Abstract

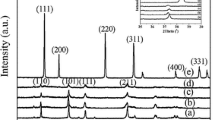

The anticorrosion and wear resistance, in addition to the biocompatibility are among the most important considerations in the selection of biomaterials for implants (prosthesis). It is toward this goal that titanium-based ceramic coatings were fabricated by a magnetron sputtering method. Surface characteristics, microstructures, anticorrosion behavior, calcium-phosphorus (Ca-P) layer ability formation, and antibacterial adhesion resistance were systematically investigated. Obtained results showed superior anticorrosion resistance in blood plasma of specimen coated with TiO2 (the corrosion current density (Icorr) = 0.02 µA/cm2) when compared to the specimen coated with TiN (Icorr = 0.81 µA/cm2). Moreover, the in vitro bioactivity test results carried out in Hank’s solution and the anti-adhesion resistance against Staphylococcus aureus (S. aureus) and Escherichia coli (E. coli) bacteria, revealed a higher performance of the TiO2 surface when compared to TiN surface. The optimum performances (i.e., 7.3 .103 CFU/cm2 versus S. aureus and 1.13 .103 CFU/cm2 versus E. coli) were shown for TiO2 (O2 = 20%) coating characterized by fine grain microstructure, high wettability angle, and low defects density.

Graphical Abstract

Similar content being viewed by others

Data Availability

The statistical data used to support the findings of this study are available from the corresponding author upon request.

References

F. Batool, H. Özçelik, C. Stutz, P.Y. Gegout, N.B. Jessel, C. Petit, and O. Hunk, Modulation of Immune-Inflammatory Responses Through Surface Modifications of Biomaterials to Promote Bone Healing and Regeneration, J. Tissue. Eng., 2021, 12, p 1-19. https://doi.org/10.1177/20417314211041428

H. Liu, X. Zhang, S. Jin, Y. Zhao, L. Ren, and K. Yang, Effect of Copper-Doped Titanium Nitride Coating on Angiogenesis, Mater. Lett., 2020, 269, p 127634. https://doi.org/10.1016/j.matlet.2020.127634

C.R. Arciola, D. Campoccia, G.D. Ehrlich, Montanaro L, Biofilm-Based Implant Infections in Orthopaedics. In: Donelli, G. (eds) Biofilm-Based Healthcare-Associated Infections. Adv Exp Med Biol, 2015, 830, 29-46. https://doi.org/10.1007/978-3-319-11038-7_2

Y. Huang, X. Zhang, R. Zhao, H. Mao, Y. Yan, and X. Pang, Antibacterial Efficacy, Corrosion Resistance, and Cytotoxicity Studies of Copper-Substituted Carbonated Hydroxyapatite Coating on Titanium Substrate, J. Mater. Sci., 2015, 50, p 1688-1700. https://doi.org/10.1007/s10853-014-8730-1

L.C. Zhang and L.Y. Chen, A Review on Biomedical Titanium Alloys: Recent Progress and Prospect, Adv. Eng. Mater., 2019, 21, p 1801215. https://doi.org/10.1002/adem.201801215

M. Kaur and K. Singh, Review on Titanium and Titanium Based Alloys as Biomaterials for Orthopaedic Applications, Mater. Sci. Eng. C, 2019, 102, p 844-862. https://doi.org/10.1016/j.msec.2019.04.064

M.A. Hussein, N.K. Ankah, A.M. Kumar, M.A. Azeem, S. Saravanan, A.A. Sorour, and N. Al Aqeeli, Mechanical, Biocorrosion, and Antibacterial Properties of Nanocrystalline TiN Coating for Orthopedic Applications, Ceram. Int., 2020, 46, p 18573-18583. https://doi.org/10.1016/j.ceramint.2020.04.164

S. Piscanec, L.C. Ciacchi, E. Vesselli, G. Comelli, O. Sbaizero, S. Meriani, and A. De Vita, Bioactivity of TiN-Coated Titanium Implants, Acta Mater., 2004, 52, p 1237-1245. https://doi.org/10.1016/j.actamat.2003.11.020

J. Zuo, Y. Xie, J. Zhang, Q. Wei, B. Zhou, J. Luo, Y. Wang, Z.M. Yu, and Z.G. Tang, TiN Coated Stainless Steel Bracket: Tribological, Corrosion Resistance, Biocompatibility and Mechanical Performance, Surf. Coat. Technol., 2015, 277, p 227-233. https://doi.org/10.1016/j.surfcoat.2015.07.009

