Abstract

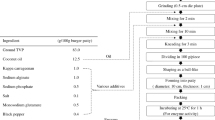

Polysaccharides are widely applied in meat industries due to the excellent gelling, water-holding, and thickening properties. In the current work, carrageenan (CAR), curdlan (CUR) and potato starch (PS), were involved in the process of high-moisture extrusion (HME) of pea protein isolate (PPI) in order to improve the textural and structural characteristics of HME-PPI. Results showed that the addition of CAR and CUR increased the hardness and chewiness of HME-PPI while the presence of PS led to the opposite textural attributes. Compared to the PPI alone, blending 0.4 wt% CAR resulted in the formation of a fine fibrous structure, and adding 0.4 wt% CUR contributed to the generation of short and flat fibers. The FTIR analysis suggested that incorporating polysaccharides resulted in a reduction of the α-helix and random coil contents of PPI, and correspondingly an increase in β-sheet and β-turn contents. Based on the sensory evaluation, the HME-PPI in the presence of 0.4 wt% CAR or 0.4 wt% CUR or 2.0 wt% PS, respectively, were preferred by the panelists. These findings would provide valuable insights into the polysaccharide-modulated product quality of HME-PPI, which is important for the development of PPI as an alternative protein source for meat analogs.

Similar content being viewed by others

References

M.A. Asgar, A. Fazilah, N. Huda, R. Bhat, A.A. Karim, Nonmeat protein alternatives as meat extenders and meat analogs. Compr. Rev. Food Sci. Food Saf. 9, 513–529 (2010)

Y. Yang, Y. Zheng, W. Ma, Y. Zhang, C. Sun, Y. Fang, Meat and plant-based meat analogs: nutritional profile and in vitro digestion comparison. Food Hydrocoll. 143, 108886 (2023)

L. Sha, Y.L. Xiong, Plant protein-based alternatives of reconstructed meat: Science, technology, and challenges. Trends Food Sci. Technol. 102, 51–61 (2020)

J. Zhang, L. Liu, H. Liu, A. Yoon, S.S.H. Rizvi, Q. Wang, Changes in conformation and quality of vegetable protein during texturization process by extrusion. Crit. Rev. Food Sci. Nutr. 59, 3267–3280 (2019)

R. Osen, S. Toelstede, F. Wild, P. Eisner, U. Schweiggert-Weisz, High moisture extrusion cooking of pea protein isolates: raw material characteristics, extruder responses, and texture properties. J. Food Eng. 127, 67–74 (2014)

M. Palanisamy, S. Töpfl, K. Aganovic, R.G. Berger, Influence of iota carrageenan addition on the properties of soya protein meat analogues. LWT–Food Sci. Technol. 87, 546–552 (2018)

J. Zhang, L. Liu, Y. Jiang, F. Shah, Y. Xu, Q. Wang, High-moisture extrusion of peanut protein-/carrageenan/sodium alginate/wheat starch mixtures: Effect of different exogenous polysaccharides on the process forming a fibrous structure. Food Hydrocoll. 99, 105311 (2020).

M. Yuan, G. Fu, Y. Sun, D. Zhang, Biosynthesis and applications of curdlan. Carbohydr. Polym. 273, 118597 (2021)

Q. Chen, J. Zhang, Y. Zhang, S. Meng, Q. Wang, Rheological properties of pea protein isolate-amylose/amylopectin mixtures and the application in the high-moisture extruded meat substitutes. Food Hydrocoll. 117, 106732 (2021)

W. Zhang, S. Li, B. Zhang, S.R. Drago, J. Zhang, Relationships between the gelatinization of starches and the textural properties of extruded texturized soybean protein-starch systems. J. Food Eng. 174, 29–36 (2016)

F.L. Chen, Y.M. Wei, B. Zhang, Chemical cross-linking and molecular aggregation of soybean protein during extrusion cooking at low and high moisture content. LWT–Food Sci. Technol. 44, 957–962 (2011)

Y. Fang, B. Zhang, Y. Wei, Effects of the specific mechanical energy on the physicochemical properties of texturized soy protein during high-moisture extrusion cooking. J. Food Eng. 121, 32–38 (2014)

M. Palanisamy, K. Franke, R.G. Berger, V. Heinz, S. Topfl, High moisture extrusion of lupin protein: influence of extrusion parameters on extruder responses and product properties. J. Sci. Food Agric. 99, 2175–2185 (2019)

W. Huang, H. Tan, S. Nie, Beneficial effects of seaweed-derived dietary fiber: highlights of the sulfated polysaccharides. Food Chem. 373, 131608 (2022)

R. Zhang, K.J. Edgar, Properties, chemistry, and applications of the bioactive polysaccharide curdlan. Biomacromolecules. 15, 1079–1096 (2014)

M. McIntosh, B.A. Stone, V.A. Stanisich, Curdlan and other bacterial (1–>3)-beta-D-glucans. Appl. Microbiol. Biotechnol. 68, 163–173 (2005)

