Abstract

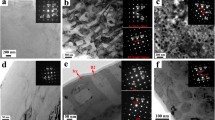

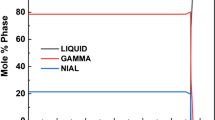

High-entropy alloys (HEAs) have become important candidates for structural materials of nuclear reactors because of their excellent mechanical properties and irradiation resistance. Recently, eutectic HEAs (EHEAs) have exhibited improved properties by double-phase strengthening. In this study, the effect of Ti on the microstructure and mechanical properties of the EHEAs AlCrFeNi was investigated. Results show that the eutectic microstructure consisted of a disordered body-center cubic (A2) phase and an ordered body-center cubic (B2) phase. Smaller nanoparticles were formed with Ti addition. Ti significantly influenced the microstructure of AlCrFeNi, thus changing the mechanical properties of AlCrFeNi. The compressive strength of AlCrFeNi increased, and the toughness of AlCrFeNi decreased with the increase in Ti content. The application of AlCrFeNiTi0.2 alloy is promising because of its high mechanical properties and superior specific strength. In addition, the AlCrFeNiTix alloys showed great softening resistance at a high temperature (500 °C).

Similar content being viewed by others

References

S. Chu and A. Majumdar, Opportunities and Challenges for a Sustainable Energy Future, Nature, 2012, 488(7411), p 294–303.

U.S. Doe, "A Technology Roadmap for Generation IV Nuclear Energy Systems," 2002

S.J. Zinkle and G. Was, Materials Challenges in Nuclear Energy, Acta Mater., 2013, 61(3), p 735–758.

S.Q. Xia, X. Yang, T.F. Yang, S. Liu and Y. Zhang, Irradiation Resistance in AlxCoCrFeNi High Entropy Alloys, JOM, 2015, 67(10), p 2340–2344.

P. Song, D. Morrall, Z. Zhang, K. Yabuuchi and A. Kimura, Radiation Response of ODS Ferritic Steels with Different Oxide Particles Under Ion-Irradiation at 550 °C, J. Nucl. Mater., 2018, 502, p 76–85.

P. Jin, T. Shen, M. Cui, Y. Zhu, B. Li, T. Zhang, J. Li, S. Jin, E. Lu, X. Cao and Z. Wang, Study on Vacancy-type Defects in SIMP Steel Induced by Separate and Sequential H and He Ion Implantation, J. Nucl. Mater., 2019, 520, p 131–139.

V. Shivam, J. Basu, V.K. Pandey, Y. Shadangi and N.K. Mukhopadhyay, Alloying Behaviour, Thermal Stability and Phase Evolution in Quinary AlCoCrFeNi High Entropy Alloy, Adv. Powder Technol., 2018, 29(9), p 2221–2230.

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303.

C.W. Tsai, M.H. Tsai, J.W. Yeh and C.C. Yang, Effect of Temperature on Mechanical Properties of Al0.5CoCrCuFeNi Wrought Alloy, J. Alloys Compd., 2010, 490(1), p 160–165.

T. Shi, P.H. Lei, X. Yan, J. Li, Y.D. Zhou, Y.P. Wang, Z.X. Su, Y.K. Dou, X.F. He, D. Yun, W. Yang and C.Y. Lu, Current Development of Body-Centered Cubic High-Entropy Alloys for Nuclear Applications, Tungsten, 2021, 3(2), p 197–217.

Z. Jiang, W. Chen, Z. Xia, W. Xiong and Z. Fu, Influence of Synthesis Method on Microstructure and Mechanical Behavior of Co-free AlCrFeNi Medium-Entropy Alloy, Intermetallics, 2019, 108, p 45–54.

M. Shabani, J. Indeck, K. Hazeli, P.D. Jablonski and G.J. Pataky, Effect of Strain Rate on the Tensile Behavior of CoCrFeNi and CoCrFeMnNi High-Entropy Alloys, J. Mater. Eng. Perform., 2019, 28(7), p 4348–4356.

H.A. Aly, K.A. Abdelghafar, G.A. Gaber and L.Z. Mohamed, Fabrication, Characterization, and Corrosion Behavior of a New Cu40Mn25Al20Fe5Co5Ni5 High-Entropy Alloy in HNO3 Solution, J. Mater. Eng. Perform., 2021, 30(2), p 1430–1443.

