Abstract

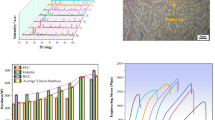

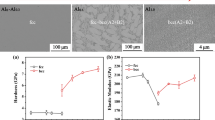

Al15Cr15Fe50Ni20−xBx (x = 0, 2, 4, 5, 6 and 8; x values in molar ratio) high-entropy alloys were prepared by vacuum arc melting, and the effects of B content on the microstructures and mechanical properties of Al15Cr15Fe50Ni20−xBx high-entropy alloys were systematically studied. The results showed that the Al15Cr15Fe50Ni20 high-entropy alloy was composed of FCC and BCC phases. With the addition of B, boride phases could be observed in the studied alloys. Moreover, lattice distortion was formed according to theoretical calculations. When the content of B was 2, 4 or 5, the studied alloys showed a typical hypoeutectic structure. When the content of B increased to 6 or 8, a hypereutectic structure could be observed. With increasing B content, the fracture strength and hardness values of the Al15Cr15Fe50Ni20−xBx high-entropy alloys showed a trend of first increasing and then decreasing. The Al15Cr15Fe50Ni15B5 high-entropy alloy had the best comprehensive mechanical properties, with a hardness of 575 HV, fracture strength of 2595 MPa and compression rate of 31%. The main strengthening mechanisms of the studied alloys were fine grain strengthening, second phase strengthening and solid solution strengthening. By combining theoretical statistics and experimental results, B-containing high-entropy alloys were found to be composed of FCC + BCC + boride phases when the following criteria were met: − 17.12(kJ/mol) ≤ ΔHmix ≤ − 10.11(kJ/mol), 5.64 (%) ≤ δr ≤ 11.02 (%) and 1.11 ≤ Ω ≤ 1.47.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375–377, p 213–218

Z.P. Lu, H. Wang, M.W. Chen, I. Baker, J.W. Yeh, C.T. Liu, and T.G. Nieh, An Assessment on the Future Development of High-Entropy Alloys: Summary from a Recent Workshop, Intermetallics, 2015, 66, p 67–76

D. Miracle and O. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Mater., 2016, 122, p 448–511

S. Kumar, A. Patnaik, A.K. Pradhan, and V. Kumar, Effect of Cobalt Content on Thermal, Mechanical, and Microstructural Properties of Al0.4FeCrNiCox (x= 0, 0.25, 0.5, 1.0 mol) High-Entropy Alloys, J. Mater. Eng. Perform., 2019, 28(7), p 4111–4119

C.Y. Liu, X.S. Jiang, H.L. Sun et al., Microstructure and Mechanical Properties of Bioinspired Laminated CoCrFeNiMn High Entropy Alloy Matrix Composites Reinforced with Graphene, Mater. Sci. Eng. A, 2022, 859, p 144198

Y.D. Wu, Y.H. Cai, T. Wang, J.J. Si, J. Zhu, Y.D. Wang, and X.D. Hui, A Refractory Hf25Nb25Ti25Zr25 High-Entropy Alloy with Excellent Structural Stability and Tensile Properties, Mater. Lett., 2014, 130, p 277–280

H. Wu, J. Xie, H.Y. Yang, D.L. Shu, G.C. Hou, J.G. Li, Y.Z. Zhou, and X.F. Sun, Comparative Study of Mechanical and Corrosion Behaviors of Cost-Effective AlCrFeNi High Entropy Alloys, J. Mater. Eng. Perform., 2022, 31, p 4472–4482

M. Zhu, M. Zhang, L.J. Yao, Z.Q. Jie, Y.Q. Liu, K. Li, and Z.Y. Jian, Effect of V Content on Phase Formation and Mechanical Properties of the CoFeNiMnVx High-Entropy Alloys, J. Mater. Eng. Perform., 2022, 31(4), p 3151–3158

M. Zhang, L.J. Yao, M. Zhu, Y.Q. Liu, and Z.Y. Jian, Structural Evolution and Mechanical and Magnetic Properties of Nonequiatomic CoFe2NiMn0.3Alx (0.25≤ x≤ 1.00) High-Entropy Alloys, J. Mater. Eng. Perform., 2021, 30(2), p 1472–1478

H. Liu, W.P. Gao, J. Liu, X.T. Du, X.J. Li, and H.F. Yang, Microstructure and properties of CoCrFeNiTi High-Entropy Alloy Coating Fabricated by Laser Cladding, J. Mater. Eng. Perform., 2020, 29(11), p 7170–7178

Y. Liu, S.G. Ma, M.C. Gao, C. Zhang, T. Zhang, H.J. Yang, Z.H. Wang, and J.W. Qiao, Tribological Properties of AlCrCuFeNi2 High-Entropy Alloy in Different Conditions, Metall. Mater. Trans. A, 2016, 47(7), p 3312–3321

