Abstract

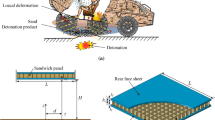

The underbody of a vehicle system, either military or civil, is typically made of a relatively thin metallic plate, thus vulnerable to mine blast attacks. To improve the blast resistance, a multitude of protective structures have been proposed as attachments to the thin plate. In the present study, a novel ultralight all-metallic sandwich panel with three-dimensional (3D) tube cellular cores mounted to the vehicle underbody was envisioned as such a protective system. A metallic substrate (mimicking vehicle bottom) was placed above the proposed sandwich panel to construct a sandwich-substrate combinative structure. A series of sandwich panels having 3D tube cellular cores were fabricated via argon protected welding and laser welding. Mechanical responses of the combinative structure subjected to the denotation of 6 kg TNT explosives shallow-buried in dry sand were experimentally measured. Full numerical simulations with the method of finite elements (FE) were subsequently carried out to explore the physical mechanisms underlying the observed dynamic performance and quantify the effects of key geometrical parameters and connection conditions of the protective system. The performance of the proposed sandwich panel under shallow-buried explosives was also compared with competing sandwich constructions having equal mass. Finally, a preliminary optimal design of the 3D tube cellular core was carried out.

Similar content being viewed by others

References

Taylor L C, Skaggs R R, Gault W. Vertical impulse measurements of mines buried in saturated sand. Fragblast, 2005, 9: 19–28

Bocchieri R T, Kirkpatrick S W, Peterson B. Simulation-based design of vehicles exposed to blast threats for improved occupant survivability. WIT Trans Built Env, 2009, 1: 459–170

Børvik T, Olovsson L, Hanssen A G, et al. A discrete particle approach to simulate the combined effect of blast and sand impact loading of steel plates. J Mech Phys Solids, 2011, 59: 940–958

Pickering E G, Chung Kim Yuen S, Nurick G N, et al. The response of quadrangular plates to buried charges. Int J Impact Eng, 2012, 49: 103–114

Zhang X, Zhou Y, Wang X, et al. Modelling and analysis of the vehicle underbody and the occupants subjected to a shallow-buried-mine blast impulse. Proc Institution Mech Engineers Part D-J Automobile Eng, 2016, 231: 214–224

Dey S, Børvik T, Hopperstad O S, et al. The effect of target strength on the perforation of steel plates using three different projectile nose shapes. Int J Impact Eng, 2004, 30: 1005–1038

Uth T, Wadley H N G, Deshpande V S. The effect of inclination and stand-off on the dynamic response of beams impacted by slugs of a granular material. Int J Solids Struct, 2015, 56–57: 154–174

Johnson T E, Basudhar A. A metamodel-based shape optimization approach for shallow-buried blast-loaded flexible underbody targets. Int J Impact Eng, 2015, 75: 229–240

Goel A, Uth T, Wadley H N G, et al. Effect of surface properties on momentum transfer to targets impacted by high-velocity sand slugs. Int J Impact Eng, 2017, 103: 90–106

Kyner A, Deshpande V S, Wadley H N G. Impulse transfer during granular matter impact with inclined sliding surfaces. Int J Impact Eng, 2019, 130: 79–96

Grujicic M, Yavari R, Snipes J, et al. A combined finite-element/discrete-particle analysis of a side-vent-channel-based concept for improved blast-survivability of light tactical vehicles. Int J Struct Integr, 2016, 7: 106–141

Uth T, Deshpande V S. Response of clamped sandwich beams subjected to high-velocity impact by sand slugs. Int J Impact Eng, 2014, 69: 165–181

Geneviève T, Amal B, Robert D, et al. Numerical evaluation of an add-on vehicle protection system. In: Proceedings of the 9th European LS-DYNA Conference. Manchester, 2013

Rimoli J J, Talamini B, Wetzel J J, et al. Wet-sand impulse loading of metallic plates and corrugated core sandwich panels. Int J Impact Eng, 2011, 38: 837–848

Zhang P, Cheng Y, Liu J, et al. Experimental and numerical investigations on laser-welded corrugated-core sandwich panels subjected to air blast loading. Mar Struct, 2015, 40: 225–246

Dharmasena K P, Wadley H N G, Liu T, et al. The dynamic response of edge clamped plates loaded by spherically expanding sand shells. Int J Impact Eng, 2013, 62: 182–195

Liang Y, Spuskanyuk A V, Flores S E, et al. The response of metallic sandwich panels to water blast. J Appl Mech, 2007, 74: 81–99

Vaziri A, Hutchinson J W. Metal sandwich plates subject to intense air shocks. Int J Solids Struct, 2007, 44: 2021–2035

