Abstract

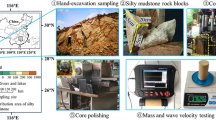

In this study, the undrained mechanical behavior of saturated completely decomposed granite (CDG) with different weathering degrees is investigated. To this end, a series of consolidation undrained (CU) triaxial compression tests are conducted on saturated CDG, and the effects of weathering degree on the main undrained mechanical properties are analyzed. Based on the experimental results, a poromechanical model is then established with the concept of effective plastic stress in a poroplasticity framework. Plastic distortion is described using a particular yield surface and a nonassociated plastic potential, which are both functions of the effective plastic stress and a subtly unified smooth hardening/softening variable. As an original contribution, an enhanced semi-implicit return mapping (ESRM) algorithm is developed to integrate the proposed model. This algorithm is based on a semi-implicit return mapping procedure and is combined with a new adaptive substepping technique. The model is subsequently implemented and validated by comparing the numerical simulation results with the experimental data. The main undrained mechanical characteristics of saturated CDG with different weathering degrees are well reproduced. A discussion follows regarding the parameter sensitivity analysis and robustness of the ESRM algorithm. Interestingly, the high accuracy of the ESRM algorithm is almost step-size independent, and the computational efficiency is also greatly improved.

Similar content being viewed by others

References

Abbo AJ, Sloan SW (1996) An automatic load stepping algorithm with error control. Int J Numer Meth Eng 39(10):1737–1759

ASTM (2020) Astm d4767–11 (2020) Standard test method for consolidated undrained triaxial compression test for cohesive soils. ASTM, Pennsylvania, pp 1–14

Borja RI, Koliji A (2009) On the effective stress in unsaturated porous continua with double porosity. J Mech Phys Solids 57(8):1182–1193

Bushnell D (1977) A strategy for the solution of problems involving large deflections, plasticity and creep. Int J Numer Meth Eng 11(4):683–708

Chiu CF, Ng CWW (2003) A state-dependent elasto-plastic model for saturated and unsaturated soils. Géotechnique 53(9):809–829

Chiu CF, Ng CWW (2014) Relationships between chemical weathering indices and physical and mechanical properties of decomposed granite. Eng Geol 179:76–89

Coussy O (1995) Mechanics of porous continua. John Wiley & Sons, New Jersey

Coussy O (2004) Poromechanics. John Wiley & Sons, New Jersey

Du SH, Li DY, Zhang CS, Mao DW, Ruan B (2021) Deformation and strength properties of completely decomposed granite in a fault zone. Geomech Geophys Geo-Energy Geo-Resour 7(1):1–21

Elkamhawy E, Zhou B, Wang HB (2019) Mineralogy, micro-fabric and the behavior of the completely decomposed granite soils. Civ Eng J 5(12):2762–2772

Halilovič M, Vrh M, Štok B (2013) Nice h: a higher-order explicit numerical scheme for integration of constitutive models in plasticity. Eng Comput 29(1):55–70

Ham TG, Nakata Y, Orense R, Hyodo M (2010) Influence of water on the compression behavior of decomposed granite soil. J Geotech Geoenviron Eng 136(5):697–705

Han B, Shen WQ, Xie SY, Shao JF (2020) Plastic modeling of porous rocks in drained and undrained conditions. Comput Geotech 117:103277

Hiyama H, Takayama M, Noda T (2000) Shear strength properties of compacted decomposed granite soil. Transactions of the Japanese Society of Irrigation, Drainage and Reclamation Engineering (Japan)

Hong Y, Wang X, Wang L, Gao Z (2021) A state-dependent constitutive model for coarse-grained gassy soil and its application in slope instability modelling. Comput Geotech 129:103847

Hoxha D, Giraud A, Homand F, Auvray C (2007) Saturated and unsaturated behaviour modelling of meuse-haute/marne argillite. Int J Plast 23(5):733–766

Hu D, Zhou H, Shao J (2013) An anisotropic damage-plasticity model for saturated quasi-brittle materials. Int J Numer Anal Meth Geomech 37(12):1691–1710

Jafari MK, Shafiee A (2004) Mechanical behavior of compacted composite clays. Can Geotech J 41(6):1152–1167

Jeong J, Kang B, Lee K, Yang J (2000) Shear strength properties of decomposed granite soil in korea. In: Computing in civil and building engineering, pp 1466–1473

Kang X, Liao H, Leng X (2020) An enhanced bounding surface plasticity model for soft rock subjected to drained and undrained condition. Comput Geotech 127(10):103742

Kumruzzaman M, Yin JH (2010) Influences of principal stress direction and intermediate principal stress on the stress-strain-strength behaviour of completely decomposed granite. Can Geotech J 47(2):164–179

Kumruzzaman M, Yin JH (2012) Influence of the intermediate principal stress on the stress-strain-strength behaviour of a completely decomposed granite soil. Géotechnique 62(3):275–280

Kwon Y, Sewook O et al (2011) Physical and mechanical properties of decomposed granite soils sampled in cheongju, korea. Int J Phys Sci 6(24):5774–5794

