Abstract

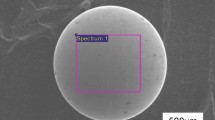

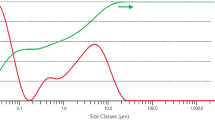

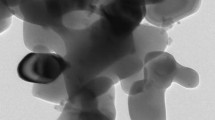

Ni-P-Ti composite coatings have been prepared by co-depositing Ni-P and nano-Ti particles which were then annealed. Tensile tests were conducted on standalone coatings to acquire the mechanical properties of the coatings without the effect of the steel substrate. The Hertzian indentation tests were performed on coating-steel substrate bilayer systems to investigate the indentation behavior of the coatings. After annealing, Ni3Ti and superelastic NiTi phases are identified in composite coatings by XRD and EDS. Compared to the as-deposited Ni-P coatings, the toughness of the annealed composite coatings improved significantly. The superelastic effect of NiTi particles was observed in the Hertzian indentation behavior of the annealed composite coatings. The strengthening mechanisms as well as toughening mechanisms such as crack bridging, crack deflection, crack arresting, and transformation toughening were discussed. Recovery ratio (η) values as well as Hertzian indentation stress distribution were computed to analyze and explain the indentation behavior of the as-deposited and annealed coatings.

Similar content being viewed by others

References

[1] M. Crobu, A. Scorciapino, B. Elsener, and A. Rossi, Electrochimica Acta, 2008, vol.53, pp.3364-70.

[2] D. Vojtěch, M. Novák, M. Zelinková, P. Novák, A. Michalcová, and T. Fabián, Applied Surface Science, 2009, vol.255,3745-51.

[3] C.K. Lee, Materials Chemistry and Physics, 2009, vol. 114, pp. 125-33.

[4] X.Q. Xu, J. Miao, Z.Q. Bai, Y.R. Feng, Q.R. Ma, and W.Z. Zhao, Applied Surface Science, 2012, vol. 258, pp. 8802-06.

[5] M. Islam, M.R. Azhar, N. Fredj, T.D. Burleigh, O.R. Oloyede, A.A. Almajid, and S. I. Shah, Surface and Coatings Technology, 2015, vol. 261, pp. 141-48.

[6] M. Palaniappa and S.K. Seshadri, Wear, 2008, vol. 265, pp. 735-40.

[7] S. Duari, A. Mukhopadhyay, T.K. Barman, and P. Sahoo, Surfaces and Interfaces, 2017, vol. 6, pp. 177-89.

[8] C.J. Lin, K.C. Chen, and J.L. He, Wear, 2006, vol. 261, pp. 1390-96.

[9] M. MacLean, Z. Farhat, G. Jarjoura, E. Fayyad, A. Abdullah, and M. Hassan, Wear, 2019, vol. 426-427, pp. 265-76.

[10] R. Neupane and Z. Farhat, Wear, 2013, vol. 301, pp. 682-87.

[11] Q.J. Zhou, J.Y. He, D.B. Sun, W.Y. Chu, and L.J. Qiao, Scripta Materialia, 2006, vol. 54, pp. 603-08.

[12] B. Bozzini and M. Boniardi, Zeitschrift Fuer Metallkunde, 1997, vol. 88, pp. 493-97.

[13] C. Wang, Z. Farhat, G. Jarjoura, M.K. Hassan, and A.M. Abdullah, Wear, 2017, vol. 376-377, pp. 1630-39.

[14] R.F. Cook and G.M. Pharr, Journal of American ceramic society, 1990, vol. 73, pp. 787-817.

[15] H. Chai and B.R. Lawn, Journal of Materials Research, 2011, vol. 19, pp. 1752-61.

[16] B.R. Lawn, Journal of American Ceramic Society, 1998, vol. 81, pp. 1977-94.

[17] J. Chen, Journal of Physics D: Applied Physics, 2012, vol. 45, pp. 1-14.

[18] H.H. Hertz, J. Reine Angew. Math, 1881, vol. 92, pp. 156-71

[19] N. Schwarzer, F. Richter, and G. Hecht, Surface and Coatings Technology, 1999, vol. 114, pp. 292-304.

[20] A.C.F. Cripps, Journal of Materials Science, 1997, vol. 32, pp. 1277-1285.

[21] C. Kocer and R.E. Collins, Journal of American Ceramic Society, 1998, vol. 81, pp. 1736-42.

[22] F. Frank, Proceeding of the Royal Society of London. Series A. Mathematical and Physical Sciences, 1967, vol. 299, pp. 291-306.

[23] S. Y. Chen, T.N. Farris, and S. Chandrasekar, International Journal of Solids and Structures, 1995, vol. 32, pp. 329-40.

[24] D. Louapre and K. Breder, International Journal of Applied Ceramic Technology, 2015, vol. 12, pp. 1071-79.

H. Hertz, Hertz’s Miscellaneous Papers, 1896, pp. 1–383.

[26] K.L. Johnson, Contact mechanics, Cambridge University Press, Cambridge, UK 1985

[27] Z. Li, Z.N. Farhat, G. Jarjoura, E. Fayyad, A. Abdullah, and M. Hassan, Tribology Transactions, 2019, vol. 62, pp. 880-96.

J.I.C.F.D. Data®, Powder Diffraction File(PDF) No. 00-004-0850, JCPDS: Netwon Square, PA, USA, 2019.

