Abstract

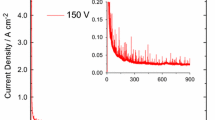

Porous titanium sheets are attractive for application as the porous transport layer (PTL) for polymer electrolyte membrane (PEM) water electrolyzers. However, the titanium passivation increases its surface contact resistance, deteriorating the electrolyzer performance. A solution for long-term operation has been to coat titanium-based PTLs with platinum or gold, which considerably increases PEM electrolyzer costs. To overcome this limitation, a NbN coating is proposed as an alternative to decrease materials costs while avoiding titanium surface oxidation. Therefore, porous titanium sheets of ca. 250 μm were powder metallurgically produced by tape casting and then sputter-coated with a NbN thin film. A systematic investigation of NbN film deposition on porous titanium sheets by reactive magnetron sputtering was undertaken. Coating microstructure and constitution were evaluated before and after electrochemical characterization. First electrochemical characterizations throughout cyclic voltammetry and potentiodynamic polarization curves demonstrate that the addition of NbN coatings decreases titanium surface oxidation and improves electrochemical performance of the porous titanium sheets. These results indicated that NbN-coated PTLs are promising candidates for PEM electrolyzer application.

Similar content being viewed by others

References

A.W. Jason Marcinkoski, Spendelow Jacob, D. Papageorgopoulos, “DOE Hydrogen and Fuel Cells Program Record,” 2015. [Online]. https://www.hydrogen.energy.gov/pdfs/15015_fuel_cell_system_cost_2015.pdf.

M. Carmo, D.L. Fritz, J. Mergel, and D. Stolten, A Comprehensive Review on PEM Water Electrolysis, Int. J. Hydrogen Energy, 2013, 38, p 4901–4934

S.A. Grigoriev, V.I. Porembsky, and V.N. Fateev, Pure Hydrogen Production by PEM Electrolysis for Hydrogen Energy, Int. J. Hydrogen Energy, 2006, 31, p 171–175

S. Grigoriev, P. Millet, S. Volobuev, and V. Fateev, Optimization of Porous Current Collectors for PEM Water Electrolysers, Int. J. Hydrogen Energy, 2009, 34(11), p 4968–4973

J.O. Majasan, F. Iacoviello, J.I.S. Cho, M. Maier, X. Lu, T.P. Neville, I. Dedigama, P.R. Shearing, and D.J.L. Brett, Correlative Study of Microstructure and Performance for Porous Transport Layers in Polymer Electrolyte Membrane Water Electrolysers by X-ray Computed Tomography and Electrochemical Characterization, Int. J. Hydrogen Energy, 2019, 44(36), p 19519–19532

F.J. Hackemüller, E. Borgardt, O. Panchenko, M. Müller, and M. Bram, Manufacturing of Large-Scale Titanium-Based Porous Transport Layers for Polymer Electrolyte Membrane Electrolysis by Tape Casting, Adv. Eng. Mater., 2019, 21, p 1801201

P. Lettenmeier, S. Kolb, N. Sata, A. Fallisch, L. Zielke, S. Thiele, A.S. Gago, and K.A. Friedrich, Comprehensive Investigation of Novel Pore-Graded Gas Diffusion Layers for High-Performance and Cost-Effective Proton Exchange Membrane Electrolyzers, Energy Environ. Sci., 2017, 10, p 2521–2533

E.T. Ojong, J.T.H. Kwan, A. Nouri-Khorasani, A. Bonakdarpour, D.P. Wilkinson, and T. Smolinka, Development of an Experimentally Validated Semiempirical Fully-Coupled Performance Model of a PEM Electrolysis Cell with a 3-D Structured Porous Transport Layer, Int. J. Hydrogen Energy, 2017, 42, p 25831–25847

