Abstract

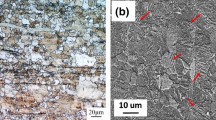

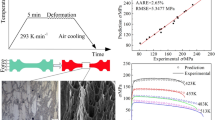

ZK-based magnesium alloy has high rigidity and excellent machinability. It is an ideal lightweight material in the field of military industry and has a broad application prospect. Traditional processing technology can't meet the special requirements of local area microstructure adjustment of sheet metal. In the experiment, the same area of the plate was subjected to several reverse Erichsen processes with a certain stamping stroke, and the local deformation area of the plate was subjected to annular tensile and compressive stress. The experimental samples were divided into two groups for microstructure characterization and comparison. The results show that the grain size in the deformed area of the plate is significantly finer than that of the original sample, and \(\langle10\overline{1}2\rangle\) tensile twins appear in some grains. In the repeated Erichsen test, the grain slip leads to the accumulation of dislocations, which increases the dislocation density and KAM value, and plays an obvious strengthening effect on the plate. Compared with the original plate, after repeated Erichsen test for three times, the dislocation strengthening effect of the plate is obvious with ultimate tensile strength increased by 26%.

Similar content being viewed by others

References

B.-C. Suh, M.-S. Shim, K.S. Shin, and N.J. Kim, Current Issues in Magnesium Sheet Alloys: Where do we go from here?, Scripta Mater., 2014, 84–85, p 1–6.

X.J. Wang, D.K. Xu, R.Z. Wu, X.B. Chen, Q.M. Peng, L. Jin, Y.C. Xin, Z.Q. Zhang, Y. Liu, X.H. Chen, G. Chen, K.K. Deng, and H.Y. Wang, What is Going on in Magnesium Alloys?, J. Mater. Sci. Technol., 2018, 34(2), p 245–247.

Q. Wang, B. Jiang, A. Tang, S. Ma, Z. Jiang, Y. Chai, B. Liu, and F. Pan, Ameliorating the Mechanical Properties of Magnesium alloy: Role of Texture, Mater. Sci. Eng. A, 2017, 689, p 395–403.

J. Tian, H. Lu, W. Zhang, H. Nie, Q. Shi, J. Deng, W. Liang, and L. Wang, An Effective Rolling Process of Magnesium Alloys for Suppressing Edge Cracks: Width-Limited Rolling, J. Magnes. Alloys, 2021, 10, p 2193.

J. Tian, J.-F. Deng, Y. Chang, Q.-X. Shi, W. Liang, and J. Ma, A Study of Unstable Fracture of a Magnesium alloy Caused by Uneven Microstructure, Mater. Lett., 2022, 314, p 131799.

X. Huang, K. Suzuki, A. Watazu, I. Shigematsu, and N. Saito, Microstructural and Textural Evolution of AZ31 Magnesium Alloy during Differential Speed Rolling, J. Alloy. Compd., 2009, 479(1), p 726–731.

J.-Y. Li, J.-X. Xie, J.-B. Jin, and Z.-X. Wang, Microstructural Evolution of AZ91 Magnesium Alloy during Extrusion and Heat Treatment, Trans. Nonferrous Metals Soc. China, 2012, 22(5), p 1028–1034.

J. Zou, L. Ma, W. Jia, Q. Le, G. Qin, and Y. Yuan, Microstructural and Mechanical Response of ZK60 Magnesium Alloy Subjected to Radial Forging, J. Mater. Sci. Technol., 2021, 83, p 228–238.

K.S. Fong, A. Danno, M.J. Tan, and B.W. Chua, Tensile Flow Behavior of AZ31 Magnesium Alloy Processed by Severe Plastic Deformation and Post-Annealing at Moderately High Temperatures, J. Mater. Process. Technol., 2017, 246, p 235–244.

J. Tian, J. Deng, R. Ma, Y. Chang, W. Liang, and J. Ma, Pre-Control of Annealing Temperature on the Uniformity of Deformed Structure of Wrought Magnesium Alloy, Mater. Lett., 2021, 305, p 130820.

