Abstract

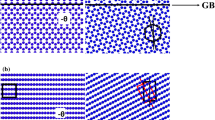

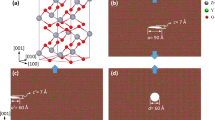

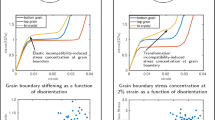

The effects of tensile temperatures ranging from 100 K to 900 K on the phase transition of hexagonal close-packed (HCP) zirconium were investigated by molecular dynamics simulations, which were combined with experimental observation under high resolution transmission electron microscopy. The results show that externally applied loading first induced the HCP to body-centered cubic (BCC) phase transition in the Pitsch-Schrader (PS) orientation relationship (OR). Then, the face-centered cubic (FCC) structure transformed from the BCC phase in the Bain path. However, the HCP-to-BCC transition was incomplete at 100 K and 300 K, resulting in a prismatic-type OR between the FCC and original HCP phase. Additionally, at the temperature ranging from 100 K to 600 K, the inverse BCC-to-HCP transition occurred locally following other variants of the PS OR, resulting in a basal-type relation between the newly generated HCP and FCC phases. A higher tensile temperature promoted the amount of FCC phase transforming into the BCC phase when the strain exceeded 45%. Besides, the crystal stretched at lower temperatures exhibits relatively higher strength but by the compromise of plasticity. This study reveals the deformation mechanisms in HCP-Zr at different temperatures, which may provide a better understanding of the deformation mechanism of zirconium alloys under different application environments.

摘要

本文采用分子动力学模拟方法研究了不同拉伸温度(100~900 K)对密排六方结构(HCP)的锆单晶 相变的影响,并将模拟结果与实验观察中高分辨率透射电子显微图片相结合。结果表明:外加载荷会 诱发沿Pitsch-Schrader(PS)的位向关系(OR)的HCP 到体心立方结构(BCC)的相变,随后,BCC 相沿贝 茵路径(Bain path)转化为FCC 相。在100 K 和300 K 温度下,HCP-BCC 的相变不完全,导致FCC 和 原始HCP 相之间呈柱面型关系;当温度在100~600 K 时,会发生局部的BCC-HCP 逆相变,其位向关 系符合PS 关系的其他变体形式,从而导致新生成的HCP 和FCC 相呈基面型关系。当应变高于45% 时,较高的拉伸温度能够促进FCC 相向BCC 相的转变。另外,在较低的拉伸温度下,晶体表现出较 高的强度但塑性有所降低。本研究揭示了HCP-Zr 在不同温度下的变形机理,为进一步了解锆合金在 不同应用环境下的变形规律提供了依据。

Similar content being viewed by others

References

BANERJEE S. Encyclopedia of materials: Science and technology [M]. Oxford: Elsevier, 2001: 6287–6299. DOI: https://doi.org/10.1016/b0-08-043152-6/01117-7.

ROBERTSON J A L. Zirconium-an international nuclear material [J]. Journal of Nuclear Materials, 1981, 100(1–3): 108–118. DOI: https://doi.org/10.1016/0022-3115(81)90525-0.

JAYARAMAN A, KLEMENT W, KENNEDY G C. Solid-solid transitions in titanium and zirconium at high pressures [J]. Physical Review, 1963, 131(2): 644–649. DOI: https://doi.org/10.1103/PhysRev.131.644.

XIA H, DUCLOS S J, RUOFF A L, VOHRA Y K. New high-pressure phase transition in zirconium metal [J]. Physical Review Letters, 1990, 64(2): 204–207. DOI: https://doi.org/10.1103/PhysRevLett.64.204.

ZONG H X, LOOKMAN T, DING X D, NISOLI C, BROWM D, NIEZGODA S R, SUN J. The kinetics of the a to a phase transformation in Zr, Ti: Analysis of data from shock-recovered samples and atomistic simulations [J]. Acta Materialia, 2014, 77: 191–199. DOI: https://doi.org/10.1016/j.actamat.2014.05.049.

WENK H R, KAERCHER P, KANITPANYACHAROEN W, ZEPEDA-ALARCON E, WANG Y. Orientation relations during the α-ω phase transition of zirconium: In situ texture observations at high pressure and temperature [J]. Physical Review Letters, 2013, 111(19): 195701. DOI: https://doi.org/10.1103/physrevlett.111.195701.

