Abstract

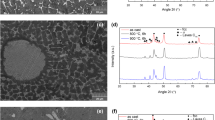

The goal of this research was to propose a combined modeling approach to design a stable alloy based on the FeMnNiCoMo system. First, phase stability calculations were made using valence electron calculations (VEC) and density functional theory (DFT) methods. The effect of Mo alloying in the FeMnNiCo system was investigated by calculating characteristics of solid solution combined with the different methods. The DFT method was used to obtain formation enthalpy in the (FeMnNiCo)100–xMox system for stable face-centered-cubic (fcc) and body-centered-cubic (bcc) structures. The calculations were made for Mo contents from 0 to 20 at. pct. Classic thermodynamic calculations, such as mixing enthalpy, configurational entropy, or valence electron concentration (VEC), were used. Based on these calculations, the proposed alloy should be characterized by fcc structure in the entire considered Mo content, without occurrence of any intermetallic phases. Subsequently, three alloys with 0, 5, and 10 at. pct Mo were produced using arc melting and were further investigated. Alloys were homogenized and then hot rolled into flat bars. Microstructural analysis was performed using as-cast, after-homogenization, and hot-rolled specimens. The microstructures were characterized by means of scanning electron microscopy–energy-dispersive spectroscopy (EDS) analysis. Mechanical properties were evaluated using tensile and compression tests. In addition, X-ray diffraction (XRD) and differential scanning calorimetry (DSC) analyses were also conducted. The results from EDS and XRD showed the occurrence of intermetallic phases in investigated alloys, as phase with Fm3-m space group and in µ phase in (FeMnNiCo)90Mo10 alloy. Based on the comparison of the experimental and calculated results, conclusions regarding the structural changes with Mo content were drawn and the validity of the proposed modeling approach was tested and discussed.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang: Adv. Eng. Mater., 2004, vol. 6, pp. 299–303.

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent: Mater. Sci. Eng. A., 2004, vol. 375–377, pp. 213–18.

J.W. Yeh: JOM., 2013, vol. 65, pp. 1759–71.

F.J. Wang, Y. Zhang, G.L. Chen, and H.A. Davies: Int. J. Mod. Phys. B., 2009, vol. 23(6–7), pp. 1254–59.

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw: Intermetallics., 2010, vol. 18(9), pp. 1758–65.

Y.J. Zhou, Y. Zhang, Y.L. Wang, and G.L. Chen: Appl. Phy. Lett., 2007, vol. 90, p. 181904.

M.C. Gao, B. Zhang, S.M. Guo, J.W. Qiao, and J.A. Hawk: Metall. Mater. Trans. A., 2015, vol. 47A, pp. 3322–32.

S. Guo and C.T. Liu: Progr. Nat. Sci., 2011, vol. 21, pp. 433–46.

C.J. Tong, Y.L. Chen, S.K. Chen, J.W. Yeh, T.T. Shun, C.H. Tsau, S.J. Lin, and S.Y. Chang: Metall. Mater. Trans. A., 2015, vol. 36A, pp. 881–93.

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle: Intermetallics., 2011, vol. 19, pp. 698–706.

S. Gangireddy, B. Gwalani, V. Soni, R. Banerjee, and R.S. Mishra: Mater. Sci. Eng., 2019, vol. 739, pp. 158–66.

X. Yang and Y. Zhang: Mater. Chem. Phys., 2012, vol. 132(2–3), pp. 233–38.

X.G. Li, C. Chen, and H. Zheng: npj Comput. Mater., 2020, vol. 6.

M.C. Gao and D.E. Alman: Entropy., 2013, vol. 15, pp. 4504–19.

J.M. Zhu, H.F. Zhang, H.M. Fu, A.M. Wang, H. Li, and Z.Q. Hu: J. Alloys Compd., 2010, vol. 497, pp. 52–56.

J.M. Zhu, H.M. Fu, H.F. Zhang, A.M. Wang, H. Li, and Z.Q. Hu: Mater. Sci. Eng. A., 2010, vol. 527, pp. 6975–79.

T.T. Shun, L.Y. Chang, and M.H. Shiu: Mater. Charact., 2012, vol. 70, pp. 63–67.

G. Qin, R. Chen, H. Zheng, H. Fang, L. Wang, Y. Su, J. Guo, and H. Fu: J. Mater. Sci. Technol., 2019, vol. 35, pp. 578–83.

F. Otto, Y. Yang, H. Bei, and E.P. George: Acta Mater., 2013, vol. 61, pp. 2628–38.

P.E.J. Rivera Díaz del Castillo and H. Fu: J. Mater. Res., 2018, vol. 33(19), pp. 2970–82.

Z. Wu, H. Bei, G.M. Pharr, and E.P. George: Acta Mater., 2014, vol. 81, pp. 428–41.

H. Okamoto: J. Phys. Equil. Diff., 2007, vol. 28, p. 300.

U. Mizutani: Hume-Rothery Rules for Structurally Complex Alloy Phases, CRC Press, Boca Raton, 2011, pp. 249–81.

H.L. Chen, H. Mao, and Q. Chen: Mater. Chem. Phys., 2018, vol. 210, pp. 279–90.

