Abstract

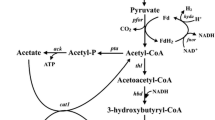

Acidogenic clostridia naturally producing acetic and butyric acids has attracted high interest as a novel host for butyrate and n-butanol production. Among them, Clostridium tyrobutyricum is a hyper butyrate-producing bacterium, which re-assimilates acetate for butyrate biosynthesis by butyryl-CoA/acetate CoA transferase (CoAT), rather than the phosphotransbutyrylase-butyrate kinase (PTB-BK) pathway widely found in clostridia and other microbial species. To date, C. tyrobutyricum has been engineered to overexpress a heterologous alcohol/aldehyde dehydrogenase, which converts butyryl-CoA to n-butanol. Compared to conventional solventogenic clostridia, which produce acetone, ethanol, and butanol in a biphasic fermentation process, the engineered C. tyrobutyricum with a high metabolic flux toward butyryl-CoA produced n-butanol at a high yield of > 0.30 g/g and titer of > 20 g/L in glucose fermentation. With no acetone production and a high C4/C2 ratio, butanol was the only major fermentation product by the recombinant C. tyrobutyricum, allowing simplified downstream processing for product purification. In this review, novel metabolic engineering strategies to improve n-butanol and butyrate production by C. tyrobutyricum from various substrates, including glucose, xylose, galactose, sucrose, and cellulosic hydrolysates containing the mixture of glucose and xylose, are discussed. Compared to other recombinant hosts such as Clostridium acetobutylicum and Escherichia coli, the engineered C. tyrobutyricum strains with higher butyrate and butanol titers, yields and productivities are the most promising hosts for potential industrial applications.

Similar content being viewed by others

References

Alam S, Stevens D, Bajpai R (1988) Production of butyric acid by batch fermentation of cheese whey with Clostridium beijerinckii. J Ind Microbiol 2:359–364

Amiri H, Karimi K (2018) Pretreatment and hydrolysis of lignocellulosic wastes for butanol production: challenges and perspectives. Bioresour Technol 270:702–721

Baltz RH (2018) Bacteriophage-resistant industrial fermentation strains: from the cradle to CRISPR/Cas9. J Ind Microbiol Biot 45:1003–1006

Bao G, Wang R, Zhu Y, Dong H, Mao S, Zhang Y, Chen Z, Li Y, Ma Y (2011) Complete genome sequence of Clostridium acetobutylicum DSM 1731, a solvent-producing strain with multireplicon genome architecture. J Bacteriol 193:5007–5008

Baroi GN, Baumann I, Westermann P, Gavala HN (2015) Butyric acid fermentation from pretreated and hydrolysed wheat straw by an adapted Clostridium tyrobutyricum strain. Microbiol Biotechnol 8:874–882

Bassi D, Fontana C, Gazzola S, Pietta E, Puglisi E, Cappa F, Cocconcelli PS (2013) Draft genome sequence of Clostridium tyrobutyricum strain UC7086, isolated from grana padano cheese with late-blowing defect. Genome Announc 1(4):e00614–e713

Biggs B, De Paepe B, Santos CNS, De Mey M, Ajikumar PK (2014) Multivariate modular metabolic engineering for pathway and strain optimization. Curr Opin Biotechnol 29:156–162

Cao X, Chen Z, Liang L, Guo L, Jiang Z, Tang F, Yun Y, Wang Y (2020) Co-valorization of paper mill sludge and corn steep liquor for enhanced n-butanol production with Clostridium tyrobutyricum Δcat1:adhE2. Bioresour Technol 296:122347

Chen T, Zhang L, Luo G, Yuan W (2017) Butyric acid production by Clostridium tyrobutyricum in sugar mixtures and corncob hydrolysate containing arabinose. BioResources 12:7931–7942

Cheng C, Bao T, Yang ST (2019a) Engineering Clostridium for improved solvent production: recent progress and perspective. Appl Microbiol Biotechnol 103:5549–5566

Cheng C, Lin M, Jiang W, Zhao J, Li W, Yang ST (2019b) Development of an in vivo fluorescence based gene expression reporter system for Clostridium tyrobutyricum. J Biotechnol 305:18–22