RIGG P A, GREEFF C W, KNUDSON M D, GRAY G T, HIXSON R S. Influence of impurities on the α to ω phase transition in zirconium under dynamic loading conditions [J]. Journal of Applied Physics, 2010, 106(12): 123532. DOI: https://doi.org/10.1063/1.3267325.

CERRETA E, GRAY G T III, HIXSON R S, RIGG P A, BROWN W. The influence of interstitial oxygen and peak pressure on the shock loading behavior of zirconium [J]. Acta Materialia, 2005, 53(6): 1751–1758. DOI: https://doi.org/10.1016/j.actamat.2004.12.024.

LI Sheng-ci, KANG Yong-lin, ZHU Guo-ming, KUANG Shuang. Austenite formation during intercritical annealing in C-Mn cold-rolled dual phase steel [J]. Journal of Central South University, 2015, 22: 1203–1211. DOI: https://doi.org/10.1007/s11771-015-2634-3.

ZHAO H L, NI S, SONG M, XIONG X, LIAO X P, LI H Z. Grain refinement via formation and subdivision of microbands and thin laths structures in cold-rolled hafnium [J]. Materials Science and Engineering A, 2015, 645: 328–332. DOI: https://doi.org/10.1016/j.msea.2015.08.019.

ZHAO H L, SONG M, NI S, SHAO S, WANG J, LIAO X Z. Atomic-scale understanding of stress-induced phase transformation in cold-rolled Hf [J]. Acta Materialia, 2017, 131: 271–279. DOI: https://doi.org/10.1016/j.actamat.2017.03.058.

ZHAO H L, HU X Y, SONG M, NI S. Mechanisms for deformation induced hexagonal close-packed structure to face-centered cubic structure transformation in zirconium [J]. Scripta Materialia, 2017, 132: 63–67. DOI: https://doi.org/10.1016/j.scriptamat.2017.01.034.

HU X Y, ZHAO H L, NI S, SONG M. Grain refinement and phase transition of commercial pure zirconium processed by cold rolling [J]. Materials Characterization, 2017, 129: 149–155. DOI: https://doi.org/10.1016/j.matchar.2017.04.037.

ZHENG X D, GONG M Y, XIONG T, GE H L, YANG L X, ZHOU Y T, ZHENG S J, WANG J, MA X L. Deformation induced FCC lamellae and their interaction in commercial pure Ti [J]. Scripta Materialia, 2019, 162: 326–330. DOI: https://doi.org/10.1016/j.scriptamat.2018.11.037

HONG D H, LEE T W, LIM S H, KIM W Y, HWANG S K. Stress-induced hexagonal close-packed to face-centered cubic phase transformation in commercial-purity titanium under cryogenic plane-strain compression [J]. Scripta Materialia, 2013, 69(5): 405–408. DOI: https://doi.org/10.1016/j.scriptamat.2013.05.038.

WU H C, KUMAR A, WANG J, BI X F, TOMÉ C N, ZHANG Z, MAO S X. Rolling-induced face centered cubic titanium in hexagonal close packed titanium at room temperature [J]. Scientific Reports, 2016, 6: 24370. DOI: https://doi.org/10.1038/srep24370.

YANG J X, ZHAO H L, GONG H R, SONG M, REN Q Q. Proposed mechanism of HCP→FCC phase transition in titianium through first principles calculation and experiments [J]. Scientific Reports, 2018, 8(1): 1–9. DOI: https://doi.org/10.1038/s41598-018-20257-9.

JING R, LIU C Y, MA M Z, LIU R P. Microstructural evolution and formation mechanism of FCC titanium during heat treatment processing [J]. Journal of Alloys and Compounds, 2013, 552: 202–207. DOI: https://doi.org/10.1016/j.jallcom.2012.10.083.

JING R, LIANG S X, LIU C Y, MA M Z, LIU R P. Aging effects on the microstructures and mechanical properties of the Ti-20Zr-6.5Al-4V alloy [J]. Materials Science and Engineering A, 2013, 559: 474–479. DOI: https://doi.org/10.1016/j.msea.2012.08.128.

KOIZUMI Y, FUJITA T, MINAMINO Y, HATA S. Effects of plastic deformation on lamellar structure formation in Ti-39 at.% Al single crystals [J]. Acta Materialia, 2010, 58(3): 1104–1115. DOI: https://doi.org/10.1016/j.actamat.2009.10.027.

