Abstract

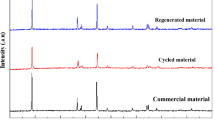

The worldwide consumption of lithium ion batteries grows year by year, and the process of recycling batteries is complex and harmful today. To solve this problem, a novel method which is green and simple is proposed. The process for recycling and regeneration from spent lithium ion batteries is acid-free, which is different from conventional chemical leaching and solid-state synthesis approach. The impacts of reaction temperature and time, solution concentration on the regeneration of the cathode materials are investigated systematically. Lots of characterizations, such as XRD, SEM, and ICP, are adopted to investigate the properties of the regenerate NCM523, which conclude it has ideal stoichiometry and phase purity; the electrochemical results certify that the regenerated NCM523 meet the commercial requirements for reuse.

Similar content being viewed by others

References

Bian D, Sun Y, Li S (2016) A novel process to recycle spent LiFePO4 for synthesizing LiFePO4/C hierarchical microflowers. Electrochim Acta 190:134–140

Chen J, Qi L, Song J (2016) Environmentally friendly recycling and effective repairing of cathode powders from spent LiFePO4 batteries. Green Chem 18:2500–2506

Yang L, Xi G, Xi Y (2015) Recovery of Co, Mn, Ni, and Li from spent lithium ion batteries for the preparation of LiNixCoyMnzO2 cathode materials. Ceram Int 41:11498–11503

Sa Q, Gratz E, He M (2015) Synthesis of high performance LiNi1/3Mn1/3Co1/3O2 from lithium ion battery recovery stream. J Power Sources 282:140–145

Li H, Xing S, Liu Y (2017) Recovery of lithium, iron, and phosphorus from spent LiFePO4 batteries using stoichiometric sulfuric acid leaching system. ACS Sustain Chem Eng 5:8017–8024

Shangguan E, Li F, Li J et al (2015) FeS/C composite as high-performance anode material for alkaline nickel-iron rechargeable batteries. J Power Sources 291:29–39

Zheng X, Gao W, Zhang X et al (2017) Spent lithium ion battery recycling-reductive ammonia leaching of metals from cathode scrap by sodium sulphite. Waste Manage 60:680–688

Song X, Hu T, Liang C et al (2017) Direct regeneration of cathode materials from spent lithium iron phosphate batteries using a solid phase sintering method. RSC Adv 7:4783–4790

Meshram P, Pandey BD, Mankhand TR (2015) Hydrometallurgical processing of spent lithium ion batteries (LIBs) in the presence of a reducing agent with emphasis on kinetics of leaching. Chem Eng J 281:418–427

Patel P, Ellis T, Howes J (2017) How green is your electric vehicle? Int environ reporter 42:416–417

Heelan J, Gratz E, Zheng Z et al (2016) Current and prospective Li ion battery recycling and recovery processes. JOM 68:2632–2638

Shin EJ, Kim S, Noh JK et al (2015) A green recycling process designed for LiFePO4 cathode materials for Li-ion batteries. J Mater Chem A 3:11493–11502

Li X, Zhang J, Song D et al (2017) Direct regeneration of recycled cathode material mixture from scrapped LiFePO4 batteries. J Power Sources 345:78–84

Shi Y, Zhang M, Qian D et al (2016) Ultrathin Al2O3 coatings for improved cycling performance and thermal stability of LiNi0.5Co0.2Mn0.3O2 cathode material. Electrochim Acta 203:154–161

Sa Q, Gratz E, Heelan JA et al (2016) Synthesis of diverse LiNixMnyCozO2 cathode materials from lithium ion battery recovery stream. J Sustain Metall 2:248–256

Li L, Fan E, Guan Y et al (2017) Sustainable recovery of cathode materials from spent lithium ion batteries using lactic acid leaching system. ACS Sustain Chem Eng 5:5224–5233

Kowal J, Arzberger A, Blanke H, Sauer DU (2015) How to determine the time for temperature equalisation in batteries and supercaps for reliable laboratory measurements. J Energy Storage 4:113–120

Li L, Bian Y, Zhang X et al (2018) Process for recycling mixed cathode materials from spent lithium ion batteries and kinetics of leaching. Waste Manage 71:362–371

Bach TC, Schuster SF, Fleder E, Müller J, Brand MJ, Lorrmann H, Jossen A, Sextl G (2016) Nonlinear aging of cylindrical lithium-ion cells linked to heterogeneous compression. J Energy Storage 5:212–223

Li L, Bian Y, Zhang X et al (2018) Economical recycling process for spent lithium ion batteries and macro- and micro-scale mechanistic study. J Power Sources 377:70–79

Chen LC, Liu D, Liu TJ et al (2016) Improvement of lithium-ion battery performance using a two-layered cathode by simultaneous slot-die coating. J Energy Storage 5:156–162

Chen Y, Li P, Li Y et al (2018) Enhancing the high-voltage electrochemical performance of the LiNi0.5Co0.2Mn0.3O2 cathode materials via hydrothermal lithiation. J Mater Sci 53:2115–2126