Choi O, Um Y, Sang B-I (2012) Butyrate production enhancement by Clostridium tyrobutyricum using electron mediators and a cathodic electron donor. Biotechnol Bioeng 109:2494–2502

Cummins CS, Johnson JL (1971) Taxonomy of clostridia: Wall composition and DNA homologies in Clostridium butyricum and other butyric acid-producing clostridia. J Gen Microbiol 67:33–46

D'Incecco P, Faoro F, Silvetti T, Schrader K, Pellegrino L (2015) Mechanisms of Clostridium tyrobutyricum removal through natural creaming of milk: A microscopy study. J Dairy Sci 98:5164–5172

Du Y, Jiang W, Yu M, Tang IC, Yang ST (2015) Metabolic process engineering of Clostridium tyrobutyricum Δack-adhE2 for enhanced n-butanol production from glucose: effects of methyl viologen on NADH availability, flux distribution, and fermentation kinetics. Biotechnol Bioeng 112:705–715

Dwidar M, Park JY, Mitchell RJ, Sang BI (2012) The future of butyric acid in industry. Sci World J 2012:471417

Fu H, Yu L, Lin M, Wang J, Xiu Z, Yang S-T (2017a) Metabolic engineering of Clostridium tyrobutyricum for enhanced butyric acid production from glucose and xylose. Metab Eng 40:50–58

Fu H, Yang S-T, Wang M, Wang J, Tang IC (2017b) Butyric acid production from lignocellulosic biomass hydrolysates by engineered Clostridium tyrobutyricum overexpressing xylose catabolism genes for glucose and xylose co-utilization. Bioresour Technol 234:389–396

Fu H, Hu J, Guo X, Feng J, Zhang Y, Wang J (2020) High-selectivity butyric acid production from Saccharina japonica hydrolysate by Clostridium tyrobutyricum. Ind Eng Chem Res. https://doi.org/10.1021/acs.iecr.0c01279

Guo X, Fu H, Feng J, Hu J, Wang J (2020) Direct conversion of untreated cane molasses into butyric acid by engineered Clostridium tyrobutyricum. Bioresour Technol 301:122764

He F, Qin S, Yang Z, Bai X, Suo Y, Wang J (2020) Butyric acid production from spent coffee grounds by engineered Clostridium tyrobutyricum overexpressing galactose catabolism genes. Bioresour Technol 304:122977

Heap JT, Pennington OJ, Cartman ST, Carter GP, Minton NP (2007) The ClosTron: a universal gene knock-out system for the genus Clostridium. J Microbiol Meth 70:452–464

Heap JT, Pennington OJ, Cartman ST, Minton NP (2009) A modular system for Clostridium shuttle plasmids. J Microbiol Meth 78:79–85

Heap JT, Kuehne SA, Ehsaan M, Cartman ST, Cooksley CM, Scott JC, Minton NP (2010) The ClosTron: Mutagenesis in Clostridium refined and streamlined. J Microbiol Meth 80:49–55

Huang J, Cai J, Wang J, Zhu XC, Huang L, Yang ST, Xu ZN (2011) Efficient production of butyric acid from Jerusalem artichoke by immobilized Clostridium tyrobutyricum in a fibrous-bed bioreactor. Bioresour Technol 102:3923–3926

Huang J, Dai H, Yan R, Wang P (2016a) Butyric acid production from recycled waste paper by immobilized Clostridium tyrobutyricum in a fibrous-bed bioreactor. J Chem Technol Biotechnol 91:1048–1054

Huang J, Zhu H, Tang W, Wang P, Yang S-T (2016b) Butyric acid production from oilseed rape straw by Clostridium tyrobutyricum immobilized in a fibrous bed bioreactor. Proc Biochem 51:1930–1934

Huang J, Du Y, Bao T, Lin M, Wang J, Yang ST (2019) Production of n-butanol from cassava bagasse hydrolysate by engineered Clostridium tyrobutyricum overexpressing adhE2: Kinetics and cost analysis. Bioresour Technol 292:121969

Jang YS, Im JA, Choi SY, Lee JI, Lee SY (2014) Metabolic engineering of Clostridium acetobutylicum for butyric acid production with high butyric acid selectivity. Metab Eng 23:165–174

