Abstract

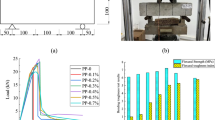

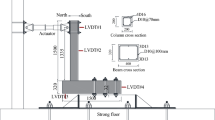

The present paper summarizes the experimental study of the mechanical behavior of high-density polyethylene structure welded by butt-welding process, subjected to tensile loading. In this work, we based on experimental tests in order to characterize the studied material, introducing the ductility and the fragility of the bead-welded section material, seeing the influence of the crosshead speed of 10 and 50 mm/min and taking into account the weld parameters such as the fusion temperature for a such given inner diameter. The welding parameters had a direct impact on microstructure of bead weld which itself is very heterogeneous.

Similar content being viewed by others

References

A.P.D. Costa, E.C. Botelho, M.L. Costa, N.E. Narita, J.R. Tarpani, A review of welding technologies for thermoplastic composites in aerospace applications. Aerosp. Technol. Manag. São José dos Campos 4(3), 255–265 (2012)

K.W. Neale, P. Tugcu, Analysis of necking and neck propagation in polymericmaterials. J. Mech. Phys. Solids 33(4), 323–337 (1985)

H. Potente, P. Tappe, Heated Tool-Butt Welding of Polyethylene-Pipes-Welding Parameters and Testing Technique. Technologie der Kunststoffe, Universftat-GH Pohlweg 47/49 Paderborn, Postfach. Federal Republic of Germany

P.Y. Zhang, Yi, B. Jar, Phenomenological modelling of tensile fracture in PE pipe by considering damage evolution. Mater. Des. 77, 72–82 (2015)

M.F. Butler, A.M. Donald, Deformation of spherulitic polyethylene thin film. J. Mater. Sci. 32, 3675–3685 (1997)

M.F. Butler, A.M. Donald, A.J. Ryan, Time resolved simultaneous smallandwide-angle X-ray scattering during polyethylene deformation-II. Cold drawing of linearpolyethylene. Polymer 1(39), 39–52 (1998)

M. Aboulfaraj, C. G’sell, B. Ulrich, A. Dahoun, In situ observation of plastic deformation of polypropylene spherulites under uniaxial tension and simple shear in the scanning electron microscope. Polymer 36, 731–742 (1995)

A. Djebli, A. Aid, M. Bendouba, A. Talha, N. Benseddiq, M. Benguediab, S. Zengah, Uniaxial fatigue of HDPE-100 pipe. Eng. Technol. Appl. Sci. Res. 4(2), 600–604 (2004)

ASTM F2620, Standard Practice for Heat Fusion Joining of Polyethylene Pipe and Fittings (2011). www.astm.org

Laboratoire Mécanique et Physique des matériaux. (Université Djillali Liabes, Sidi Bel Abbès)

ASTM D638, Standard test method for tensile properties of plastics. Part IIB Plast. (I) 8(1), 1–15 (2003)

ASTM D2240, Standard test method for rubber property-durometer hardness. Part IIB Rubber Nat. Synth. Gen. Test Methods Carbon Black 9(1), 1–8 (2000)

F. Rietsch, B. Bouette, The compression yield behaviour of polycarbonate over a wide range of strain rates and temperatures. Eur. Polym. J. 26, 1071–1075 (1990)

J. Richeton, S. Ahzi, L. Daridon, Y. Rémond, A formulation of the cooperative model for the yield stress of amorphous polymers for a wide range of strain rates and temperatures. Polymer 46, 6035–6043 (2005)

J. Richeton, S. Ahzi, K.S. Vecchio, F.C. Jiang, R.R. Adharapurapu, Influence of temperature and strain rate on the mechanical behavior of three amorphous polymers: Characterization and modelling of the compressive yield stress. Int. J. Solids Struct. 43, 2318–2335 (2006)

T. Fawad, N. Nausheen, A.K. Muhammad, A.B. Rasheed, Failure analysis of high density polyethylene butt weld joint. J. Fail. Anal. Prev. (2005). https://doi.org/10.1007/s11668-011-9536-y

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belaziz, A., Mohamed, M. Experimental Study of the Weld Bead Zones of a High-Density Polyethylene Pipe (HDPE). J Fail. Anal. and Preven. 18, 667–676 (2018). https://doi.org/10.1007/s11668-018-0462-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-018-0462-0