, 2006, 26(16): 3515–3524. DOI: https://doi.org/10.1016/j.jeurceramsoc.2005.12.008.

DOU P, KIMURA A, OKUDA T, INOUE M, UKAI S, OHNUKI S, FUJISAWA T, ABE F. Polymorphic and coherency transition of Y-Al complex oxide particles with extrusion temperature in an Al-alloyed high-Cr oxide dispersion strengthened ferritic steel [J]. Acta Materialia, 2011, 59(3): 992–1002. DOI: https://doi.org/10.1016/j.actamat.2010.10.026.

HSIUNG L L, FLUSS M J, TUMEY S J, CHOI B W, SERRUYS Y, WILLAIME F, KIMURA A. Formation mechanism and the role of nanoparticles in Fe−Cr ODS steels developed for radiation tolerance [J]. Physical Review B, 2010, 82(18): 184103. DOI: https://doi.org/10.1103/PhysRevB.82.184103.

KASADA R, TODA N, YUTANI K, CHO H S, KISHIMOTO H, KIMURA A. Pre- and post-deformation microstructures of oxide dispersion strengthened ferritic steels [J]. Journal of Nuclear Materials, 2007, 367: 222–228. DOI: https://doi.org/10.1016/j.jnucmat.2007.03.141.

ZHANG C H, KIMURA A, KASADA R, JANG J, KISHIMOTO H, YANG Y T. Characterization of the oxide particles in Al-added high-Cr ODS ferritic steels [J]. Journal of Nuclear Materials, 2011, 417(1–3): 221–224.

CZYRSKA-FILEMONOWICZ A, DUBIEL B. Mechanically alloyed, ferritic oxide dispersion strengthened alloys: Structure and properties [J]. Journal of Materials Processing Technology, 1997, 64(1): 53–64.

MILLER M K, HOELZER D T, KENIK E A, RUSSELL K F. Stability of ferritic MA/ODS alloys at high temperatures [J]. Intermetallics, 2005, 13(3, 4): 387–392. https://doi.org/10.1016/j.intermet.2004.07.036.

DONG H, YU L, LIU Y, LIU C, LI H, WU J. Effect of hafnium addition on the microstructure and tensile properties of aluminum added high-Cr ODS steels [J]. Journal of Alloys and Compounds, 2017, 702: 538–545. DOI: https://doi.org/10.1016/j.jallcom.2017.01.298.

XIE R, LU Z, LU C, LI Z, DING X, LIU C. Microstructures and mechanical properties of 9Cr oxide dispersion strengthened steel produced by spark plasma sintering [J]. Fusion Engineering and Design, 2017, 115: 67–73.

ZHAO Q, QIAO Z, LIU Y, YU L, HUANG Y, GUO Q, LI H. Characterization of 14Cr ODS steel fabricated by spark plasma sintering [J]. Metals, 2019, 9(2): 200. DOI: https://doi.org/10.3390/met9020200.

HUANG S G, LI L, VANMEENSEL K, van der BIEST O, VLEUGELS J. VC, Cr3C2 and NbC doped WC-Co cemented carbides prepared by pulsed electric current sintering [J]. International Journal of Refractory Metals and Hard Materials, 2007, 25(5, 6): 417–422.

ZHANG Qian-kun, JIANG Yao, SHEN Wei-jun, ZHANG Hui-bin, HE Yue-hui, LIN Nan, LIU C T, HUANG Han, HUANG Xiao-lin. Direct fabrication of high-performance high speed steel products enhanced by LaB6 [J]. Materials & Design, 2016, 112: 469–478.

ZHAO L, LIN N, HE Y. Improvement in microstructure and properties of Ti(C,N)-based cermets with ruthenium additions [J]. Ceramics International, 2018, 44(14): 17553–17561. DOI: https://doi.org/10.1016/j.ceramint.2018.06.156.

HE P, KLIMENKOV M, LINDAU R, MOSLANG A. Characterization of precipitates in nano structured 14% Cr ODS alloys for fusion application [J]. Journal of Nuclear Materials, 2012, 428(1–3): 131–138.

ZHANG G, ZHOU Z, MO K, WANG P, MIAO Y, LI S, WANG M, LIU X, GONG M, ALMER J, STUBBINS J F. The microstructure and mechanical properties of Al-containing 9Cr ODS ferritic alloy [J]. Journal of Alloys and Compounds, 2015, 648: 223–228. DOI: 10.1016/j.jallcom.2015.06.214.

KUMAR P K, SAI N V, KRISHNA A G, RENGANATHAN N G. Fabrication and micro-structural evaluation of ODS austenitic stainless steels through mechanical alloying [J]. Materials Today: Proceedings, 2020, 23: 465–468. DOI: https://doi.org/10.1016/j.matpr.2019.04.207.

MIHALACHE V, MERCIONIU I, VELEA A, PALADE P. Effect of the process control agent in the ball-milled powders and SPS-consolidation temperature on the grain refinement, density and Vickers hardness of Fe14Cr ODS ferritic alloys [J]. Powder Technology, 2019, 347: 103–113. DOI: https://doi.org/10.1016/j.powtec.2019.02.006.

BHATTACHARYYA D, DICKERSON P, ODETTE G R, MALOY S A, MISRA A, NASTASI M A. On the structure and chemistry of complex oxide nanofeatures in nanostructured ferritic alloy U14YWT [J]. Philosophical Magazine, 2012, 92(16): 2089–2107.