Kambouchev N, Noels L, Radovitzky R. Nonlinear compressibility effects in fluid-structure interaction and their implications on the airblast loading of structures. J Appl Phys, 2006, 100: 063519

Xue Z, Hutchinson J W. A comparative study of impulse-resistant metal sandwich plates. Int J Impact Eng, 2004, 30: 1283–1305

Dharmasena K P, Wadley H N G, Xue Z, et al. Mechanical response of metallic honeycomb sandwich panel structures to high-intensity dynamic loading. Int J Impact Eng, 2008, 35: 1063–1074

Jing L, Wang Z, Zhao L. The dynamic response of sandwich panels with cellular metal cores to localized impulsive loading. Compos Part B-Eng, 2016, 94: 52–63

Wadley H N G, Børvik T, Olovsson L, et al. Deformation and fracture of impulsively loaded sandwich panels. J Mech Phys Solids, 2013, 61: 674–699

Yu B, Han B, Ni C Y, et al. Dynamic crushing of all-metallic corrugated panels filled with close-celled aluminum foams. J Appl Mech, 2015, 82: 47–55

Yu B, Han B, Su P B, et al. Graded square honeycomb as sandwich core for enhanced mechanical performance. Mater Des, 2016, 89: 642–652

Wang X, Yu R P, Zhang Q C, et al. Dynamic response of clamped sandwich beams with fluid-fillied corrugated cores. Int J Impact Eng, 2020, 139: 103533

Kyner A, Dharmasena K, Williams K, et al. Response of square honeycomb core sandwich panels to granular matter impact. Int J Impact Eng, 2018, 117: 13–31

Liu T, Fleck N A, Wadley H N G, et al. The impact of sand slugs against beams and plates: Coupled discrete particle/finite element simulations. J Mech Phys Solids, 2013, 61: 1798–1821

Li L, Han B, He S Y, et al. Shock loading simulation using density-graded metallic foam projectiles. Mater Des, 2019, 164: 107546

Zok F W, Waltner S A, Wei Z, et al. A protocol for characterizing the structural performance of metallic sandwich panels: Application to pyramidal truss cores. Int J Solids Struct, 2004, 41: 6249–6271

Holloman R L, Deshpande V, Wadley H N G. Impulse transfer during sand impact with a cellular structure. Int J Impact Eng, 2015, 82: 36–58

Holloman R, Deshpande V, Hanssen A, et al. Tubular aluminum cellular structures: Fabrication and mechanical response. J Mech Mater Struct, 2013, 8: 65–94

Holloman R, Kandan K, Deshpande V, et al. Dynamic compression of square tube cellular structures. J Mech Mater Struct, 2014, 9: 149–182

Tremblay J E. Impulse on blast deflectors from a landmine explosion. Technical Report. Quebec: Defence Research Establishment Valcartier, 1998. DREV-TM-9814

Clarke S D, Fay S D, Warren J A, et al. Predicting the role of geotechnical parameters on the output from shallow buried explosives. Int J Impact Eng, 2017, 102: 117–128

Yu R P, Wang X, Zhang Q C, et al. Effects of sand filling on the dynamic response of corrugated core sandwich beams under foam projectile impact. Compos Part B-Eng, 2020, 197: 108135

Jones N. Structural Impact. Cambridge: Cambridge University Press, 1989

Barsoum I, Faleskog J. Rupture mechanisms in combined tension and shear—Experiments. Int J Solids Struct, 2007, 44: 1768–1786

Nahshon K, Pontin M, Evans A, et al. Dynamic shear rupture of steel plates. J Mech Mater Struct, 2007, 2: 2049–2066

Author information

Authors and Affiliations

Corresponding authors

Additional information

This work was supported by the National Natural Science Foundation of China (Grant Nos. 11972185, 12002156 and 11902148), China Post-doctoral Science Foundation (Grant No. 2020M671473), State Key Laboratory of Smart Manufacturing for Special Vehicles and Transmission System (Grant No. GZ2019KF015), Natural Science Fund Project in Jiangsu Province (Grant Nos. BK20190392 and BK20190424), Open Fund of State Key Laboratory of Mechanics and Control of Mechanical Structures (Grant Nos. MCMS-E-0219K02 and MCMS-I-0219K01), and the Priority Academic Program Development of Jiangsu Higher Education Institutions (PAPD).

Rights and permissions

About this article

Cite this article

Zhang, D., Zhao, Z., Du, S. et al. Dynamic response of ultralight all-metallic sandwich panel with 3D tube cellular core to shallow-buried explosives. Sci. China Technol. Sci. 64, 1371–1388 (2021). https://doi.org/10.1007/s11431-020-1774-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11431-020-1774-1