Abstract

Fe-based bulk metallic glass (BMG) presents unique tribological and electrochemical properties. Given the inherent brittle nature and dimensional limitations of Fe-based BMGs, technological and scientific efforts are focused on their use for surface engineering solutions. Fe-based BMG coatings are promising to protect steel components operating in a wide array of hostile environments, with encouraging resistance against corrosion and wear. This article summarizes the progress of Fe-Cr-Nb-B glassy coatings in terms of alloy design, glass-forming ability, crystallization, powder production, thermally-sprayed coatings, and how the microstructural features dictate the basket of properties. The strategy for selecting the alloy composition with high glass-forming ability is discussed based on thermodynamic calculations. Two main methods are presented for feedstock powder production: gas-atomization and high-energy ball milling. Different processing routes to produce Fe-Cr-Nb-B coatings and deposits are summarized: detonation spraying, high-velocity oxygen fuel, flame spraying, non-vacuum electron beam cladding, and spray forming. The resulting phases (glassy and crystalline), microstructures, porosity levels, and hardness values are comparatively discussed and related to the corrosion and wear resistances. The final part of the work is dedicated to a new generation of Fe-based BMGs that emerged as contender to further enhance the corrosion and wear resistances.

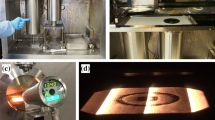

Graphical Abstract

Illustration of the processes used to produce Fe-Cr-Nb-B alloys covered in this review. The thermal spraying routes considered are flame spraying (FS), high-velocity oxygen fuel (HVOF), and detonation spraying. Spray forming (SF) and non-vacuum electron beam cladding were also evaluated. (a) Secondary electron (SE) scanning electron (SEM) micrographs of gas-atomized, GA, and milled, M, feedstock powders. Cross-sectional backscattered electron (BSE) SEM imaging of coatings: (b) ~220-μm-thick from detonation spraying from gas-atomized feedstock, (c) ~280-μm-thick HVOF from gas-atomized feedstock, (d) ~200-μm-thick HVOF from milled feedstock, (e) ~200-μm flame spraying from gas-atomized feedstock, (f) ~220-μm flame spraying from milled feedstock, (g) ~1300-μm non-vacuum electron beam cladding from gas-atomized feedstock, and (h) spray formed ~5000-μm-thick deposit formed from the liquid. All images for the Fe60Cr8Nb8B24 alloy, except (b) Fe66Cr10Nb5B19 alloy and (g) Fe62Cr10Nb12B16 alloy. Bright phases identified as (Fe,Cr)NbB. [This figure is related to the manuscript "An overview of thermally sprayed Fe-Cr- Nb-B metallic glass coatings – From the alloy development to the coating’s performance against corrosion and wear"].

Similar content being viewed by others

References

H.K.D.H. Bhadeshia and R.W.K. Honeycombe, “Steels: Microstructure and Properties: Fourth Edition,” Steels: Microstructure and Properties: Fourth Edition, 2017, https://www.scopus.com/inward/record.uri?eid=2-s2.0-85026700713&partnerID=40&md5=2f26d8ad6598a0135eee3d37408a337c.

R.O. Ritchie, The Conflicts between Strength and Toughness, Nat. Mater., 2011, 10(11), p 817-822. https://doi.org/10.1038/nmat3115

D. Raabe, B. Sun, A.K. da Silva, B. Gault, H.-W. Yen, K. Sedighiani, P.T. Sukumar, I.R.S. Filho, S. Katnagallu, E. Jägle, P. Kürnsteiner, N. Kusampudi, L. Stephenson, M. Herbig, C.H. Liebscher, H. Springer, S. Zaefferer, V. Shah, S.-L. Wong, C. Baron, M. Diehl, F. Roters and D. Ponge, Current Challenges and Opportunities in Microstructure-Related Properties of Advanced High-Strength Steels, Metall. Mater. Trans. A, 2020, 51(11), p 5517-5586. https://doi.org/10.1007/s11661-020-05947-2

Worldsteel Association, “2021 World Steel in Figures,” (Brussels), 2021, https://www.worldsteel.org/en/dam/jcr:976723ed-74b3-47b4-92f6-81b6a452b86e/World%2520Steel%2520in%2520Figures%25202021.pdf.

United Nations, “World Population Prospects 2019,” Department of Economic and Social Affairs. World Population Prospects 2019, 2019.

R.T. Loto, Study of the Corrosion Behaviour of S32101 Duplex and 410 Martensitic Stainless Steel for Application in Oil Refinery Distillation Systems, J. Mater. Res. Technol., 2017, 6(3), p 203-212. https://doi.org/10.1016/j.jmrt.2016.11.001

ISSF, “Stainless Steel in Figures 2020,” (Belgium), 2020, https://www.worldstainless.org/Files/issf/non-image-files/PDF/ISSF_Stainless_Steel_in_Figures_2020_English_public_version.pdf.

E. McCafferty, “Introduction to Corrosion Science”, Introduction to Corrosion Science, (Alexandria), Springer, Berlin, 2010.

J. Soyama, G. Zepon, T.P. Lopes, L. Beraldo, C.S. Kiminami, W.J. Botta and C. Bolfarini, Microstructure Formation and Abrasive Wear Resistance of a Boron-Modified Superduplex Stainless Steel Produced by Spray Forming, J. Mater. Res., 2016, 31(19), p 2987-2993. https://doi.org/10.1557/jmr.2016.323

G. Zepon, A.R.C. Nascimento, A.H. Kasama, R.P. Nogueira, C.S. Kiminami, W.J. Botta and C. Bolfarini, Design of Wear Resistant Boron-Modified Supermartensitic Stainless Steel by Spray Forming Process, Mater. Des., 2015, 83, p 214-223. https://doi.org/10.1016/j.matdes.2015.06.020

M. Kulka, Trends in Physical Techniques of Boriding, 2019, p 99-253, https://doi.org/10.1007/978-3-030-06782-3_5.

J.R. Davis, “Surface Engineering for Corrosion and Wear,” Surface Engineering for Corrosion and Wear Resistance, (Materials Park, Ohio), ASM International, 2001.

M. Stoica, Fe-Based Bulk Metallic Glasses, J. Mater. Sci. (Wiesbaden), 2017 https://doi.org/10.1007/978-3-658-17018-9

L. Liu and C. Zhang, Fe-Based Amorphous Coatings: Structures and Properties, Thin Solid Films, 2014, 561, p 70-86. https://doi.org/10.1016/j.tsf.2013.08.029

B. Huang, C. Zhang, G. Zhang and H. Liao, Wear and Corrosion Resistant Performance of Thermal-Sprayed Fe-Based Amorphous Coatings: A Review, Surf. Coat. Technol., 2019, 377(4), p 124896. https://doi.org/10.1016/j.surfcoat.2019.124896

C. Suryanarayana and A. Inoue, Iron-Based Bulk Metallic Glasses, Int. Mater. Rev., 2013, 58, p 131-166. https://doi.org/10.1179/1743280412Y.0000000007

W. Guo, Y. Wu, J. Zhang, S. Hong, G. Li, G. Ying, J. Guo and Y. Qin, Fabrication and Characterization of Thermal-Sprayed Fe-Based Amorphous/Nanocrystalline Composite Coatings: An Overview, J. Therm. Spray Technol., 2014, 23(7), p 1157-1180. https://doi.org/10.1007/s11666-014-0096-z

C.A.C. Souza, D.V. Ribeiro and C.S. Kiminami, Corrosion Resistance of Fe-Cr-Based Amorphous Alloys: An Overview, J. Non. Cryst. Solids, 2016, 442, p 56-66. https://doi.org/10.1016/j.jnoncrysol.2016.04.009

H.X. Li, Z.C. Lu, S.L. Wang, Y. Wu and Z.P. Lu, Fe-Based Bulk Metallic Glasses: Glass Formation, Fabrication, Properties and Applications, Prog. Mater. Sci., 2019, 103, p 235-318. https://doi.org/10.1016/j.pmatsci.2019.01.003

