Abstract

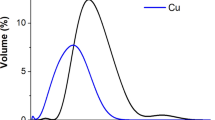

Chemical mechanical polishing (CMP) has been used to achieve local and global planarization for fabricating copper interconnects. Corrosion inhibitors in slurries are critical to realizing planarization. This study used polyacrylic acid (PAA) as a lubricant and a complement to 1,2,4-triazole for copper CMP. It is revealed that in the presence of a primary corrosion inhibitor of 1,2,4-triazole, adding a relatively low content of PAA can lead to an ultra-smooth copper surface with 1 nm surface roughness Sa, which is conducive to planarization. A relatively uniform surface film of approximately 1.9 nm is formed. The surface film mainly contains Cu–PAA, Cu-1,2,4-triazole, and copper oxides. Moreover, microscopic atomic force microscopy experiments in liquid were conducted to simulate CMP. After adding PAA, the interfacial friction between the probe and the copper surface significantly decreases to 27%, indicating that the adsorbed PAA can serve as an effective lubricant, presumably due to electrostatic repulsion. In addition, after adding PAA to the 1,2,4-triazole solution, the surface film becomes thicker and denser, suggesting that PAA can complement 1,2,4-triazole to construct a relatively compact passivating film. Therefore, the copper surface quality improves. The findings provide mechanistic insight into the unrecognized role of polymers in copper CMP.

Graphical Abstract

Similar content being viewed by others

References

Havemann, R.H., Hutchby, J.A.: High-performance interconnects: an integration overview. Proc. IEEE 89(5), 586–601 (2001)

Lee, D., Lee, H., Jeong, H.: Slurry components in metal chemical mechanical planarization (CMP) process: a review. Int. J. Precis. Eng. Manuf. 17(12), 1751–1762 (2016)

Li, Y.: Microelectronic Applications of Chemical Mechanical Planarization. Wiley, Hoboken (2007)

Li, Y., Gong, M., Ramji, K., Li, Y.: Role of Cu−benzotriazole nanoparticles in passivation film formation. J. Phys. Chem. C 113(42), 18003–18013 (2009)

Jiang, L., Lan, Y., He, Y., Li, Y., Li, Y., Luo, J.: 1,2,4-Triazole as a corrosion inhibitor in copper chemical mechanical polishing. Thin Solid Films 556, 395–404 (2014)

Zhou, J., Niu, X., Wang, Z., Cui, Y., Wang, J., Yang, C., Huo, Z., Wang, R.: Roles and mechanism analysis of chitosan as a green additive in low-tech node copper film chemical mechanical polishing. Colloids Surf. A 586, 124293 (2020)

Zhang, Z., Cui, J., Zhang, J., Liu, D., Yu, Z., Guo, D.: Environment friendly chemical mechanical polishing of copper. Appl. Surf. Sci. 467–468, 5–11 (2019)

Yang, G., Wang, H., Wang, N., Sun, R., Wong, C.-P.: Integrated electrochemical analysis of polyvinyl pyrrolidone (PVP) as the inhibitor for copper chemical mechanical planarization (Cu-CMP). J. Alloys Compd. 770, 175–182 (2019)

Chou, H., Kim, W., Noh, J., Lee, I.: A study on the impact of polymer additives in bulk copper slurry on copper CMP. In: 2007 International Conference on Planarization/CMP Technology (ICPT), October 25–27, pp. 1–6. VDE, Dresden (2007)

Chen, K.-W., Wang, Y.L.: Study of non-preston phenomena induced from the passivated additives in copper CMP. J. Electrochem. Soc. 154(1), H41 (2007)

Jang, S., Song, J., Amalnerkar, D., Qin, H., Kim, T.: Effect of secondary inhibitors on material removal rate and nano-roughness of Cu chemical mechanical planarization. Mater. Express 6(5), 383–393 (2016)

Tamilmani, S., Huang, W., Raghavan, S., Small, R.: Potential-pH diagrams of interest to chemical mechanical planarization of copper. J. Electrochem. Soc. 149(12), G638–G642 (2002)

Wu, Y., Jiang, L., Qian, L.: Achieving smooth PZT surface via chemical mechanical polishing with ethylenediamine dihydrochloride. Ceram. Int. 48(13), 18891–18898 (2022)

Stewart, K.L., Keleher, J.J., Gewirth, A.A.: Relationship between molecular structure and removal rates during chemical mechanical planarization: comparison of benzotriazole and 1,2,4-triazole. J. Electrochem. Soc. 155(10), D625 (2008)