A. Kozlovskiy, I. Shlimas, K. Dukenbayev, and M. Zdorovets, Structure and Corrosion Properties of Thin TiO2 Films Obtained by Magnetron Sputtering, Vacuum, 2019, 164, p 224-232. https://doi.org/10.1016/j.vacuum.2019.03.026

H. Sugisawa, H. Kitaura, K. Ueda, K. Kimura, M. Ishida, Y. Ochi, A. Kishikawa, S. Ogawa, and T.T. Yamamoto, Corrosion Resistance and Mechanical Properties of Titanium Nitride Plating on Orthodontic Wires, Dent. Mater. J., 2018, 37(2), p 286-292. https://doi.org/10.4012/dmj.2016-348

Z. Wang and Q.Z. Zhao, Friction Reduction of Steel by Laser-Induced Periodic Surface Nanostructures with Atomic Layer Deposited TiO2 Coating, Surf. Coat. Technol., 2018, 344, p 269-275. https://doi.org/10.1016/j.surfcoat.2018.03.036

M. Łępicka, M.G. Dahlke, D. Pieniak, K. Pasierbiewicz, K. Kryńska, and A. Niewczas, Tribological Performance of Titanium Nitride Coatings: A Comparative Study on TiN-Coated Stainless Steel and Titanium Alloy, Wear, 2019, 422, p 68-80. https://doi.org/10.1016/j.wear.2019.01.029

L. Visai, L. De Nardo, C. Punta, L. Melone, A. Cigada, M. Imbriani, and C.R. Arciola, Titanium Oxide Antibacterial Surfaces in Biomedical Devices, Int. J. Artif. Organs, 2011, 34(9), p 929-946. https://doi.org/10.5301/ijao.5000050. (PMID: 22094576)

D. Wiedmer, C. Cui, F. Weber, F. Petersen, and H. Tiainen,Antibacterial Surface Coating for Bone Scaffolds Based on the Dark Catalytic Effect of Titanium Dioxide, ACS Appl. Mater. Interfaces, 2018, 10(42), p 35784-35793. https://doi.org/10.1021/acsami.8b12623

X. Zhang, Y. Wu, Y. Lv, Y. Yu, and Z. Dong, Formation Mechanism, Corrosion Behaviour and Biological Property of Hydroxyapatite/TiO2 Coatings Fabricated by Plasma Electrolytic Oxidation, Surf. Coat. Technol., 2020, 386, p 125483. https://doi.org/10.1016/j.surfcoat.2020.125483

E.M. Saeed, N.M. Dawood, and S.F. Hasan,Improvement Corrosion Resistance of Ni-Ti Alloy by TiO2 Coating and Hydroxyaptite/TiO2 Composite Coating Using Micro Arc Oxidation Process, Mater. Today Proc., 2021, 42(5), p 2789-2796. https://doi.org/10.1016/j.matpr.2020.12.723

R. Bahi, C. Nouveau, N.E. Beliardouh, C.E. Ramoul, S. Meddah, and O. Ghelloudj, Surface Performances of Ti-6Al-4V Substrates Coated PVD Multilayered Films in Biological Environments, Surf. Coat. Technol., 2020, 385, p 125412. https://doi.org/10.1016/j.surfcoat.2020.125412

E. Győri, I. Fábián, and I. Lázár,Effect of the Chemical Composition of Simulated Body Fluids on Aerogel-Based Bioactive Composites, J. Compos. Sci., 2017, 1(2), p 15-27. https://doi.org/10.3390/jcs1020015

C.C. Chien, K.T. Liu, J.G. Duh, K.W. Chang, and K.H. Chung,Effect of Nitride Film Coatings on Cell Compatibility, Dent. Mater. J., 2008, 24(7), p 986-993. https://doi.org/10.1016/j.dental.2007.11.020

M. Atapour, V. Rajaei, S. Trasatti, M.P. Casaletto, and G.L. Chiarello, Thin Niobium and Niobium Nitride PVD Coatings on AISI 304 Stainless Steel as Bipolar Plates for PEMFCs, Coatings, 2020, 10(9), p 889-916. https://doi.org/10.3390/coatings10090889

V. Vishwakarma, G.S. Kaliaraj, D. Ramachandran, and A. Ramadoss, Bacterial Adhesion and Hemocompatibility Behavior of TiN, TiO2 Single and TiN/tio2 Multilayer Coated 316L SS for Bioimplants, J. Biomimet. Biomater. Biomed. Eng., 2015, 25, p 73-82. https://doi.org/10.4028/www.scientific.net/jbbbe.25.73