D.H. Milanez, L.I.L. Faria, D.R. Leiva, C.S. Kiminami and W.J. Botta, Assessing Technological Developments in Amorphous/Glassy Metallic Alloys Using Patent Indicators, J. Alloys Compd., 2017, 716, p 330-335. https://doi.org/10.1016/j.jallcom.2017.05.105

W. Klement, R.H. Willens and P. Duwez, Non-Crystalline Structure in Solidified Gold-Silicon Alloys, Nature, 1960, 187(4740), p 869-870. https://doi.org/10.1038/187869b0

P. Duwez and S.C.H. Lin, Amorphous Ferromagnetic Phase in Iron-Carbon-Phosphorus Alloys, J. Appl. Phys., 1967, 38(10), p 4096-4097. https://doi.org/10.1063/1.1709084

R. Ray, R. Hasegawa, C.-P. Chou and L.A. Davis, Iron-Boron Glasses: Density, Mechanical and Thermal Behavior, Scr. Metall., 1977, 11(11), p 973-978. https://doi.org/10.1016/0036-9748(77)90249-6

R. Hasegawa and R. Ray, Iron-boron Metallic Glasses, J. Appl. Phys., 1978, 49(7), p 4174-4179. https://doi.org/10.1063/1.325328

Z.P. Lu and C.T. Liu, Role of Minor Alloying Additions in Formation of Bulk Metallic Glasses: A Review, J. Mater. Sci., 2004, 39(12), p 3965-3974. https://doi.org/10.1023/B:JMSC.0000031478.73621.64

L.A. Davis, R. Ray, C.-P. Chou and R.C. O’Handley, Mechanical and Thermal Properties of Fe80B20 Glass, Scr. Metall., 1976, 10(6), p 541-546. https://doi.org/10.1016/0036-9748(76)90257-X

A.L. Greer, K.L. Rutherford and I.M. Hutchings, Wear Resistance of Amorphous Alloys and Related Materials, Int. Mater. Rev., 2002, 47(2), p 87-112. https://doi.org/10.1179/095066001225001067

R. Klinger and H.G. Feller, Sliding Friction and Wear Resistance of the Metallic Glass Fe40Ni40B20, Wear, 1983, 86(2), p 287-297. https://doi.org/10.1016/0043-1648(83)90167-9

T. Imura, K. Hasegawa, M. Moori, T. Nishiwaki, M. Takagi and Y. Kawamura, Cyclicdeformation and Tribological Behavior of an Amorphous Iron-Based Alloy Film, Mater. Sci. Eng. A, 1991, 133, p 332-336. https://doi.org/10.1016/0921-5093(91)90081-W

W.J. Botta, J.E. Berger, C.S. Kiminami, V. Roche, R.P. Nogueira and C. Bolfarini, Corrosion Resistance of Fe-Based Amorphous Alloys, J. Alloys Compd., 2014, 586(SUPPL. 1), p S105-S110. https://doi.org/10.1016/j.jallcom.2012.12.130

Y. Fan, S. Zhang, X. Xu, J. Miao, W. Zhang, T. Wang, C. Chen, R. Wei and F. Li, Effect of the Substitution of Si for B on Thermal Stability, Magnetic Properties and Corrosion Resistance in Novel Fe-Rich Amorphous Soft Magnetic Alloy, Intermetallics, 2021, 138, 107306. https://doi.org/10.1016/j.intermet.2021.107306

S.L. Wang and S. Yi, The Corrosion Behaviors of Fe-Based Bulk Metallic Glasses in a Sulfuric Solution at 70°C, Intermetallics, 2010, 18(10), p 1950-1953. https://doi.org/10.1016/j.intermet.2010.01.020

V. Maurice, W.P. Yang and P. Marcus, XPS and STM Study of Passive Films Formed on Fe-22Cr(110) Single-Crystal Surfaces, J. Electrochem. Soc., 1996, 143(4), p 1182-1200. https://doi.org/10.1149/1.1836616

H.M. Cobb, “The History of Stainless Steel,” (Materials Park, Ohio), ASM International, 2010.

B. Elsener and A. Rossi, XPS Investigation of Passive Films on Amorphous Fe-Cr Alloys, Electrochim. Acta, 1992, 37(12), p 2269-2276. https://doi.org/10.1016/0013-4686(92)85122-2

B.-M. Im, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami and K. Hashimoto, Electrochemical and XPS Studies of the Effects of Alloying Elements on the Corrosion Behavior of Amorphous Fe-Cr-Metalloid Alloys in 9 M H2SO4, Corros. Sci., 1993, 34(11), p 1829-1839. https://doi.org/10.1016/0010-938X(93)90020-H

M.D. Archer, C.C. Corke and B.H. Harji, The Electrochemical Properties of Metallic Glasses, Electrochim. Acta, 1987, 32(1), p 13-26. https://doi.org/10.1016/0013-4686(87)87002-0

M. Naka, K. Hashimoto and T. Masumoto, High Corrosion Resistance of Chromium-Bearing Amorphous Iron Alloys in Neutral and Acidic Solutions Containing Chloride, Corrosion, 1976, 32(4), p 146-152. https://doi.org/10.5006/0010-9312-32.4.146

M. Madinehei, P. Bruna, M.J. Duarte, E. Pineda, J. Klemm and F.U. Renner, Glass-Formation and Corrosion Properties of Fe-Cr-Mo-C-B Glassy Ribbons with Low Cr Content, J. Alloys Compd., 2014, 615, p S128-S131. https://doi.org/10.1016/j.jallcom.2013.12.245

Z.L. Long, Y. Shao, X.H. Deng, Z.C. Zhang, Y. Jiang, P. Zhang, B.L. Shen and A. Inoue, Cr Effects on Magnetic and Corrosion Properties of Fe-Co-Si-B-Nb-Cr Bulk Glassy Alloys with High Glass-Forming Ability, Intermetallics, 2007, 15(11), p 1453-1458. https://doi.org/10.1016/j.intermet.2007.05.002

A. Inoue and J.S. Gook, Fe-Based Ferromagnetic Glassy Alloys with Wide Supercooled Liquid Region, Mater. Trans. JIM, 1995, 36(9), p 1180-1183. https://doi.org/10.2320/matertrans1989.36.1180

A. Inoue, Y. Shinohara and J.S. Gook, Thermal and Magnetic Properties of Bulk Fe-Based Glassy Alloys Prepared by Copper Mold Casting, Mater. Trans. JIM, 1995, 36(12), p 1427-1433. https://doi.org/10.2320/matertrans1989.36.1427

J. Shen, Q. Chen, J. Sun, H. Fan and G. Wang, Exceptionally High Glass-Forming Ability of an FeCoCrMoCBY Alloy, Appl. Phys. Lett., 2005, 86(15), p 151907. https://doi.org/10.1063/1.1897426

V. Ponnambalam, S.J. Poon and G.J. Shiflet, Fe-Based Bulk Metallic Glasses with Diameter Thickness Larger than One Centimeter, J. Mater. Res., 2004, 19(5), p 1320-1323. https://doi.org/10.1557/JMR.2004.0176

A. Inoue and X. Wang, Bulk Amorphous FC20 (Fe-C-Si) Alloys with Small Amounts of B and Their Crystallized Structure and Mechanical Properties, Acta Mater., 2000, 48(6), p 1383-1395. https://doi.org/10.1016/S1359-6454(99)00394-8

J. Cheney and K. Vecchio, Development of Quaternary Fe-Based Bulk Metallic Glasses, Mater. Sci. Eng. A, 2008, 492(1-2), p 230-235. https://doi.org/10.1016/j.msea.2008.03.019

Y. Guo, A.M. Jorge, A.C. de Silva, C.S. Kiminami, C. Bolfarini and W.J. Botta, Experimental and Thermodynamic Investigation of the Microstructural Evolution of a Boron-Rich Fe-Cr-Nb-B Alloy, J. Alloys Compd., 2017, 713, p 119-124. https://doi.org/10.1016/j.jallcom.2017.04.153

