Abstract

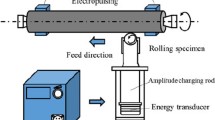

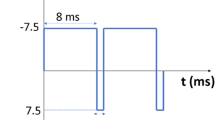

In the present study, the effect of ultrasonic shot peening (USSP) on electrodeposited Ni/Ni-TiO2 coatings on mild steel substrate was analyzed in terms of surface-mechanical and electrochemical properties. USSP was performed on the Ni/Ni-TiO2 coatings surface deposited mainly from Watt baths with varying peening vibrational amplitude and peening time, and the resulting hybrid coating was analyzed using XRD, SEM, microhardness, scratch test, and corrosion analysis. The XRD analysis revealed a prominent texturing effect and residual compressive stress, which resulted in changes in surface-mechanical and corrosion properties. SEM morphology revealed pore closure following USSP, as well as a positive effect at the coating interface. Surface roughness and dimple size also had an impact on the properties. Microhardness and scratch results showed improvement after peening. The noticeable effect of peening was observed during a corrosion study using potentiodynamic polarization and EIS analysis.

Similar content being viewed by others

References

S. Wang, N. Zhou, and F.C. Walsh, Diverse Electrodeposits from Modified Acid Sulphate (Watts Nickel) Baths, Trans. Inst. Met. Finish., 2016, 94(5), p 274–282.

V.S. Protsenko, D.A. Bogdanov, S.A. Korniy, A.A. Kityk, A.S. Baskevich, and F.I. Danilov, Application of a Deep Eutectic Solvent to Prepare Nanocrystalline Ni and Ni/TiO2 Coatings as Electrocatalysts for the Hydrogen Evolution Reaction, Int. J. Hydrogen Energy, 2019, 44(45), p 24604–24616. https://doi.org/10.1016/j.ijhydene.2019.07.188

I. Gurrappa and L. Binder, Electrodeposition of Nanostructured Coatings and Their Characterization: A Review, Sci. Technol. Adv. Mater., 2008, 9(4), p 2456.

W.W. Sellers, Plat. Surf. Finish., 1984, 71(6), p 64–70.

M.R. Zamanzad-Ghavidel, K. Raeissi, and A. Saatchi, The Effect of Surface Morphology on Pitting Corrosion Resistance of Ni Nanocrystalline Coatings, Mater. Lett., 2009, 63(21), p 1807–1809. https://doi.org/10.1016/j.matlet.2009.05.043

A.P. Abbott, A. Ballantyne, R.C. Harris, J.A. Juma, and K.S. Ryder, A Comparative Study of Nickel Electrodeposition Using Deep Eutectic Solvents and Aqueous Solutions, Electrochim. Acta., 2015, 176, p 718–726. https://doi.org/10.1016/j.electacta.2015.07.051

J.P. Hoare, On the Role of Boric Acid in the Watts Bath, J. Electrochem. Soc., 1986, 133(12), p 2491–2494.

M. Lukaczynska, E.A. Mernissi Cherigui, A. Ceglia, K. van den Bergh, J. de Strycker, H. Terryn, and J. Ustarroz, Influence of Water Content and Applied Potential on the Electrodeposition of Ni Coatings from Deep Eutectic Solvents, Electrochim. Acta., 2019, 319, p 690–704. https://doi.org/10.1016/j.electacta.2019.06.161

K.R. Mamaghani and S.M. Naghib, The Effect of Stirring Rate on Electrodeposition of Nanocrystalline Nickel Coatings and Their Corrosion Behaviors and Mechanical Characteristics, Int. J. Electrochem. Sci., 2017, 12(6), p 5023–5035.

J.R. Tuck, A.M. Korsunsky, R.I. Davidson, S.J. Bull, and D.M. Elliott, Modelling of the Hardness of Electroplated Nickel Coatings on Copper Substrates, Surf. Coat. Technol., 2000, 127(1), p 1–8.

J. Pina, A.M. Dias, and J.L. Lebrun, Residual Stresses in Decorative Electroplated Coatings, Mater. Sci. Forum, 2002, 404–407, p 683–690.

Y.M. Xing and J. Lu, An Experimental Study of Residual Stress Induced by Ultrasonic Shot Peening, J. Mater. Process. Technol., 2004, 152(1), p 56–61.

C. Patta, R. Vassiliou, and V. Kasselourf, NÍ/TÍ02 Composite Electrocoatings, Madrid, 2005, 231, p 227–231.

W. Chen, Y. He, and W. Gao, Electrodeposition of Sol-Enhanced Nanostructured Ni-TiO2 Composite Coatings, Surf Coat Technol., 2010, 204(15), p 2487–2492. https://doi.org/10.1016/j.surfcoat.2010.01.036

B. Endrödi, E. Kecsenovity, K. Rajeshwar, and C. Janáky, One-Step Electrodeposition of Nanocrystalline TiO2 Films with Enhanced Photoelectrochemical Performance and Charge Storage, ACS Appl Energy Mater, 2018, 1(2), p 851–858.

C.S. Lin, C.Y. Lee, C.F. Chang, and C.H. Chang, Annealing Behavior of Electrodeposited Ni-TiO2 Composite Coatings, Surf. Coat. Technol., 2006, 200(12–13), p 3690–3697.

