Abstract

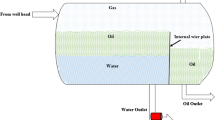

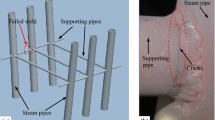

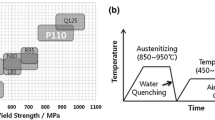

The failure of pipe ASTM A351 HK-40 in reaction plant unit has been reported. The failure occurs after 1.5 years in service. The present investigation aims to analyze the main cause of the failure by conducting a standard failure analysis test including chemical composition test, visual examination, microstructure examination by optical microscope and scanning electron microscope–energy-dispersive spectroscopy (SEM–EDS), x-ray diffraction, hardness Vickers and stress calculation. The sulfide corrosion, leakage and erosion were found at the bottom of the longitudinal pipe ASTM A351 HK-40. The results of this investigation suggest that the causes of failure are the high content of the sulfide in the reactant, and the high-temperature process up to 650 °C will potentially rapid the corrosion, the fluid flow and fluid phases will erode the surface of the pipe and form the leak on the surface, and the formation of the sigma phase in the material. Thus, the other material used is suggested such as ASTM A351 HP which has higher corrosion resistance and heat resistance.

Similar content being viewed by others

References

Designation: ASTM A351/A351M-05-Standard Specification for Castings, Austenitic, for Pressure-Containing Parts (ASTM International, United States, 2005)

Designation: ASTM A781/A781M-18C-Standard Specification for Castings, Steel and Alloy, Common Requirements, for General Industrial Use (ASTM International, United States, 2018)

A.M. Babakr, A. Al-Ahmari, K. Al-Jumayiah, F. Habiby, Sigma phase formation and embrittlement of cast iron-chromium-nickel (Fe-Cr-Ni) alloys. J. Mineral. Mater. Charact. Eng. 7(2), 127–145 (2008)

S.R. Haro, D.L. Lopez, A.T. Velasco, R.B. Viramontes, Microstructural factors that determine the weldability of a high Cr-high Si HK 40 alloy. Mater. Chem. Phys. 66, 90–96 (2000)

A. Ibrahim, Y. Ryu, M. Saidpour, Stress analysis of thin-walled pressure vessels. Modern. Mech. Eng. 5, 1–9 (2015)

G.V. Raynor, V.G. Rivlin, Phase Equilibria in Iron Ternary Alloys in ASM Metal Hanbook Volume 3: Alloy Phase Diagrams (The Institute of Metals, London, 1988)

R.L. Plaut, C. Herrera, D.M. Escriba, P.R. Rios, A.F. Padilha, A short review on wrought austenitic stainless steels at high temperatures: processing, microstructure, properties and performance. Mater. Res. 10(4), 453–460 (2007)

M.L. Saucedo-Muñoz, A. Ortiz-Mariscal, V.M. Lopez-Hirata, J.D. Villegas-Cardenas, O. Soriano-Vargas, E.O. Avila-Davila, Precipitation analysis of as-cast HK40 steel after isothermal aging. Int. J. Mineral. Metall. Mater. 24(10), 1125–1134 (2017)

H.S. Khatak, B. Raj, Corrosion of Austenitic Stainless Steel: Mechanism, Mitigation, and Monitoring (Woodhead Publishing Ltd., Sawston, 2002)

A.A. Vostrikov, O.N. Fedyaeva, A.V. Shishkin, M.Y. Sokol, Oxidation of hydrogen sulfide and corrosion of stainless steel in gas mixtures containing H2S, O2, H2O, and CO2. J. Eng. Thermophys. 26(3), 314–324 (2017)

E.B. Backensto, R.D. Drew, C.C. Staplford, High temperature hydrogen sulfide corrosion. Corrosion 12(1), 22–32 (1956)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yushandiana, F., Setiana, H. & Pujiyulianto, E. Case Study: The Failure Analysis of Pipe ASTM A351 HK-40 in Reaction Plant Unit. J Fail. Anal. and Preven. 20, 663–670 (2020). https://doi.org/10.1007/s11668-020-00885-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-020-00885-y