Y. Guo, A.M. Jorge, C.S. Kiminami, C. Bolfarini and W.J. Botta, On the Ternary Eutectic Reaction in the Fe 60 Cr 8 Nb 8 B 24 Quaternary Alloy, J. Alloys Compd., 2017, 707, p 281-286. https://doi.org/10.1016/j.jallcom.2016.11.293

B. Sundman, B. Jansson and J.-O. Andersson, The Thermo-Calc Databank System, Calphad, 1985, 9(2), p 153-190. https://doi.org/10.1016/0364-5916(85)90021-5

K. Yamada, H. Ohtani and M. Hasebe, Thermodynamic Analysis of the Fe-Cr-B Ternary System, High Temp. Mater. Process., 2008, 27(4), p 269-283. https://doi.org/10.2355/isijinternational

M.H. Cohen and D. Turnbull, Composition Requirements for Glass Formation in Metallic and Ionic Systems, Nature, 1961, 189(4759), p 131-132. https://doi.org/10.1038/189131b0

A.L. Greer, Confusion by Design, Nature, 1993, 366(6453), p 303-304. https://doi.org/10.1038/366303a0

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans., 2005, 46(12), p 2817-2829. https://doi.org/10.2320/matertrans.46.2817

A. Inoue, High Strength Bulk Amorphous Alloys with Low Critical Cooling Rates (<I>Overview</I>), Mater. Trans. JIM, 1995, 36(7), p 866-875. https://doi.org/10.2320/matertrans1989.36.866

A. Inoue, Stabilization of Metallic Supercooled Liquid and Bulk Amorphous Alloys, Acta Mater., 2000, 48(1), p 279-306. https://doi.org/10.1016/S1359-6454(99)00300-6

M. Rahm, R. Hoffmann, and N.W. Ashcroft, Atomic and Ionic Radii of Elements 1-96, Chem. A Eur. J., 2016.

M.A.B. Mendes, A.K. Melle, C.A.C. de Souza, C.S. Kiminami, R.D. Cava, C. Bolfarini and W.J.B. Filho, The Effect of Cr Content on the Glass Forming Ability of Fe68-XCrxNb8B24 (x =8,10,12) Alloys, Mater. Res., 2016, 19(suppl 1), p 92-96. https://doi.org/10.1590/1980-5373-mr-2016-0290

C.S. Kiminami, C.A.C. Souza, L.F. Bonavina, L.R.P. de Andrade Lima, S. Suriñach, M.D. Baró, C. Bolfarini, and W.J. Botta, Partial Crystallization and Corrosion Resistance of Amorphous Fe-Cr-M-B (M=Mo, Nb) Alloys, J. Non. Cryst. Solids, 2010, 356(44-49), p 2651-2657, https://doi.org/10.1016/j.jnoncrysol.2010.04.051.

C.A. Souza, J. May, L. Bolfarini, S. Kuri, M. de Oliveira and C. Kiminami, Influence of Composition and Partial Crystallization on Corrosion Resistance of Amorphous Fe-M-B-Cu (M=Zr, Nb, Mo) Alloys, J. Non. Cryst. Solids, 2001, 284(1-3), p 99-104. https://doi.org/10.1016/S0022-3093(01)00386-6

S.J. Pang, T. Zhang, K. Asami and A. Inoue, Bulk Glassy Fe-Cr-Mo-C-B Alloys with High Corrosion Resistance, Corros. Sci., 2002, 44(8), p 1847-1856. https://doi.org/10.1016/S0010-938X(02)00002-1

C.G. Jia, J. Pang, S.P. Pan, Y.J. Zhang, K.B. Kim, J.Y. Qin and W.M. Wang, Tailoring the Corrosion Behavior of Fe-Based Metallic Glasses through Inducing Nb-Triggered Netlike Structure, Corros. Sci., 2019, 147, p 94-107. https://doi.org/10.1016/j.corsci.2018.11.008

H. Zhang, Z.C. Yan, K.C. Shen, Q. Chen, L.C. Zhang, X.Y. Li and W.M. Wang, Potentiodynamic and Potentiostatic Investigation on the Passivation of Fe Based Glassy Alloys in Alkaline Solution, J. Alloys Compd., 2021, 857, 157573. https://doi.org/10.1016/j.jallcom.2020.157573

F. Zhai, E. Pineda, M.J. Duarte and D. Crespo, Role of Nb in Glass Formation of Fe-Cr-Mo-C-B-Nb BMGs, J. Alloys Compd., 2014, 604, p 157-163. https://doi.org/10.1016/j.jallcom.2014.03.095

J.H. Yao, J.Q. Wang and Y. Li, Ductile Fe-Nb-B Bulk Metallic Glass with Ultrahigh Strength, Appl. Phys. Lett., 2008, 92(25), p 251906. https://doi.org/10.1063/1.2949747

M.J. Duarte, A. Kostka, D. Crespo, J.A. Jimenez, A.-C. Dippel, F.U. Renner and G. Dehm, Kinetics and Crystallization Path of a Fe-Based Metallic Glass Alloy, Acta Mater., 2017, 127, p 341-350. https://doi.org/10.1016/j.actamat.2017.01.031

P. Marcus and V. Maurice, Atomic Level Characterization in Corrosion Studies, Philos. Trans. R. Soc. A Math. Phys. Eng. Sci., 2017, 375(2098), p 20160414, https://doi.org/10.1098/rsta.2016.0414.

K. Asami, K. Hashimoto, T. Masumoto and S. Shimodaira, ESCA Study of the Passive Film on an Extremely Corrosion-Resistant Amorphous Iron Alloy, Corros. Sci., 1976, 16(12), p 909-914. https://doi.org/10.1016/S0010-938X(76)80010-8

S. Virtanen, E.M. Moser and H. Böhni, XPS Studies on Passive Films on Amorphous Fe-Cr-(B, P)-C Alloys, Corros. Sci., 1994, 36(2), p 373-384. https://doi.org/10.1016/0010-938X(94)90163-5

X.-Y. Li, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami and K. Hashimoto, Electrochemical and XPS Studies of the Corrosion Behavior of Sputter-Deposited Amorphous Fe-Cr-Ni-Nb Alloys in 6 M HCl, Corros. Sci., 1999, 41(6), p 1095-1118. https://doi.org/10.1016/S0010-938X(98)00174-7

G.Y. Koga, R.P. Nogueira, V. Roche, A.R. Yavari, A.K. Melle, J. Gallego, C. Bolfarini, C.S. Kiminami and W.J. Botta, Corrosion Properties of Fe-Cr-Nb-B Amorphous Alloys and Coatings, Surf. Coatings Technol., 2014, 254, p 238-243. https://doi.org/10.1016/j.surfcoat.2014.06.022

C. Suryanarayana and A. Inoue, “Bulk Metallic Glasses, Second Edition,” Bulk Metallic Glasses: Second Edition, CRC Press, 2017, https://doi.org/10.1201/9781315153483.

M. Belkhaouda, L. Bazzi, A. Benlhachemi, R. Salghi, B. Hammouti and S. Kertit, Effect of the Heat Treatment on the Corrosion Behaviour of Amorphous Fe-Cr-P-C-Si Alloy in 0.5M H2SO4, Appl. Surf. Sci., 2006, 252(22), p 7921-7925. https://doi.org/10.1016/j.apsusc.2005.09.063

S.M. Gravano, S. Torchio, E. Angelini, C. Antonione and M. Baricco, Structural Aspects and the Anodic Behaviour of Fe34Ni36Cr10P14B6 Amorphous Alloy Submitted to Different Heat Treatments, Corros. Sci., 1991, 32(5–6), p 509-519. https://doi.org/10.1016/0010-938X(91)90104-W

I. Chattoraj, S. Baunack, M. Stoica and A. Gebert, Electrochemical Response of Fe65.5Cr4Mo4Ga4P12 C5B5.5 Bulk Amorphous Alloy in Different Aqueous Media, Mater. Corros., 2004, 55(1), p 36-42. https://doi.org/10.1002/maco.200303693

F. Marzo, Effect of Irreversible Structural Relaxation on the Electrochemical Behavior of Fe78−xSi13B9Cr(X=3,4,7) Amorphous Alloys, J. Non. Cryst. Solids, 2003, 329(1–3), p 108-114. https://doi.org/10.1016/j.jnoncrysol.2003.08.022

