Abstract

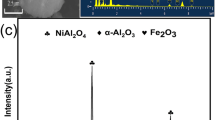

The application of organic acids towards the extraction of both Cu and Cr from the Cu–Cr spent catalyst was investigated. A series of organic acid such as acetic acid, citric acid, formic acid, ascorbic acid and tartaric acid were adopted, and after screening, acetic acid showed a profound effect on dissolution of either of the metals over other green reagents. The spent catalyst was characterized by XRD and SEM–EDAX to confirm the existence of the oxide phase due to both Cu and Cr metals. For efficient dissolution of metals, the critical parameters such as agitation speed, acetic acid concentration, temperature, particle size, as well as S/L ratio affecting on it was systematically investigated. It was observed that at approximately 99.99% of Cu along with 62% of Cr was extracted at the optimised conditions (agitation speed: 800 rpm, 1.0 M CH3COOH, 353 K temperature, particle size of (75–105) µm and S/L: 2% (W/V). The leach residue obtained after the first stage of leaching was analysed by SEM-EDAX and XRD, indicating no peaks due to the presence of Cu ensures complete dissolution of Cu at the optimum conditions. Further, to attain the quantitative leaching yield of Cr, the leach residue obtained after the first stage was sequentially investigated using varied acetic acid concentration and temperature. Leaching kinetics was established based on obtained results at the varied operating parameters, and it revealed support for fitting a model of the leaching data to the shrinking core chemical control model (R2 = 0.99) for both metals (Cu and Cr). The activation energy determined to be 34.05 kJ mol−1 and 43.31 kJ mol−1 for Cu and Cr, respectively, validates the proposed leaching kinetics mechanism.

Similar content being viewed by others

Data availability

Not applicable.

References

Abdel-Aal EA (2000) Kinetics of sulfuric acid leaching of low-grade zinc silicate ore. Hydrometallurgy 55:247–254

Balaz P, Ebert I (1991) Oxidative leaching of mechanically activated sphalerite. Hydrometallurgy 27(2):141–150

Behera SS, Parhi PK (2016) Leaching kinetics study of neodymium from the scrap magnet using acetic acid. Sep Purif Technol 160:59–66

Behera SS, Panda SK, Mandal D, Parhi PK (2019) Ultrasound and microwave assisted leaching of neodymium from waste magnet using organic solvent. Hydrometallurgy 185:61–70

Behera SS, Panda SK, Das D, Mohapatra RK, Kim HI, Lee JY, Jyothi RK, Parhi PK (2020) Microwave assisted leaching investigation for the extraction of copper (II) and chromium (III) from spent catalyst. Sep Purif Technol 244:116842

Borra CR, Pontikes Y, Binnemans K, Gerven TV (2015) Leaching of rare earths from bauxite residue (red mud). Miner Eng 76:20–27

Dunbar RE, Arnold MR (1944) Preparation and reclamation of copper-chromium oxide catalyst. Ind Eng Chem Anal Ed 16(7):441–441

Kim CJ, Yoon HS, Chung KW, Lee JY, Kim SD, Shin SM, Lee SJ, Joe AR, Lee S, Yoo SJ, Kim SH (2014) Leaching kinetics of lanthanum in sulphuric acid from rare earth element (REE) slag. Hydrometallurgy 146:133–137

Larba R, Boukerche I, Alane N, Habbache N, Djerad S, Tifouti L (2013) Citric acid as an alternative lixiviant for zinc oxide dissolution. Hydrometallurgy 134:117–123

Li L, Ge J, Chen R, Wua F, Chen S, Zhang XX (2010) Environmental friendly leaching reagent for cobalt and lithium recovery from spent lithium-ion batteries. Waste Manage 30:2615–2621

Meshram P, Pandey BD, Mankhand TR (2015) Leaching of base metals from spent Ni–metal hydride batteries with emphasis on kinetics and characterization. Hydrometallurgy 158:172–179

Meshram P, Pandey BD, Mankhand TR (2016) Process optimization and kinetics for leaching of rare earth metals from the spent Ni–metal hydride batteries. Waste Manage 51:196–203

Mohanty C, Behera SS, Marandi B, Tripathy SK, Parhi PK, Sanjay K (2021) Citric acid mediated leaching kinetics study and comprehensive investigation on extraction of vanadium (V) from the spent catalyst. Sep Purif Technol 276:119377

Nikiforova A, Kozhura O, Pasenko O (2016) Leaching of vanadium by sulfur dioxide from spent catalysts for sulfuric acid production. Hydrometallurgy 164:31–37