[29] Y. Zhao, C. Jiang, Z. Xu, F. Cai, Z. Zhang, and P. Fu, Materials & Design, 2015, vol. 85, pp. 39-46.

J.I.C.F.D. Data®, Powder Diffraction File (PDF) No. 00-008-5982, JCPDS: Netwon Square, PA, USA, 2019.

J.I.C.F.D. Data®, Powder Diffraction File (PDF) No. 00-015-7502, JCPDS: Netwon Square, PA, USA, 2019.

[32] S. Guo, L. Li, G. Zhang, W. Wang, and X. Zhao, Applied Surface Science, 2009, vol. 255, pp. 3691-95.

[33] S. Karthikeyan, L. Vijayaraghavan, S. Madhavan, and A. Almeida, Metallurgical and Materials Transactions A, 2016, vol. 47, pp. 2223-31.

[34] J. K. Luo, A.J. Flewitt, S. M. Spearing, N. A. Fleck, and W. I. Milne, Materials Letters, 2004, vol. 58, pp. 2306-09.

[35] J.N. Balaraju, T.S.N.S. Narayanan, and S.K. Seshadri, Journal of Applied Electrochemistry, 2003, vol. 33, pp. 807-16.

[36] Y. Motemani, M.N. Ahmadabadi, M.J. Tan, M. Bornapour, and S. Rayagan, Journal of Alloys and Compounds, 2009, vol. 469, pp. 164-68.

[37] C. Wang, Z. Farhat, G. Jarjoura, M.K. Hassan, and A.M. Abdullah, Surface and Coatings Technology, 2018, vol. 334, pp. 243-52.

[38] C. Wang, Z. Farhat, G. Jarjoura, M.K. Hassan, A.M. Abdullah, and E.M. Fayyad, Surface and Coatings Technology, 2017, vol. 326, pp. 336-42.

[39] B.T. Lester, T. Baxevanis, Y. Chemisky, and D.C. Lagoudas, Acta Mechanica, 2015, vol. 226, pp. 3907-60.

ASTM, Standard Test Method for Adhesion Strength and Mechannical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing, ASTM International, 2015, C1624-05, pp. 1–29.

[41] V. D. Papachristos, C.N. Panagopoulos, L. W. Christoffersen, and A. Markaki, Thin Solid Films, 2001, vol. 396, pp. 173-82.

[42] A. Roman, D. Chicot and J. Lesage, Surface and Coatings Technology, 2002, vol. 155, pp. 161-68.

[43] C.S. Chang, K.H. Hou, M.D. Ger, C.K. Chung, and J.F. Lin, Surface and Coatings Technology, 2016, vol. 288, pp. 135-43.

[44] Y.J. Li, A.M.F. Muggerud, A. Olsen, and T. Furu, Acta Materialia, 2012, vol. 60, pp. 1004-14.

[45] F. Qian, S. Jin, G. Sha, and Y. Li, Acta Materialia, 2018, vol. 157, pp. 114-25.

[46] R.O. Ritchie, Materials Science and Engineering: A, 1988, vol. 103, pp. 15-28.

[47] X. Sun and J.A. Yeomans, Journal of Materials and Science, 1996, vol. 31, pp. 875-80.

[48] K.T. Faber, T. Iwagoshi, and A. Ghosh, Communications of the American Ceramic Society, 1988, vol. 71, pp. 399-401.

[49] D.R. Ni and Z.Y. Ma, Acta Metallurgica Sinica (English Letters), 2014, vol. 27, pp. 739-61.

[50] J.S.C. Jang, S.R. Jian, T.H. Li, J.C. Huang, C.Y.A. Tsao, and C.T. Liu, Journal of Alloys and Compounds, 2009, vol. 485, pp. 290-94.

[51] J.S.C. Jang, J.B. Li, S.L. Lee, Y.S. Chang, S.R. Jian, J.C. Huang, and T.G. Nieh, Intermetallics, 2012, vol. 30, pp. 25-29.

[52] R. Liu, D.Y. Li, Y.S. Xie, R. Llewellyn, and H.M. Hawthorne, Scripta Materialia, 1999, vol. 41, pp. 691-96.

[53] R. Neupane, Indentation and Wear Behavior of Superelastic TiNi Shape Memory Alloy, Dalhousie University, Halifax, 2014.

[54] C. Greiner, S.M. Oppenheimer, and D.C. Dunand, Acta Biomater, 2005, vol. 1, pp. 705-16.

[55] Y. Chen, O. Tyc, O. Molnárová, L. Heller, and P. Šittner, Shape Memory and Superelasticity, 2018, vol. 5, pp. 42-62.

[56] M.M. Sherif and O.E. Ozbulut, Smart Materials and Structures, 2018, vol. 27, pp. 1-13.

[57] Z. Farhat, G. Jarjoura, and M. Shahirnia, Metallurgical and Materials Transactions A, 2013, vol. 44, pp. 3544-51.

Acknowledgments

Authors are grateful to Natural Scientific and Engineering Research Council of Canada for financial contribution (Grant Number RGPIN 327449) toward this research study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted December 16, 2019.

Rights and permissions

About this article

Cite this article

Li, Z., Farhat, Z. Hertzian Indentation Behavior of Electroless Ni-P-Ti Composite Coatings. Metall Mater Trans A 51, 3674–3691 (2020). https://doi.org/10.1007/s11661-020-05795-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-020-05795-0