Jawed K, Mattam AJ, Fatma Z, Wajid S, Abdin MZ, Yazdani SS (2016) Engineered production of short chain fatty acid in Escherichia coli using fatty acid synthesis pathway. PLoS ONE 11:e0160035

Jha AK, Li J, Yuan Y, Baral N, Ai B (2014) A review on bio-butyric acid production and its optimization. Int J Agric Biol 16:1019–1024

Jiang L, Wang J, Liang S, Cai J, Xu Z, Cen P, Yang ST, Li S (2011) Enhanced butyric acid tolerance and bioproduction by Clostridium tyrobutyricum immobilized in a fibrous bed bioreactor. Biotechnol Bioeng 108:31–40

Jiang L, Zhu L, Xu X, Li YP, Li S, Huang H (2013) Genome sequence of Clostridium tyrobutyricum ATCC 25755, a butyric acid-overproducing strain. Genome Announc 1:e00308–e313

Jiang L, Wu Q, Xu Q, Zhu LY, Huang H (2017) Fermentative hydrogen production from Jerusalem artichoke by Clostridium tyrobutyricum expressing exo-inulinase gene. Sci Rep 7(1):7940

Jiang L, Fu H, Yang HK, Xu W, Wang J, Yang ST (2018) Butyric acid: Applications and recent advances in its bioproduction. Biotechnol Adv 36:2101–2117

Jo JH, Jeon CO, Lee SY, Lee DS, Park JM (2010) Molecular characterization and homologous overexpression of [FeFe]-hydrogenase in Clostridium tyrobutyricum JM1. Int J Hydrogen Energy 35:1065–1073

Jones DT, Shirley M, Wu X, Keis S (2000) Bacteriophage infections in the industrial acetone butanol (AB) fermentation process. J Mol Microbiol Biotechnol 2:21–26

Jönsson LJ, Alriksson B, Nilvebrant N-O (2013) Bioconversion of lignocellulose: inhibitors and detoxification. Biotechnol Biofuels 6:16–25

Joseph RC, Kim NM, Sandoval NR (2018) Recent developments of the synthetic biology toolkit for Clostridium. Front Microbiol 9:154

Kataoka N, Vangnai AS, Pongtharangkul T, Yakushi T, Matsushita K (2017) Butyrate production under aerobic growth conditions by engineered Escherichia coli. J Biosci Bioeng 123:562–568

Kumar M, Goyal Y, Sarkar A, Gayen K (2013) Comparative economic assessment of ABE fermentation based on cellulosic and non-cellulosic feedstocks. Appl Energy 93:193–204

Kwon SW, Paari KA, Malaviya A, Jang YS (2020) Synthetic biology tools for genome and transcriptome engineering of solventogenic Clostridium. Front Bioeng Biotech 8:282

Lee KM, Kim KY, Choi O, Woo HM, Kim Y, Han SO, Sang BI, Um Y (2015) In situ detoxification of lignocellulosic hydrolysate using a surfactant for butyric acid production by Clostridium tyrobutyricum ATCC 25755. Proc Biochem 50:630–635

Lee J, Jang YS, Han MJ, Kim JY, Lee SY (2016) Deciphering Clostridium tyrobutyricum metabolism based on the whole-genome sequence and proteome analyses. mBio 7:e00743-16

Li C, Wang Y, Xie G, Peng B, Zhang B, Chen W, Huang X, Wu H, Zhang B (2016) Complete genome sequence of Clostridium butyricum JKY6D1 isolated from the pit mud of a Chinese flavor liquor-making factory. J Biotechnol 220:23–24

Li J, Du Y, Bao T, Dong J, Lin M, Shim H, Yang ST (2019) n-Butanol production from lignocellulosic biomass hydrolysates without detoxification by Clostridium tyrobutyricum △aack-adhE2 in a fibrous-bed bioreactor. Bioresour Technol 289:121749

Liu X, Yang ST (2006) Kinetics of butyric acid fermentation of glucose and xylose by Clostridium tyrobutyricum wild type and mutant. Process Biochem 41:801–808

Liu S, Bischoff KM, Leathers TD, Qureshi N, Rich JO, Hughes SR (2013) Butyric acid from anaerobic fermentation of lignocellulosic biomass hydrolysates by Clostridium tyrobutyricum strain RPT-4213. Bioresour Technol 143:322–329

