Abstract

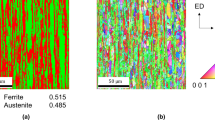

Transporting substances with high radioactivity used in nuclear medicine is strategic. Lean duplex stainless steel UNS S32304 is a candidate for external construction of a cask for transporting radioactive material. Thin sheet lean duplex stainless steel specimens were welded by autogenous TIG processing (tungsten inert gas) in order to avoid neutron activation of the filler metal. Post-welding heat treatments were studied considering a possible scenario of fire or crash during transportation. The metallographic analysis indicated that post-welding heat treatments promoted a change in austenitic phase content in the fusion zone. An analysis of the stress-strain curves using work hardening models revealed that only the Voce and Hockett–Sherby models presented goodness-of-fit to the experimental data. It was demonstrated that the parameters of both models are correlated to the volumetric austenitic phase content present in the fusion zone, being equivalent to the quantification of the bulk phase. This work proposes a new direct evaluation methodology for volumetrically quantifying phases using both mathematical work hardening models fitted to the experimental data from stress-strain curves.

Similar content being viewed by others

References

CNEN NE 5.01, Transporte de materiais radioativos (Transport of Radioactive Materials)—Resolution CNEN 013/88, Brazilian Nuclear and Energy Commission, August 1988 (in Portuguese)

D.H.S. Hara, M. Fiore, R.F. Lucchesi, V.A. Mancini, and J.L. Rossi, Materials Selection for a Transport Packaging of Mo-99, International Nuclear Atlantic Conference - INAC 2015, São Paulo, 2015, available in https://inis.iaea.org/search/search.aspx?orig_q=RN:47042492

R.N. Gunn, Duplex Stainless Steel: Microstructure, Properties and Application, 1st ed. Woodhead Publishing Ltd, Abington, England, 1997.

J. Charles, Duplex Stainless Steels, A Review After DSS’ 07 Held in Grado, Revue de Métallurgie, Int. J. Metall., 2008, 105(3), p 155–171. https://doi.org/10.1051/metal:2008028

IMOA, Practical Guidelines for the Fabrication of Duplex Stainless Steels, 3rd ed. International Molybdenum Association, London, 2014.

J.-O. Nilsson, Super Duplex Stainless Steels, Mater. Sci. Technol., 1992, 8(8), p 685–700. https://doi.org/10.1179/mst.1992.8.8.685

M. Pohl, O. Storz and T. Glogowski, Effect of Intermetallic Precipitations on the Properties of Duplex Stainless Steel, Mater. Charact., 2007, 58(1), p 65–71. https://doi.org/10.1016/j.matchar.2006.03.015

J.C. Lippold and D.J. Kotecki, Welding Metallurgy and Weldability of Stainless Steels, John Wiley & Sons Inc, Haboken, New Jersey, 2005.

J.K. Sahu, U. Krupp, R.N. Ghosh and H.J. Christ, Effect of 475 °C Embrittlement on the Mechanical Properties of Duplex Stainless Steel, J. Mater. Sci. Eng. A, 2009, 508(1–2), p 1–14. https://doi.org/10.1016/j.msea.2009.01.039

G.S. da Fonseca, L.O.R. Barbosa, E.A. Ferreira, C.R. Xavier and J.A. de Castro, Microstructural Mechanical, and Electrochemical Analysis of Duplex and Superduplex Stainless Steels Welded with the Autogenous TIG Process Using Different Heat Input, Metals, 2017, 7(12), p 538–558. https://doi.org/10.3390/met7120538

D.C.D. Santos and R. Magnabosco, Kinetic Study to Predict Sigma Phase Formation in Duplex Stainless Steels, Metall. Mater. Trans. A, 2016, 47A, p 1554–1565. https://doi.org/10.1007/s11661-016-3323-z

D.P. Tumu, P. Subramani, K.G. Kumar, M. Manikandan, C.G. Mohan, N. Arivazhagan and D.N. Rajan, Investigation on Microstructure and Tensile Properties of Dissimilar Weld Joints Between AISI 316l and Duplex 2205 Stainless Steel, IOP Conf. Series J. Mater. Sci. Eng. A, 2018, 402(1), p 012075. https://doi.org/10.1088/1757-899X/402/1/012075

E.G. Betini, M.P. Gomes, M.X. Milagre, C.D.S.C. Machado, L.A.M. dos Reis, C.S. Mucsi, M.T.D. Orlando, T.S. Luz, L.G. Martinez and J.L. Rossi, Study on Welding Thermal Cycle and Residual Stress of UNS S32304 Duplex Stainless Steel Selected as External Shield for a Transport Packaging of Mo, Brazilian J. Radiat. Sci., 2019, 7(2A), p 1–13. https://doi.org/10.15392/bjrs.v7i2A.679