ZHENG G P, WANG Y M, LI M. Atomistic simulation studies on deformation mechanism of nanocrystalline cobalt [J]. Acta Materialia, 2005, 53(14): 3893–3901. DOI: https://doi.org/10.1016/j.actamat.2005.04.038.

WAITZ T, KARNTHALER H P. The FCC to HCP martensitic phase transformation in CoNi studied by TEM and AFM methods [J]. Acta Materialia, 1997, 45(2): 837–847. DOI: https://doi.org/10.1016/S1359-6454(96)00184-X.

LIU Y N, YANG H, TAN G, MIYAZAKI S, JIANG B H, LIU Y. Stress-induced FCC↔HCP martensitic transformation in CoNi [J]. Journal of Alloys & Compounds, 2004, 368(1, 2): 157–163. DOI: https://doi.org/10.1016/j.jallcom.2003.07.015.

ZHENG H, WANG J, HUANG J Y, WANG J B, ZHANG Z, MAO S X. Dynamic process of phase transition from wurtzite to zinc blende structure in InAs nanowires [J]. Nano Letters, 2013, 13(12): 6023–6027. DOI: https://doi.org/10.1021/nl403240r.

KASCHNER G C, TOMÉ C N, BEYERLEIN I J, VOGEL S C, BROWN D W, MCCABE R J. Role of twinning in the hardening response of zirconium during temperature reloads [J]. Acta Materialia, 2006, 54(11): 2887–2896. DOI: https://doi.org/10.1016/j.actamat.2006.02.036.

KNEZEVIC M, ZECEVIC M, BEYERLEIN I J, BINGERT J F, MCCABE R J. Strain rate and temperature effects on the selection of primary and secondary slip and twinning systems in HCP Zr [J]. Acta Materialia, 2015, 88: 55–73. DOI: https://doi.org/10.1016/j.actamat.2015.01.037.

YOO M H. Slip, twinning, and fracture in hexagonal close-packed metals [J]. Metallurgical Transactions A, 1981, 12(3): 409–418. DOI: https://doi.org/10.1007/BF02648537.

KADAU K, LOMDAHL P S, HOLIAN B L, GERMANN T C, KADAU D, ENTEL P, WESTERHOFF F. Molecular-dynamics study of mechanical deformation in nano-crystalline aluminum [J]. Metallurgical and Materials Transactions A, 2004, 35(9): 2719–2723. DOI: https://doi.org/10.1007/s11661-004-0217-2.

XU S, GUO Y F, NGAN A H W. A molecular dynamics study on the orientation, size, and dislocation confinement effects on the plastic deformation of Al nanopillars [J]. International Journal of Plasticity, 2013, 43: 116–127. DOI: https://doi.org/10.1016/j.ijplas.2012.11.002.

OU X Q, SONG M. Deformation mechanisms of mechanically induced phase transformations in iron [J], Computational Materials Science, 2019, 162: 12–20. DOI: https://doi.org/10.1016/j.commatsci.2019.02.028.

ZU Q, GUO Y F, YAO X. Surface and orientation effects on stress-induced hcp-fcc phase transformation in Ti nanopillars [J]. Applied Surface Science, 2020, 509: 145234. DOI: https://doi.org/10.1016/j.apsusc.2019.145234.

RAWAT S, MITRA N. Molecular dynamics investigation of c-axis deformation of single crystal Ti under uniaxial stress conditions: Evolution of compression twinning and dislocations [J]. Computational Materials Science, 2018, 141: 19–29. DOI: https://doi.org/10.1016/j.commatsci.2017.09.015.

GONG Y D, ZHONG Z X, ZHOU Y G, SUN Y. Research on the nanometric machining of a single crystal nickel via molecular dynamics simulation [J]. Science China Technological Science, 2016(12): 47–56. DOI: https://doi.org/10.1007/s11431-016-0251-y.

SUN B, OUYANG W, REN J J, MIN L W, GUO W. FCC→BCC→HCP successive phase transformations in the strained ultrathin copper film: A molecular dynamic simulation study [J]. Materials Chemistry and Physics, 2019, 223: 171–182. DOI: https://doi.org/10.1016/j.matchemphys.2018.09.045.

TANG F, JIAN Z, XIAO S, LI X, HU W. Molecular dynamics simulation of cylindrically converging shock response in single crystal Cu [J]. Computational Materials Science, 2020, 183: 109845. DOI: https://doi.org/10.1016/j.commatsci.2020.109845.