Liu X, Turchi B, Mok KC, Taga ME, Miller MJ (2017) HM2-phage resistant solventogenic Clostridium saccharoperbutylacetonicum N1–4 shows increased exopolysaccharide production. FEMS Microbiol Lett 364:fnx191

Liu X, Zhu Y, Yang ST (2006a) Butyric acid and hydrogen production by Clostridium tyrobutyricum ATCC 25755 and mutants. Enzyme Microb Technol 38:521–528

Liu X, Zhu Y, Yang ST (2006b) Construction and characterization of ack deleted mutant of Clostridium tyrobutyricum for enhanced butyric acid and hydrogen production. Biotechnol Progr 22:1265–1275

Lu C, Dong J, Yang ST (2013) Butanol production from wood pulping hydrolysate in an integrated fermentation-gas stripping process. Bioresour Technol 143:467–475

Luo H, Yang R, Zhao Y, Wang Z, Liu Z, Huang M, Zeng Q (2018) Recent advances and strategies in process and strain engineering for the production of butyric acid by microbial fermentation. Bioresour Technol 253:343–354

Ma C, Kojima K, Xu N, Mobley J, Zhou L, Yang ST, Liu XM (2015) Comparative proteomics analysis of high n-butanol producing metabolically engineered Clostridium tyrobutyricum. J Biotechnol 193:108–119

Mayer MJ, Payne J, Gasson MJ, Narbad A (2010) Genomic sequence and characterization of the virulent bacteriophage ΦCTP1 from Clostridium tyrobutyricum and heterologous expression of its endolysin. Appl Environ Microbiol 76(16):5415–5422

Mo SJ, Kim BS, Yun SJ, Lee JJ, Yoon SH, Oh CH (2015) Genome sequencing of Clostridium butyricum DKU-01, isolated from infant feces. Gut Pathog 7:1–7

Morandi S, Cremonesi P, Silvetti T, Castiglioni B, Brasca M (2015) Development of a triplex real-time PCR assay for the simultaneous detection of Clostridium beijerinckii, Clostridium sporogenes and Clostridium tyrobutyricum in milk. Anaerobe 34:44–49

Munier E, Licandro-Seraut H, Achilleos C, Cachon R, Beuvier E (2019) Whole-genome sequencing and annotation of Clostridium tyrobutyricum strain Cirm BIA 2237, isolated from silage. Microbiol Resour Ann 8:e00492–e519

Nguyen NPT, Raynaud C, Meynial-Salles I, Soucaille P (2018) Reviving the Weizmann process for commercial n-butanol production. Nat Commun 9:3682

Oh HJ, Kim K-Y, Lee KM, Lee S-M, Gong G, Oh M-K, Um Y (2019) Enhanced butyric acid production using mixed biomass of brown algae and rice straw by Clostridium tyrobutyricum ATCC25755. Bioresour Technol 273:446–453

Ou J, Bao T, Ernst P, Si Y, Prabhu SD, Wu H, Zhang JJ, Zhou L, Yang ST, Liu XM (2020) Intracellular metabolism analysis of Clostridium cellulovorans via modeling integrating proteomics, metabolomics and fermentation. Process Biochem 89:9–19

Saini M, Wang ZW, Chiang CJ, Chao YP (2014) Metabolic engineering of Escherichia coli for production of butyric acid. J Agric Food Chem 62:4342–4348

Sharma HK, Xu C, Qin W (2019) Biological pretreatment of lignocellulosic biomass for biofuels and bioproducts: An overview. Waste Biomass Valor 10:235–251

Shen CR, Lan EI, Dekishima Y, Baez A, Cho KM, Liao JC (2011) Driving forces enable high-titer anaerobic 1-butanol synthesis in Escherichia coli. Appl Environ Microbiol 77:2905–2915

Sillers R, Chow A, Tracy B, Papoutsakis ET (2008) Metabolic engineering of the non-sporulating, non-solventogenic Clostridium acetobutylicum strain M5 to produce butanol without acetone demonstrate the robustness of the acid-formation pathways and the importance of the electron balance. Metab Eng 10:321–332

Sjoblom M, Matsakas L, Christakopoulos P, Rova U (2016) Catalytic upgrading of butyric acid towards fine chemicals and biofuels. Fems Microbiol Lett 363:7