S.K. Dewangan, D. Kumar, S. Samal, and V. Kumar, Microstructure and Mechanical Properties of Nanocrystalline AlCrFeMnNiWx (x= 0, 0.05, 0.1, 0.5) High-Entropy Alloys Prepared by Powder Metallurgy Route, J. Mater. Eng. Perform., 2021, 30(6), p 4421–4431

H. Zhang, X.C. Zhong, Y.Z. He, W.H. Li, W.F. Wu, G. Chen, and S. Guo, Effect of High Configuration Entropy and Rare Earth Addition on Boride Precipitation and Mechanical Properties of Multi-principal-Element Alloys, J. Mater. Eng. Perform., 2017, 26(8), p 3750–3755

H. Ma and C.H. Shek, Effects of Hf on the Microstructure and Mechanical Properties of CoCrFeNi High Entropy Alloy, J. Alloy. Compd., 2020, 827, p 154159

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Mechanical Properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 Refractory High Entropy Alloys, Intermetallics, 2011, 19, p 698–706

L.J. Wang, L. Wang, S.C. Zhou, Q. Xiao, Y. Xiao, X.T. Wang, T.Q. Cao, Y. Ren, Y.J. Liang, L. Wang, and Y.F. Xue, Precipitation and Micromechanical Behavior of the Coherent Ordered Nanoprecipitation Strengthened Al-Cr-Fe-Ni-V High Entropy Alloy, Acta Mater., 2021, 216, p 117121

Y.P. Lu, Y. Dong, H. Jiang, Z.J. Wang, Z.Q. Cao, S. Guo, T.M. Wang, T.J. Li, and P.K. Liaw, Promising Properties and Future Trend of Eutectic High Entropy Alloys, Scripta Mater., 2020, 187, p 202–209

J.H. Yan, M.J. Li, K.L. Li, J.W. Qiu, and Y.J. Guo, Effects of Cr Content on Microstructure and Mechanical Properties of WMoNbTiCr High-Entropy Alloys, J. Mater. Eng. Perform., 2020, 29(4), p 2125–2133

Z.Q. Lv, Q. Zhang, R.X. Li, Y. Hong, and X.H. Zhang, Combined Effects of Carbon and Nitrogen in Fe20Cr6Mn6CN Alloys from First-Principles Calculation, J. Mater. Eng. Perform., 2021, 30(11), p 8322–8335

L. Guo, X.Q. Ou, S. Ni, Y. Liu, and M. Song, Effects of Carbon on the Microstructures and Mechanical Properties of FeCoCrNiMn High Entropy Alloys, Mater. Sci. Eng. A, 2019, 746, p 356–362

J.Y. Wang, J.H. Fang, H.L. Yang, Z.L. Liu, R.D. Li, S.X. Ji, Y. Wang, and J.M. Ruan, Mechanical Properties and Wear Resistance of Medium Entropy Fe40Mn40Cr10Co10/TiC Composites, Trans. Nonferr. Met. Soc. China, 2019, 29(7), p 1484–1494

J. Svoboda, W. Ecker, V.L. Razumovskiy, G.A. Zickler, and F.D. Fischer, Kinetics of Interaction of Impurity Interstitials with Dislocations Revisited, Prog. Mater. Sci., 2019, 101, p 172–206

L.B. Chen, R. Wei, K. Tang, J. Zhang, F. Jiang, L. He, and J. Sun, Heavy Carbon Alloyed FCC-Structured High Entropy Alloy with Excellent Combination of Strength and Ductility, Mater. Sci. Eng. A, 2018, 716, p 150–156

C. Liu, W.J. Lu, W.Z. Xia, C.W. Du, Z.Y. Rao, J.P. Best, S. Brinckmann, J. Lu, B. Gault, G. Dehm, G. Wu, Z.M. Li, and D. Raabe, Massive Interstitial Solid Solution Alloys Achieve Near-Theoretical Strength, Nat. Commun., 2022, 13(1), p 1–9

Y.D. Wu, Q.J. Wang, D. Lin, X.H. Chen, T. Wang, W. Wang, Y.D. Wang, and X. Hui, Phase Stability and Deformation Behavior of TiZrHfNbO High-Entropy Alloys, Front. Mater., 2020, 7, p 589052

Z.F. Lei, X.J. Liu, Y. Wu, H. Wang, S.H. Jiang, S.D. Wang, X.D. Hui, Y.D. Wu, B. Gault, P. Kontis, D. Raabe, L. Gu, Q.H. Zhang, H.W. Chen, H.T. Wang, J.B. Liu, K. An, Q.S. Zeng, T.-G. Nieh, and Z.P. Lu, Enhanced strength and Ductility in a High-Entropy Alloy via Ordered Oxygen Complexes, Nature, 2018, 563(7732), p 546–550

K. Yamanaka, M. Mori, and A. Chiba, Refinement of Solidification Microstructures By Carbon Addition in Biomedical Co-28Cr-9W-1Si alloys, Mater. Lett., 2014, 116, p 82–85

