Abstract

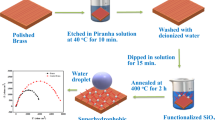

Spraying process is an alternative way to replace Chromium electroplating technique which presents industrial, economic and ecological disadvantages. The investigated work aims to develop non-usual coatings to protect the brass substrate and to ameliorate the faucets performance. Several materials with the viable deposition capability and with the excellent properties have been processed through spraying process, including polymers, thereby creating the fluorinated-ethylene-propylene and the poly-tetra-fluoro-ethylene coatings. The painting process is one of the innovative and the simple spraying techniques with growing scientific interests and industrial applications in the field of faucets. This method offers corrosion protection and results in increases in mechanical and physical durability and wear resistance. Experiments subsequently confirmed the successful deposition of polymer suspensions onto the brass substrate. Based on the results, it was determined that both coatings exhibit a hydrophobic character owing the low values of surface energy obtained and the FEP coating presents the best friction results. This review extensively exploits the latest developments in the experimental analysis of spraying processes. Coating formation, characterization of deposit development, description of process parameter and principles, are summarized.

Similar content being viewed by others

References

A. Liang, Y. Li, H. Liang, L. Ni and J. Zhang, A Favorable Chromium Coating Electrodeposited from Cr(III) Electrolyte Reveals Anti-wear Performance Similar to Conventional Hard Chromium, Mater. Lett., 2017, 189, p 221–224.

P. Lima-Neto, A.N. Correia and G.P. Silva, Structural and Morphological Investigations of the Electrodeposited Cr and Ni-Cr-P Coatings and Their Electrochemical Behaviors in Chloride Aqueous Medium, J. Braz. Chem. Soc., 2006, 17(7), p 1419–1427.

J.T. Gau, Ch. Principe and M. Yu, Springback Behavior of Brass in Micro Sheet Forming, J. Mater. Process. Technol., 2007, 19, p 7–10.

H. Li and B. Wu, Development of a Hybrid Cutting Force Model for Micromilling of Brass, Int. J. Mech. Sci., 2016, 115–116, p 586–595.

D.E. Kimbrough, Y. Cohen, A.M. Winer, L. Creelman and C. Mabuni, A Critical Assessment of Chromium in the Environment, Crit. Rev. Environ. Sci. Technol., 1999, 29(1), p 1–46.

P.T. de Souza e Silva, N.T. de Mello, M.M. Menezes Duarte, M.C. Montenegro, A.N. Araújo, B. de Barros Neto and V.L. da Silva, Extraction and Recovery of Chromium from Electroplating Sludge, J. Hazard. Mater., 2006, 128(1), p 39–43.

B.J. Stoecker, Chromium Absorption, Safety, and Toxicity, J. Trace Elem. Exp. Med., 1999, 12, p 163–169.

S. Zouari, H. Ghorbel, Y. Danlos, H. Liao and R. Elleuch, Comparative Study of HVOF-Sprayed NiCrBSi Alloy and 316L Stainless Steel Coatings on a Brass Substrate, J. Therm. Spray Technol., 2019, 28, p 1284–1294.

H.-J. Song and Z.-Z. Zhang, Study on the Tribological and Hydrophobic Behaviors of Phenolic Coatings Reinforced with PFW, PTFE and FEP, Surf. Coat. Technol., 2006, 201(3), p 1037–1044.

E. Leivo, T. Wilenius, T. Kinos, P. Vuoristo and T. Mäntylä, Properties of Thermally Sprayed Fluoropolymer PVDF, ECTFE, PFA and FEP Coatings, Prog. Org. Coat., 2004, 49(1), p 69–73.

J.L. Daure, M.J. Carrington, P.H. Shipway, D.G. McCartney and D.A. Stewart, A Comparison of the Galling Wear Behaviour of PVD Cr and Electroplated Hard Cr Thin Films, Surf. Coat. Technol., 2018, 350, p 40–47.

L. Vernhes, M. Azzi and J.E. Klemberg-Sapieha, Alternatives for Hard Chromium Plating: Nanostructured Coatings for Severe-Service Valves, Mater. Chem. Phys., 2013, 140(2–3), p 522–528.

K.O. Legg, M. Graham, P. Chang, F. Rastagar, A. Gonzales and B. Sartwelld, The Replacement of Electroplating, Surf. Coat. Technol., 1996, 81(1), p 99–105.

M.C.B. Jemaa, R. Mnif and R. Elleuch, Tribological Behavior of CW614 Brass Coated with Ni-Cr Layers Sliding Against 52100 Steel, J. Mater. Eng. Perform., 2013, 22(6), p 1729–1734.

ISO, NF EN 2409: Peintures et vernis-Essai de quadrillage, 2013.

D.K. Owens and R.C. Wendt, Estimation of the Surface Free Energy of Polymers, Appl. Polym., 1969, 13(8), p 1741–1747.

AFNOR MARQUE NF 077, robinetterie sanitaire, document technique1: Spécifications complémentaires applicables à certaines familles de produits. 1982.

R. Mnif, C.B. Jemaa, N. Hadjkacem and R. Elleuch, Impact of Viscoelasticity on the Tribological Behavior of PTFE Composites for Valve Seals Application, Tribol. Trans., 2013, 56(5), p 879–886.

A. Fourmentin: Revêtements polyuréthane-acrylate organiques/inorganiques superhydrophobes. Matériaux. Thesis, Université de Lyon, 2016.

Z. Feng, H. Xu and F. Yan, Preparation of flame sprayed poly(tetrafluoroethylene-co-hexafluoropropylene) coatings and their tribological properties under water lubrication, Appl. Surf. Sci., 2008, 255(5), p 2408–2413.

T. Kosec, L. Škrlep, E.Š Fabjan, A.S. Škapin, G. Masi, E. Bernardi, C. Chiavari, C. Josse, J. Esvan and L. Robbiola, Development of Multi-component Fluoropolymer Based Coating on Simulated Outdoor Patina on Quaternary Bronze, Prog. Org. Coat., 2019, 131, p 27–35.

T. Nishino, M. Meguro, K. Nakamae, M. Matsushita and Y. Ueda, The Lowest Surface Free Energy Based on—CF3 Alignment, Langmuir, 1999, 15(13), p 4321–4323.

S. Zouari, Elaboration et caractérisation mécanique et physico-chimique des revêtements déposés sur des substrats en laiton par les techniques de projection thermique et pulvérisation pneumatique pour application d'industrie sanitaire, 2019, Belfort

H. Wu, L. Zhu, W. Yue, Z. Fu and J. Kang, Wear-Resistant and Hydrophobic Characteristics of PTFE/CF Composite Coatings, Prog. Org. Coat., 2019, 128, p 90–98.

S.K. Biswas and K. Vijayan, Friction and Wear of PTFE—A Review, Wear, 1992, 158(1–2), p 193–211.

Acknowledgments

This project was carried out under the MOBIDOC scheme, funded by the EU through the EMORI program, and managed by the ANPR. The authors gratefully acknowledge the SOPAL society (Tunisia) for providing us the material samples.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zouari, S., Ghorbel, H., Langlade, C. et al. Painting Process Design and Characterization of Polymer Coatings on Brass. J. of Materi Eng and Perform 31, 180–190 (2022). https://doi.org/10.1007/s11665-021-06217-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06217-x