Arkhipushkin, I.A., Agafonkina, M.O., Kazansky, L.P., Kuznetsov, Y.I., Shikhaliev, K.S.: Characterization of adsorption of 5-carboxy-3-amino-1,2,4-triazole towards copper corrosion prevention in neutral media. Electrochim. Acta 308, 392–399 (2019)

Mínguez-Bacho, I., Courté, M., Shi, C., Fichou, D.: Controlling the nanomorphology of thin conformal Cu2S overlayers grown on Cu2O compact layers and nanowires. Mater. Lett. 159, 47–50 (2015)

Song, G., Liu, S., Xia, C., Song, L., Yang, T., Li, Q.: Synthesis and application of Cu(OH)2 nanowires on nanoporous copper prepared by dealloying Ti50Cu50 and Ti25Zr25Cu50 amorphous alloys. Mater. Charact. 178, 111258 (2021)

Jiang, D., Zhang, Y., Li, X.: Synergistic effects of CuO and Au nanodomains on Cu2O cubes for improving photocatalytic activity and stability. Chin. J. Catal. 40(1), 105–113 (2019)

McIntyre, N.S., Cook, M.G.: X-ray photoelectron studies on some oxides and hydroxides of cobalt, nickel, and copper. Anal. Chem. 47(13), 2208–2213 (1975)

Schnieders, H., Ozcan, O., Grundmeier, G.: Self-localization of mixed organophosphonic acid and organothiol monolayers on patterned Al–Cu substrates. Appl. Surf. Sci. 287, 397–403 (2013)

Oh, S., Shin, C., Kwak, D., Kim, E., Kim, J., Bae, C., Kim, T.: Effect of ionic strength on amorphous carbon during chemical mechanical planarization. Diam. Relat. Mater. 127, 109124 (2022)

Sharma, C., Kaur, M., Choudhary, A., Sharma, S., Paul, S.: Nitrogen doped carbon-silica based Cu(0) nanometal catalyst enriched with well-defined N-moieties: synthesis and application in one-pot synthesis of 1,4-disubstituted-1,2,3-triazoles. Catal. Lett. 150(1), 82–94 (2020)

Liu, G., Xiao, J., Liu, J., Qu, X., Liu, Q., Zeng, H., Yang, X., Xie, L., Zhong, H., Liu, Q., Xu, Z.: In situ probing the self-assembly of 3-hexyl-4-amino-1,2,4-triazole-5-thione on chalcopyrite surfaces. Colloids Surf. A 511, 285–293 (2016)

Park, H., Kim, S.E.: Two-step plasma treatment on copper surface for low-temperature Cu thermo-compression bonding. IEEE Trans. Compon. Packag. Manuf. Technol. 10(2), 332–338 (2020)

Seal, S., Kuiry, S.C., Heinmen, B.: Effect of glycine and hydrogen peroxide on chemical–mechanical planarization of copper. Thin Solid Films 423(2), 243–251 (2003)

Chen, X., Wang, X., Fang, D.: A review on C1s XPS-spectra for some kinds of carbon materials. Fullerenes Nanotubes Carbon Nanostruct. 28(12), 1048–1058 (2020)

Yin, D., Wang, Q., Zhang, S., Tan, B., Yang, F., Wang, R., Sun, X., Liu, M.: Effect of EDTA-based alkaline cleaning solution on TAZ removal in post CMP cleaning of copper interconnection. Mater. Res. Bull. 137, 111202 (2021)

Chen, L., Wen, J., Zhang, P., Yu, B., Chen, C., Ma, T., Lu, X., Kim, S.H., Qian, L.: Nanomanufacturing of silicon surface with a single atomic layer precision via mechanochemical reactions. Nat. Commun. 9(1), 1542 (2018)

Lim, M.S., Perry, S.S., Galloway, H.C., Koeck, D.C.: Microscopic studies of friction and wear at the benzotriazole/copper interface. Tribol. Lett. 14(4), 261–268 (2003)

Tocha, E., Schönherr, H., Vancso, G.J.: Quantitative nanotribology by AFM: a novel universal calibration platform. Langmuir 22(5), 2340–2350 (2006)

Paul, E., Kaufman, F., Brusic, V., Zhang, J., Sun, F., Vacassy, R.: A model of copper CMP. J. Electrochem. Soc. 152(4), G322 (2005)