REN J Q, SUN Q Y, XIAO L, DING X D, SUN J. Phase transformation behavior in titanium single-crystal nanopillars under [0001] orientation tension: A molecular dynamics simulation [J]. Computational Materials Science, 2014, 92: 8–12. DOI: https://doi.org/10.1016/j.commatsci.2014.05.018.

ISLAM Z, HAQUE A. Strain induced phase transformation in zirconium thin films [J]. Computational Materials Science, 2018, 143: 425–430. DOI: https://doi.org/10.1016/j.commatsci.2017.11.032.

MENDELEV M I, ACKLAND G J. Development of an interatomic potential for the simulation of phase transformations in zirconium [J]. Philosophical Magazine Letters, 2017, 87(5): 349–359. DOI: https://doi.org/10.1080/09500830701191393.

DOLGUSHEVA E B, TRUBITSIN V Y. Study of size effects in structural transformations of BCC Zr films by molecular-dynamics simulation [J]. Computational Materials Science, 2014, 84: 23–30. DOI: https://doi.org/10.1016/j.commatsci.2013.11.051.

LI S Z, DING X D, LI Ju, REN X B, SUN J, MA E, LOOKMAN T. Inverse martensitic transformation in Zr nanowires [J]. Physical Review B, 2010, 81(24): 27–39. DOI: https://doi.org/10.1103/PhysRevB.81.245433.

STUKOWSKI A. Structure identification methods for atomistic simulations of crystalline materials [J]. Modelling and Simulation in Materials Science and Engineering, 2012, 20(4): 045021. DOI: https://doi.org/10.1088/0965-0393/20/4/045021.

STUKOWSKI A. Visualization and analysis of atomistic simulation data with OVITO—the open visualization tool [J]. Modelling and Simulation in Materials Science and Engineering, 2009, 18(1): 015012. DOI: https://doi.org/10.1088/0965-0393/18/1/015012.

PLIMPTON S. Fast parallel algorithms for short-range molecular dynamics [J]. Journal of Computational Physics, 1995, 117(1): 1–19. DOI: https://doi.org/10.1006/jcph.1995.1039.

ZHANG H, OU X Q, WEI B Q, NI S, SONG M. Strain direction dependency of deformation mechanisms in an HCP-Ti crystalline by molecular dynamics simulations [J]. Computational Materials Science, 2020, 172: 109328. DOI: https://doi.org/10.1016/j.commatsci.2019.109328.

ACKERMANN O R J, GARG S P, RAUH E G. High-temperature phase diagram for the system Zr [J]. Journal of the American Ceramic Society, 1977, 60(7, 8): 341–345. DOI: https://doi.org/10.1111/j.1151-2916.1977.tb15557.x.

ZHANG J Z, ZHAO Y S, PANTEA C, JIANG Q, DAEMEN L L, RIGG P A, HIXSON R S, GREEFF C W, GRAYIII G T, YANG Y P, WANG L P, WANG Y B, UCHIDA T. Experimental constraints on the phase diagram of elemental zirconium [J]. Journal of Physics and Chemistry of Solids, 2005, 66(7): 1213–1219. DOI: https://doi.org/10.1016/j.jpcs.2005.03.004.

MATSUKAWA Y, OKUMA I, MUTA H, SHINOHARA Y, SUZUEA R. YANG H L, MARUYAMA T, TOYAMA T, SHEN J J, LI Y F, SATOH Y, YAMANAKA S, ABE H. Crystallographic analysis on atomic-plane parallelisms between BCC precipitates and HCP matrix in recrystallized Zr-2.5Nb alloys [J]. Acta Mater, 2017, 126: 86–101. DOI: https://doi.org/10.1016/j.actamat.2016.12.053.

SANDOVAL L, URBASSEK H M, ENTEL P. The Bain versus Nishiyama-Wassermann path in the martensitic transformation of Fe [J]. New Journal of Physics, 2009, 11: 103027. DOI: https://doi.org/10.1088/1367-2630/11/10/103027.

SHEN X, YU P F, JING Q, YAO Y, GU L, WANG Y G, DUAN X F, YU R C, LIU R P. Transmission electron microscopy observations of structural modulation in the phase transition from α-Zr to ω-Zr induced by shear strain [J]. Scripta Mater, 2020, 67: 653–656. DOI: https://doi.org/10.1016/j.scriptamat.2012.07.017.

SERRA A, POND R C, BACON D J. Computer simulation of the structure and mobility of twinning disclocations in H.C.P. [J]. Metals Acta Metall Mater, 1991, 39: 1469–1480. DOI: https://doi.org/10.1016/0956-7151(91)90232-P.