J. Mo, Z. Kang, G. Yang, S.T. Retterer, D.A. Cullen, T.J. Toops, J.B. Green, Jr., and F.-Y. Zhang, Thin Liquid/Gas Diffusion Layers for High-Efficiency Hydrogen Production from Water Splitting, Appl Energy, 2016, 177, p 817–822

J. Garcia-Navarro, M. Schulze, and K. Friedrich, Understanding the Role of Water Flow and the Porous Transport Layer on the Performance of Proton Exchange Membrane Water Electrolyzers, ACS Sustain Chem Eng, 2019, 7(1), p 1600–1610

J. Mo, R.R. Dehoff, W.H. Peter, and T.J. Toops, Additive Manufacturing of Liquid/Gas Diffusion Layers for Low-Cost and High-Efficiency Hydrogen Production, Int. J. Hydrogen Energy, 2016, 41, p 3128–3135

Z. Kang, J. Mo, G. Yang, S.T. Retterer, D.A. Cullen, T.J. Toops, J.B. Green, Jr., and F.-Y. Zhang, Investigation of Thin/Well-Tunable Liquid/Gas Diffusion Layers Exhibiting Superior Multifunctional Performance in Low-Temperature Electrolytic Water Splitting, Energy Environ Sci, 2017, 10(1), p 166–175

E. Borgardt, O. Panchenko, F.J. Hackemüller, J. Giffina, M. Bram, M. Müller, W. Lehnert, and D. Stolten, Mechanical Characterization and Durability of Sintered Porous Transport Layers for Polymer Electrolyte Membrane Electrolysis, J. Power Sources, 2018, 374, p 84–91

T. Bystron, M. Vesely, M. Paidar, G. Papakonstantinou, K. Sundmacher, and B. Bensmann, Enhancing PEM Water Electrolysis Efficiency by Reducing the Extent of Ti Gas Diffusion Layer Passivation, J. Appl. Electrochem., 2018, 48, p 713–723

C. Rakousky, U. Reimer, K. Wippermann, M. Carmo, W. Lueke, and D. Stolten, An Analysis of Degradation Phenomena in Polymer Electrolyte Membrane Water Electrolysis, J. Power Sources, 2006, 326, p 120–128

C. Rakousky, G.P. Keeley, K. Wippermann, M. Carmo, and D. Stolten, The Stability Challenge on the Pathway to High-Current-Density Polymer Electrolyte Membrane Water Electrolyzers, Electrochim. Acta, 2018, 278, p 324–331

C. Liu, M. Carmo, G. Bender, A. Everwand, T. Lickert, J.L. Young, T. Smolinka, D. Stolten, and W. Lehnert, Performance Enhancement of PEM Electrolyzers Through Iridium-Coated Titanium Porous Transport Layers, Electrochem. Commun., 2018, 97, p 96

H.S. Choi, D.H. Han, W.H. Hong, and J.J. Lee (Titanium, chromium) nitride Coatings for Bipolar Plate of Polymer Electrolyte Membrane Fuel Cell, J. Power Sources, 2009, 189(2), p 966–971

M. Li, S. Luo, C. Zeng, J. Shen, H. Lin, and C. Cao, Corrosion Behavior of TiN Coated Type 316 Stainless Steel in Simulated PEMFC Environments, Corros. Sci., 2004, 46(6), p 1369–1380

L. Wang, J. Sun, J. Sun, Y. Lv, S. Li, S. Ji, and Z. Wen, Niobium Nitride Modified AISI, 304 Stainless Steel Bipolar Plate for Proton Exchange Membrane Fuel Cell, J. Power Sources, 2012, 199, p 195–200

K. Havey, J. Zabinski, and S. Walck, The Chemistry, Structure, and Resulting Wear Properties of Magnetron-Sputtered NbN Thin Films, Thin Solid Films, 1997, 303(1–2), p 238–245

J.J. Olaya, S.E. Rodil, and S. Muhl, Comparative Study of Niobium Nitride Coatings Deposited by Unbalanced and Balanced Magnetron Sputtering, Thin Solid Film, 2008, 516(23), p 8319–8326