Lan HX, Hu RL, Yue ZQ, Lee C, Wang S (2003) Engineering and geological characteristics of granite weathering profiles in south china. J Asian Earth Sci 21(4):353–364

Lee IK (1995) The intrinsic behaviour of a decomposed granite soil. Geotechniqué 45:117–130

Li YD, Zhao LY, Lai YM (2023) A novel elastoplastic damage model for hard rocks under true triaxial compression: Analytical solutions and numerical implementation. Int J Geomech 23(2):04022268

Liu P, Yang XQ, Zhou XW (2021) Mechanics of completely decomposed granite: example of transitional behavior. Int J Geomech 21(9):06021023

Liu XY, Zhang XW, Kong LW, An R, Xu GF (2021) Effect of inherent anisotropy on the strength of natural granite residual soil under generalized stress paths. Acta Geotech 16(12):3793–3812

Liu XY, Zhang XW, Kong LW, Li XM, Wang G (2021) Effect of cementation on the small-strain stiffness of granite residual soil. Soils Found 61(2):520–532

Liu XY, Zhang XW, Kong LW, Yin S, Xu YQ (2022) Shear strength anisotropy of natural granite residual soil. J Geotech Geoenviron Eng 148(1):04021168

Lloret-Cabot M, Sloan SW, Sheng D, Abbo AJ (2016) Error behaviour in explicit integration algorithms with automatic substepping. Int J Numer Meth Eng 108(9):1030–1053

Lumb Peter (1962) The properties of decomposed granite. Geotechnique 12(3):226–243

Moghadam SI, Taheri E, Ahmadi M, Ghoreishian Amiri SA (2022) Unified bounding surface model for monotonic and cyclic behaviour of clay and sand. Acta Geotech 1–17

Nayak GC, Zienkiewicz OC (1972) Elasto-plastic stress analysis. A generalization for various contitutive relations including strain softening. Int J Numer Methods Eng 5(1):113–135

Ng CWW, Cai WL, So PS, Liao JX, Lau SY (2022) Effects of biochar on shear strength of completely decomposed granite. Environ Sci Pollut Res 29(32):49422–49428

Ng CWW, Chiu ACF (2003) Laboratory study of loose saturated and unsaturated decomposed granitic soil. J Geotech Geoenviron Eng 129(6):550–559

Ng TT, Zhou W, Chang XL (2017) Effect of particle shape and fine content on the behavior of binary mixture. J Eng Mech 143(1):C4016008

Oh S, Kwon Y (2016) Use of lade’s single surface work-hardening model to investigate mechanical behavior of decomposed soils. Mar Georesour Geotechnol 34(1):57–64

Okewale IA (2020) Applicability of chemical indices to characterize weathering degrees in decomposed volcanic rocks. CATENA 189:104475

Ortiz M, Simo J (1986) An analysis of a new class of integration algorithms for elastoplastic constitutive relations. Int J Numer Meth Eng 23(3):353–366

Pineda JA, Colmenares JE, Hoyos LR (2014) Effect of fabric and weathering intensity on dynamic properties of residual and saprolitic soils via resonant column testing. Geotech Test J 37(5):800–816

Reiche P (1943) Graphic representation of chemical weathering. J Sediment Res 13:58–68

Ren L, Zhao LY, Niu FJ (2022) A physically-based elastoplastic damage model for quasi-brittle geomaterials under freeze-thaw cycles and loading. Appl Math Model 106:276–298

Sheng D, Sloan SW, Yu HS (2000) Aspects of finite element implementation of critical state models. Comput Mech 26(2):185–196

Shi X, Zhao J, Gao Y (2021) A homogenization-based state-dependent model for gap-graded granular materials with fine-dominated structure. Int J Numer Anal Meth Geomech 45(8):1007–1028

Shi XS, Yin JH (2017) Experimental and theoretical investigation on the compression behavior of sand-marine clay mixtures within homogenization framework. Comput Geotech 90:14–26

Shi XS, Zhao JD, Yin JH, Yu ZJ (2019) An elastoplastic model for gap-graded soils based on homogenization theory. Int J Solids Struct 163:1–14

Simo JC, Hughes TJR (2006) Computational inelasticity, vol 7. Springer Science & Business Media, Berlin

Sloan SW, Abbo AJ, Sheng DC (2001a) Refined explicit integration of elastoplastic models with automatic error control. Engineering Computations

Sloan SW, Abbo AJ, Sheng DC (2001) Refined explicit integration of elastoplastic models with automatic error control. Eng Comput 18(1/2):121–194

Sun MM, Yu JG, Wu X, Ding Y, Fu TF, Yang YW, Jiang JQ (2021) Mechanical behavior of weathered granite exposed to water. Appl Sci 11(21):10356

Sun ZC, Chu J, Xiao Y (2021) Formulation and implementation of an elastoplastic constitutive model for sand-fines mixtures. Int J Numer Anal Meth Geomech 45(18):2682–2708

Tamagnini C, Ciantia MO (2016) Plasticity with generalized hardening: constitutive modeling and computational aspects. Acta Geotech 11(3):595–623