H. Watanabe, T. Mukai, and K. Ishikawa, Effect of Temperature of Differential Speed Rolling on Room Temperature Mechanical Properties and Texture in an AZ31 Magnesium Alloy, J. Mater. Process. Technol., 2007, 182(1), p 644–647.

F. Guo, D. Zhang, X. Fan, J. Li, L. Jiang, and F. Pan, Microstructure, Texture and Mechanical Properties Evolution of Pre-Twinning Mg Alloys Sheets during Large Strain Hot Rolling, Mater. Sci. Eng., A, 2016, 655, p 92–99.

Y. Chino, K. Sassa, A. Kamiya, and M. Mabuchi, Enhanced Formability at Elevated Temperature of a Cross-Rolled Magnesium Alloy Sheet, Mater. Sci. Eng., A, 2006, 441(1), p 349–356.

Q. Yang, B. Jiang, B. Song, Z. Yu, D. He, Y. Chai, J. Zhang, and F. Pan, The Effects of Orientation Control via Tension-Compression on Microstructural Evolution and Mechanical Behavior of AZ31 Mg Alloy Sheet, J. Magnes. Alloys, 2020, 28, p 1705.

W. He, Q. Zeng, H. Yu, Y. Xin, B. Luan, and Q. Liu, Improving the Room Temperature stretch Formability of a Mg Alloy thin Sheet by Pre-Twinning, Mater. Sci. Eng., A, 2016, 655, p 1–8.

J. Singh, M.-S. Kim, S.-E. Lee, E.-Y. Kim, J.-H. Kang, J.-H. Park, J.-J. Kim, and S.-H. Choi, Heterogeneity in Deformation and Twinning Behaviors Through the thickness Direction in E-form Mg Alloy Sheets during an Erichsen test, Mater. Sci. Eng., A, 2018, 729, p 370–384.

C.S. Hyun, M.S. Kim, S.H. Choi, and K.S. Shin, Crystal plasticity FEM Study of twinning and slip in a Mg Single Crystal by Erichsen Test, Acta Mater., 2018, 156, p 342–355.

J. Wang, M.R.G. Ferdowsi, S.R. Kada, S. Babaniaris, B. Hutchinson, P.A. Lynch, and M.R. Barnett, Appearance of Textures with a c-Axis Parallel to the Extrusion Direction in Mg Alloys, Scripta Mater., 2022, 210, p 114422.

L. Zhao, B. Zhou, W. Zhu, C. Yan, Z. Jin, and X. Guo, A Comprehensive Study on the Mechanical Behavior, deformation Mechanism and Texture Evolution of Mg Alloys with Multi Texture Components, J. Alloy. Compd., 2022, 907, p 164342.

S. Sanyal, P. Bhuyan, T.K. Bandyopadhyay, and S. Mandal, Insights into the Effect of Different Thermomechanical Processing on the Microstructure Phases, Texture and Tensile Properties in Mg-0.9Al-0.6Mn-0.2Si-0.1Ca Alloy, Intermetallics, 2022, 146, p 107564.

J.-F. Deng, J. Tian, Y. Zhou, Y. Chang, W. Liang, and J. Ma, Plastic Deformation Mechanism and Hardening Mechanism of Rolled Rare-Earth Magnesium Alloy thin Sheet, Mater. Des., 2022, 218, p 110678.

J. Tian, J. Deng, Q. Shi, Y. Chang, W. Liang, and W. Zhang, Effect of Temperature Field and Stress Field of Different Crack Behavior on Twins and Dislocations under Mg Alloy Rolling, Materials, 2021, 14(19), p 84.

S.-F. Chen, H.-W. Song, S.-H. Zhang, M. Cheng, C. Zheng, and M.-G. Lee, An Effective Schmid Factor in Consideration of Combined Normal and Shear Stresses for Slip/Twin Variant Selection of Mg-3Al-1Zn alloy, Scripta Mater., 2019, 167, p 51–55.