HIRTH J P, POND R C, HOAGLAN R G, LIU X Y, WANG J. Interface defects, reference spaces and the Frank-Bilby equation [J]. Progress in Materials Science, 2013, 58: 749–823. DOI: https://doi.org/10.1016/j.pmatsci.2012.10.002.

NISHIYAMA Z. X-ray investigation of the mechanism of the transformation from face-centred to body-centred cubic lattice [J]. The Science Reports of Tohoku University, 1934(23): 637–664.

KURDJUMOV G V, SACHS G. Über den mechanismus der stahlhärtung [J]. Zeitschrift für Physik, 1930, 64: 325–343.

AN X L, AN K Y, ZHANG H, OU X Q, NI S, SONG M. A new phase transformation route for the formation of metastable beta-Zr [J]. Journal of Materials Science, 2020, 3(56): 2672–2683. DOI: https://doi.org/10.1007/s10853-020-05387-8.

OU X Q, SIETSMA J, SANTOFIMI M J. Coalescence of martensite under uniaxial tension of iron crystallites by atomistic simulations [J]. Materials Science and Technology, 2020, 36(11): 1191–1199. DOI: https://doi.org/10.2139/ssrn.3427500.

LI Z M, PRADEEP K G, DENG Yun, RAABE D, TASAN C C. Metastable high-entropy dual-phase alloys overcome the strength-ductility trade-off [J]. Nature, 2016, 534(1): 227–230. DOI: https://doi.org/10.1038/nature17981.

DIAO J K, GALL K, DUNN M L. Surface-stress-induced phase transformation in metal nanowires [J]. Nature Materials, 2003, 2(10): 656–660. DOI: https://doi.org/10.1038/nmat977.

LI J, FANG Q H, LIU B, LIU Y. Transformation induced softening and plasticity in high entropy alloys [J]. Acta Materialia, 2018, 147: 35–41. DOI: https://doi.org/10.1016/j.actamat.2018.01.002.

MULLER M, ERHART P, ALBE K. Analytic bond-order potential for bcc and fcc iron-comparison with established embedded-atom method potentials [J]. Journal of Physics: Condensed Matter, 2007, 19: 326220. DOI: https://doi.org/10.1088/0953-8984/19/32/326220.

NNAMCHI P, YOUNES A, GONZÁLEZ S. A review on shape memory metallic alloys and their critical stress for twinning [J]. Intermetallics, 2019, 105(1): 61–78. DOI: https://doi.org/10.1016/j.intermet.2018.11.005.

ZHOU Y K, LIANG S X, JING R, JIANG X J, MA M Z, TAN C L, LIU R P. Microstructure and tensile properties of hot-rolled Zr50-Ti50 binary alloy [J]. Materials Science and Engineering A, 2015, 621: 259–264. DOI: https://doi.org/10.1016/j.msea.2014.10.079.

Acknowledgements

We would like to thank the financial support from Natural Science Foundation of China (51901248, 51828102), Natural Science Foundation of Hunan Province (2018JJ3649) and Project of Innovation-driven Plan in Central South University (2019CX026). The Advanced Research Center of Central South University is sincerely appreciated for TEM technical support.

Funding

Projects(51901248, 51828102) supported by the National Natural Science Foundation of China; Project(2018JJ3649) supported by the Natural Science Foundation of Hunan Province, China; Project(2019CX026) supported by the Innovation-driven Plan in Central South University, China

Author information

Authors and Affiliations

Contributions

AN Ke-ying performed simulations, analyzed data, and wrote original draft. OU Xiao-qin analyzed data, supervised the writing, review and editing of the paper, administrated the project and funding. AN Xing-long provided the TEM images. ZHANG Hao analyzed simulation data. NI Song administrated the project and funding. SONG Min administrated the project and funding, revised the paper.

Corresponding author

Additional information

Conflict of interest

AN Ke-ying, OU Xiao-qin, AN Xing-long, ZHANG Hao, NI Song, and SONG Min declare that they have no conflict of interest.

Data availability

The raw data required to reproduce these findings are available on request.

Rights and permissions

About this article

Cite this article

An, Ky., Ou, Xq., An, Xl. et al. Effects of tensile temperatures on phase transformations in zirconium by molecular dynamics simulations. J. Cent. South Univ. 28, 1932–1945 (2021). https://doi.org/10.1007/s11771-021-4665-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4665-2