H. Habazaki, A. Kawashima, K. Asami and K. Hashimoto, The Effect of Structural Relaxation on the Passivation Behavior of Amorphous Fe-Cr-W-P-C Alloys, Corros. Sci., 1990, 31, p 343-348. https://doi.org/10.1016/0010-938X(90)90129-S

G. Li, L. Huang, Y. Dong, G. He, L. Qi, Q. Jing, M. Ma and R. Liu, Corrosion Behavior of Bulk Metallic Glasses in Different Aqueous Solutions, Sci. China Phys. Mech. Astron., 2010, 53(3), p 435-439. https://doi.org/10.1007/s11433-010-0139-5

M.J. Duarte, A. Kostka, J.A. Jimenez, P. Choi, J. Klemm, D. Crespo, D. Raabe and F.U. Renner, Crystallization, Phase Evolution and Corrosion of Fe-Based Metallic Glasses: An Atomic-Scale Structural and Chemical Characterization Study, Acta Mater., 2014, 71, p 20-30. https://doi.org/10.1016/j.actamat.2014.02.027

H.X. Li and S. Yi, Corrosion Behaviors of Bulk Metallic Glasses Fe66.7C7.0Si3.3B5.5P8.7Cr2.3Al2.0Mo4.5 Having Different Crystal Volume Fractions, Mater. Chem. Phys., 2008, 112(1), p 305-309, https://doi.org/10.1016/j.matchemphys.2008.05.061.

H.M. Ha and J.H. Payer, Devitrification of Fe-Based Amorphous Metal SAM 1651: A Structural and Compositional Study, Metall. Mater. Trans. A, 2009, 40(11), p 2519-2529. https://doi.org/10.1007/s11661-009-9977-z

C.A.C. Sousa and C.S. Kiminami, Crystallization and Corrosion Resistance of Amorphous FeCuNbSiB, J. Non. Cryst. Solids, 1997, 219, p 155-159. https://doi.org/10.1016/S0022-3093(97)00323-2

D. Szewieczek and A. Baron, Electrochemical Corrosion and Its Influence on Magnetic Properties of Fe755Si13.5B9Nb3Cu1 Alloy, J. Mater. Process. Technol., 2005, 164-165, p 940-946, doi:https://doi.org/10.1016/j.jmatprotec.2005.02.084.

C.A.C. Souza, S.E. Kuri, F.S. Politti, J.E. May and C.S. Kiminami, Corrosion Resistance of Amorphous and Polycrystalline FeCuNbSiB Alloys in Sulphuric Acid Solution, J. Non. Cryst. Solids, 1999, 247(1–3), p 69-73. https://doi.org/10.1016/S0022-3093(99)00034-4

R. Holm, The Contact Resistance. General Theory, Electric Contacts, (Berlin, Heidelberg), Springer Berlin Heidelberg, 1967, p 9-11, doi:https://doi.org/10.1007/978-3-662-06688-1_3.

J.F. Archard, Contact and Rubbing of Flat Surfaces, J. Appl. Phys., 1953, 24(8), p 981-988. https://doi.org/10.1063/1.1721448

I. Hutchings and P. Shipway, “Tribology: Friction and Wear of Engineering Materials: Second Edition,” Tribology: Friction and Wear of Engineering Materials: Second Edition, 2nd ed., (Butterworth-Heinemann), Elsevier, 2017.

A. Inoue, L. Arnberg, M. Oguchi, U. Backmark, N. Bäckström and T. Masumoto, Preparation of Fe-Cr-Mo-C Amorphous Powders and Microstructure and Mechanical Properties of Their Hot-Pressed Products, Mater. Sci. Eng., 1987, 95, p 101-114. https://doi.org/10.1016/0025-5416(87)90502-7

K. Miyoshi and D.H. Buckley, Mechanical-Contact-Induced Transformation from the Amorphous to the Partially Crystalline State in Metallic Glass, Thin Solid Films, 1984, 118(3), p 363-373. https://doi.org/10.1016/0040-6090(84)90206-2

K. Miyoshi and D.H. Buckley, Microstructure and Surface Chemistry of Amorphous Alloys Important to Their Friction and Wear Behavior, Wear, 1986, 110(3–4), p 295-313. https://doi.org/10.1016/0043-1648(86)90105-5

F.A. de Lucena, C.S. Kiminami, and C. R. M. Afonso, New Compositions of Fe-Co-Nb-B-Y BMG with Wide Supercooled Liquid Range, over 100 K, J. Mater. Res. Technol., Korea Institute of Oriental Medicine, 2020, 9(4), p 9174-9181, https://doi.org/10.1016/j.jmrt.2020.06.035.

G.Y. Koga, T. Ferreira, Y. Guo, D.D. Coimbrão, A.M. Jorge Jr., C.S. Kiminami, C. Bolfarini and W.J. Botta, Challenges in Optimizing the Resistance to Corrosion and Wear of Amorphous Fe-Cr-Nb-B Alloy Containing Crystalline Phases, J. Non. Cryst. Solids, 2021, 555, 120537. https://doi.org/10.1016/j.jnoncrysol.2020.120537

E.V. Shadrichev and A.E. Ivanov, Relative Wear-Resistance of Single-Phase and Two-Phase Boride Layers, Met. Sci. Heat Treat., 1984, 26(3), p 235-239. https://doi.org/10.1007/BF00703870

A.L. Greer, Partially or Fully Devitrified Alloys for Mechanical Properties, Mater. Sci. Eng. A, 2001, 304–306, p 68-72. https://doi.org/10.1016/S0921-5093(00)01449-0

M. Anis, W.M. Rainforth and H.A. Davies, Wear Behaviour of Rapidly Solidified Fe68Cr18Mo2B12 Alloys, Wear, 1994, 172(2), p 135-145. https://doi.org/10.1016/0043-1648(94)90281-X

G.R. Khanolkar, M.B. Rauls, J.P. Kelly, O.A. Graeve, A.M. Hodge and V. Eliasson, Shock Wave Response of Iron-Based In Situ Metallic Glass Matrix Composites, Sci. Rep., 2016, 6(1), p 22568. https://doi.org/10.1038/srep22568

S.F. Guo, L. Liu, N. Li and Y. Li, Fe-Based Bulk Metallic Glass Matrix Composite with Large Plasticity, Scr. Mater., 2010, 62(6), p 329-332. https://doi.org/10.1016/j.scriptamat.2009.10.024

R.G. Ehl and A.J. Ihde, Faraday’s Electrochemical Laws and the Determination of Equivalent Weights, J. Chem. Educ., 1954, 31(5), p 226, doi:https://doi.org/10.1021/ed031p226.

N. Mahata, A. Banerjee, P.K. Rai, P. Bijalwan, A.S. Pathak, S. Kundu, M. Dutta and K. Mondal, Glassy Blast Furnace Pig Iron and Design of Other Glassy Compositions Using Thermodynamic Calculations, J. Non. Cryst. Solids, 2018, 484, p 95-104. https://doi.org/10.1016/j.jnoncrysol.2018.01.029

K. Sarkar, P.K. Rai, P. Kumar Katiyar, B. Satapathy, A.S. Pathak, M. Dutta, A. Banerjee and K. Mondal, Composite (Glass + Crystalline) Coatings from Blast Furnace Pig Iron by High Velocity Oxy-Fuel (HVOF) Process and Their Electrochemical Behavior, Surf. Coat. Technol., 2019, 372, p 72-83, https://doi.org/10.1016/j.surfcoat.2019.05.025.