P. Giannozzil, S. Baroni, N. Bonini, M. Calandra, R. Car, C. Cavazzoni, D. Ceresoli, G.L. Chiarotti, M. Cococcioni, I. Dabo, A. Dal Corsa, S. de Gironcoli, S. Fabris, G. Fratesi, R. Gebauer, U. Gerstmann, C. Gougoussis, A. Kokalj, M. Lazzeri, L. Martin-Samos, N. Marzari, F. Mauri, R. Mazzarello, S. Paolini, A. Pasquarello, L. Paulatto, C. Sbraccia, S. Scandolo, G. Sclauzero, A.P. Seitsonen, A. Smogunov, P. Umari, and R.M. Wentzcovitch: J. Phys., 2009, vol. 21 (39).

A. van de Walle: Calphad., 2009, vol. 33(2), pp. 266–78.

A. van de Walle, M. Asta, and G. Ceder: Calphad., 2002, vol. 26(4), pp. 539–53.

J.P. Perdew, K. Burke, and M. Ernzerhof: Phys. Rev. Lett., 1996, vol. 77, pp. 3865–68.

D. Vanderbilt: Phys. Rev. B., 1990, vol. 41, pp. 7892–95.

E. Kuckukbenli, M. Monni, B.I. Adetunji, X. Ge, G.A. Adebayo, N. Marzari, S. de Gironcoli, and A. Dal Corso: Cond. Mat. Mater. Sci., 2014, arXiv:abs/1404.3015.

Y. Zhang, Z.P. Lu, S.G. Ma, P.K. Liaw, Z. Tang, Y.Q. Cheng, and M.C. Gao: MRS Commun., 2014, vol. 4(2), pp. 57–62.

R.W. Cahn and P. Hassen: Physical Metallurgy, vol. 1, 4th edn. North Holland, Amsterdam, 1996.

Y. Zhang, X. Yang, and P.K. Liaw: JOM., 2012, vol. 64(7), pp. 830–38.

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw: Adv. Eng. Mater., 2008, vol. 10(6), pp. 534–38.

A. Takeuchi and A. Inoue: Mater. Trans., 2005, vol. 46, pp. 2817–29.

S. Müller, W. Wolf, and R. Podloucky: Alloy Physics: Ab-Initio Methods and Applications, Wiley, Hoboken, 2007, pp. 589–652.

V.G. de Paula and M.S. Reis: Chem. Mater., 2021, vol. 33(14), pp. 5483–95.

D. Choudhuri, T. Alam, T. Borkar, B. Gwalani, A.S. Mantri, S.G. Srinivasan, M.A. Gibson, and R. Banerjee: Scripta Mater., 2015, vol. 100, pp. 36–39.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P. Liaw, and Z.P. Kand Lu: Prog. Mater. Sci., 2014, vol. 61, pp. 1–93.

C.W. Bale, E. Bélisle, P. Chartrand, S.A. Decterov, G. Eriksson, A.E. Gheribi, K. Hack, I.H. Jung, Y.B. Kang, J. Melançon, A.D. Pelton, S. Petersen, C. Robelin, J. Sangster, P. Spencer, and M.-A. Van Ende: Calphad., 2016, vol. 54, pp. 35–53.

H. Loyer Danflou, M. Macia, T.H. Sanders, and T. Khan: Superalloys, 1996, pp. 119–27.

I. Basu and J.T.M. De Hosson: Scripta Mater., 2020, vol. 187, pp. 148–56.

H. Kwon, J. Moon, J.W. Bae, J.M. Park, S. Son, H.-S. Do, B.-J. Lee, and H.S. Kim: Scripta Mater., 2020, vol. 188, pp. 140–45.

D. Wen, C.H. Chang, S. Matsunaga, G. Park, L. Ecker, S.K. Gill, M. Topsakal, M.A. Okuniewski, S. Antonov, D.R. Johnson, and M.S. Titus: Materialia., 2020, vol. 9, p. 100539.

A.F. Guillermet: Bull. Alloy Phase Diagr., 1982, vol. 3, pp. 359–67.

J.W. Bae, J.M. Park, J. Moon, W.M. Choi, B.J. Lee, and H.S. Kim: J. Alloys Compd., 2019, vol. 781, pp. 75–83.

H. Kwon, P. Asghari-Rad, J. Park, P. Sathiyamoorthi, J.W. Bae, J. Moon, A. Zargaran, Y.T. Choi, S. Son, and H.S. Kim: Intermetallics., 2021, vol. 135, p. 107212.

W. Jiao, H. Jiang, D. Qiao, J. He, H. Zhao, Y. Lu, and T. Li: Mater. Chem. Phys., 2021, vol. 260, p. 124175.

K. Ming, X. Bi, and J. Wang: Scripta Mater., 2017, vol. 137, pp. 88–93.

X. Li, Z. Li, Z. Wu, S. Zhao, W. Zhang, H. Bei, and Y. Gao: J. Mater. Sci. Technol., 2021, vol. 94, pp. 264–74.

Y. Dong, Y. Lu, J. Kong, J. Zhang, and T. Li: J. Alloys Compd., 2013, vol. 573, pp. 96–101.

Acknowledgments

The authors acknowledge the research project supported by the program “Excellence initiative—research university” for the AGH University of Science and Technology. Calculations have been carried out in the Wroclaw Centre for Networking and Supercomputing (http://www.wcss.pl.)

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all of the authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cichocki, K., Bała, P., Kozieł, T. et al. Effect of Mo on Phase Stability and Properties in FeMnNiCo High-Entropy Alloys. Metall Mater Trans A 53, 1749–1760 (2022). https://doi.org/10.1007/s11661-022-06629-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-022-06629-x