M. Wang, H. Cui, Y. Zhao, C. Wang, N. Wei, Y. Zhao, X. Zhang and Q. Song, A Simple Strategy for Fabrication of an FCC-based Complex Concentrated Alloy Coating with Hierarchical Nanoprecipitates and Enhanced Mechanical Properties, Mater. Design, 2019, 180, p 107893.

Y. Lu, H. Huang, X. Gao, C. Ren, J. Gao, H. Zhang, S. Zheng, Q. Jin, Y. Zhao, C. Lu, T. Wang and T. Li, A Promising New Class of Irradiation Tolerant Materials: Ti2ZrHfV0.5Mo0.2 High-Entropy Alloy, J. Mater. Sci. Technol., 2019, 35(3), p 369–373.

M. Wang, Y. Lu, G. Zhang, H. Cui, D. Xu, N. Wei and T. Li, A Novel High-Entropy Alloy Composite Coating with Core-Shell Structures Prepared by Plasma Cladding, Vacuum, 2021, 184, p 109905.

C. Lu, T. Yang, K. Jin, N. Gao, P. Xiu, Y. Zhang, F. Gao, H. Bei, W.J. Weber, K. Sun, Y. Dong and L. Wang, Radiation-Induced Segregation on Defect Clusters in Single-Phase Concentrated Solid-Solution Alloys, Acta Mater., 2017, 127, p 98–107.

S. Xia, M.C. Gao, T. Yang, P.K. Liaw and Y. Zhang, Phase Stability and Microstructures of High Entropy Alloys Ion Irradiated to High Doses, J. Nucl. Mater., 2016, 480, p 100–108.

S. Shen, F. Chen, X. Tang, G. Ge, J. Gao and Z. Sun, Irradiation Damage and Swelling of Carbon-Doped Fe38Mn40Ni11Al4Cr7 High-Entropy Alloys Under Heavy Ion Irradiation at Elevated Temperature, J. Mater. Sci., 2020, 55(36), p 17218–17231.

Y. Lu, X. Gao, L. Jiang, Z. Chen, T. Wang, J. Jie, H. Kang, Y. Zhang, S. Guo, H. Ruan, Y. Zhao, Z. Cao and T. Li, Directly Cast Bulk Eutectic and Near-Eutectic High Entropy Alloys with Balanced Strength and Ductility in a Wide Temperature Range, Acta Mater., 2017, 124, p 143–150.

M. Wang, Y. Lu, T. Wang, C. Zhang, Z. Cao, T. Li and P.K. Liaw, A Novel Bulk Eutectic High-Entropy Alloy with Outstanding As-cast Specific Yield Strengths at Elevated Temperatures, Scripta Mater, 2021, 204, p 114132.

Y. Lu, Y. Dong, H. Jiang, Z. Wang, Z. Cao, S. Guo, T. Wang, T. Li and P.K. Liaw, Promising Properties and Future Trend of Eutectic High Entropy Alloys, Scripta Mater., 2020, 187, p 202–209.

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, Z. Wang, J. Jie, Z. Cao, H. Ruan and T. Li, A Promising New Class of High-Temperature Alloys: Eutectic High-Entropy Alloys, Sci Rep, 2014, 4, p 6200.

S. Wolff-Goodrich, A. Marshal, K.G. Pradeep, G. Dehm, J.M. Schneider and C.H. Liebscher, Combinatorial Exploration of B2/L21 Precipitation Strengthened AlCrFeNiTi Compositionally Complex Alloys, J. Alloys Compd., 2021, 853, p 156111.

M. Kang, K.R. Lim, J.W. Won and Y.S. Na, Effect of Co Content on the Mechanical Properties of A2 and B2 Phases in AlCoxCrFeNi High-Entropy Alloys, J. Alloys Compd., 2018, 769, p 808–812.

L. Meshi, Y. Linden, A. Munitz, S. Salhov and M. Pinkas, Retardation of the σ Phase Formation in the AlCoCrFeNi Multi-Component Alloy, Mater. Charact., 2019, 148, p 171–177.