Storari M, Wüthrich D, Bruggmann R, Berthoud H, Arias-Roth E (2015a) Draft genome sequences of Clostridium tyrobutyricum strains FAM22552 and FAM22553, isolated from Swiss semihard red-smear cheese. Genome Announc 3:e00078–e115

Soggiu A et al (2015) Draft genome sequence of Clostridium tyrobutyricum strain DIVETGP, isolated from cow's milk for grana padano production. Microbiol Resour Ann 3:e00213–e215

Song J-H, Ventura J-RS, Lee C-H, Jahng D (2011) Butyric acid production from brown algae using Clostridium tyrobutyricum ATCC 25755. Biotechnol Bioprocess Eng 16:42–49

Steiner E, Dago AE, Young DI, Heap JT, Minton NP, Hoch JA, Young M (2011) Multiple orphan histidine kinases interact directly with Spo0A to control the initiation of endospore formation in Clostridium acetobutylicum. Mol Microbiol 80:641–654

Storari M, Wuthrich D, Bruggmann R, Berthoud H, Arias-Roth E (2015b) Draft genome sequences of Clostridium tyrobutyricum strains FAM22552 and FAM22553, isolated from swiss semihard red-smear cheese. Microbiol Resour Ann 3:e00078–e115

Suo YK, Luo S, Zhang YA, Liao ZP, Wang JF (2017) Enhanced butyric acid tolerance and production by Class I heat shock protein-overproducing Clostridium tyrobutyricum ATCC 25755. J Ind Microbiol Biotechnol 44:1145–1156

Suo Y, Ren M, Yang X, Liao Z, Fu H, Wang J (2018a) Metabolic engineering of Clostridium tyrobutyricum for enhanced butyric acid production with high butyrate/acetate ratio. Appl Microbiol Biotechnol 102:4511–4522

Suo Y, Fu H, Ren M, Liao Z, Ma Y, Wang J (2018b) Enhanced butyric acid production in Clostridium tyrobutyricum by overexpression of rate-limiting enzymes in the Embden-Meyerhof-Parnas pathway. J Biotechnol 272:14–21

Suo Y, Fu H, Ren M, Yang X, Liao Z, Wang J (2018c) Butyric acid production from lignocellulosic biomass hydrolysates by engineered Clostridium tyrobutyricum overexpressing Class I heat shock protein GroESL. Bioresour Technol 250:691–698

Suo Y, Liao Z, Qu C, Fu H, Wang J (2019) Metabolic engineering of Clostridium tyrobutyricum for enhanced butyric acid production from undetoxified corncob acid hydrolysate. Bioresour Technol 271:266–273

Sushkova VI, Zhukovskii SV, Berezina OV, Yarotskii SV (2013) Biosynthesis of butyric acid from cabbage stem and molasses by the strain Clostridium butyricum VKPM B-9619. Russ J Bioorg Chem 39:771–776

Tamaru Y, Miyake H, Kuroda K, Nakanishi A, Kawade Y, Yamamoto K, Uemura M, Fujita Y, Doi RH, Ueda M (2010) Genome sequence of the cellulosome-producing mesophilic organism Clostridium cellulovorans 743B. J Bacteriol 192:901–902

Wang JF, Yang XR, Chen CC, Yang ST (2014) Engineering clostridia for butanol production from biorenewable resources: from cells to process integration. Curr Opin Chem Eng 6:43–54

Wang L, Ou MS, Nieves I, Erickson JE, Vermerris W, Ingram LO, Shanmugam KT (2015) Fermentation of sweet sorghum derived sugars to butyric acid at high titer and productivity by a moderate thermophile Clostridium thermobutyricum at 50 °C. Bioresour Technol 198:533–539

Wang J, Lin M, Xu M, Yang ST (2016) Anaerobic fermentation for production of carboxylic acids as bulk chemicals from renewable biomass. Adv Biochem Eng Biotechnol 156:323–361

Wasels F, Clement B, Ferreira NL (2016) Draft genome sequence of the butyric acid producer Clostridium tyrobutyricum strain CIP I-776 (IFP923) Microbiol Resour Ann 4:e00048–16

