Abstract

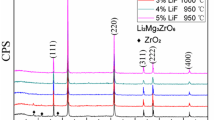

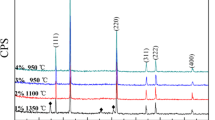

Low-firing 1–4 wt.% LiF-doped Li2Mg3Ti0.95(Mg1/3Ta2/3)0.05O6 (LMTT) ceramics were synthesized via solid state reaction method. The effects of LiF on the phase composition, sintering behavior as well as microwave dielectric properties were systematically discussed. Adding LiF additives could lower the sintering temperature to 950°C for LMTT ceramics. X-ray powder diffraction analysis indicated that all the compounds prepared in this work have cubic symmetry with space group Fm-3m. Typically, LMTT with 2 wt.% LiF exhibited a dense uniform microstructure and optimized microwave dielectric properties of εr ∼ 15.1 (± 0.2), Q·f ∼ 60,100 GHz (at 8.3 GHz), and τf ∼ − 20.45 ppm/°C at 950°C. In addition, the good chemical compatibility with Ag electrode made LMTT-2 wt.% LiF ceramic an appropriate candidate for low temperature co-fired ceramic.

Similar content being viewed by others

References

M.T. Sebastian and H. Jantunen, Int. Mater. Rev. 53, 57 (2008).

M. Rakhi and G. Subodh, J. Eur. Ceram. Soc. 38, 4962 (2018).

M.T. Sebastian, R. Ubic, and H. Jantunen, Int. Mater. Rev. 60, 392 (2015).

D. Zhou, L.X. Pang, D.W. Wang, C. Li, B.B. Jin, and I.M. Reaney, J. Mater. Chem. C 5, 10094 (2017).

T.L. Tang, W.S. Xia, B. Zhang, Y. Wang, M.X. Li, and L.W. Shi, J. Mater. Sci. Mater. Electron. 30, 15293 (2019).

W.S. Xia, S.B. Zhang, T.L. Tang, Y. Wang, and L.W. Shi, Physica B 572, 148 (2019).

L.X. Pang and D. Zhou, J. Am. Ceram. Soc. 102, 2278 (2019).

Y.H. Zhang and H.T. Wu, J. Am. Ceram. Soc. 102, 4092 (2019).

Y.H. Zhang, J.J. Sun, N. Dai, Z.C. Wu, H.T. Wu, and C.H. Yang, J. Eur. Ceram. Soc. 39, 1127 (2019).

J.X. Bi, C.F. Xing, C.H. Yang, and H.T. Wu, J. Eur. Ceram. Soc. 38, 3840 (2018).

Y. Wang, T.L. Tang, J.T. Zhang, W.S. Xia, and L.W. Shi, J. Alloys Compd. 778, 576 (2019).

Y. Wang, S.B. Zhang, T.L. Tang, W.S. Xia, and L.W. Shi, Mater. Lett. 231, 1 (2018).

W.S. Xia, L.Y. Zhang, Y. Wang, S.E. Jin, Y.P. Xu, Z.W. Zuo, and W. Shi, J. Mater. Sci. Mater. Electron. 27, 11325 (2016).

S. George and M.T. Sebastian, J. Am. Ceram. Soc. 93, 2164 (2010).

S. George and M.T. Sebastian, J. Eur. Ceram. Soc. 30, 2585 (2010).

Y.W. Tseng, J.Y. Chen, Y.C. Kuo, and C.L. Huang, J. Alloys Compd. 509, L308 (2011).

Z.F. Fu, P. Liu, J.L. Ma, X.M. Chen, and H.W. Zhang, Mater. Lett. 164, 436 (2016).

H.C. Xiang, C.C. Li, C.Z. Yin, C.Z. Tang, and L. Fang, Ceram. Int. 44, 5817 (2018).

P. Zhang, H. Xie, Y.G. Zhao, and M. Xiao, J. Alloys Compd. 689, 246 (2016).

H.L. Pan, Y.X. Mao, Y.K. Yang, Y.W. Zhang, and H.T. Wu, Mater. Res. Bull. 105, 296 (2018).

S. George and M.T. Sebastian, Int. J. Appl. Ceram. Technol. 8, 1400 (2011).

Y. Wang, L.Y. Zhang, S.B. Zhang, W.S. Xia, and L.W. Shi, Mater. Lett. 219, 233 (2018).

W.S. Xia, L.Y. Zhang, Y. Wang, J.T. Zhang, R.R. Feng, and L.W. Shi, J. Mater. Sci. Mater. Electron. 28, 18437 (2017).

W.S. Xia, F. Jin, M. Wang, X. Wang, G.Y. Zhang, and L.W. Shi, J. Mater. Sci. Mater. Electron. 27, 1100 (2016).

A. Rose, B. Masin, H. Sreemoolanadhan, K. Ashok, and T. Vijayakumar, Appl. Surf. Sci. 449, 96 (2018).

P. Zhang, K.X. Sun, L. Lu, and M. Xiao, J. Alloy Compd. 765, 1209 (2018).

F. Fu, J.L. Ma, and P. Liu, J. Alloys Compd. 752, 354 (2018).

D. Zhu, F.T. Kong, and X.S. Ma, Ceram. Int. 44, 20006 (2018).

F. Yuan, L. Gan, F.F. Ning, S.B. An, J. Jiang, and T.J. Zhang, Ceram. Int. 44, 20566 (2018).

E. Courtney, IEEE Trans. Microw. Theory Technol. 18, 476 (1970).

W. Hakki and P.D. Coleman, IRE Trans. Microw. Theory Technol. 8, 402 (1960).

V.B. Braginsky, V.S. Ilchenko, and K.S. Bagdassarov, Phys. Lett. A 120, 300 (1987).

V.L. Gurevich and A.K. Tagantsev, Adv. Phys. 40, 719 (1991).

J.D. Breeze, J.M. Perkins, D.W. McComb, and N.M. Alford, J. Am. Ceram. Soc. 92, 671 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, J., Xu, H., Yang, Y. et al. Sintering Behavior and Microwave Dielectric Properties of LiF-Doped Li2Mg3Ti0.95(Mg1/3Ta2/3)0.05O6 Ceramics for LTCC Applications. J. Electron. Mater. 49, 773–779 (2020). https://doi.org/10.1007/s11664-019-07803-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-019-07803-5