D. Xia, X. Chen, G. Huang, B. Jiang, A. Tang, H. Yang, S. Gavras, Y. Huang, N. Hort, and F. Pan, Calculation of Schmid Factor in Mg Alloys: Influence of Stress State, Scripta Mater., 2019, 171, p 31–35.

W. Fu, Y. Li, S. Hu, P. Sushko, and S. Mathaudhu, Effect of Loading Path on Grain Misorientation and Geometrically Necessary Dislocation Density in Polycrystalline Aluminum Under Reciprocating Shear, Comput. Mater. Sci., 2022, 205, p 111221.

B. Song, Q. Yang, T. Zhou, L. Chai, N. Guo, T. Liu, S. Guo, and R. Xin, Texture Control by 10-12 Twinning to Improve the Formability of Mg alloys: A review, J. Mater. Sci. Technol., 2019, 35(10), p 2269–2282.

A. Malik, U.M. Chaudry, T. Yan, J. Long, C. Li, and Y. Wang, Achieving Higher Dynamic Mechanical Response by Adjusting Texture Through Twinning in a ZK61 Mg Alloy, J. Alloy. Compd., 2022, 902, p 163755.

Z. Zhang, J. Zhang, J. Xie, S. Liu, Y. He, K. Guan, and R. Wu, Developing a low-Alloyed Fine-Grained Mg Alloy with High Strength-Ductility Based on Dislocation Evolution and Grain Boundary Segregation, Scripta Mater., 2022, 209, p 114414.

Z. Zribi, H.H. Ktari, F. Herbst, V. Optasanu, and N. Njah, EBSD, XRD and SRS Characterization of a Casting Al-7wt%Si Alloy Processed by Equal Channel Angular Extrusion: Dislocation density evaluation, Mater. Charact., 2019, 153, p 190–198.

J.-F. Deng, J. Tian, Y. Chang, Y. Zhou, W. Liang, J. Ma, The role of {10–12} tensile twinning in plastic deformation and fracture prevention of magnesium alloys, Mater. Sci. Eng. A, 2022, 853, p 143678.

J. Tian, Q.-X. Shi, L.-X. Meng, J.-F. Deng, W. Liang, and J.-Y. Ma, Initiation and Suppression of Crack Propagation during Magnesium Alloy Rolling, Materials, 2021, 14(18), p 5217.

K. Zhang, Z. Shao, and J. Jiang, Effects of Twin-Twin Interactions and Deformation Bands on the Nucleation of Recrystallization in AZ31 Magnesium Alloy, Mater. Des., 2020, 194, p 108936.

T. Mizuno and H. Mulki, Changes in Surface Texture of Zinc-Coated Steel Sheets Under Plastic Deformation, Wear, 1996, 198(1), p 176–184.

S. Liu, H. Liu, X. Chen, G. Huang, Q. Zou, A. Tang, B. Jiang, Y. Zhu, and F. Pan, Effect of Texture on Deformation Behavior of Heterogeneous Mg-13Gd Alloy with Strength-Ductility Synergy, J. Mater. Sci. Technol., 2022, 113, p 271–286.

P. Mansoor and S.M. Dasharath, Microstructural and Mechanical Properties of Magnesium Alloy Processed by Severe Plastic Deformation (SPD) – A Review, Mater. Today: Proc., 2020, 20, p 145–154.

M.A. Hassan, M.A.E. Saleh, N. Takakura, S. Ramesh, and J. Purbolaksono, Effect of Bulge Shape on Wrinkling Formation and Strength of Stainless Steel Thin Sheet, Mater. Design, 2012, 42, p 37–45.

Acknowledgment

This study was supported by National Natural Science Foundation of China under Grant No. U1810208; Nos. 51474152, and 52005362; Shanxi province science and technology major projects under Grant No. 20181101008; Shanxi province Science Foundation for Youths under Grant No. 20210302124659.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chang, Y., Tian, J., Deng, Jf. et al. Microstructure Evolution of ZK61m Magnesium Alloy Sheet during Erichsen Test. J. of Materi Eng and Perform 32, 5483–5492 (2023). https://doi.org/10.1007/s11665-022-07473-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-07473-1