A.J. Ramirez, S.D. Brandi and J.C. Lippold, Secondary Austenite and Chromium Nitride Precipitation in Simulated Heat Affected Zones of Duplex Stainless Steels, Sci. Technol. Weld. Join., 2004, 9(4), p 301–313. https://doi.org/10.1179/136217104225021715

H. Khatami-Hamedani, A. Zarei-Hanzaki, H.R. Abedi, A.S. Anoushe and L.P. Karjalainen, Dynamic Restoration of the Ferrite and Austenite Phases During hot Compressive Deformation of a Lean Duplex Stainless Steel, J. Mater. Sci. Eng. A, 2020, 788, p 139400. https://doi.org/10.1016/j.msea.2020.139400

A.J. Ramirez, J.C. Lippold and S.D. Brandi, The Relationship Between Chromium Nitride and Secondary Austenite Precipitation in Duplex Stainless Steel, Metall. Mater. Trans. A, 2003, 34A, p 1575–1597. https://doi.org/10.1007/s11661-003-0304-9

P.V. Marques, P.J. Modenesi and A.Q. Bracarense, Soldagem: Fundamentos e Tecnologia (Welding: Fundamentals and Technology), 3rd ed. Editora UFMG, Belo Horizonte, Brazil, 2011. (in Portuguese)

V. Chiaverini, Tecnologia Mecânica: Processos de Fabricação e Tratamento (Mechanical Technology: Manufacturing Processes and Treatment), 2nd ed. McGraw-Hill, Ltda, 1986. (in Portuguese)

H. Fu, T. Nagasaka, N. Kometani, T. Muroga, W. Guan, S. Nogami, K. Yabuuchi, T. Iwata, A. Hasegawa, M. Yamazaki, S. Kano, Y. Satoh, H. Abe and H. Tanigawa, Effect of Post-Weld Heat Treatment and Neutron Irradiation on a Dissimilar-Metal Joint Between F82H Steel and 316L Stainless Steel, Fusion Eng. Des., 2015, 98, p 1968–1972. https://doi.org/10.1016/j.fusengdes.2015.06.079

Z. Li, W.-Y. Lo, Y. Chen, J. Pakarinen, Y. Wu, T. Allen and Y. Yang, Irradiation Response of Delta Ferrite in As-Cast and Thermally Aged Cast Stainless Steel, J. Nucl. Mater., 2015, 466, p 201–207. https://doi.org/10.1016/j.jnucmat.2015.08.006

O. Gregóire and J. Ladrière, Activation of Stainless Steel with High Energy Neutrons, J. Nucl. Mater., 2001, 298, p 309–315. https://doi.org/10.1016/S0022-3115(01)00647-X

T.Ferreira and W.Rasband, ImageJ User Guide, 2012, available in http://imagej.nih.gov/ij/docs/guide

A.H. Feng, D.L. Chen, Z.Y. Ma, W.Y. Ma and R.J. Song, Microstructure and Strain Hardening of a Friction Stir Welded High-Strength Al–Zn–Mg Alloy, Acta Metall. Sin. Engl. Lett., 2014, 27(4), p 723–729. https://doi.org/10.1007/s40195-014-0109-4

L.C. Reis, M.C. Oliveira, A.D. Santos and J.V. Fernandes, On the Determination of the Work Hardening Curve Using the Bulge Test, Int. J. Mech. Sci., 2016, 105, p 158–181. https://doi.org/10.1016/j.ijmecsci.2015.11.009

S. Hertelé, W.D. Waele and R. Denys, A Generic Stress–Strain Model for Metallic Materials with Two-Stage Strain Hardening Behaviour, Int. J. Non-Linear Mech., 2011, 46(3), p 519–531. https://doi.org/10.1016/j.ijnonlinmec.2010.12.004

Z. Gronostajski, A Generic Stress–Strain Model for Metallic Materials with Two-Stage Strain Hardening Behaviour, J. Mater. Process. Technol., 2000, 106(1–3), p 40–44. https://doi.org/10.1016/S0924-0136(00)00635-X

J.H. Hollomon, Tensile Deformation, Trans. AIME, 1945, 162, p 268–290.

E. Voce, The Relationship Between Stress and Strain for Homogeneous Deformation, J. Inst. Met., 1948, 74, p 537–562.

H.W. Swift, Plastic Instability Under Plane Stress, J. Mech. Phys. Solids, 1952, 1(1), p 1–18. https://doi.org/10.1016/0022-5096(52)90002-1

D.C. Ludwigson, Modified Stress-Strain Relation for FCC Metals and Alloys, Metall. Trans., 1971, 2(10), p 2825–2828.