P.K. Rai, D. Naidu, B. Satapathy, K. Sarkar, A.S. Pathak, P. Bijalwan, M. Dutta, A. Banerjee and K. Mondal, Amorphous/Nanocrystalline Composite Coatings Using Blast Furnace Pig Iron Composition by Atmospheric Plasma Spray and Their Electrochemical Response, J. Therm. Spray Technol., 2020, 29(4), p 843-856. https://doi.org/10.1007/s11666-020-00995-x

T. Xu, Z. Jian, F. Chang, L. Zhuo, M. Shi, M. Zhu, J. Xu, Y. Liu and T. Zhang, Synthesis of Fe 75 Cr 5 (PBC) 20 Bulk Metallic Glasses with a Combination of Desired Merits Using Industrial Ferro-Alloys without High-Purity Materials, J. Alloys Compd., 2017, 699, p 92-97. https://doi.org/10.1016/j.jallcom.2016.12.322

M. Shi, S. Pang and T. Zhang, Towards Improved Integrated Properties in FeCrPCB Bulk Metallic Glasses by Cr Addition, Intermetallics, 2015, 61, p 16-20. https://doi.org/10.1016/j.intermet.2015.02.010

A. Kumar, R. Kumar, P. Bijalwan, M. Dutta, A. Banerjee, and T. Laha, Fe-Based Amorphous/Nanocrystalline Composite Coating by Plasma Spraying: Effect of Heat Input on Morphology, Phase Evolution and Mechanical Properties, J. Alloys Compd., Elsevier B.V, 2019, 771, p 827-837, https://doi.org/10.1016/j.jallcom.2018.09.024.

A. Kumar, S.K. Nayak, P. Bijalwan, M. Dutta, A. Banerjee and T. Laha, Mechanical and Corrosion Properties of Plasma-Sprayed Fe-Based Amorphous/Nanocrystalline Composite Coating, Adv. Mater. Process. Technol., 2019, 5(2), p 371-377. https://doi.org/10.1080/2374068X.2019.1598129

P. Bijalwan, A. Kumar, S.K. Nayak, A. Banerjee, M. Dutta and T. Laha, Microstructure and Corrosion Behavior of Fe-Based Amorphous Composite Coatings Developed by Atmospheric Plasma Spraying, J. Alloys Compd., 2019, 796, p 47-54. https://doi.org/10.1016/j.jallcom.2019.05.046

A. Kumar, S.K. Nayak, K. Sarkar, A. Banerjee, K. Mondal and T. Laha, Investigation of Nano- and Micro-Scale Structural Evolution and Resulting Corrosion Resistance in Plasma Sprayed Fe-Based (Fe-Cr-B-C-P) Amorphous Coatings, Surf. Coatings Technol., 2020, 397, 126058. https://doi.org/10.1016/j.surfcoat.2020.126058

S.K. Nayak, A. Kumar, K. Sarkar, A. Pathak, A. Banerjee and T. Laha, A Study on the Corrosion Inhibition of Fe-Based Amorphous/Nanocrystalline Coating Synthesized by High-Velocity Oxy-Fuel Spraying in an Extreme Environment, J. Therm. Spray Technol., 2019, 28(7), p 1433-1447. https://doi.org/10.1007/s11666-019-00907-8

S.K. Nayak, A. Kumar, A. Pathak, A. Banerjee and T. Laha, Multi-Scale Mechanical Properties of Fe-Based Amorphous/Nanocrystalline Composite Coating Synthesized by HVOF Spraying, J. Alloys Compd., 2020, 825, 154120. https://doi.org/10.1016/j.jallcom.2020.154120

K. Kishitake, H. Era and F. Otsubo, Thermal-Sprayed Fe-10CM3P-7C Amorphous Coatings Possessing Excellent Corrosion Resistance, J. Therm. Spray Technol., 1996, 5(4), p 476-482. https://doi.org/10.1007/BF02645279

A. Kumar, S.K. Nayak and T. Laha, Comparative Study on Wear and Corrosion Behavior of Plasma Sprayed Fe73Cr2Si11B11C3 and Fe63Cr9P5B16C7 Metallic Glass Composite Coatings, J. Therm. Spray Technol., 2022. https://doi.org/10.1007/s11666-021-01280-1

S.K. Nayak, A. Kumar and T. Laha, Developing an Economical Wear and Corrosion Resistant Fe-Based Metallic Glass Composite Coating by Plasma and HVOF Spraying, J. Therm. Spray Technol., 2021. https://doi.org/10.1007/s11666-021-01277-w

S.F. Guo, J.L. Qiu, P. Yu, S.H. Xie and W. Chen, Fe-Based Bulk Metallic Glasses: Brittle or Ductile? Appl. Phys. Lett. 2014, 105(16), p 161901, https://doi.org/10.1063/1.4899124.

Z.L. Long, C.T. Chang, Y.H. Ding, Y. Shao, P. Zhang, B.L. Shen and A. Inoue, Corrosion Behavior of Fe-Based Ferromagnetic (Fe, Ni)-B-Si-Nb Bulk Glassy Alloys in Aqueous Electrolytes, J. Non. Cryst. Solids, 2008, 354(40–41), p 4609-4613. https://doi.org/10.1016/j.jnoncrysol.2008.06.009

J. Guo, Z. Gao, X. Ni, D. Li and Z. Lu, Electrochemical Behavior of Bulk Amorphous Steel Fe55M2Cr12Mo10B6C13Y2(M=Ni, Cu, Nb), J. Iron Steel Res. Int., 2010, 17(5), p 69-73. https://doi.org/10.1016/S1006-706X(10)60102-1

Y. Li, X. Jia, W. Zhang, C. Fang, X. Wang, F. Qin, S. Yamaura and Y. Yokoyama, Effects of Alloying Elements on the Thermal Stability and Corrosion Resistance of an Fe-Based Metallic Glass with Low Glass Transition Temperature, Metall. Mater. Trans. A, 2014, 45(5), p 2393-2398. https://doi.org/10.1007/s11661-013-2071-6

F. Otsubo, H. Era and K. Kishitake, Formation of Amorphous Fe-Cr-Mo-8P-2C Coatings by the High Velocity Oxy-Fuel Process, J. Therm. Spray Technol., 2000, 9(4), p 494-498. https://doi.org/10.1361/105996300770349700

K. Kishitake, H. Era and F. Otsubo, Characterization of Plasma Sprayed Fe-10Cr-10Mo-(C, B) Amorphous Coatings, J. Therm. Spray Technol., 1996, 5(2), p 145-153. https://doi.org/10.1007/BF02646428

F. Otsubo and K. Kishitake, Corrosion Resistance of Fe-16%Cr-30%Mo-(C, B, P) Amorphous Coatings Sprayed by HVOF and APS Processes, Mater. Trans., 2005, 46(1), p 80-83. https://doi.org/10.2320/matertrans.46.80

K. Kishitake, H. Era and F. Otsubo, Characterization of Plasma Sprayed Fe-17Cr-38Mo-4C Amorphous Coatings Crystallizing at Extremely High Temperature, J. Therm. Spray Technol., 1996, 5(3), p 283-288. https://doi.org/10.1007/BF02645879

M.-W. Tan, E. Akiyama, A. Kawashima, K. Asami and K. Hashimoto, The Effect of Air Exposure on the Corrosion Behavior of Amorphous Fe-8Cr-Mo-13P-7C Alloys in 1 M HCl, Corros. Sci., 1995, 37(8), p 1289-1301. https://doi.org/10.1016/0010-938X(95)00035-I

M.-W. Tan, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami and K. Hashimoto, The Role of Chromium and Molybdenum in Passivation of Amorphous Fe-Cr-Mo-P-C Alloys in Deaerated 1 M HCl, Corros. Sci., 1996, 38(12), p 2137-2151. https://doi.org/10.1016/S0010-938X(96)00071-6

M.-W. Tan, E. Akiyama, H. Habazaki, A. Kawashima, K. Asami and K. Hashimoto, The Effect of Molybdenum on the Stability of Passive Films Formed on Amorphous Fe-Cr-Mo-P-C Alloys by Potentiostatic Polarization in Deaerated 1 M HCl, Corros. Sci., 1997, 39(3), p 589-603. https://doi.org/10.1016/S0010-938X(96)00148-5

X. Li, C. Qin, H. Kato, A. Makino, and A. Inoue, Mo Microalloying Effect on the Glass-Forming Ability, Magnetic, Mechanical and Corrosion Properties of (Fe0.76Si0.096B0.084P0.06)100-XMox Bulk Glassy Alloys, J. Alloys Compd., 2011, 509(29), p 7688-7691, https://doi.org/10.1016/j.jallcom.2011.04.081.