Wei D, Liu X, Yang ST (2013) Butyric acid production from sugarcane bagasse hydrolysate by Clostridium tyrobutyricum immobilized in a fibrous-bed bioreactor. Bioresour Technol 129:553–560

Wen Z, Ledesma-Amaro R, Lin JP, Jiang Y, Yang S (2019) Improved n-butanol production from Clostridium cellulovorans by integrated metabolic and evolutionary engineering. Appl Environ Microbiol 85:e02560–e2618

Wu ZT, Yang ST (2003) Extractive fermentation for butyric acid production from glucose by Clostridium tyrobutyricum. Biotechnol Bioeng 82:93–102

Wu Q, Liu TT, Zhu LY, Huang H, Jiang L (2017a) Insights from the complete genome sequence of Clostridium tyrobutyricum provide a platform for biotechnological and industrial applications. J Ind Microbiol Biotechnol 44:1245–1260

Wu Q, Zhu L, Xu Q, Huang H, Jiang L, Yang ST (2017b) Tailoring the oxidative stress tolerance of Clostridium tyrobutyricum CCTCC W428 by introducing trehalose biosynthetic capability. J Agric Food Chem 65:8892–8901

Xiao H, Li Z, Jiang Y, Yang Y, Jiang W, Gu Y, Yang S (2012) Metabolic engineering of D-xylose pathway in Clostridium beijerinckii to optimize solvent production from xylose mother liquid. Metab Eng 14:569–578

Xiao Z, Cheng C, Bao T, Liu L, Wang B, Tao W, Pei X, Yang ST, Wang M (2018) Production of butyric acid from acid hydrolysate of corn husk in fermentation by Clostridium tyrobutyricum: kinetics and process economic analysis. Biotechnol Biofuels 11:164

Xu M, Zhao J, Yu L, Tang IC, Xue C, Yang ST (2015) Engineering Clostridium acetobutylicum with a histidine kinase knockout for enhanced n-butanol tolerance and production. Appl Microbiol Biotechnol 99:1011–1022

Xu M, Zhao J, Yu L, Yang ST (2017) Comparative genomic analysis of Clostridium acetobutylicum for understanding the mutations contributing to enhanced butanol tolerance and production. J Biotechnol 263:36–44

Xue C, Zhao JB, Chen LJ, Yang ST, Bai FW (2017) Recent advances and state-of-the-art strategies in strain and process engineering for biobutanol production by Clostridium acetobutylicum. Biotechnol Adv 35:310–322

Yang ST, Lu C (2013) Extraction-fermentation hybrid (extractive fermentation). In: Ramaswamy S, Ramarao BV, Huang H (eds) Separation and purification technologies in biorefineries. Wiley, Chichester, pp 409–437

Yang ST, Zhao J (2013) Adaptive engineering of Clostridium for increased butanol production, US Patent 8450093

Yang ST, Yu M, Chang WL, Tang IC (2013) Anaerobic fermentations for the production of acetic and butyric acids. In: Yang ST, El-Enshasy HA, Thongchul N (eds) Bioprocessing technologies in biorefinery for sustainable production of fuels, chemicals, and polymers. Wiley, Hoboken, pp 351–373

Yang X, Xu M, Yang ST (2015) Metabolic and process engineering of Clostridium cellulovorans for biofuel production from cellulose. Metab Eng 32:39–48

Yoo M, Soucaille P (2020) Trends in systems biology for the analysis and engineering of Clostridium acetobutylicum metabolism. Trends Microbiol 28(2):118–140

Yu L, Zhao J, Xu M, Dong J, Varghese S, Yu M, Tang IC, Yang ST (2015) Metabolic engineering of Clostridium tyrobutyricum for n-butanol production: effects of CoA transferase. Appl Microbiol Biotechnol 99:4917–4930

Yu L, Xu M, Tang IC, Yang ST (2015a) Metabolic engineering of Clostridium tyrobutyricum for n-butanol production from maltose and soluble starch by overexpressing α-glucosidase. Appl Microbiol Biotechnol 99:6155–6165

Yu L, Xu M, Tang IC, Yang ST (2015b) Metabolic engineering of Clostridium tyrobutyricum for n-butanol production through co-utilization of glucose and xylose. Biotechnol Bioeng 112:2134–2141