M. Tahara, H.Y. Kim, H. Hosoda, T. Nam, and S. Miyazaki, Effect of Nitrogen Addition and Annealing Temperature on Superelastic Properties of Ti-Nb-Zr-Ta Alloys, Mater. Sci. Eng. A, 2010, 527(26), p 6844–6852

C.Y. Hsu, J.W. Yeh, S.K. Chen, and T.T. Shun, Wear Resistance and High-Temperature Compression Strength of FCC CuCoNiCrAl0.5Fe Alloy with Boron Addition, Metall. Mater. Trans. A, 2004, 35(5), p 1465–1469

F. Chang, B.J. Cai, C. Zhang, B. Huang, S. Li, and P.Q. Dai, Thermal Stability and Oxidation Resistance of FeCrxCoNiB High-Entropy Alloys Coatings by Laser Cladding, Surf. Coat. Technol., 2019, 359, p 132–140

Z.M. Li and D. Raabe, Influence of Compositional Inhomogeneity on Mechanical Behavior of an Interstitial Dual-Phase High-Entropy Alloy, Mater. Chem. Phys., 2018, 210, p 29–36

Q.S. Chen, Y. Dong, J.J. Zhang, and Y.P. Lu, Microstructure and Properties of AlCoCrFeNiBx (x = 0, 0.1, 0.25, 0.5, 0.75, 1.0) High Entropy Alloys, Rare Met. Mater. Eng., 2017, 46(3), p 651–656

B. Tripathy, S.R.K. Malladi, and P.P. Bhattacharjee, Development of Ultrafine Grained Cobalt-Free AlCrFe2Ni2 High Entropy Alloy with Superior Mechanical Properties by Thermo-Mechanical Processing, Mater. Sci. Eng. A, 2022, 831, p 142190

B. Tripathy and P.P. Bhattacharjee, Superior Strength-Ductility Synergy of a Cost-Effective AlCrFe2Ni2 High Entropy Alloy with Heterogeneous Microstructure Processed by Moderate Cryo-Rolling and Annealing, Mater. Lett., 2022, 326, p 132981

J.J. Feng, S. Gao, K. Han, Y.D. Miao, J.Q. Qi, F.X. Wei, Y.J. Ren, Z.Z. Zhan, Y.W. Sui, and S. Zhi, Effects of Minor B Addition on Microstructure and Properties of Al19Co20Fe20Ni41 Eutectic High-Entropy Alloy, Trans. Nonferrous Met. Soc. China, 2021, 31(4), p 1049–1058

Y. Jiang, X.M. Li, G.T. Zhou, and B.X. Zhu, Effects of B Content on Microstructure and Properties of CrFeCoNiTi0.6 High-Entropy Alloy, Mater. Sci. Eng. Powder Metall., 2020, 25(5), p 403–409

X.T. Liu, W.B. Lei, L.J. Ma, J.L. Liu, J. Liu, and J.Z. Cui, Effect of boron on the Microstructure, Phase Assemblage and Wear Properties of Al0.5CoCrCuFeNi High-Entropy Alloy, Rare Met. Mater. Eng., 2016, 45(9), p 2201–2207

J. Ding, A. Inoue, Y. Han, F.L. Kong, S.L. Zhu, Z. Wang, E. Shalaan, and F. Al-Marzouki, High Entropy Effect on Structure and Properties of (Fe Co, Ni, Cr)-B Amorphous Alloys, J. Alloy. Compd., 2017, 696, p 345–352

M.X. Xia, H.X. Zheng, C.L. Ma, and J. Li, Preparation and Properties of High Strength Bulk Metallic Glass Ti53Cu15Ni18.5Al7M3Si3B0.5(M = Zr, Hf, Sc), Acta Metall. Sin., 2005, 41(2), p 199–202

L.L. Hou, X.Y. Liang, Y.H. Yao, J. Chen, and J.N. Liu, Effect of B Content on Microstructure and Mechanical Properties of FeCrCoNiMn High-Entropy Alloy, Rare Met. Mater. Eng., 2018, 47(10), p 3203–3207

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-component Alloys, Adv. Eng. Mater., 2008, 10(6), p 534–538

S. Guo, C. Ng, J. Lu and C.T. Liu, Effect of Valence Electron Concentration on Stability of FCC or BCC Phase in High Entropy Alloys, J. Appl. Phys., 2011, 109(10), p 103505

W.J. Huang, P. Martin, and H.L.L. Zhuang, Machine-Learning Phase Prediction of High-Entropy Alloys, Acta Mater., 2019, 169, p 225–236

Acknowledgments

This research is financially supported by the Key Projects of Hubei Provincial Department of Education (No. D20201206), the Open Research Fund of Hubei Engineering Research Center for Graphite Additive Manufacturing Technology and Equipment (No. HRCGAM202102) and National Natural Science Foundation of China (No. 52031017), the Technology Development Fund of China Academy of Machinery Science &Technology (No. 912201Q9).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, W., Li, B., Sun, F. et al. Effect of B Content on the Microstructures and Mechanical Properties of Al15Cr15Fe50Ni20−xBx High-Entropy Alloys. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08899-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08899-x