F.L. Chen, Y.M. Wei, B. Zhang, A.O. Ojokoh, System parameters and product properties response of soybean protein extruded at wide moisture range. J. Food Eng. 96, 208–213 (2010)

B. Mu, H. Xu, W. Li, L. Xu, Y. Yang, Spinnability and rheological properties of globular soy protein solution. Food Hydrocoll. 90, 443–451 (2019)

P. Guerrero, J.P. Kerry, K. de la Caba, FTIR characterization of protein-polysaccharide interactions in extruded blends. Carbohydr. Polym. 111, 598–605 (2014)

Z.W. Guo, F. Teng, Z.X. Huang, B. Lv, X.Q. Lv, O. Babich, W.H. Yu, Y. Li, Z.J. Wang, L.Z. Jiang, Effects of material characteristics on the structural characteristics and flavor substances retention of meat analogs. Food Hydrocoll. 105, 105752 (2020)

Z.Y. Sun, M. Sun, X. Sun, C. Fang, Y. The role of protein concentration in heat-induced particulation of soy proteins at different pHs: structure and functional properties. Food Front. 4, 955–965 (2023)

G. Meng, C. Ma, Characterization of globulin from Phaseolus angularis (red bean). Int. J. Food Sci. Technol. 37, 687–695 (2002)

B. Zhang, X. Kang, Y. Cheng, B. Cui, A.M. Abd El-Aty, Impact of high moisture contents on the structure and functional properties of pea protein isolate during extrusion. Food Hydrocoll. 127, 107508 (2022)

C.J.R. Verbeek, L.E. van den Berg, Extrusion processing and properties of protein-based thermoplastics. Macromol. Mater. Eng. 295, 10–21 (2010)

J. Zhang, Q. Chen, L. Liu, Y. Zhang, N. He, Q. Wang, High-moisture extrusion process of transglutaminase-modified peanut protein: Effect of transglutaminase on the mechanics of the process forming a fibrous structure. Food Hydrocoll. 112, 106346 (2021)

S. Xia, Y. Xue, C. Xue, X. Jiang, J. Li, Structural and rheological properties of meat analogues from Haematococcus pluvialis residue-pea protein by high moisture extrusion. LWT–Food Sci. Technol. 154, 112756 (2022)

I. Zahari, F. Ferawati, A. Helstad, C. Ahlstrom, K. Ostbring, M. Rayner, J.K. Purhagen, Development of high-moisture meat analogues with hemp and soy protein using Extrusion Cooking. Foods. 9, 772 (2020)

M. Karbasi, G. Askari, A. Madadlou, Surface decoration of whey protein microgels through the Maillard conjugation with maltodextrin. Food Hydrocoll. 91, 190–197 (2019)

V.L. Pietsch, M.A. Emin, H.P. Schuchmann, Process conditions influencing wheat gluten polymerization during high moisture extrusion of meat analog products. J. Food Eng. 198, 28–35 (2017)

G.A. Krintiras, J. Göbel, A.J. van der Goot, G.D. Stefanidis, Production of structured soy-based meat analogues using simple shear and heat in a Couette cell. J. Food Eng. 160, 34–41 (2015)

M. Du, Y. Zhang, Y. Zhao, Y. Fang, Agarose/konjac glucomannan double network hydrogels to mimic the texture of beef tripe. Food Hydrocoll. 135, 108173 (2023)

D. Sun, M. Wu, T. Zhang, D. Wei, C. Zhou, N. Shang, Conformational changes and physicochemical attributes of texturized pea protein isolate-konjac gum: with a new perspective of residence time during extrusion. Food Res. Int. 165, 112500 (2023)

J.H. Chiang, S.M. Loveday, A.K. Hardacre, M.E. Parker, Effects of soy protein to wheat gluten ratio on the physicochemical properties of extruded meat analogues. Food Struct. 19, 100102 (2019)

P.G.I. Dias, J.W.A. Sajiwani, R. Rathnayaka, Consumer perception and sensory profile of probiotic yogurt with added sugar and reduced milk fat. Heliyon. 6, e04328 (2020)

K. Shevkani, N. Singh, A. Kaur, J.C. Rana, Structural and functional characterization of kidney bean and field pea protein isolates: a comparative study. Food Hydrocoll. 43, 679–689 (2015)

Funding

This work was supported by the National Natural Science Foundation of China (31972023, 32272260).

Author information

Authors and Affiliations

Contributions

Jialing Fu.: Investigation, Writing-Original draft preparation. Yixin Zheng: Methodology, Revising the manuscript. Yixin Gao.: Methodology. Yin Zhang.: Reviewing. Cuixia Sun: Methodology, Writing-Reviewing, Editing. Yapeng Fang.: Supervision. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing Interests

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fu, J., Zheng, Y., Gao, Y. et al. Effect of Different Polysaccharides on the Texture and Fibrous Structure of High-Moisture Extruded Pea Protein Isolate. Food Biophysics 18, 606–618 (2023). https://doi.org/10.1007/s11483-023-09805-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11483-023-09805-7