Abstract

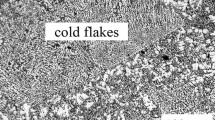

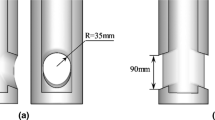

Oscillation marks (OMs) are regular, transverse indentations formed on the surface of continuously cast (CC) steel products. OMs are widely considered defects because these are associated with segregation and transverse cracking. A variety of mechanisms for their formation has been proposed (e.g., overflow, folding, and meniscus freezing), whereas different mark types have also been described (e.g., folded, hooks, and depressions). The current work uses numerical modeling to formulate a unified theory for the onset of OMs. The initial formation mechanism is demonstrated to be caused by fluctuations in the metal and slag flow near the meniscus, which in turn causes thermal fluctuations and successive thickening and thinning of the shell, matching the thermal fluctuations observed experimentally in a mold simulator. This multiphysics modeling of the transient shell growth and explicit prediction of OMs morphology was possible for the first time through a model for heat transfer, fluid flow, and solidification coupled with mold oscillation, including the slag phase. Strategies for reducing OMs in the industrial practice fit with the proposed mechanism. Furthermore, the model provides quantitative results regarding the influence of slag infiltration on shell solidification and OM morphology. Control of the precise moment when infiltration occurs during the cycle could lead to enhanced mold powder consumption and decreased OM depth, thereby reducing the probability for transverse cracking and related casting problems.

Similar content being viewed by others

Abbreviations

- d liquid :

-

liquid slag film thickness

- d OM :

-

oscillation mark depth

- d solid :

-

liquid slag film thickness

- f :

-

frequency (cycles/min)

- k :

-

thermal conductivity (W/m-K)

- m disp :

-

mold displacement (m)

- \( q^{\prime} \) :

-

fluctuating heat flux (W/m2)

- \( \bar{q} \) :

-

mean heat flux (W/m2)

- q peak :

-

peak heat flux (W/m2)

- Q c :

-

mass flow rate (kg/s)

- Q s :

-

powder consumption (kg/m2)

- r int :

-

interfacial resistance (m2-K/W)

- s :

-

stroke (m)

- T br :

-

break temperature (K)

- t n :

-

negative strip time

- t p :

-

positive strip time

- v c :

-

casting speed (m/min or m/s)

- v m :

-

mold velocity (m/s)

- v slag :

-

slag velocity in the gap (m/s)

- ∆T :

-

superheat (K)

- η :

-

slag viscosity at 1573 K (100 °C) (dPa-s)

- OM:

-

oscillation mark

- SEN:

-

submerged entry nozzle

References

A. Badri, T.T. Natarajan, C.C. Snyder, K.D. Powers, F.J. Mannion, and A.W. Cramb: Metall. Mater. Trans. B, 2005, vol. 36B, pp. 373-83.

A. Badri, T.T. Natarajan, C.C. Snyder, K.D. Powers, F.J. Mannion, and A.W. Cramb: Metall. Mater. Trans. B, 2005, vol. 36B, p. 355.

J.M. Hill, Y.H. Wu, and B. Wiwatanapataphee: Metall. Mater. Trans. A, 1999, vol. 36A, pp. 311-26.

H. Tomono: Ph.D. Dissertation: École Polytechnique Fédérale de Lausanne Lausanne, Switzerland, 1979.

P. Ackermann: Ph.D. Dissertation: École Polytechnique Fédérale de Lausanne Lausanne, Switzerland, 1983.

B.G. Thomas, C. Lee, J. Park, G. Lee, S. Kim, and H. Shin: Mater. Sci. Technol., 2004, vol. 2, pp. 11-26.

J. Sengupta and B.G. Thomas: JOM, 2006, vol. 58, pp. 16–18.

R. Aigner and H. Steinruck: Eurotherm 82, Eds. R.A. Białecki and A. Nowak, Gliwice–Cracow, Poland, 2005.

H.J. Shin, S.H. Kim, B.G. Thomas, G.G. Lee, J.M. Park, and J. Sengupta: ISIJ Int., 2006, vol. 46, no. 11, pp. 1635-44.

J. Sengupta, C. Ojeda, and B.G. Thomas: Int. J. Cast Met. Res., 2009, vol. 22, nos. 1-4, pp. 8-14.

C. Ojeda, J. Sengupta, B.G. Thomas, J. Barco, and J.L. Arana: AISTech 2006 Steelmaking Conference Proceedings, Cleveland, OH, AIST, Warrendale, PA, 2006, vol. 1, pp. 1017–28.

