Abstract

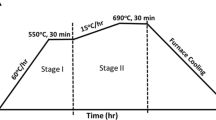

The forming process of high-strength sheet metal alloys is in great demand, and its applications in nuclear and defense industries are much significant. In the present investigation, the A516-Gr70 carbon steel plates are deep-drawing under warm (700 °C) and cold (27 °C) conditions using 1000 Ton hydraulic press. Numbers of deep-drawing experiments are conducted in two different states to study the microstructure and hardness at ambient temperature and also to study the impact strength at sub-zero temperature for different regions of the cup. In this study, changes in the microstructure of the deep-drawing cups with having two different samples subjected to normalizing heat treatment are observed.

Similar content being viewed by others

References

T. Heggemann, W. Homberg, Deep drawing of fiber metal laminates for automotive lightweight structures. Compos. Struct. 216, 53–57 (2019)

Doege E, Behrens B.-A., Handbuch Umformtechnik, (2007)

S.K. Singh, K.G. Amit, K. Mahesh, Prediction of mechanical properties of extra deep drawn steel in blue brittle region using artificial neural network. Mater. Des. 31, 2288–2295 (2010)

L. Jayaharia, B.B. Naik, S.K. Singh, Effect of process parameters and metallographic studies of ASS-304 stainless steel at various temperatures under warm deep drawing. Procedia Mater. Sci. 6, 115–122 (2014)

H. Zein, M. El-Sherbiny, M. Abd-Rabou, M. El Shazly, Effect of die design parameters on thinning of sheet metal in the deep drawing process. Am. J. Mech. Eng. 1, 20–29 (2013)

R. Dwivedi, G. Agnihotri, Study of deep drawing process parameters. Mater. Today Proc. 4, 820–826 (2017)

A.C.S. Reddy, S. Rajesham, Determination of LDR in deep drawing using reduced number of blanks. Mater. Today Proc. 5, 27136–27141 (2018)

A.K. Choubey, G. Agnihotri, C. Sasikumar, M. Singh, Analysis of die angle in deep drawing process using FEM. Mater. Today Proc. 4, 2511–2515 (2017)

A. Brosius, A. Mousavi, Lubricant free deep drawing process by macro structured tools. CIRP Ann. Manuf. Technol. 65, 253–256 (2016)

I. Irthiea, Experimental and numerical evaluation of micro flexible deep drawing technique using floating ring. J. Manuf. Process. 38, 556–563 (2019)

Y.Q. Li, Z.S. Cui, X.Y. Ruan, D.J. Zhang, CAE-based six sigma robust optimization for deep- drawing process of sheet metal. Int. J. Adv. Manuf. Technol. 30, 631–637 (2006)

S. Yoshihara, K. Manabe, H. Nishimura, Effect of blank holder force control in deep-drawing process of magnesium alloy sheet. J. Mater. Process. Technol. 170(3), 579–585 (2005)

V. Mehta, Evaluation of the fracture parameters for SA - 516 grade 70 material. (Mechanical Engineering Department, India, 2016)

B. Sarkar, B.K. Jha, A. Deva, Optimization of annealing parameters for improvement in formability of extra deep drawing quality steel. J. Mater. Eng. Perform. 13(3), 361–365 (2004)

F.J. Ruiz-Cabañas, C. Prieto, R. Osuna, V. Madina, A.I. Fernández, L.F. Cabeza, Corrosion testing device for in-situ corrosion characterization in operational molten salts storage tanks: A516 Gr70 carbon steel performance under molten salts exposure. Solar Energy Mater. Solar Cells. 157, 383–392 (2016)

W. Johnson, P.B. Mellor, Engineering plasticity. (Van Nostrand Reinhold, London, 1973)

E. Brinksmeier, J.T. Cammett, W. Konig, P. Leskovar, J. Peters, H.K. Tonshoff, Residual stresses, measurements and causes in machining processes. CIRP Ann. 3, 491–510 (1982)

A.P. Anaraki, M. Shahabizadeh, B. Babaee, Finite element simulation of multi-stage deep drawing processes & comparison with experimental results. World Acad. Sci. Eng. Technol. 61, 670–674 (2012)

A Ng and J Nathwani, Paths to sustainable energy, p 251, (2010)

S. Mazdak, H. Golmakani, E. Sharifi, M.R. Sheykholeslami, Numerical and experimental investigation of deep drawing process in square section of single-layer and two-layer sheets. IJMF. Iran. J. Mater. Form. 5(1), 58–70 (2018)

M.A. Myers, S. Traiviratana, V.A. Lubarda, D.J. Benson, E.M. Bringa, The role of dislocations in the growth of nanosized voids in ductile failure of metals. J. Met. 61, 35–41 (2009)

S.H. Zhanga, K. Zhang, Y.C. Xu, Z.T. Wang, Y. Xu, Z.G. Wang, Deep-drawing of magnesium alloy sheets at warm temperatures. J. Mater. Process. Technol. 185, 147–151 (2007)

C. Herrera, N.B. Lima, A. Ferreira Filho, R.L. Plaut, A.F. Padilha, Texture and mechanical properties evolution of a deep drawing medium carbon steel during cold rolling and subsequent recrystallization. J. Mater. Process. Technol. 209, 3518–3524 (2009)

J. Lade, B.N. Banoth, A.K. Gupta, S. Kumar, Metallurgical studies of austenitic stainless steel 304 under warm deep drawing. J. Iron Steel Res. Int. 21(12), 1147–1151 (2014)

A. Vaidyanathan, A.K. Gupta, M.A. Wahed, Deep Drawing of constrained groove pressed EDD steel sheets. Mater. Today Proc. 5, 3713–3718 (2018)

A. Di Gianfrancesco, Materials for ultra-supercritical and advanced ultra-supercritical power plants. (Woodhead Publishing, Cambridge, 2017)

ASTM E18-20, Standard test methods for rockwell hardness of metallic materials, ASTM International, West Conshohocken, PA, (2020)

H. Pan, X. Shen, D. Li, Y. Liu, J. Cao, Y. Tian, H. Zhan, H. Wang, Z. Wang, Y. Xiao, Effect of annealing process on microstructure, texture, and mechanical properties of a Fe-Si-Cr-Mo-C deep drawing dual-phase steel. Crystals. 10(9), 777 (2020)

Acknowledgment

This research was supported by MACHINE SAZI ARAK (M.S.A) Co. The authors wish to thank M.S.A Co. for the financial support and the provision of the research facilities used in this work.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hoseini, S.M.H., Hoseini, S.A., Nouri, A.R. et al. Process Parameters and Metallurgical Studies of A516-Gr70 Steel at Various Temperatures Under Warm Deep-Drawing. J Fail. Anal. and Preven. 21, 1894–1901 (2021). https://doi.org/10.1007/s11668-021-01253-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-021-01253-0