Abstract

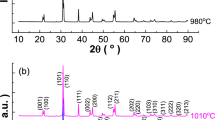

A high-pressure hot-pressing process was applied to densify a commercial boron carbide-titanium diboride (B4C-TiB2) powder mixture. Nearly fully dense (98.6%) materials were obtained at 1 700 °C under a pressure of 100 MPa. Compared to the sintering temperature required to achieve similar results when a pressure of only 30 MPa was applied, the sintering temperature was found to decrease by about 200 °C under pressure of 100 MPa. Analysis of the thermodynamics and microstructure showed that the plastic deformation of the B4C grains induced by high pressure dominated the densification mechanism when high pressure was applied. Furthermore, higher pressure resulted in remarkably improved mechanical properties of the composites, which could be traced back to the generation of stacking faults in the B4C grains and aggregation of TiB2.

Similar content being viewed by others

References

Kim KH, Chae JH, Park JS, et al. Sintering Behavior and Mechanical Properties of B4C Ceramics Fabricated by Spark Plasma Sintering[J]. J. Ceram. Process. Res., 2009, 10: 716–720

Johnson WC. Advanced Materials and Powders[J]. Am. Ceram. Soc. Bull., 2001, 80: 64–66

Schwetz KA, Sigl LS, Greim J, et al. Wear of Boron Carbide Ceramics by Abrasive Waterjets[J]. Wear, 1995, 181–183: 148–155

Basu B, Raju GB, Suri AK. Processing and Properties of Monolithic TiB2 based Materials[J]. Int. Mater. Rev., 2006, 51: 352–374

Thevenot F. A Review on Boron Carbide[J]. Key. Eng. Mater., 1991, 56–57: 59–88

Lee H, Speyer RF. Hardness and Fracture Toughness of Pressurless-sintered Boron Carbide (B4C)[J]. J. Am. Ceram. Soc., 2002, 85: 1 291–1 293

Wang WM, Fu ZY, Wang H, et al. Influence of Hot Pressing Sintering Temperature and Time on Microstructure and Mechanical Properties of TiB2 Ceramics[J]. J. Eur. Ceram. Soc., 2002, 22: 1 045–1 049

Ji W, Zhang J, Wang WM, et al. Fabrication and Properties of TiB2-Based Cermets by Spark Plasma Sintering with CoCrFeNiTiAl High-Entropy Alloy as Sintering Aid[J]. J. Eur. Ceram. Soc., 2014, 35: 879–886

Ji W, Todd RI, Wang WM, et al. Transient Liquid Phase Spark Plasma Sintering Of B4C-Based Ceramics using Ti-Al Intermetallics as Sintering Aid[J]. J. Eur. Ceram. Soc., 2016, 36: 2 419–2 426

Guo WM, Zhang ZL, Li JX, et al. Improvement of Densification and Mechanical Properties of Al2O3-B4C Ceramics[J]. Ceram. Int., 2016, 42: 11 486–11 489

Wang JL, Lin WS, Jiang ZW, et al. The Preparation and Properties of SiCw/B4C Composites Infiltrated with Molten Silicon[J]. Ceram. Int., 2014, 40: 6 793–6 798

Lee SH, Guo SQ, Tanaka H, et al. Thermal Decomposition, Densification and Mechanical Properties of AlN-SiC(-TiB2) Systems with and without B, B4C and C[J]. J. Eur. Ceram. Soc., 2008, 28: 1 715–1 722

Wang DW, Sun HF, Deng QH, et al. Synthesis of B4C-TiB2 Composite Powders by the Carbide Boronizing Process[J]. Ceram. Int., 2014, 40: 15 341–15 344

Skorokhod V, Krsti V D. High Strength-High Toughness B4C-TiB2 Composites[J]. J. Mater. Sci. Lett., 2000, 19: 237–239

Tuffe S, Dubois J, Fantozzi G, et al. Microstructure and Mechanical Properties of TiB2-B4C based Composites[J]. Int. J. Refr. Met.Hard Mater., 1996, 14: 305–310

Yamada S, Hirao K, Yamauchi Y, et al. B4C-CrB2 Composites with Improved Mechanical Properties[J]. J. Eur. Ceram. Soc., 2003, 23: 561–565

Yue XY, Zhao SM, Lü P, et al. Synthesis and Properties of Hot Pressed B4C-TiB2 Ceramic Composite[J]. Mater. Sci. Eng.A., 2010, 527: 7 215–7 219

Ji W, Rehman SS, Wang WM, et al. Sintering Boron Carbide Ceramics without Grain Growth by Plastic Deformation as the Dominant Densification Mechanism[J]. Sci. Rep., 2015, 5: 15 827

Chen IW, Wang XH. Sintering Dense Nanocrystalline Ceramics without Final-Stage Grain Growth[J]. Nature, 2000, 404: 168–171

Kang SJL. Sintering Densification, Grain Growth and Microstructure[J]. J. Phys. IV., 2005, 7: 674–742

Grady DE. Dynamic Properties of Ceramic Materials[J]. Sand., 1994, 94: 3 266

Vogler TJ, Reinhart WD, Chhabildas LC. Dynamic Behavior of Boron Carbide[J]. J. Appl. Phys., 2004, 95: 4 173–4 183

Zhang JY, Hu W, Zhang F, et al. (AlN)xMo1−x (x=0.5) Composite Fabricated by Spark Plasma Sintering (SPS)[J]. Int. J. Refract. Met.Hard Mater., 2016, 54: 378–382

Chen MW, McCauley JW, Hemker KJ. Shock-induced Localized Amorphization in Boron Carbide[J]. Science, 2003: 1 563–1 566

White RM, Dickey EC. Mechanical Properties and Deformation Mechanisms of B4C-TiB2 Eutecticcomposites[J]. J. Eur. Ceram. Soc., 2014, 34: 2 043–2 050

Hillig WB. Strength and Toughness of the Ceramic Matrix Composites[J]. Annu. Rev. Mater. Sci., 2003, 17: 341–383

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the National Natural Science Foundation of China (51672197)

Rights and permissions

About this article

Cite this article

Gao, J., Wang, D., Lei, L. et al. High-pressure Sintering of Boron Carbide-Titanium Diboride Composites and Its Densification Mechanism. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 35, 356–362 (2020). https://doi.org/10.1007/s11595-020-2264-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-020-2264-y