Zheng J, Yan P, Zhang J et al (2017) Suppressed oxygen extraction and degradation of LiNixMnyCozO2 cathodes at high charge cut-off voltages. Nano Res 10:4221–4231

Dunn JB, Gaines L, Kelly JC et al (2015) The significance of Li-ion batteries in electric vehicle life-cycle energy and emissions and recycling’s role in its reduction. Energy Environ Sci 8:158–168

Xu Y, Dong Y, Han X et al (2015) Application for simply recovered LiCoO2 material as a high performance candidate for supercapacitor in aqueous system. ACS Sustain Chem Eng 3:2435–2442

Nie H, Xu L, Song D et al (2015) LiCoO2: Recycling from spent batteries and regeneration with solid state synthesis. Green Chem 17:1276–1280

Zhao T, Li L, Chen R et al (2015) Design of surface protective layer of LiF/FeF3 nanoparticles in Li-Rich cathode for high-capacity Li-ion batteries. Nano Energy 15:164–176

Kondrakov AO, Schmidt A et al (2017) Anisotropic lattice strain and mechanical degradation of high- and low-nickel NCM cathode materials for Li-ion batteries. J Phys Chem C 121:3286–3294

Li H, Liu A, Zhang N et al (2019) An unavoidable challenge for Ni-rich positive electrode materials for lithium ion batteries. Chem Mater 31:7574–7583

Lin Q, Guan W, Meng J et al (2018) A new insight into continuous performance decay mechanism of Ni-rich layered oxide cathode for high energy lithium ion batteries. Nano Energy 54:313–321

Park KJ, Hwang JY, Ryu HH et al (2019) Degradation mechanism of Ni-enriched NCA cathode for lithium batteries: are microcracks really critical? ACS Energy Lett 4:1394–1400

Nam GW, Park NY, Park K-J et al (2019) Capacity fading of Ni-rich NCA cathodes: effect of microcracking exten. ACS Energy Lett 4:2995–3001

Kim JH, Ryu HH, Kim SJ et al (2019) Degradation mechanism of highly Ni-rich Li[NixCoyMn1-x-y]O2 cathodes with x > 0.9. ACS Appl Mater Interfaces 11:30936–30942

Yang J, Xia YY (2016) Suppressing the phase transition of the layered Ni-rich oxide cathode during high-voltage cycling by introducing low-content Li2MnO3. Appl Mate Inter 8:1297–1308

Park KJ, Jung HG, Kuo LY et al (2018) Improved cycling stability of Li[Ni0.90Co0.05Mn0.05]O2 through microstructure modification by boron doping for Li ion batteries. Adv Energy Mater 1801202:1–9

Kumar J, Shen X, Li B, Liu HZ, Zhao JM (2020) Selective recovery of Li and FePO4 from spent LiFePO4 cathode scraps by organic acids and the properties of the regenerated LiFePO4. Waste Managet 113:32–40

Du KD, Edison HA, Wu XL, LiuYC, (2022) Progresses in sustainable recycling technology of spent lithium-ion batteries. Energy Environ Mater. https://doi.org/10.1002/eem2.12271

Meng YF, Liang HJ, Zhao CD (2022) Concurrent recycling chemistry for cathode/anode in spent graphite/LiFePO4 batteries: designing a unique cation/anion-co-workable dual-ion battery. J Energy Chem 64:166–171

Cui BH, Liu C, Hu WB (2021) Waste to wealth: defect-rich Ni-incorporated spent LiFePO4 for efficient oxygen evolution reaction. Sci China Mater 01:2710–2718

Mrozik W, Rajaeifar MA, Heidrich O et al (2021) Environmental impacts, pollution sources and pathways of spent lithium-ion batteries. Energy Environ Sci 12:6099–6121

Huang GX, Guo PM, Wang J et al (2020) Lithiophilic V2O5 nanobelt arrays decorated 3D framework hosts for highly stable composite lithium metal anodes. Chem Eng 384:123313

Du KD, Meng YF, Zhao XX et al (2022) A unique co-recovery strategy of cathode and anode from spent LiFePO4 battery. Sci China Mater 65:637–645

Fan M, Chang X, Guo YJ et al (2021) Increased residual lithium compounds guided design for green recycling of spent lithium-ion cathodes. Energy Environ Sci 14:1461–1468

Liang HJ, Hou BH, Li WH et al (2019) Staging Na/K-ion de-/intercalation of graphite retrieved from spent Li-ion batteries: in operando X-ray diffraction studies and an advanced anode material for Na/K-ion batteries. Energy Environ Sci 12:3575–3584

Acknowledgements

This project was supported by the science and technology project of State Grid Zhejiang Electric Power Co., Ltd. (5211UZ2000K1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lou, P., Guan, M., Wu, G. et al. Recycle cathode materials from spent lithium-ion batteries by an innovative method. Ionics 28, 2135–2141 (2022). https://doi.org/10.1007/s11581-022-04497-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11581-022-04497-4