Abstract

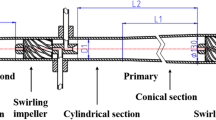

When circulating degassing or emergency blowout is required during oil and natural gas drilling, it is necessary to use separation equipment to separate waste gas, waste liquid, natural gas, or other impurities to avoid environmental pollution caused by the combustion of mixed fluids. In this paper, a structural scheme of spindle-shaped axial gas–liquid cyclone separator is proposed, and the Reynolds stress model (RSM) and DPM model are used to numerically simulate the gas–liquid two-phase flow, the flow field distribution law of the separator is obtained, the influence of structural parameters on the flow field is analyzed, and the multiobjective and multiparameter structure optimization research of the separator is carried out by orthogonal test method. Through the extreme difference analysis and ANOVA, the optimal level of separation performance of the separator was obtained by the combination of parameters B3A3C2, i.e., the combination of parameters with the outlet angle of 60°, the number of blades of 6, and the ratio of the length of the separation chamber to the depth of the overflow pipe M of 0.4, and the design and optimized structure were verified by the field experiments. The results show that the velocity in the cyclone separator is approximately “M” type distribution, and the velocity decays gradually along the axial direction due to energy loss. With the increase of the inlet gas velocity, the tangential velocity in the separator increases, and the separation efficiency and pressure drop increase. At the same time, with the increase of particle diameter, the centrifugal force of particles increases, the number of particle “escapes” decreases, and the separation efficiency increases, but the particle diameter has little effect on pressure drop. After the optimization of the structure, the separation efficiency is improved, the pressure drop is also reduced, and the comprehensive working performance of the separator is significantly improved.

Similar content being viewed by others

References

F. Yang, Research on high-speed cyclone separator for gas-liquid two-phase flow [D]. Xi'an University of Petroleum (2011)

C.L. Yu, Research and safety analysis of a new gas-liquid two-phase separator for test oil testing [D]. China University of Petroleum (East China) (2013)

W.J. Li, Numerical simulation of natural gas cyclone gas-liquid separator [D]. China University of Petroleum (2009)

F. Li, R.Z. Cao, T. Huang, CFD simulation of steady flow type gas-liquid cyclone separator [J]. Oil-Gas Field Surf. Eng. 28(05), 13–15 (2009)

Z.C. Wang, H. Cui, S. Li et al., Numerical simulation of separation performance of downhole spiral gas-liquid separator [J]. Sci. Technol. Eng. 10(06), 1358–1361 (2010)

J. Kou, B.B. Qi, C.W. Guo, Status of research on axial flow gas-liquid separators [J]. Process Equip. Pip. 54(04), 31–34 (2017)

J.P. Wu, Development of tangential axial flow type gas-liquid cyclone separator [D]. East China University of Science and Technology (2014)

Q.F. Gao, Structural optimization study of axial flow gas-liquid cyclone separator [D]. Chain University of Petroleum (2022)

K. Anderson, X. Zhang, B. Abbasi, A method to design and optimize axial flow cyclones for gas-liquid separation[J] (2021)

D.L. Sun, Y.J. Deng, B. Yu et al., Efficient numerical solution algorithm for direct current gas-liquid cyclone separator [J]. Oil Gas Storage Transp. 36(06), 728–733 (2017)

X.H. Jin, Y.H. Jin, J.J. Wang et al., Numerical study of the gas-phase flow field in an axial flow gas-liquid cyclone separator [J]. J. Chem. Eng. Chin. Univ. 23(05), 748–755 (2009)

Y.X. Jing, Development of an axially guided-vane cyclone separator [D]. China University of Petroleum (2010)

W.W. Yang, Optimization study of gas-liquid separation characteristics of axially guided vane cyclone separator [D]. Beijing Jiaotong University (2016)

B.B. Lei, Numerical simulation and experimental performance study of axial guide vane cyclone separator [D]. Beijing Jiaotong University (2017)

Y. Zhao, Research progress of axial guide vane cyclone separator [J]. Chem. Eng. Manag. 23, 203–204 (2019)

J. Kou, Z. Li, Numerical simulation of new axial flow gas-liquid separator[J]. Processes. 10(1), 64 (2022)

J.G. Valdez, L.D. Pérez, R. Cabello, et al. Experimental Evaluation of a Gas Liquid Axial Cyclone Separator [Z].

J. Chen, W. Jiang, X. Lai, et al. Effect of a New Type of Adherent Axisymmetric Cyclone on Internal Flow Field Characteristics of Supersonic Separator[M] (Springer Singapore, Singapore, 2021), pp. 222–231

Q.Q. Wang, Design analysis and experimental study of tubular separator with large gas-to-liquid ratio range [D]. Beijing Institute of Petrochemical Technology (2018)

G.Q. Ji, Numerical simulation of separation characteristics of columnar spiral guide vane cyclone separator [J]. J. Chengde Pet. Coll. 19(06), 29–34 (2017)

B.W. Zhang, Y.Q. Dai, J.P. Zhu, Flow field analysis and performance study of axial guide vane degasser [J]. J. Eng. Therm. Energy Power. 35(11), 100-105.0 (2020)

D.X. Hou, D.Z. Wei, B.Y. Cui et al., Effect of feed volume fraction on the separation performance of cyclonic columns [J]. J. Northeast. Univ. (Nat. Sci.). 43(05), 718–723 (2022)

M. Marinuc, F. Rus, The effect of particle size and input velocity on cyclone separation process [J]. Bull. Transilv. Univ. Brasov. For. Wood Ind. Agric. Food Eng. Ser. II. 4(2) (2011).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Tong, R., Li, H., Li, Y. et al. Working Performance and Structure Optimization of Spindle-Shaped Axial Gas–Liquid Cyclone Separator. J Fail. Anal. and Preven. 23, 2496–2510 (2023). https://doi.org/10.1007/s11668-023-01792-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-023-01792-8