Abstract

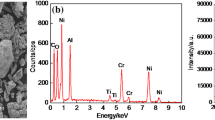

Ti-Al-Cr-N coatings were synthesized by manipulating the nitrogen (N2) flow rate and via a hybrid physical vapor deposition process. The morphologies, microstructures, mechanical properties, tribological behavior, and milling performance of Ti-Al-Cr-N coatings were systematically investigated. Results indicated Ti-Al-Cr-N coatings were composed of Ti(Al, Cr)N, which grew preferentially along the (111), (200), and (220) crystal planes. Furthermore, low N2 flow rates of 40 sccm and 60 sccm facilitated the formation of the amorphous-like metallic. Ti-Al-Cr-N coating with the N2 flow rate of 100 sccm showed the maximum hardness (18.5 GPa) and elastic modulus (207.7 GPa), inferior toughness, a minimum friction coefficient of 0.62, and the lowest wear rate of 1.68 × 10−11 m3·N−1·m−1. Meanwhile, the Ti-Al-Cr-N-coated mill with the N2 flow rate of 100 sccm presented an enhanced wear life of about 1.8 times than that of the uncoated mill when dry milling aluminum alloy and the wear modes were mainly abrasion and diffusion wear. This article provides a novel way of processing soft metal materials, such as aluminum alloy.

Similar content being viewed by others

References

J.B. Jia, Z.G. Yang, B. Xu, W.T. Xie, Y. Xu, J.T. Luo and Q. Wang, Microstructure Evolution, Mechanical Properties, and Strengthening Mechanisms of 6061 Aluminum Alloy Processed via Corrugated Constrained Groove Pressing, Mater. Sci. EEG. A, 2023, 878, p 145218. https://doi.org/10.1016/j.msea.2023.145218

J.Y. Zang, Y.J. Lee and H. Wang, Mechanochemical Effect on the Microstructure and Mechanical Properties in Ultraprecision Machining of AA6061 Alloy, J. Mater. Sci. Technol., 2021, 69, p 228–238. https://doi.org/10.1016/j.jmst.2020.08.024

Z. Imed, S. Victor and K. Riad, Fine and Ultrafine Particle Characterization and Modeling in High-Speed Milling of 6061–T6 Aluminum Alloy, J. Mater. EEG. Perform., 2009, 18, p 38–48. https://doi.org/10.1007/s11665-008-9265-x

D.G. Sunhedar, K.V. Chauhan and D.A. Patel, An Experimental Investigation of TiN Coating on Cutting Force and Surface Finish in Milling of Aluminum, Mater. Today, 2022, 59, p 161–165. https://doi.org/10.1016/j.matpr.2021.10.384

J.F. Zhao, Z.Q. Liu, B. Wang, Q.H. Song, X.P. Ren and Y. Wan, Effects of Al Content in TiAlN Coatings on Tool Wear and Cutting Temperature During Dry Machining In718, Tribol. Int., 2022, 171, 107540. https://doi.org/10.1016/j.triboint.2022.107540

R. Žamlička, M. Alishahi, M. Jílek, P. Souček, J. Daniel, J. Kluson, H. Bolvardi, A. Lümkemann and P. Vašina, Enhancing Mechanical Properties and Cutting Performance of Industrially Sputtered AlCrN Coatings by Inducing Cathodic Arc Glow Discharge, Surf. Coat. Technol., 2021, 422, 127563. https://doi.org/10.1016/j.surfcoat.2021.127563

C.H. Chen, W.M. Tang, X.Y. Li, W.J. Wang and C.Y. Xu, Structure and Cutting Performance of Ti-DLC Films Prepared by Reactive Magnetron Sputtering, Diam. Relat. Mater., 2020, 104, 107735. https://doi.org/10.1016/j.diamond.2020.107735

U. Wahlstrom, L. Hultman, J.E. Sundgren, F. Adibi, I. Petrov and J.E. Greene, Crystal Growth and Microstructure of Polycrystalline Ti1-xAlxN Alloy Films Deposited by Ultra-High-Vacuum Dual-Target Magnetron Sputtering, Thin Solid Films, 1993, 235, p 62–70. https://doi.org/10.1016/0040-6090(93)90244-J

M. Danek, F. Fernandes, A. Cavaleiro and T. Polcar, Influence of Cr Additions on the Structure and Oxidation Resistance of Multilayered TiAlCrN Films, Surf. Coat. Technol., 2017, 313, p 158–167.