B. Bochtler, O. Gross, I. Gallino, and R. Busch, Thermo-Physical Characterization of the Fe67Mo6Ni3.5Cr3.5P12C5.5B2.5 Bulk Metallic Glass Forming Alloy, Acta Mater., 2016, 118, p 129-139, https://doi.org/10.1016/j.actamat.2016.07.031.

J.H. Na, M. Floyd, G. Garrett, M.D. Demetriou, and W.L. Johnson, “Bulk Glass Steel with High Glass Forming Ability,” (United States), 2015, p 6.

G.Y. Koga, R. Schulz, S. Savoie, A.R.C. Nascimento, Y. Drolet, C. Bolfarini, C.S. Kiminami, and W.J. Botta, Microstructure and Wear Behavior of Fe-Based Amorphous HVOF Coatings Produced from Commercial Precursors, Surf. Coatings Technol., Elsevier B.V., 2016, 309, p 938-944, https://doi.org/10.1016/j.surfcoat.2016.10.057.

G.Y. Koga, A.M. Jorge Junior, V. Roche, R.P. Nogueira, R. Schulz, S. Savoie, A.K. Melle, C. Loable, C. Bolfarini, C.S. Kiminami, and W.J. Botta, Production and Corrosion Resistance of Thermally Sprayed Fe-Based Amorphous Coatings from Mechanically Milled Feedstock Powders, Metall. Mater. Trans. A, 2018, 49(10), p 4860-4870, https://doi.org/10.1007/s11661-018-4785-y.

J.E. Berger, A.M. Jorge, G.Y. Koga, V. Roche, C.S. Kiminami, C. Bolfarini and W.J. Botta, Influence of Chromium Concentration and Partial Crystallization on the Corrosion Resistance of FeCrNiB Amorphous Alloys, Mater. Charact., 2021, 179, 111369. https://doi.org/10.1016/j.matchar.2021.111369

M.J. Duarte, J. Klemm, S.O. Klemm, K.J.J. Mayrhofer, M. Stratmann, S. Borodin, a H. Romero, M. Madinehei, D. Crespo, J. Serrano, S.S. a Gerstl, P.P. Choi, D. Raabe, and F.U. Renner, Element-Resolved Corrosion Analysis of Stainless-Type Glass-Forming Steels, Science, 2013, 341, p 372-376, https://doi.org/10.1126/science.1230081.

G. Koga, L. Otani, A. Silva, V. Roche, R. Nogueira, A. Jorge, C. Bolfarini, C. Kiminami, and W. Botta, Characterization and Corrosion Resistance of Boron-Containing-Austenitic Stainless Steels Produced by Rapid Solidification Techniques, Materials (Basel)., 2018, 11(11), p 2189, https://doi.org/10.3390/ma11112189.

J.E. Berger, R. Schulz, S. Savoie, J. Gallego, C.S. Kiminami, C. Bolfarini, and W.J. Botta, Wear and Corrosion Properties of HVOF Coatings from Superduplex Alloy Modified with Addition of Boron, Surf. Coatings Technol., Elsevier B.V., 2017, 309, p 911-919, https://doi.org/10.1016/j.surfcoat.2016.10.062.

H.-R. Jiang, M.-L. Li, X.-S. Wei, T.-C. Ma, Y. Dong, C.-X. Ying, Z.-Y. Liao and J. Shen, Numerical Investigation of In-Flight Behavior of Fe-Based Amorphous Alloy Particles in AC-HVAF Thermal Spray Process, J. Therm. Spray Technol., 2019, 28(6), p 1146-1159. https://doi.org/10.1007/s11666-019-00889-7

N. Zeoli, S. Gu and S. Kamnis, Numerical Simulation of In-Flight Particle Oxidation during Thermal Spraying, Comput. Chem. Eng., 2008, 32(7), p 1661-1668. https://doi.org/10.1016/j.compchemeng.2007.08.008

E. Dongmo, M. Wenzelburger and R. Gadow, Analysis and Optimization of the HVOF Process by Combined Experimental and Numerical Approaches, Surf. Coatings Technol., 2008, 202(18), p 4470-4478. https://doi.org/10.1016/j.surfcoat.2008.04.029

N.C. Wu, K. Chen, W.H. Sun and J.Q. Wang, Correlation between Particle Size and Porosity of Fe-Based Amorphous Coating, Surf. Eng., 2019, 35(1), p 37-45. https://doi.org/10.1080/02670844.2018.1447782

H. Zhang, Y. Xie, L. Huang, S. Huang, X. Zheng and G. Chen, Effect of Feedstock Particle Sizes on Wear Resistance of Plasma Sprayed Fe-Based Amorphous Coatings, Surf. Coatings Technol., 2014, 258, p 495-502. https://doi.org/10.1016/j.surfcoat.2014.08.050

G.Y. Koga, W. Wolf, R. Schulz, S. Savoie, C. Bolfarini, C.S. Kiminami and W.J. Botta, Corrosion and Wear Properties of FeCrMnCoSi HVOF Coatings, Surf. Coatings Technol., 2019, 357, p 993-1003. https://doi.org/10.1016/j.surfcoat.2018.10.101

M.S. Bakare, K.T. Voisey, K. Chokethawai and D.G. McCartney, Corrosion Behaviour of Crystalline and Amorphous Forms of the Glass Forming Alloy Fe43Cr16Mo16C15B10, J. Alloys Compd., 2012, 527, p 210-218. https://doi.org/10.1016/j.jallcom.2012.02.127

E. Sadeghimeresht, N. Markocsan and P. Nylén, Microstructural Characteristics and Corrosion Behavior of HVAF- and HVOF-Sprayed Fe-Based Coatings, Surf. Coatings Technol., 2017, 318, p 365-373. https://doi.org/10.1016/j.surfcoat.2016.11.088

A. Nouri and A. Sola, Metal Particle Shape: A Practical Perspective, Met. Powder Rep., 2018, 73(5), p 276-282. https://doi.org/10.1016/j.mprp.2018.04.001

P. Fauchais, G. Montavon and G. Bertrand, From Powders to Thermally Sprayed Coatings, J. Therm. Spray Technol., 2010, 19(1–2), p 56-80. https://doi.org/10.1007/s11666-009-9435-x

A. Nouri and A. Sola, Powder Morphology in Thermal Spraying, J. Adv. Manuf. Process., 2019. https://doi.org/10.1002/amp2.10020

A. Inoue, T. Masumoto, T. Ekimoto, S. Furukawa, Y. Kuroda and H.S. Chen, Preparation of Fe-, Co-, and Ni-Based Amorphous Alloy Powders by High-Pressure Gas Atomization and Their Structural Relaxation Behavior, Metall. Trans. A, 1988, 19(2), p 235-242. https://doi.org/10.1007/BF02652531

K.L. Alvarez, J.M. Martín, N. Burgos, M. Ipatov, L. Domínguez and J. González, Structural and Magnetic Properties of Amorphous and Nanocrystalline Fe-Si-B-P-Nb-Cu Alloys Produced by Gas Atomization, J. Alloys Compd., 2019, 810, 151754. https://doi.org/10.1016/j.jallcom.2019.151754

T. Dai and N. Wang, Study on Magnetic Properties and Degradability of Gas Atomization Fe-Based (Fe-Si-B-P) Amorphous Powder, J. Supercond. Nov. Magn., 2019, 32(11), p 3699-3702. https://doi.org/10.1007/s10948-019-05164-y

N. Ciftci, N. Ellendt, E. Soares Barreto, L. Mädler, and V. Uhlenwinkel, Increasing the Amorphous Yield of {(Fe 0.6 Co 0.4 ) 0.75 B 0.2 Si 0.05} 96 Nb 4 Powders by Hot Gas Atomization, Adv. Powder Technol., 2018, 29(2), p 380-385, https://doi.org/10.1016/j.apt.2017.11.025.