J.E. Hockett and O.D. Sherby, Large Strain Deformation of Polycrystalline Metals at Low Homologous Temperatures, J. Mech. Phys. Solids, 1975, 23(2), p 87–98. https://doi.org/10.1016/0022-5096(75)90018-6

R.P. Madeira and P.J. Modenesi, Utilização do ensaio erichsen para a avaliação do desempenho de juntas soldadas (Using Erichsen Testing to Evaluate the Performance of Welded Joints), Rev. Soldagem Insp, 2010, 15(1), p 22–30. https://doi.org/10.1590/S0104-92242010000100004

D. Jenko, S. Mandziej, C. Toffolon-Masclet, B. Šuštaršič and M. Jenko, TEM Study of Dislocations in Duplex Stainless Steel, Mater. Technol., 2014, 48(1), p 131–135.

J.-O. Nilsson, L. Karlsson and J.-O. Andersson, Secondary Austenite Formation and its Relation to Pitting Corrosion in Duplex Stainless Steel Weld Metal, Mater. Sci. Technol., 1995, 11(3), p 276–283. https://doi.org/10.1179/mst.1995.11.3.276

American Welding Society - AWS B4.0:2007, Standard Methods for Mechanical Testing of Welds, 7th ed. American Welding Society, Miami, 2007.

British Standard—BS EN 895:1995, Destructive Tests on Welds in Metallic Materials—Transverse Tensile Test, British Standard Institution, London, 1995.

D. Raabe, Simulation of Rolling Textures of b.c.c. Metals Considering Grain Interactions and Crystallographic Slip on {110}, {112} and {123} Planes, J. Mater. Sci. Eng. A, 1995, 197(1), p 31–37. https://doi.org/10.1016/0921-5093(94)09770-4

D. Raabe, Investigation of Contribution of 123 Slip Planes to Development of Rolling Textures in bcc Metals by use of Taylor Models, Mater. Sci. Technol., 1995, 11(5), p 455–460. https://doi.org/10.1179/mst.1995.11.5.455

A.F. Padilha and F. S. Jr., Encruamento, recristalização, crescimento de grão e textura (Hardening, recrystallization, grain growth, and texture). 3rd ed, Associação Brasileira de Metalurgia e Materiais - ABM, São Paulo, 2005, (in Portuguese)

J. Christopher, B.K. Choudhary, E.I. Samuel, M.D. Mathew and T. Jayakumar, Tensile Stress–Strain and Work Hardening Behaviour of P9 Steel for Wrapper Application in Sodium Cooled Fast Reactors, J. Nucl. Mater., 2012, 420(1–3), p 583–590. https://doi.org/10.1016/j.jnucmat.2011.11.038

G. Sainath, B.K. Choudhary, J. Christopher, E.I. Samuel and M.D. Mathew, Applicability of Voce Equation for Tensile Flow and Work Hardening Behavior of P92 Ferritic Steel, Int. J. Pressure Vessels Piping, 2015, 132–133, p 1–9. https://doi.org/10.1016/j.ijpvp.2015.05.004

J. Cao, F.G. Li, X.-K. Ma and Z.K. Sun, Tensile Stress−Strain Behavior of Metallic Alloys, Trans. Nonferrous Met. Soc. China, 2017, 27(11), p 2443–2453. https://doi.org/10.1016/S1003-6326(17)60271-1

P. Movahed, S. Kolahgar, S.P.H. Marashi, M. Pouranvari and N. Parvin, The Effect of Intercritical Heat Treatment Temperature on the Tensile Properties and Work Hardening Behavior of Ferrite–Martensite Dual Phase Steel Sheets, J. Mater. Sci. Eng. A, 2009, 518(1–2), p 1–6. https://doi.org/10.1016/j.msea.2009.05.046

U.F. Kocks, Laws for Work-Hardening and Low-Temperature Creep, J. Eng. Mater. Technol., 1976, 98(1), p 76–85. https://doi.org/10.1115/1.3443340

H. Mecking and U.F. Kocks, Kinetics of Flow and Strain-Hardening, Acta Metall., 1981, 29(11), p 1865–1875. https://doi.org/10.1016/0001-6160(81)90112-7

Y.C. Lin and X.M. Chen, Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des, 2011, 32(4), p 1733–1759. https://doi.org/10.1016/j.matdes.2010.11.048

Acknowledgments

The authors acknowledge CAPES, CNPQ, and FAPES for scientific support. LNNano (proposal: STC 22766 and SEM_FEG_24285), LNLS (proposal: XTMS 20170659), and CNPEM for allowing us to use their Gleeble® and scanning electron microscope facilities, and Federal Institute of Espírito Santo for allowing the use of the scanning electron microscope.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Caetano, G.A., Gonoring, T.B., Coelho, L.M. et al. Mechanical Properties Study of a Duplex Stainless Steel Weld Using Physical Simulation and Work Hardening Models. J. of Materi Eng and Perform 31, 113–127 (2022). https://doi.org/10.1007/s11665-021-06155-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06155-8