Yu M, Du Y, Jiang W, Chang WL, Yang ST, Tang IC (2012) Effects of different replicons in conjugative plasmids on transformation efficiency, plasmid stability, gene expression and n-butanol biosynthesis in Clostridium tyrobutyricum. Appl Microbiol Biotechnol 93:881–889

Yu M, Zhang Y, Tang IC, Yang ST (2011) Metabolic engineering of Clostridium tyrobutyricum for n-butanol production. Metab Eng 13:373–382

Zhang J, Hong W, Guo L, Wang Y, Wang Y (2020) Enhancing plasmid transformation efficiency and enabling CRISPR-Cas9/Cpf1-based genome editing in Clostridium tyrobutyricum. Biotechnol Bioeng, in press, https://doi.org/10.1002/bit.27435

Zhang J, Yu L, Xu M, Yang ST, Yan Q, Lin M, Tang IC (2017) Metabolic engineering of Clostridium tyrobutyricum for n-butanol production from sugarcane juice. Appl Microbiol Biotechnol 101:4327–4337

Zhang J, Yu L, Lin M, Yan Q, Yang ST (2017) n-Butanol production from sucrose and sugarcane juice by engineered Clostridium tyrobutyricum overexpressing sucrose catabolism genes and adhE2. Bioresour Technol 233:51–57

Zhang J, Zong W, Hong W, Zhang ZT, Wang Y (2018) Exploiting endogenous CRISPR-Cas system for multiplex genome editing in Clostridium tyrobutyricum and engineer the strain for high-level butanol production. Metab Eng 47:49–59

Zhao J, Lu C, Chen CC, Yang ST (2013) Biological production of butanol and higher alcohols. In: Yang ST, El-Enshasy HA, Thongchul N (eds) Bioprocessing technologies in biorefinery for sustainable production of fuels, chemicals, and polymers. Wiley, New York, pp 235–261

Zheng W, Liu X, Zhu L, Huang H, Wang T, Jiang L (2018) Pretreatment with gamma-valerolactone/mmim dmp and enzymatic hydrolysis on corncob and its application in immobilized butyric acid fermentation. J Agric Food Chem 66:11709–11717

Zhu Y, Yang ST (2003) Adaptation of Clostridium tyrobutyricum for enhanced tolerance to butyric acid in a fibrous-bed bioreactor. Biotechnol Prog 19:365–372

Zhu Y, Yang ST (2004) Effect of pH on metabolic pathway shift in butyric acid fermentation by Clostridium tyrobutyricum. J Biotechnol 110:143–157

Zhu Y, Liu XG, Yang ST (2005) Construction and characterization of pta gene-deleted mutant of Clostridium tyrobutyricum for enhanced butyric acid fermentation. Biotechnol Bioeng 90:154–166

Zhu Y, Wu ZT, Yang ST (2002) Butyric acid production from acid hydrolysate of corn fibre by Clostridium tyrobutyricum in a fibrous-bed bioreactor. Proc Biochem 38:657–666

Zigova J, Sturdik E (2000) Advances in biotechnological production of butyric acid. J Ind Microbiol Biotechnol 24:153–160

Zigova J, Sturdik E, Vandak D, Schlosser S (1999) Butyric acid production by Clostridium butyricum with integrated extraction and pertraction. Process Biochem 34:835–843

Acknowledgments

Some of the authors’ work described in this review was supported by the National Science Foundation STTR program (IIP-0810568, IIP-1026648) and Ohio Department of Development—Third Frontier Advanced Energy Program (Tech 08-036).

Funding

Some of the work described in this review paper was supported by the National Science Foundation STTR program (IIP-0810568, IIP-1026648), Ohio Department of Development—Third Frontier Advanced Energy Program (Tech 08-036).

Author information

Authors and Affiliations

Contributions

STY had the idea for the article. TB, JF, WJ, and HF performed the literature search and data analysis. BT and JF each drafted different sections of the paper. JW and STY critically revised the work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bao, T., Feng, J., Jiang, W. et al. Recent advances in n-butanol and butyrate production using engineered Clostridium tyrobutyricum. World J Microbiol Biotechnol 36, 138 (2020). https://doi.org/10.1007/s11274-020-02914-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11274-020-02914-2