J. Elfsberg: Ph.D. Dissertation, Royal Institute of Technology, Stockholm, Sweden, 2003.

K. Schwerdtfeger and H. Sha: Metall. Mater. Trans. B, 2000, vol. 31B, pp. 813-26.

Y. Le Papillon, W. Jäaeger, M. Konig, B. Weisberger, and M. Jauhola: Final Report, RFCS, 2003, EUR 20897, p. 161.

G.-G. Lee, B.G. Thomas, S.-H. Kim, H.-J. Shin, S.-K. Baek, C.-H. Choi, D.-S. Kim, and S.-J. Yu: Acta Mater., 2007, vol. 55, no. 20, pp. 6705-12.

R. Carli, C. Carna, F. Magni, and A.C. Mapelli: 6th European Conf. on Continuous Casting, Riccione, Italy, 2008.

C. Marchionni, P. Rocabois, J.N. Pontoire, M. Roscini, L.F. Sancho, J. Diaz, M. Ridolfi, M. De Santis, O. Putz, S. Rödl, F. Ruppel, K. Spitzer, K. Scholtz, and K. Schwerdtfeger: Final Report, RFCS, 2004, EUR 20947.

P.E. Ramirez-Lopez, P.D. Lee, and K.C. Mills: in Modeling of Casting, Welding and Advanced Solidification Processes XII, D.M. Maijer and S. Cockroft, eds., Vancouver, Canada, 2009, vol. 12, TMS, pp. 61–68.

P.E. Ramirez Lopez, P.D. Lee, and K.C. Mills: ISIJ Int., 2010, vol. 50, no. 3, pp. 425-34.

P.E. Ramirez-Lopez, P.D. Lee, K.C. Mills, and B. Santillana: ISIJ Int., 2010, vol. 50, no. 12, pp. 1797-1804.

R.D. Morales and P.E. Ramirez-Lopez: AISTech Conf. Proc., Association for Iron & Steel Technology, Cleveland, OH, 2006, p. 20.

ANSYS Fluent 6.3.26 - User’s Guide, 1995-2007.

K. Spitzer, K. Schwerdtfeger, and J. Holzhauser: Steel Res., 1999, vol. 70, no. 10, pp. 430-36.

P.E. Ramirez Lopez: Ph.D. Dissertation, Imperial College London, London, UK, 2010, p. 170.

G.G. Lee, H. Shin, B.G. Thomas, S. Kim, D. Kim, and S. Yu: Iron & Steel Technol. Conf., TMS, Indianapolis, IN, 2007, pp. 1-10.

P.H. Dauby, W.H. Emling, and R. Sobolewski: Ironmaking Steelmaking, 1986, pp. 26–36.

J. Sengupta and H.J. Shin: Acta Mater., 2006, vol. 54, no. 4, p. 1165.

K.C. Mills, P.E. Ramirez-Lopez, and P.D. Lee: Sano Symposium, Tokyo, Japan, International Research Center for Sustainable Materials, University of Tokyo, 2008.

T. Miyake, M. Morishita, H. Nakata, and M. Kokita: ISIJ Int., 2006, vol. 46, no. 12, pp. 1817-22.

C.-A. Däcker and T. Sohlgren: 5th ECCC, Nice, France, 2005.

G.G. Lee, H. Shin, S.-H. Kim, S.-K. Kim, W.-Y. Choi, and B.G. Thomas: Ironmaking Steelmaking, 2009, vol. 36, no. 1, pp. 40-49.

F. Neumann: 79th Steelmaking Conf., Pittsburgh, PA, 1996, p. 86.

P. Courbe: Revue de Metall. CIT, 1996, p. 93.

S. Itoyama: CAMP-ISIJ, 2001, vol. 14, no. 4, p. 893.

S. Kunstreich and P.H. Dauby: 4th European Conf. Continuous Casting, Birmingham, UK, 2002, pp. 489-99.

J.D. Madill: Workshop on Steelmaking, EC Sci. Tech. Comm., Luxembourg, 1994, pp. 104–09.

C.-A. Däcker: KIMAB, 2003, Final report: IM-2003-154, pp. 11–12.

E. Takeuchi and J.K. Brimacombe: Metall. Trans. B, 1985, vol. 16B, pp. 605-25.

Acknowledgments

The authors would like to thank Tata Steel and EPSRC (GR/T26344) for financial support and facilities. P.R.L. thanks CONACYT and SEP (Mexico) for financial assistance to attend the PhD program at Imperial College London. P.R.L. also acknowledges Swerea MEFOS (Sweden) for further support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Manuscript Submitted December 8, 2010.

Rights and permissions

About this article

Cite this article

Ramirez Lopez, P.E., Mills, K.C., Lee, P.D. et al. A Unified Mechanism for the Formation of Oscillation Marks. Metall Mater Trans B 43, 109–122 (2012). https://doi.org/10.1007/s11663-011-9583-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11663-011-9583-5