K.R. Lim, K.S. Lee, J.S. Lee, J.Y. Kim, H.J. Chang and Y.S. Na, Dual-Phase High-Entropy Alloys for High-Temperature Structural Applications, J. Alloys Compd., 2017, 728, p 1235–1238.

X. Chen, W. Xie, J. Zhu, Z. Wang, Y. Wang, Y. Ma, M. Yang, W. Jiang, H. Yu, Y. Wu and X. Hui, Influences of Ti Additions on the Microstructure and Tensile Properties of AlCoCrFeNi2.1 Eutectic High Entropy Alloy, Intermetallics, 2021, 128, p 107024.

A. Munitz, S. Salhov, G. Guttmann, N. Derimow and M. Nahmany, Heat Treatment Influence on the Microstructure and Mechanical Properties of AlCrFeNiTi0 5 High Entropy Alloys, Mater. Sci. Eng. A, 2019, 742, p 1–14.

E. Jumaev, M.A. Abbas, S.C. Mun, G. Song, S.-J. Hong and K.B. Kim, Nano-Scale Structural Evolution of Quaternary AlCrFeNi Based High Entropy Alloys by the Addition of Specific Minor Elements and its Effect on Mechanical Characteristics, J. Alloys Compd., 2021, 868, p 159217.

G.S. Was, D. Petti, S. Ukai and S. Zinkle, Materials for Future Nuclear Energy Systems, J. Nucl. Mater., 2019, 527, p 151837.

L.J. Santodonato, Y. Zhang, M. Feygenson, C.M. Parish, M.C. Gao, R.J. Weber, J.C. Neuefeind, Z. Tang and P.K. Liaw, Deviation from High-Entropy Configurations in the Atomic Distributions of a Multi-Principal-Element Alloy, Nat. Commun., 2015, 6, p 5964.

S. Singh, N. Wanderka, B.S. Murty, U. Glatzel and J. Banhart, Decomposition in Multi-Component AlCoCrCuFeNi High-Entropy Alloy, Acta Mater., 2011, 59(1), p 182–190.

X. Chen, J.Q. Qi, Y.W. Sui, Y.Z. He, F.X. Wei, Q.K. Meng and Z. Sun, Effects of Aluminum on Microstructure and Compressive Properties of Al-Cr-Fe-Ni Eutectic Multi-Component Alloys, Mater. Sci. Eng. A, 2017, 681, p 25–31.

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans, 2005, 46(12), p 2817–2829.

J. Joseph, T. Jarvis, X. Wu, N. Stanford, P. Hodgson and D.M. Fabijanic, Comparative Study of the Microstructures and Mechanical Properties of Direct Laser Fabricated and Arc-Melted AlxCoCrFeNi High Entropy alloys, Mater. Sci. Eng., A, 2015, 633, p 184–193.

G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika and O.N. Senkov, Effect of Mn and V on Structure and Mechanical Properties of High-Entropy Alloys Based on CoCrFeNi System, J. Alloys Compd., 2014, 591, p 11–21.

O.N. Senkov, G.B. Wilks, J.M. Scott and D.B. Miracle, Mechanical Properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 Refractory High Entropy Alloys, Intermetallics, 2011, 19(5), p 698–706.

W.D. Nix and H. Gao, Indentation Size Effects in Crystalline Materials: A Law for Strain Gradient Plasticity, J. Mech. Phys. Solids, 1998, 46(3), p 411–425.

S. Liu, M.C. Gao, P.K. Liaw and Y. Zhang, Microstructures and Mechanical Properties of Al CrFeNiTi0.25 Alloys, J. Alloys Compd, 2015, 619, p 610–615.

Acknowledgments

This work was supported by China Postdoctoral Science Foundation (Grant No. 2020M671488), the Fundamental Research Funds for the Central Universities (Grant No. NS2021036), Jiangsu Planned Projects for Postdoctoral Research Funds (Grant No. 2021K222B), the Postgraduate Research & Practice Innovation Program of Jiangsu Province (Grant No. KYCX20_0196).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, S., Chen, F., Tang, X. et al. Effect of Ti on the Microstructure and Mechanical Properties of AlCrFeNiTix Eutectic High-Entropy Alloys. J. of Materi Eng and Perform 31, 8294–8303 (2022). https://doi.org/10.1007/s11665-022-06825-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06825-1