N. Ciftci, N. Ellendt, R. von Bargen, H. Henein, L. Mädler, and V. Uhlenwinkel, Atomization and Characterization of a Glass Forming Alloy {(Fe0.6Co0.4)0.75B0.2Si0.05}96Nb4, J. Non. Cryst. Solids, 2014, 394-395, p 36-42, https://doi.org/10.1016/j.jnoncrysol.2014.03.023.

N. Ciftci, N. Yodoshi, S. Armstrong, L. Mädler and V. Uhlenwinkel, Processing Soft Ferromagnetic Metallic Glasses: On Novel Cooling Strategies in Gas Atomization, Hydrogen Enhancement, and Consolidation, J. Mater. Sci. Technol., 2020, 59, p 26-36. https://doi.org/10.1016/j.jmst.2020.03.077

Y. Shi, W. Lu, W. Sun, S. Zhang, B. Yang and J. Wang, Impact of Gas Pressure on Particle Feature in Fe-Based Amorphous Alloy Powders via Gas Atomization: Simulation and Experiment, J. Mater. Sci. Technol., 2021 https://doi.org/10.1016/j.jmst.2021.06.075

C. Suryanarayana, Mechanical Alloying and Milling, Prog. Mater. Sci., 2001, 46(1–2), p 1-184. https://doi.org/10.1016/S0079-6425(99)00010-9

F.A. de Lucena, G.Y. Koga, R. Riva, and C.R.M. Afonso, Production and Characterization of Laser Cladding Coating of Fe66Co7Nb4B23 (at.%) Gas-Atomized and Ball-Milled Powders, J. Mater. Res. Technol., 2021, 14, p 2267-2280, https://doi.org/10.1016/j.jmrt.2021.07.087.

E.D. Zanotto and J.C. Mauro, The Glassy State of Matter: Its Definition and Ultimate Fate, J. Non. Cryst. Solids, 2017, 471, p 490-495. https://doi.org/10.1016/j.jnoncrysol.2017.05.019

B.S. de Oliveira, D.H. Milanez, D.R. Leiva, L.I.L. de Faria, W.J. Botta and C.S. Kiminami, Thermal Spraying Processes and Amorphous Alloys: Macro-Indicators of Patent Activity, Mater. Res., 2017, 20(suppl 1), p 89-95. https://doi.org/10.1590/1980-5373-mr-2017-0416

J.C. Farmer, J.J. Haslam, S.D. Day, T. Lian, C.K. Saw, P.D. Hailey, J.-S. Choi, R.B. Rebak, N. Yang, J.H. Payer, J.H. Perepezko, K. Hildal, E.J. Lavernia, L. Ajdelsztajn, D.J. Branagan, E.J. Buffa, and L.F. Aprigliano, Corrosion Resistance of Thermally Sprayed High-Boron Iron-Based Amorphous-Metal Coatings: Fe49.7Cr17.7Mn1.9Mo7.4W1.6B15.2C3.8Si2.4, J. Mater. Res., 2007, 22(08), p 2297-2311, https://doi.org/10.1557/jmr.2007.0291.

J. Blink, J. Farmer, J. Choi and C. Saw, Applications in the Nuclear Industry for Thermal Spray Amorphous Metal and Ceramic Coatings, Metall. Mater. Trans. A, 2009, 40(6), p 1344-1354. https://doi.org/10.1007/s11661-009-9830-4

J. Farmer, J.-S. Choi, C. Saw, J. Haslam, D. Day, P. Hailey, T. Lian, R. Rebak, J. Perepezko, J. Payer, D. Branagan, B. Beardsley, A. D’amato and L. Aprigliano, Iron-Based Amorphous Metals: High-Performance Corrosion-Resistant Material Development, Metall. Mater. Trans. A, 2009, 40(6), p 1289-1305. https://doi.org/10.1007/s11661-008-9779-8

J.C. Farmer, J.-S. Choi, C.-K. Saw, R.H. Rebak, S.D. Day, T. Lian, P.D. Hailey, J.H. Payer, D.J. Branagan, and L.F. Aprigliano, Corrosion Resistance of Amorphous Fe 49.7 Cr 17.7 Mn 1.9 Mo 7.4 W 1.6 B 15.2 C 3.8 Si 2.4 Coating: A New Criticality Control Material, Nucl. Technol., 2008, 161(2), p 169-189, https://doi.org/10.13182/NT08-A3921.

I.D. Kuchumova, I.S. Batraev, V.Y. Ulianitsky, A.A. Shtertser, K.B. Gerasimov, A. V. Ukhina, N. V. Bulina, I.A. Bataev, G.Y. Koga, Y. Guo, W.J. Botta, H. Kato, T. Wada, B.B. Bokhonov, D. V. Dudina, and A. Moreira Jorge, Formation of Metallic Glass Coatings by Detonation Spraying of a Fe66Cr10Nb5B19 Powder, Metals (Basel)., 2019, 9(8), p 846, https://doi.org/10.3390/met9080846.

I.D. Kuchumova, I.S. Batraev, N.Y. Cherkasova, D.K. Rybin, A. V. Ukhina, W. José Botta, G. Yuuki Koga, and A. Moreira Jorge, The Influence of the O2/C2H2 Ratio on the Structure and Properties of Fe66Cr10Nb5B19 Detonation Coatings, Mater. Today Proc., 2020, 17(3), p 701-704, https://doi.org/10.1016/j.matpr.2019.12.098.

I.D. Kuchumova, I.S. Batraev, A. V. Ukhina, T.A. Borisenko, U.E. Bulanova, V.Y. Ulianitsky, D. V. Dudina, V.S. Shikalov, V.F. Kosarev, I.A. Bataev, G.Y. Koga, and A. Moreira Jorge, Processing of Fe-Based Alloys by Detonation Spraying and Spark Plasma Sintering, J. Therm. Spray Technol., 2021, 30(6), p 1692-1702, doi:https://doi.org/10.1007/s11666-021-01237-4.

I.D. Kuchumova, M.A. Eryomina, N.V. Lyalina, D.V. Dudina, I.S. Batraev, V.Y. Ulianitsky, A.A. Shtertser, N.Y. Cherkasova, A.A. Ruktuev, A.V. Ukhina, T.A. Borisenko, G.Y. Koga, C.S. Kiminami and A.M. Jorge, Structural Features and Corrosion Resistance of Fe66Cr10Nb5B19 Metallic Glass Coatings Obtained by Detonation Spraying, J. Mater. Eng. Perform., 2021. https://doi.org/10.1007/s11665-021-06143-y

I.D. Kuchumova, N.Y. Cherkasova, I.S. Batraev, V.S. Shikalov, A.V. Ukhina, G.Y. Koga and A.M. Jorge, Wear-Resistant Fe-Based Metallic Glass-Al2O3 Composite Coatings Produced by Detonation Spraying, J. Therm. Spray Technol., 2022 https://doi.org/10.1007/s11666-021-01299-4

D.A. Santana, G.Y. Koga, W. Wolf, I.A. Bataev, A.A. Ruktuev, C. Bolfarini, C.S. Kiminami, W.J. Botta and A.M. Jorge Jr., Wear-Resistant Boride Reinforced Steel Coatings Produced by Non-Vacuum Electron Beam Cladding, Surf. Coatings Technol., 2020, 386, 125466. https://doi.org/10.1016/j.surfcoat.2020.125466

J. Davis, “Handbook of Thermal Spray Technology,” 2004.

G. Zepon, N. Ellendt, V. Uhlenwinkel, and C. Bolfarini, Solidification Sequence of Spray-Formed Steels, Metall. Mater. Trans. A, Springer US, 2016, 47(2), p 842-851, https://doi.org/10.1007/s11661-015-3253-1.