RAO K R, SINHA S K. Effect of sintering temperature on microstructural and mechanical properties of SPS processed CoCrCuFeNi based ODS high entropy alloy [J]. Materials Chemistry and Physics, 2020, 256: Article 123709.

LU C, LU Z, XIE R, LIU C, WANG L. Microstructure of a 14Cr-ODS ferritic steel before and after helium ion implantation [J]. Journal of Nuclear Materials, 2014, 455(1–3): 366–370. DOI: https://doi.org/10.1016/j.jnucmat.2014.06.065.

KLIMENKOV M, MÖSLANG A, LINDAU R. EELS analysis of complex precipitates in PM 2000 steel [J]. The European Physical Journal Applied Physics, 2008, 42(3): 293–303.

LIU T, WANG L, WANG C, SHEN H, ZHANG H. Feasibility of using Y2Ti2O7 nanoparticles to fabricate high strength oxide dispersion strengthened Fe−Cr−Al steels [J]. Materials & Design, 2015, 88: 862–870.

CASAS C, TEJEDOR R, RODRÍGUEZ-BARACALDO R, BENITO J A, CABRERA J M. The effect of oxide particles on the strength and ductility of bulk iron with a bimodal grain size distribution [J]. Materials Science and Engineering A, 2015, 627: 205–216.

KLUEH R L, SHINGLEDECKER J P, SWINDEMAN R W, HOELZER D T. Oxide dispersion-strengthened steels: A comparison of some commercial and experimental alloys [J]. Journal of Nuclear Materials, 2005, 341(2, 3): 103–114. DOI: https://doi.org/10.1016/j.jnucmat.2005.01.017.

ZHANG Z, CHEN D. Consideration of Orowan strengthening effect in particulate-reinforced metal matrix nanocomposites: A model for predicting their yield strength [J]. Scripta Materialia, 2006, 54(7): 1321–1326.

HALL E O. The deformation and ageing of mild steel: III Discussion of results [J]. Proceedings of the Physical Society. Section B, 1951, 64(9): 747–753. DOI: https://doi.org/10.1088/0370-1301/64/9/303.

NINGSHEN S, SAKAIRI M, SUZUKI K, UKAI S. The surface characterization and corrosion resistance of 11% Cr ferritic/martensitic and 9–15% Cr ODS steels for nuclear fuel reprocessing application [J]. Journal of Solid State Electrochemistry, 2013, 18(2): 411–425. DOI: https://doi.org/10.1007/s10008-013-2165-5.

NINGSHEN S, SAKAIRI M, SUZUKI K, UKAI S. Corrosion resistance of 9% Cr oxide dispersion-strengthened steel in different electrolytic media [J]. Corrosion, 2013, 69(9): 863–874.

PRIYA R, NINGSHEN S, SAKAIRI M, UKAI S. Corrosion behaviour of Al-containing high Cr ferritic oxide dispersion strengthened steel in nitric acid environment [J]. Journal of Nuclear Materials, 2020, 534. DOI: https://doi.org/10.1016/j.jnucmat.2020.152120.

ZHAO H, LIU T, BAI Z, WANG L, GAO W, ZHANG L. Corrosion behavior of 14Cr ODS steel in supercritical water: The influence of substituting Y2O3 with Y2Ti2O7 nanoparticles [J]. Corrosion Science, 2020, 163. DOI: https://doi.org/10.1016/j.corsci.2019.108272.

NAGINI M, JYOTHIRMAYI A, VIJAY R, RAO T N, REDDY A V, RAJULAPATI K V, SUNDARARAJAN G. Influence of dispersoids on corrosion behavior of oxide dispersion-strengthened 18cr steels made by high-energy milling [J]. Journal of Materials Engineering Performance, 2016, 25(2): 577–586. DOI: https://doi.org/10.1007/s11665-015-1859-5.

Author information

Authors and Affiliations

Contributions

SUN Yu-zhou wrote the first draft of the manuscript. LIN Nan and MA Chao provided the concept and edited the draft of manuscript. SUN Yu-zhou, LI Zhong-tao, HAN Xian-qi, WU Zheng-gang and WANG Zu-yong prepared the materials and measured the properties of materials. MA Chao, ZHANG Wu-jun and ZHANG Yong-sen carried out TEM experiments. SUN Yu-zhou analyzed the measured data.

Corresponding author

Additional information

Conflict of interest

SUN Yu-zhou, LIN Nan, ZHANG Wu-jun, ZHANG Yong-sen, LI Zhong-tao, HAN Xian-qi, WU Zheng-gang, WANG Zu-yong and MA Chao declare that they have no conflict of interest.

Foundation item: Project(2020JJ2001) supported by Outstanding Youth Scientist Foundation of Hunan Province, China; Project(6142912200102) supported by Foundation for National Key Laboratory of Science and Technology on High-strength Structural Materials, China

Rights and permissions

About this article

Cite this article

Sun, Yz., Lin, N., Zhang, Wj. et al. Microstructure and properties of Al-doped ODS steels prepared by wet-milling and SPS methods. J. Cent. South Univ. 28, 1219–1232 (2021). https://doi.org/10.1007/s11771-021-4691-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4691-0

Key words

- wet-milling

- spark plasma sintering

- ODS steels

- oxide nanoparticles

- microstructure

- tensile strength

- dispersion strengthening