H. Lind, R. Forsén, B. Alling, N. Ghafoor, F. Tasnádi, M.P. Johansson, I.A. Abrikosov and M. Odén, Improving Thermal Stability of Hard Coating Films Via a Concept of Multicomponent Alloying, Appl. Phys. Lett., 2011, 99, 091903. https://doi.org/10.1063/1.3631672

G.S. Fox-Rabinovich, A.I. Kovalev, M.H. Aguirre, B.D. Beake, K. Yamamoto, S.C. Veldhuis, J.L. Endrino, D.L. Wainstein and A.Y. Rashkovskiy, Design and Performance of AlTiN and TiAlCrN PVD Coatings for Machining of Hard to Cut Materials, Surf. Coat. Technol., 2009, 204, p 489–496. https://doi.org/10.1016/j.surfcoat.2009.08.021

F. Fernandes, M. Danek, T. Polcar and A. Cavaleiro, Tribological and Cutting Performance of TiAlCrN Films with Different Cr Contents Deposited with Multilayered Structure, Tribol. Int., 2018, 119, p 345–353. https://doi.org/10.1016/j.triboint.2017.11.008

B.H. Gui, H. Zhou, J. Zheng, X.G. Liu, X.G. Feng, Y.S. Zhang and L.M.C. Yang, Microstructure and Properties of TiAlCrN Ceramic Coatings Deposited by Hybrid HiPIMS/DC Magnetron Co-sputtering, Ceram. Int., 2021, 47, p 8175–8183. https://doi.org/10.1016/j.ceramint.2020.11.175

H.B. He, H.Y. Li, X.Y. Zhang, Q.B. Yue, J. Zhang, L. Ma and Y.M. Li, Research on the Cutting Performances and Wear Mechanisms of TiAlCrN Coated Tools During Dry Turning, Int. J. Precis. Eng. Man., 2019, 20, p 201–207. https://doi.org/10.1007/s12541-019-00026-y

C.S. Kumar, P. Zeman and T. Polcar, A 2D Finite Element Approach for Predicting the Machining Performance of Nanolayered TiAlCrN Coating on WC-Co Cutting Tool During Dry Turning Of AISI 1045 Steel, Ceram. Int., 2020, 46, p 25073–25088. https://doi.org/10.1016/j.ceramint.2020.06.294

G.S. Fox-Rabinovich, K. Yamamoto, S.C. Veldhuis, A.I. Kovalev and G.K. Dosbaeva, Tribological Adaptability of TiAlCrN PVD Coatings Under High Performance Dry Machining Conditions, Surf. Coat. Technol., 2005, 200, p 1804–1813. https://doi.org/10.1016/j.surfcoat.2005.08.057

A. Vereschaka, S. Grigoriev, V. Tabakov, M. Migranov, N. Sitnikov, F. Milovich and N. Andreev, Influence of the Nanostructure of Ti-TiN-(Ti, Al, Cr)N Multilayer Composite Coating on Tribological Properties and Cutting Tool Life, Tribol. Int., 2020, 150, 106388. https://doi.org/10.1016/j.triboint.2020.106388

F. Huang, G.H. Wei, J.A. Barnard and M.L. Weaver, Microstructure and Stress Development in Magnetron Sputtered TiAlCr(N) Films, Surf. Coat. Tech., 2001, 146–147, p 391–397. https://doi.org/10.1016/S0257-8972(01)01424-4

J.F. Sullivan, F. Huang, J.A. Barnard and M.L. Weaver, Effect of Nitrogen Pressure on the Hardness and Chemical States of TiAlCrN Coatings, J. Vac. Sci. Technol. A, 2005, 23, p 78–84. https://doi.org/10.1116/1.1830498

B. Huang, L.T. Liu, H.M. Du, Q. Chen, D.D. Liang, E.G. Zhang and Q. Zhou, Effect of Nitrogen Flow Rate on the Microstructure, Mechanical and Tribological Properties of CrAlTiN Coatings Prepared by Arc Ion Plating, Vacuum, 2022, 204, p 111336. https://doi.org/10.1016/j.vacuum.2022.111336

Q. Chen, D.D. Liang, E.G. Zhang, L. Yang, Q. Zhou, B. Huang and S. Han, Influence of C2H2/N2 Flow Ratio on the Microstructure, Mechanical Properties, and Electrochemical Behavior of TiCN Composite Coatings, Vacuum, 2023, 216, 112349. https://doi.org/10.1016/j.vacuum.2023.112349

A.E. Santana, A. Karimi, V.H. Derflinger and A. Schutze, Microstructure and Mechanical Behavior of TiAlCrN Multilayer Thin Films, Surf. Coat. Tech., 2004, 177–178, p 334–340. https://doi.org/10.1016/j.surfcoat.2003.09.023

M. Hirai, Y. Ueno, T. Suzuki, W.H. Jiang, C. Grigoriu and K. Yatsui, Characteristics of (Cr1−x, Alx)N Films Prepared by Pulsed Laser Deposition, Jpn. J. Appl. Phys., 2001, 40, p 1056–1060. https://doi.org/10.1143/JJAP.40.1056