S.D. Zhang, W.L. Zhang, S.G. Wang, X.J. Gu and J.Q. Wang, Characterisation of Three-Dimensional Porosity in an Fe-Based Amorphous Coating and Its Correlation with Corrosion Behaviour, Corros. Sci., 2015, 93, p 211-221. https://doi.org/10.1016/j.corsci.2015.01.022

G.Y. Koga, G. Zepon, L.S. Santos, C. Bolfarini, C.S. Kiminami and W.J. Botta, Wear Resistance of Boron-Modified Supermartensitic Stainless Steel Coatings Produced by High-Velocity Oxygen Fuel Process, J. Therm. Spray Technol., 2019, 28(8), p 2003-2014. https://doi.org/10.1007/s11666-019-00961-2

J. Soyama, T.P. Lopes, G. Zepon, C.S. Kiminami, W.J. Botta and C. Bolfarini, Wear Resistant Duplex Stainless Steels Produced by Spray Forming, Met. Mater. Int., 2019, 25(2), p 456-464. https://doi.org/10.1007/s12540-018-0202-8

I.A. Bataev, A.A. Bataev, M.G. Golkovski, D.S. Krivizhenko, A.A. Losinskaya and O.G. Lenivtseva, Structure of Surface Layers Produced by Non-Vacuum Electron Beam Boriding, Appl. Surf. Sci., 2013, 284, p 472-481. https://doi.org/10.1016/j.apsusc.2013.07.121

I.A. Bataev, A.A. Bataev, M.G. Golkovsky, A.Y. Teplykh, V.G. Burov and S.V. Veselov, Non-Vacuum Electron-Beam Boriding of Low-Carbon Steel, Surf. Coatings Technol., 2012, 207, p 245-253. https://doi.org/10.1016/j.surfcoat.2012.06.081

Y. Wang, S.L. Jiang, Y.G. Zheng, W. Ke, W.H. Sun and J.Q. Wang, Effect of Porosity Sealing Treatments on the Corrosion Resistance of High-Velocity Oxy-Fuel (HVOF)-Sprayed Fe-Based Amorphous Metallic Coatings, Surf. Coatings Technol., 2011, 206(6), p 1307-1318. https://doi.org/10.1016/j.surfcoat.2011.08.045

J. Jiao, Q. Luo, X. Wei, Y. Wang and J. Shen, Influence of Sealing Treatment on the Corrosion Resistance of Fe-Based Amorphous Coatings in HCl Solution, J. Alloys Compd., 2017, 714, p 356-362. https://doi.org/10.1016/j.jallcom.2017.04.179

C. Zhang, K.C. Chan, Y. Wu and L. Liu, Pitting Initiation in Fe-Based Amorphous Coatings, Acta Mater., 2012, 60(10), p 4152-4159. https://doi.org/10.1016/j.actamat.2012.04.005

D.D. Coimbrão, G. Zepon, G.Y. Koga, D.A.G. Pérez, F.H.P. de Almeida, V. Roche, J.-C. Lepretre, A.M. Jorge, C.S. Kiminami, C. Bolfarini, A. Inoue and W.J. Botta, Corrosion Properties of Amorphous, Partially, and Fully Crystallized Fe68Cr8Mo4Nb4B16 Alloy, J. Alloys Compd., 2020, 826, p 154123. https://doi.org/10.1016/j.jallcom.2020.154123

A. Inoue, F.L. Kong, S.L. Zhu and F. Al-Marzouki, Peculiarities and Usefulness of Multicomponent Bulk Metallic Alloys, J. Alloys Compd., 2017, 707, p 12-19. https://doi.org/10.1016/j.jallcom.2016.11.228

J. Ding, A. Inoue, Y. Han, F.L. Kong, S.L. Zhu, Z. Wang, E. Shalaan and F. Al-Marzouki, High Entropy Effect on Structure and Properties of (Fe Co, Ni, Cr)-B Amorphous Alloys, J. Alloys Compd., 2017, 696, p 345-352. https://doi.org/10.1016/j.jallcom.2016.11.223

F. Wang, A. Inoue, F.L. Kong, Y. Han, S.L. Zhu, E. Shalaan and F. Al-Marouki, Formation, Thermal Stability and Mechanical Properties of High Entropy (Fe Co, Ni, Cr, Mo)-B Amorphous Alloys, J. Alloys Compd., 2018, 732, p 637-645. https://doi.org/10.1016/j.jallcom.2017.10.227

F. Wang, A. Inoue, F.L. Kong, S.L. Zhu, E. Shalaan, F. Al-Marzouki, W.J. Botta, C.S. Kiminami, Y.P. Ivanov, and A.L. Greer, Formation, Stability and Ultrahigh Strength of Novel Nanostructured Alloys by Partial Crystallization of High-Entropy (Fe0.25Co0.25Ni0.25Cr0.125Mo0.125)86-89B11-14 Amorphous Phase, Acta Mater., 2019, 170, p 50-61, https://doi.org/10.1016/j.actamat.2019.03.019.

A. Inoue, F.L. Kong, S.L. Zhu, B.L. Shen, A. Churyumov and W.J. Botta, Formation, Structure and Properties of Pseudo-High Entropy Clustered Bulk Metallic Glasses, J. Alloys Compd., 2020, 820, 153164. https://doi.org/10.1016/j.jallcom.2019.153164

G.Y. Koga, D. Travessa, G. Zepon, D.D. Coimbrão, A.M. Jorge, J.E. Berger, V. Roche, J.-C. Lepretre, C. Bolfarini, C.S. Kiminami, F. Wang, S.L. Zhu, A. Inoue and W.J. Botta, Corrosion Resistance of Pseudo-High Entropy Fe-Containing Amorphous Alloys in Chloride-Rich Media, J. Alloys Compd., 2021, 884, 161090. https://doi.org/10.1016/j.jallcom.2021.161090

Acknowledgments

Guilherme Yuuki Koga gratefully acknowledges the financial support of FAPESP (Post-Doctorate Grant No. 17/09237-4 and Scientific Initiation Grant No. 12/10631-5), CNPq (Master Grant No. 153269/2013-8 and Universal Grant No. 407651/2021-7), and CAPES-BRAFITEC (Exchange Grant No. 2778/11-4). All authors are grateful for the financial support granted by FAPESP (Thematic Project Grant Nos. 13/05987-8 and 05/59594-0). The authors also thank the Laboratory of Structural Characterization (LCE) and the Center for Characterization and Development of Materials (CCDM) of the Federal University of São Carlos for the characterization facilities access. The Hydro-Quebec (HVOF and Wear facilities, Canada), Lavrentyev Institute of Hydrodynamics SB RAS (Detonation Spraying facility, Russia), Novosibirsk State Technical University (Electron Beam Cladding facility, Russia), Université Grenoble Alpes (Corrosion-LEPMI and Processing-SIMaP facilities, France), Petrobras SA (funding, Brazil), and Villares Metals SA (supply of stainless steels, Brazil) are acknowledged. This work results from the collaboration of our group with different researchers over the past decade, whose publications were used as the cornerstone of this review. We are thus thankful for the fruitful discussion and exchange consolidated with Dr. Robert Schulz (Hydro-Quebec), Prof. Ricardo Pereira Nogueira and Prof. Virginie Roche (LEPMI), Prof. Dina Dudina (Lavrentyev Institute of Hydrodynamics), Prof. Ivan Bataev (Novosibirsk State Technical University), Prof. Juno Gallego (UNESP), Prof. Akihisa Inoue (Tianjin University/King Abdulaziz University) and Dr. Alain Reza Yavari (SIMaP). We also thank the valuable effort and contribution of previous students that have worked on Fe-Cr-Nb-B alloys in our group: M.Sc. Ana Karla Melle, Dr. Alexandre Nascimento, M.Sc. Diego Santana, Dr. Tales Ferreira, M.Sc. Diego Coimbrão, and Dr. Yaofeng Guo; we also thank Ms. Ivanna Kuchumova, who conducted her Ph.D. on Fe-Cr-Nb-B coatings in the Lavrentyev Institute of Hydrodynamics SB RAS.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Koga, G.Y., Bolfarini, C., Kiminami, C.S. et al. An Overview of Thermally Sprayed Fe-Cr-Nb-B Metallic Glass Coatings: From the Alloy Development to the Coating’s Performance Against Corrosion and Wear. J Therm Spray Tech 31, 923–955 (2022). https://doi.org/10.1007/s11666-022-01371-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01371-7