J.D.C. Tardelli, V.S. Bagnato, and A.C.D. Reis, Bacterial Adhesion Strength on Titanium Surfaces Quantified by Atomic Force Microscopy: A Systematic Review, Antibiotics, 2023, 12(6), p 994-1010. https://doi.org/10.3390/antibiotics12060994

A.O. Ijaola, E.A. Bamidele, C.J. Akisin, I.T. Bello, A.T. Oyatobo, A. Abdulkareem, P.K. Farayibi, and E. Asmatulu,Wettability Transition for Laser Textured Surfaces: A Comprehensive Review, Surf. Interfaces, 2020, 21, p 100802. https://doi.org/10.1016/j.surfin.2020.100802

P.G. Grützmacher, S.V. Jalikop, C. Gachot, and A. Rosenkranz, Thermocapillary Lubricant Migration on Textured Surfaces-A Review of Theoretical and Experimental Insights, Surf. Topogr. Metrol. Prop., 2021, 9(1), p 013001. https://doi.org/10.1088/2051-672X/abd07c

R. Shah, B. Gashi, S. Hoque, M. Maria, and A. Rosenkranz, Enhancing Mechanical and Biomedical Properties of Prostheses—Surface and Material Design, Surf. Interfaces, 2021, 27, p 101498. https://doi.org/10.1016/j.surfin.2021.101498

V. Prakash, N. Priyadarshni, D. Aloc-Kumar, and S. Chattopadhyay, Fabrication of Hydrophobic Surface on Ti6Al4V by WEDM Process for Surgical Instruments and Bioimplants, Int. J. Adv. Manuf. Technol., 2022, 118, p 1111-1123. https://doi.org/10.1007/s00170-021-07857-y

K. Sarkar, P. Jaipan, J. Choi, T. Haywood, D. Tran, N.R. Mucha, and S. Yarmolenko, Enhancement in Corrosion Resistance and Vibration Damping Performance in Titanium by Titanium Nitride Coating, SN Appl. Sci., 2020, 2, p 949-963. https://doi.org/10.1007/s42452-020-2777-1

M. Aslan Çakır, T. Yetim, A.F. Yetim, and A. Çelik, Superamphiphobic TiO2 Film by Sol-Gel Dip Coating Method on Commercial Pure Titanium, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08049-3

H. Tekdir, T. Yetim, and A.F. Yetim, Corrosion Properties of Ceramic-Based TiO2 Films on Plasma Oxidized Ti6Al4V/316L Layered Implant Structured Manufactured by Selective Laser Melting, J. Bionic. Eng., 2021, 18, p 944-957. https://doi.org/10.1007/s42235-021-0055-6

T. Rajabi, M. Atapour, H. Elmkhah, and S.M. Nahvi, Nanometric CrN/CrAlN and CrN/ZrN Multilayer Physical Vapor Deposited Coatings on 316L Stainless Steel as Bipolar Plate for Proton Exchange ,Membrane Fuel Cells, Thin Solid Films, 2022, 753, p 139288. https://doi.org/10.1016/j.tsf.2022.139288

S.W.K. Kweh, K.A. Khor, and P. Cheang, Plasma-Sprayed Hydroxyapatite (HA) Coatings with Flame-Spheroidized Feedstock: Microstructure and Mechanical Properties, Biomaterials, 2000, 21(12), p 1223-1234. https://doi.org/10.1016/S0142-9612(99)00275-6

L. Muller and F.A. Muller, Preparation of SBF with Different HCO−3 Content and its Influence on the Composition of Biomimetic Apatites, Acta Biomater., 2006, 2(2), p 181-189. https://doi.org/10.1016/j.actbio.2005.11.001

J. Kunze, L. Müller, J.M. Macak, P. Greil, P. Schmuki, and F.A. Muller, TiTime-Dependent Growth of Biomimetic Apatite on Anodic TiO2 Nanotubes, Electrochim. Acta, 2008, 53(23), p 6995-7003. https://doi.org/10.1016/j.electacta.2008.01.027

H.C. Hsu, S.C. Wu, S.K. Hsu, Y.C. Chang, and W.F. Ho, Fabrication of Nanotube Arrays on Commercially Pure Titanium and Their Apatite-Forming Ability in a Simulated Body Fluid, Mater. Charact., 2015, 100, p 170-177. https://doi.org/10.1016/j.matchar.2014.12.023