Q.S. Ma, L.H. Li, Y. Xu, J.B. Gu, L. Wang and Y. Xu, Effect of Bias Voltage on TiAlSiN Nanocomposite Coatings Deposited By HiPIMS, Appl. Surf. Sci., 2017, 392, p 826–833. https://doi.org/10.1016/j.apsusc.2016.09.028

Y. Yang, H. Lu, C. Yu and J.M. Chen, First-Principles Calculations of Mechanical Properties of TiC and TiN, J. Alloy. Compd., 2009, 485, p 542–547. https://doi.org/10.1016/j.jallcom.2009.06.023

G. Elizabeth Escorcia-Salas, J. Sierra-Ortega, J.A. Rodrĺguez and M., Influence of Zr Concentration on Crystalline Structure and Its Electronic Properties in the New ZrxAl1-xN Compound in Wurtzite Phase: An ab Initio Study, Microelectron. J., 2008, 39, p 579–581. https://doi.org/10.1016/j.mejo.2007.07.100

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans., 2005, 46, p 2817–2829. https://doi.org/10.2320/matertrans.46.2817

A. SchÜler and P. Oelhafen, In Situ Core-Level and Valence-Band Photoelectron Spectroscopy of Reactively Sputtered Titanium Aluminum Nitride Films, Phys. Rev. B, 2001, 63, p 15413. https://doi.org/10.1103/PhysRevB.63.115413

D.E. Mencer Jr., T.R. Hess, T. Mebrahtu, D.L. Cocke and D.G. Naugle, Surface Reactivity of Titanium-Aluminum Alloys: Ti3Al, TiAl, and TiAl3, J. Vac. Sci. Technol. A, 1991, 9, p 1610–1615. https://doi.org/10.1116/1.577669

Y. Song, R. Yang, D. Li, Z.Q. Hu and Z.X. Guo, A First Principles Study of the Influence of Alloying Elements on TiAl: Site Preference, Intermetallics, 2000, 8, p 563–568. https://doi.org/10.1016/S0966-9795(99)00164-8

J. Musil, Hard and Superhard Nanocomposite Coatings, Surf. Coat. Technol., 2000, 125, p 322–330. https://doi.org/10.1016/S0257-8972(99)00586-1

A. Leyland and A. Matthews, On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour, Wear, 2000, 246, p 1–11. https://doi.org/10.1016/S0043-1648(00)00488-9

D. Wang, S.S. Lin, Q. Shi, Y.N. Xue, H.Z. Yang, D.C. Zhang and Z. Z. XU, C. Q. Guo, M. J. Dai, B. L. Jiang, K. S. Zhou, Microstructure Effects on Fracture Failure Mechanism of CrAl/CrAlN Coating, Ceram. Int., 2021, 47, p 3657–3664. https://doi.org/10.1016/j.ceramint.2020.09.217

T. Polcar and A. Cavaleiro, High Temperature Behavior of Nanolayered CrAlTiN Coating: Thermal Stability, Oxidation, and Tribological Properties, Surf. Coat. Technol., 2014, 257, p 70–77. https://doi.org/10.1016/j.surfcoat.2014.07.053

A. Azushima, Y. Tanno, H. Iwata and K. Aoki, Coefficients of Friction of TiN Coatings with Preferred Grain Orientations Under Dry Condition, Wear, 2008, 256, p 1017–1022. https://doi.org/10.1016/j.wear.2008.02.019

S.Y. Li, J.B. Sui, F. Ding, S.X. Wu, W.L. Chen and C.Y. Wang, Optimization of Milling Aluminum Alloy 6061–T6 Using Modified Johnson-Cook Model, Simul. Model. Pract. Theory, 2021, 111, 102330. https://doi.org/10.1016/j.simpat.2021.102330

A.S. Chaus, M.V. Sitkevich, P. Pokorný, M. Sahul, M. Harsani and P. Babincova, Wear Resistance and Cutting Performance of High-Speed Steel Ball Nose End Mills Related to the Initial State of Tool Surface, Wear, 2021, 472–473, 203711. https://doi.org/10.1016/j.wear.2021.203711

J.F. Yuan, K.J. Yamamoto, D. Covelli, M. Tauhiduzzama, T. Arif, I.S. Gershman, S.C. Veldhuis and G.S. Fox-Rabinovich, Tribo-Films Control in Adaptive TiAlCrSiYN/TiAlCrN Multilayer PVD Coating by Accelerating the Initial Machining Conditions, Surf. Coat. Tech., 2016, 294, p 54–61. https://doi.org/10.1016/j.surfcoat.2016.02.041

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant No. 52376162) and the Program of Shanghai Technology Research Leader (Grant No. 22XD1434500).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Q., Su, M., Liang, D. et al. Influence of N2 Flow Rate on the Microstructure, Mechanical, and Tribological Properties of Ti-Al-Cr-N Coating: Dry Milling Investigation on 6061 Aluminum Alloy. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09403-9

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09403-9