Lewandowski, B.R., Lytle, D.A., Garno, J.C.: Nanoscale investigation of the impact of pH and orthophosphate on the corrosion of copper surfaces in water. Langmuir 26(18), 14671–14679 (2010)

Xu, G., Liang, H., Zhao, J., Li, Y.: Investigation of copper removal mechanisms during CMP. J. Electrochem. Soc. 151(10), G688 (2004)

Deen, K.M., Mehrjoo, N., Asselin, E.: Thermo-kinetic diagrams: the Cu–H2O–acetate and the Cu-H2O systems. J. Electroanal. Chem. 895, 115467 (2021)

Hu, Y.Z., Gutmann, R.J., Chow, T.P.: Silicon nitride chemical mechanical polishing mechanisms. J. Electrochem. Soc. 145(11), 3919 (1998)

Scales, P.J., Grieser, F., Healy, T.W., White, L.R., Chan, D.Y.C.: Electrokinetics of the silica-solution interface: a flat plate streaming potential study. Langmuir 8(3), 965–974 (1992)

Gong, J., Iwasaki, Y., Osada, Y., Kurihara, K., Hamai, Y.: Friction of gels. 3. Friction on solid surfaces. J. Phys. Chem. B 103(29), 6001–6006 (1999)

Wu, Y., Wei, Q., Cai, M., Zhou, F.: Interfacial friction control. Adv. Mater. Interfaces 2(2), 1400392 (2015)

Gu, B., Mehlhorn, T.L., Liang, L., McCarthy, J.F.: Competitive adsorption, displacement, and transport of organic matter on iron oxide: I. Competitive adsorption. Geochim. Cosmochim. Acta 60(11), 1943–1950 (1996)

Shaikh, J.S., Pawar, R.C., Tarwal, N.L., Patil, D.S., Patil, P.S.: Supercapacitor behavior of CuO–PAA hybrid films: Effect of PAA concentration. J. Alloys Compd. 509(25), 7168–7174 (2011)

Seo, J., Vegi, S.S.R.K.H., Ranaweera, C.K., Baradanahalli, N.K., Han, J.-H., Koli, D., Babu, S.V.: Formation of cobalt-BTA complexes and their removal from various surfaces relevant to cobalt interconnect applications. ECS J. Solid State Sci. Technol. 8(5), 3009–3017 (2019)

Bandyopadhyay, P., Ghosh, A.K.: pH-controlled “off−on−off” switch based on Cu2+-mediated pyrene fluorescence in a PAA−SDS Micelle aggregated supramolecular system. J. Phys. Chem. B 113(41), 13462–13464 (2009)

Pan, Y., Lu, X., Pan, G., Liu, Y., Luo, J.: Performance of sodium dodecyl sulfate in slurry with glycine and hydrogen peroxide for copper-chemical mechanical polishing. J. Electrochem. Soc. 157(12), H1082 (2010)

Acknowledgements

The authors are grateful for the financial support by the National Natural Science Foundation of China (51975488 and 51991373), National Key R&D Program of China (2020YFA0711001), and Fundamental Research Funds for the Central Universities (2682021CG011). Furthermore, we would like to thank the Analytical & Testing Center of Sichuan University for XPS work and we would be grateful to Shuguang Yan for his help of XPS analysis.

Funding

Funding was provided by National Natural Science Foundation of China (Grant nos. 51975488, 51991373), National Key Research and Development Program of China (Grant no. 2020YFA0711001), Fundamental Research Funds for the Central Universities (Grant no. 2682021CG011).

Author information

Authors and Affiliations

Contributions

LJ: Conceptualization, Formal analysis, Funding acquisition, Resources, Writing—original draft, Writing—review and editing. QL: Formal analysis, Investigation, Writing—original draft. YC: Formal analysis, Investigation. YW: Investigation. MS: Investigation. LQ: Funding acquisition, Resources.

Corresponding author

Ethics declarations

Competing interests

The authors have no competing interests as defined by Springer, or other interests that might be perceived to influence the results and/or discussion reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jiang, L., Li, Q., Chen, Y. et al. Polyacrylic Acid as a Lubricant and a Complement to 1,2,4-Triazole for Copper Chemical Mechanical Polishing. Tribol Lett 71, 62 (2023). https://doi.org/10.1007/s11249-023-01732-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11249-023-01732-5