Parhi PK, Park KH, Senanayake G (2013) A kinetic study on hydrochloric acid leaching of nickel from Ni-Al2O3 spent catalyst. J Ind Eng Chem 19:589–594

Parhi PK, Sethy T, Rout P, Sarangi, K (2015). Selective dissolution of copper from copper-chromium spent catalyst by baking-leaching process. J Ind Eng Chem 21:604–609

Qiu H, Zhang H, Zhao B, Zhu J, Liu D (2013) Dynamics study on vanadium extraction technology from chloride leaching steel slag. Rare Metal Mater Eng 42:696–699

Silva JE, Soares D, Paiva AP, Labrincha JA, Castro F (2005) Leaching behaviour of a galvanic sludge in sulphuric acid and ammoniacalmedia. J Hazard Mater 121:195–202

Song L, Di H, Yang K, Zhang L (2022) Ultrasonic-enhanced sulfuric acid leaching kinetics of high-grade germanium-containing materials. Chem Eng Process 178:109045

Swaroopa S, Ghosh MK, Sanjay K, Mishra BK (2013) Extraction of Cu and Cr from a spent Cu–Cr catalyst: recovery enhancement through mechanical activation. Hydrometallurgy 136:8–14

Trimm DL (2001) The regeneration or disposal of deactivated heterogeneous catalysts. Appl Catal A: General 212(1–2):153–160

Valdes-Solis T, Marban G, Fuertes AB (2006) Nanosized catalysts for the production of hydrogen by methanol steam reforming. Catal Today 116(3):354–360

Wang Z, Xi J, Wang W, Lu G (2003) Selective production of hydrogen by partial oxidation of methanol over Cu/Cr catalysts. J Mol Catal A: Chem 191(1):123–134

Wang L, Long Z, Huang X, Yu Y, Cui D, Zhang G (2010) Recovery of rare earths from wet-process phosphoric acid. Hydrometallurgy 101:41–47

Wu J, Ahn J, Lee J (2021) Kinetic and mechanism studies using shrinking core model for copper leaching from chalcopyrite in methanesulfonic acid with hydrogen peroxide. Miner Process Extract Metall Rev 42(1):38–45

Wu W, Wang C, Wang X, Li H (2021b) Removal of V and Fe from spent denitrification catalyst by using oxalic acid: study of dissolution kinetics and toxicity. Green Energy Environ 6(5):660–669

Yang Q, Li Q, Zhang G, Shi Q, Feng H (2019) Investigation of leaching kinetics of aluminium extraction from secondary aluminium dross with use of hydrochloric acid. Hydrometallurgy 187:158–167

Zhang ZY, Zhang FS, Yao T (2017) An environmentally friendly ball milling process for recovery of valuable metals from e-waste scraps. Waste Manage 68:490–497

Acknowledgements

The co-author P. K. Parhi thankfully acknowledges S&T, Govt. of Odisha, India, for providing financial assistance under the sponsored Grant No. ST-SCST-MISC-0026-2020, No.4856/ST, during the course of the investigation.

Funding

This work was partially supported from the research Grant No. ST-SCST-MISC-0026–2020, No.4856/ST, DST, Govt. of Odisha, India.

Author information

Authors and Affiliations

Contributions

C.K. Mohanty: Conceptualization, Development of methodologies, Experimental analysis and Writing of the original draft; S.S. Behera: Conceptualization, Writing, and Analytical support, S.K. Tripathy: Data validation, Review, and Editing, P.K. Parhi: Conceptualization, Development of methodologies, Writing, Review, Editing and Supervision. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Responsible Editor: Ioannis A. Katsoyiannis

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• Adoption of organic reagents for effective leaching of Cu and Cu from spent catalyst.

• Leaching kinetics of Cu and Cr follows the shrinking core diffusion control mechanism.

• Resulted Ea of 34.05 & 43.31 kJ mol−1 for Cu and Cr supports leaching mechanism.

• Typical leach reside analysis by XRD,SEM-EDAX ensures over 99% Cu leaching.

• Two stage leaching including Cu followed by Cr with acetic acid was quantitative.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mohanty, C.K., Behera, S.S., Tripathy, S.K. et al. Extensive investigation on extraction and leaching kinetics study of Cu and Cr from spent catalyst using acetic acid. Environ Sci Pollut Res 30, 90195–90208 (2023). https://doi.org/10.1007/s11356-023-26182-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11356-023-26182-3