To EC, Tham LG, Zhou YD (2008) An elasto-plastic model for saturated loosely compacted completely decomposed granite. Geomech Geoeng Int J 3(1):13–25

Tu X, Andrade JE, Chen Q (2009) Return mapping for nonsmooth and multiscale elastoplasticity. Comput Methods Appl Mech Eng 198(30–32):2286–2296

Wagner JF (2013) Mechanical properties of clays and clay minerals. Developments in clay science, vol 5. Elsevier, Amsterdam, pp 347–381

Wang H, Li L, Li JP et al (2022) A simple stress correction method for explicit integration algorithm of elastoplastic constitutive models and its application to advanced anisotropic s-clay1 model. Comput Geotech 148:104817

Xie SY, Shao JF (2012) Experimental investigation and poroplastic modelling of saturated porous geomaterials. Int J Plast 39:27–45

Xu WQ, Yin ZY, Wang HL, Wang X (2022) Experimental study on the monotonic mechanical behavior of completely decomposed granite soil reinforced by disposable face-mask chips. J Clean Prod 352:131528

Yan WM, Li XS (2012) Mechanical response of a medium-fine-grained decomposed granite in hong kong. Eng Geol 129:1–8

Yu HS (2007) Plasticity and geotechnics, vol 13. Springer Science & Business Media, Berlin

Yuan BX, Chen WJ, Zhao J, Li LJ, Liu F, Guo YC, Zhang BF (2022) Addition of alkaline solutions and fibers for the reinforcement of kaolinite-containing granite residual soil. Appl Clay Sci 228:106644

Zhang W, Zou JQ, Bian K, Wu Y (2022) Thermodynamic-based cross-scale model for structural soil with emphasis on bond dissolution. Can Geotech J 59(1):1–11

Zhao JD, Sheng DC, Rouainia M, Sloan SW (2005) Explicit stress integration of complex soil models. Int J Numer Anal Meth Geomech 29(12):1209–1229

Zhao JJ, Wang SJ, Shang YJ, Yue ZQ (2005) Control factors on shear strength of completely decomposed granite. Rock Soil Mech 26(4):624–628

Zhao LY, Lai YM, Shao JF (2022) A new incremental variational micro-mechanical model for porous rocks with a pressure-dependent and compression-tension asymmetric plastic solid matrix. Int J Rock Mech Min Sci 153:105059

Zhao LY, Zhang WL, Lai YM, Niu FJ, Zhu QZ, Shao JF (2021) A heuristic elastoplastic damage constitutive modeling method for geomaterials: From strength criterion to analytical full-spectrum stress-strain curves. Int J Geomech 21(2):04020255

Zhao LY, Zhu QZ, Shao JF (2018) A micro-mechanics based plastic damage model for quasi-brittle materials under a large range of compressive stress. Int J Plast 100:156–176

Zhao Y, Borja RI (2020) A continuum framework for coupled solid deformation-fluid flow through anisotropic elastoplastic porous media. Comput Methods Appl Mech Eng 369:113225

Zhao YR, Yang HQ, Huang LP, Chen R, Chen XS, Liu S (2019) Mechanical behavior of intact completely decomposed granite soils along multi-stage loading-unloading path. Eng Geol 260:105242

Zhu QZ, Zhao LY, Shao JF (2016) Analytical and numerical analysis of frictional damage in quasi brittle materials. J Mech Phys Solids 92:137–163

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Grant Nos. 42107373, 42001053).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Derivation of hardening modulus \(H_{\text {har}}\)

The loading/unloading conditions of plasticity are expressed in the so-called Kuhn-Tucker form, i.e.,

It follows the condition in incremental form

Under plastic loading, one has \(\lambda ^p \ge 0\) and \(\text {d}\mathcal {F}=0\), so that

On the other hand, the effective stress increment can be obtained by differentiating Eq. (13), i.e.,

Substituting Eqs.(A.4) and (22) into (A.3), one finally has

with the hardening modulus

Appendix B: SRM with IPCP in substep

It is noted that the yield criterion in effective stress space \(\mathcal {F}(\varvec{\sigma }^{\prime }, \alpha )\) could also be rewritten with the function of \(\varvec{\varepsilon }\) and \(\varvec{\varepsilon }^{p}\) with the aid of Eqs. (13) and (19), i.e., \(\mathcal {F}(\varvec{\varepsilon }, \varvec{\varepsilon }^{p})\). During the plastic correction procedure, the yield function can be linearized using the first-order Taylor expansion as follows:

where superscript j is used to represent the inter iterations related to the plastic correction. Besides, for the sake of clarity, the subscript substep loading m is omitted. Combined with Eq. (22), one further obtains

Then one has

The plastic strain and effective stress can be updated as follows:

The IPCP stops when \(|\mathcal {F}^{j+1}|\le \epsilon _{\text {local}}\), with \(\epsilon _{\text {local}}\) being the local convergence tolerance.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, WL., Zhao, LY. & Lv, ZM. Undrained mechanical behavior of saturated completely decomposed granite: experimental investigation and constitutive modeling. Acta Geotech. (2024). https://doi.org/10.1007/s11440-023-02105-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11440-023-02105-x