M. Svetina, L.C. Ciacchi, O. Sbaizero, S. Meriani, and A. De Vita, Deposition of Calcium Ions on Rutile (110): A First-Principles Investigation, Acta Mater., 2001, 49(12), p 2169-2177. https://doi.org/10.1016/S1359-6454(01)00136-7

A. Roguska, M. Pisarek, A. Belcarz, L. Marcon, M. Holdynski, M. Andrzejczuk, and M. Janik-Czachor, Improvement of the Bio-Functional Properties of TiO2 Nanotubes, Appl. Surf. Sci., 2016, 388, p 775-785. https://doi.org/10.1016/j.apsusc.2016.03.128

H.R. Bakhsheshi-Rad, E. Hamzah, M.R. Abdul-Kadir, S.N. Saud, M. Kasiri-Asgarani, and R. Ebrahimi-Kahrizsangi,The Mechanical Properties and Corrosion Behavior of Double-Layered Nano Hydroxyapatite-Polymer Coating on Mg-Ca Alloy, J. Mater. Eng. Perform, 2015, 24, p 4010-4021. https://doi.org/10.1007/s11665-015-1661-4

N.K. Nga, N.T.T. Chau, and P.H. Viet,Facile Synthesis of Hydroxyapatite Nanoparticles Mimicking Biological Apatite from Eggshells for Bone-Tissue Engineering, Colloids Surf. B Biointerfaces, 2018, 172, p 769-778. https://doi.org/10.1016/j.colsurfb.2018.09.039

R. Malhotra, B. Dhawan, B. Garg, V. Shankar, and T.C. Nag, A Comparison of Bacterial Adhesion and Biofilm Formation on Commonly Used Orthopaedic Metal Implant Materials: An in Vitro Study, Indian J. Orthop., 2019, 53, p 148-153. https://doi.org/10.4103/ortho.IJOrtho_66_18

B. Del Curto, M.F. Brunella, C. Giordano, M.P. Pedeferri, V. Valtulina, L. Visai, and A. Cigada,Decreased Bacterial Adhesion to Surface-Treated Titanium, Int. J. Artif. Organs, 2005, 28(7), p 718-730. https://doi.org/10.1177/039139880502800711

I. Yoda, H. Koseki, M. Tomita, T. Shida, H. Horiuchi, H. Sakoda, and M. Osaki, Effect of Surface Roughness of Biomaterials on Staphylococcus Epidermidis Adhesion, BMC Microbiol., 2014, 14(1), p 1-7. https://doi.org/10.1186/s12866-014-0234-2

C. Lüdecke, M. Roth, W. Yu, U. Horn, J. Bossert, and K.D. Jandt, Nanorough Titanium Surfaces Reduce Adhesion of Escherichia Coli and Staphylococcus Aureus Via Nano Adhesion Points, Colloids Surf. B Biointerfaces, 2016, 145, p 617-625. https://doi.org/10.1016/j.colsurfb.2016.05.049

Y. Wu, J.P. Zitelli, K.S. TenHuisen, X. Yu, and M.R. Libera,Differential Response of Staphylococci and Osteoblasts to Varying Titanium Surface Roughness, Biomaterials, 2011, 32, p 951-960. https://doi.org/10.1016/j.biomaterials.2010.10.001

P.A. Slullitel, M.A. Buttaro, G. Greco, J.I. Oñativia, M.L. Sánchez, S. Mc Loughlin, C. García-Ávila, F. Comba, G. Zanotti, and F. Piccaluga, No Lower Bacterial Adhesion for Ceramics Compared to Other Biomaterials: An in Vitro Analysis, Orthop. Traumatol. Sur., 2018, 104(4), p 439-443. https://doi.org/10.1016/j.otsr.2018.03.003

Acknowledgments

The authors would like to thank the Ministry of Higher Education and Scientific Research of Algeria for supporting this work. The authors are also grateful to Pr. Said BOUKHERCHE for his assistance in corrosion tests.

Funding

The authors declare that no funds, grants, or financial supports were received during the preparation of this work.

Author information

Authors and Affiliations

Contributions

All authors equally contributed to the study conception and the experimental activities.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical Approval

The experiments carried out in this study did not involve human tissue.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Boudjeda, K., Bahi, R., Beliardouh, N.E. et al. Analysis of the Anticorrosion Performance and Antibacterial Efficacy of Ti-Based Ceramic Coatings for Biomedical Applications. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08705-8

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08705-8