M. Larsson, P. Hollman, P. Hedenqvist, S. Hogmark, U. Wahlström, and L.M. Hultman, Deposition and Microstructure of PVD TiN-NbN Multilayered Coatings by Combined Reactive Electron Beam Evaporation and DC Sputtering, Surface Coat Tech, 1996, 286–87, p 351–356

A. Nigro, G. Nobile, M. Rubino, and R. Vaglio, Electrical Resistivity Of Polycrystalline Niobium Nitride Films, Phys Rev B, 1988, 37(8), p 3970–3972

N.D. Tomashov, G.P. Chernova, Y.S. Ruscol, and G.A. Ayuyan, The Passivation of Alloys on Titanium Bases, Electrochim. Acta, 1974, 19(4), p 159–172

A. Yildiz, S.B. Lisesivdin, M. Kasap, and D. Mardare, Electrical properties of TiO2 thin films, J Non-Crystalline Solids, 2008, 354, p 4944–4947

C. Nico, T. Monteiro, and M.P.F. Graça, Niobium Oxides and Niobates Physical Properties: Review and Prospects, Prog. Mater Sci., 2016, 80, p 1–37

F. Tietz, H.P. Buchkremer, and D. Stöver, Components Manufacturing for Solid Oxide Fuel Cell, Solid State Ionics, 2002, 373–381, p 152–153

A. D. Schneider,, Formação de texturas cristalográficas em filmes finos de NbN (MSc thesis), Graduate program in physics, Universidade Federal de Santa Maria, 2017 (in Portuguese). https://repositorio.ufsm.br/handle/1/13950

Z. Han, X. Hu, J. Tian, G. Li, and G. Mingyuan, Magnetron Sputtered NbN Thin Films and Mechanical Properties, Surf Coat Techn, 2004, 179(2–3), p 188–192

X.-K. Du, T.-M. Wang, C. Wang, B.-L. Chen, and L. Zhou, Microstructure and Optical Characterization of Magnetron Sputtered NbN Thin Films, Chin J Aeronaut, 2007, 20(2), p 140–144

C.-Y. Tsao, J.W. Weber, P. Campbell, P.I. Widenborg, D. Song, and M.A. Green, Low-Temperature Growth of Polycrystalline Ge Thin Film on Glass by in Situ Deposition and Ex Situ Solid-Phase Crystallization for Photovoltaic Applications, Appl. Surf. Sci., 2009, 255(15), p 7028–7035

M. Fenker, M. Balzer, R.V. Büchi, H.A. Jehn, H. Kappl, and J.-J. Lee, Deposition of NbN Thin Films Onto High-Speed Steel Using Reactive Magnetron Sputtering for Corrosion Protective Applications, Surf Coat Tech, 2003, 163164, p 169–175

E. Arslan, Structural, Mechanical and Corrosion Properties of NbN Films Deposited using dc and Pulsed Dc Reactive Magnetron Sputtering, Surf. Eng., 2010, 26(8), p 615–619

Acknowledgments

This study was partially funded by the Funding Agency of the Brazilian Ministry of Education (CAPES)—Finance Code 001. L.S. Dorneles acknowledges the support from CNPq under grant 302950/2017-6. The authors also thank F.J. Hackemüller and Dr. M. Bram from the Institute of Climate and Energy Research (IEK-1), the Forschungszentrum Jülich, for the support with tape casting manufacturing and Prof. Dr. L.O. Bulhões from Universidade Franciscana (UFN) for the support with the electrochemical analyses.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Daudt, N.F., Schneider, A.D., Arnemann, E.R. et al. Fabrication of NbN-Coated Porous Titanium Sheets for PEM Electrolyzers. J. of Materi Eng and Perform 29, 5174–5183 (2020). https://doi.org/10.1007/s11665-020-05026-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05026-y