R. Kullaiah, L. Elias, and A.C. Hegde, Effect of TiO2 Nanoparticles on Hydrogen Evolution Reaction Activity of Ni Coatings, Int. J. Miner. Metall. Mater., 2018, 25(4), p 472–479.

I. Birlik, N.F. Ak Azem, M. Toparli, E. Celik, T. Koc Delice, S. Yildirim, O. Bardakcioglu, and T. Dikici, Preparation and Characterization of Ni-TiO2 Nanocomposite Coatings Produced by Electrodeposition Technique, Front. Mater., 2016, 3, p 1–7.

E.S. Statnikov, O.V. Korolkov, and V.N. Vityazev, Physics and Mechanism of Ultrasonic Impact, Ultrasonics, 2006, 44(SUPPL), p e533–e538.

M.P. Nascimento, M.A.S. Torres, R.C. Souza, and H.J.C. Voorwald, Effect of a Shot Peening Pre Treatment on the Fatigue Behaviour of Hard Chromium on Electroless Nickel Interlayer Coated AISI 4340 Aeronautical Steel, Mater. Res., 2002, 5(2), p 95–100.

M.A.S. Torres and H.J.C. Voorwald, “An Evaluation of Shot Peening, Residual Stress and Stress Relaxation on the Fatigue Life of AISI 4340 Steel. Int. J. Fatigue, (2002), www.elsevier.com/locate/ijfatigue. Accessed 28 May 2021.

M. Malaki and H. Ding, A Review of Ultrasonic Peening Treatment, Mater. Des., 2015, 87, p 1072–1086.

K. Lu and J. Lu, Surface Nanocrystallization (SNC) of Metallic Materials-Presentation of the Concept behind a New Approach, J. Mater. Sci. Technol., 1999, 102, p 193–197.

C. Pilé, M. François, D. Retraint, E. Rouhaud, and J. Lu, Modelling of the Ultrasonic Shot Peening Process, Mater. Sci. Forum., 2005, 490–491, p 67–72.

F. Yin, M. Rakita, S. Hu, and Q. Han, Overview of Ultrasonic Shot Peening, Surf. Eng., 2017, 33(9), p 651–666.

J. Badreddine, E. Rouhaud, M. Micoulaut, and S. Remy, Simulation of Shot Dynamics for Ultrasonic Shot Peening: Effects of Process Parameters, Int. J. Mech. Sci., 2014, 82, p 179–190. https://doi.org/10.1016/j.ijmecsci.2014.03.006

Y. Todaka, M. Umemoto, and K. Tsuchiya, Comparison of Nanocrystalline Surface Layer in Steels Formed by Air Blast and Ultrasonic Shot Peening, Mater. Trans., 2004, 45(2), p 376–379.

F. Belahcene, X. Zhou, and J. Lu, Ultrasonic Evaluation of Compressive Residual Stress of Surface Treated Metals, Mater. Sci. Forum, 2005, 490–491, p 184–189.

K. Li, Y. He, H. Ma, C. Fang, J. Kim, H. Lee, and J. Song, Surface Nanocrystallization of Pure Ni Induced by Ultrasonic Shot Peening, Sci. Adv. Mater., 2017, 9, p 188–192.

X. Wang, C. Xu, D. Hu, C. Li, C. Liu, and Z. Tang, Effect of Ultrasonic Shot Peening on Surface Integrity and Fatigue Performance of Single-Crystal Superalloy, J. Mater. Process. Technol., 2021, 296, p 117–209.

M. Industries, From Portable Systems to Robotic Production Lines Ultrasonic Shot Peening (2016).

G. Parida, D. Chaira, M. Chopkar, and A. Basu, Synthesis and Characterization of Ni-TiO2 Composite Coatings by Electro-Co-Deposition, Surf. Coat. Technol., 2011, 205(21–22), p 4871–4879. https://doi.org/10.1016/j.surfcoat.2011.04.102

L. Zhu, Y. Guan, Y. Wang, Z. Xie, and J. Lin, Influence of Process Parameters of Ultrasonic Shot Peening on Surface Nanocrystallization and Hardness of Pure Titanium, Surf. Coat. Technol.., 2017, 317, p 38–53.

J.M. Zhang, Y. Zhang, and K.W. Xu, Dependence of Stresses and Strain Energies on Grain Orientations in FCC Metal Films, J. Cryst. Growth North-Holland, 2005, 285(3), p 427–435.

D.E. Rusu, A. Ispas, A. Bund, C. Gheorghies, and G. Cârâ, Corrosion Tests of Nickel Coatings Prepared from a Watts-Type Bath, J. Coat. Technol. Res., 2012, 9(1), p 87–95.

L. Jinlong, L. Tongxiang, and W. Chen, Effect of Electrodeposition Temperature on Grain Orientation and Corrosion Resistance of Nanocrystalline Pure Nickel, J. Solid State Chem., 2016, 240, p 109–114. https://doi.org/10.1016/j.jssc.2016.05.025

Acknowledgments

Partial financial support for this work from the Science and Engineering Research Board (SERB) under the Department of Science and Technology, Govt. of India (File No. CRG/2018/001050/MMM) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kushwaha, A., Basu, A. Effect of Peening Parameters on the Ultrasonic Shot-Peened Surfaces of Electro-co-deposited Ni/Ni-TiO2 Coatings. J. of Materi Eng and Perform 32, 9525–9539 (2023). https://doi.org/10.1007/s11665-023-07822-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07822-8