Abstract

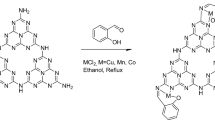

Sulfamic acid functionalized polyvinyl chloride catalysts (PVC-N-SO3H, N = EDA, DTA, TTA, TPA, PHA) were prepared as efficient heterogeneous solid acid catalysts via two-step treatment processes. The prepared catalysts were characterized by X-ray diffraction analysis (XRD), TG thermograms/derivative thermogravimetric (TG/DTG), transmission electron microscope (TEM), elemental mappings and energy-dispersive spectroscopy analyses (STEM-EDS), and FTIR measurements (FTIR) as well as acid–base back-titration. The acetalization of aldehydes (ketones) and alcohols to acetal (ketal) was selected to evaluate the acid catalytic performance of PVC-N-SO3H. The results showed that PVC-EDA-SO3H exhibit excellent activity and reusability due to its highly exposed sulfonic acid sites, high surface acid density (2.28 mmol g−1) for the conversion of aldehydes (ketones) to acetal (ketal). This new solid acid has obvious advantages in reusability and catalytic activity over traditional homogeneous concentrated sulfuric acid and heterogeneous sulfonated resin catalysts. Furthermore, PVC-EDA-SO3H exhibited an excellent catalytic performance in the synthesis of 12 acetals (ketals) as well as a good compatibility in the hydroxyalkylation of phenol with formaldehyde to bisphenol F (BPF) and the esterification reaction of oleic acid and methanol to biodiesel. More importantly, it could also be recovered easily and used repeatedly at least nine times without an obvious decrease in the activity.

Similar content being viewed by others

References

K.S. Kanakikodi, S.R. Churipard, A.B. Halgeri, S.P. Maradur, Sci. Rep. 10, 13103 (2020)

Z. Qi, Q. Wang, C. Liang, J. Yue, S. Liu, S. Ma, X. Wang, Z. Wang, Z. Li, W. Qi, Ind. Eng. Chem. Res. 59(39), 17046 (2020)

L. Cai, D. Meng, S. Zhan, X. Yang, T. Liu, H. Pu, X. Tao, RSC Adv. 5(88), 72146 (2015)

W. Wang, L. Meng, K. Leng, Y. Huang, Polym. Degrad. Stabil. 136, 112 (2017)

F. Lin, Y.H. Chin, J. Catal. 341, 136 (2016)

A.S. Amarasekaraa, B. Wiredua, T.L. Gradya, R.G. Obregona, D. Margetić, Catal. Commun. 124, 6 (2019)

S. Karnjanakoma, P. Maneechakra, C. Samartb, G. Guan, Mol. Catal. 479, 110632 (2019)

Y. He, T.C. Hoff, L. Emdadi, Y. Wu, J. Bouraima, D. Liu, Catal. Sci. Technol. 4, 3064 (2014)

J. Tian, J. Wang, S. Zhao, C. Jiang, X. Zhang, X. Wang, Cellulose 17, 587 (2010)

X. Qian, J. Lei, S.R. Wickramasinghe, Rsc Adv. 3, 24280 (2013)

X. Qi, Y. Lian, L. Yan, R.L. Smith, Catal. Commun. 57, 50 (2014)

C. Huang, J. Wei, P. Qi, R. Wu, Q. Ye, L. Han, Y. Li, Tetrahedron 135, 133340 (2023)

H. Xu, S. Xiong, Y. Zhao, L. Zhu, S. Wang, Sustain. Energ. Fuels. 35, 9961 (2021)

X. Tang, S. Niu, J. Ind, Eng. Chem. 69, 187 (2019)

Z. Fu, H. Wan, Q. Cui, J. Xie, Y. Tang, G. Guan, React. Kinet. Mech. Cat. 104, 313 (2011)

Y. Liu, W. Liu, L. Wang, M. Su, F. Liu, Ind. Eng. Chem. Res. 57, 5207 (2018)

A. Allahresani, B. Taheri, M.A. Nasseri, Res. Chem. Intermed. 44, 6979 (2018)

L. Molinero, J. Esteban, F. Sanchez, F. Garcia-Ochoa, M. Ladero, J. Ind. Eng. Chem. 109, 109 (2022)

G.M. Ziarania, N.L. Ashgari, A. Badiei, J. Mol. Catal. A Chem. 397, 166 (2015)

Z. Hasan, J.-S. Hwang, S.H. Jhung, Catal. Commun. 26, 30 (2012)

M.N. Timofeeva, V.N. Panchenko, Z. Hasan, N.A. Khan, M.S. Mel’gunov, A.A. Abel, M. Matrosova, K.P. Volchod, S.H. Jhung, Appl. Catal. A Gen. 469, 427 (2014)

N.A. Khan, D.K. Mishra, I. Ahmed, J.W. Yoon, J.-S. Hwang, S.H. Jhung, Appl. Catal. A Gen. 452, 34 (2013)

M.N. Timofeeva, Appl. Catal. A Gen. 256, 19 (2003)

M.G. Goestena, J. Juan-Alcañiz, E.V. Ramos-Fernandez, G. Kbss, E. Stavitski, H. Vbekkum, J. Gascon, F. Kapteijn, J. Catal. 281, 177 (2011)

G. Akiyama, R. Matsuda, H. Sato, M. Takata, S. Kitagawa, Adv. Mater. 23, 3294 (2011)

Z. Hasan, S.H. Jhung, Eur. J. Inorg. Chem. 21, 3420 (2014)

R.I. Kureshy, I. Ahmad, K. Pathak, N.H. Khan, S.H.R. Abdi, R.V. Jasra, Catal Commun. 10, 572 (2009)

G. Zhang, X. Zhang, J. Lv, H. Liu, J. Qiu, K.L. Yeung, Catal Today. 193, 221 (2012)

B.M. Reddy, B. Thirupathi, M.K. Patil, J. Mol. Catal. A Chem. 307, 154 (2009)

A.K. Bhattacharya, K.C. Rana, Tetrahedron Lett. 49, 2598 (2008)

S.D. Mitragotri, D.M. Pore, U.V. Desai, P.P. Wadgaonkar, Catal. Commun. 9, 1822 (2008)

M.G.M. D’Oca, R.M. Soares, R.R. de Moura, V.F. de Granjão, Fuel 97, 884 (2012)

W. Gong, B. Wang, Y. Gu, L. Yan, L. Yang, J. Suo, Syn. Commun. 34, 4243 (2011)

J.S. Yadav, P.P. Rao, D. Sreenu, R.S. Rao, V.N. Kumar, K. Nagaiah, A.R. Prasad, Tetrahedron Lett. 46, 7249 (2005)

M.M. Heravi, L. Ranjbar, F. Derikvand, B. Alimadadi, Mol. Divers. 12, 191 (2008)

K. Kumar, S. Pathak, S. Upadhyayula, Renew. Energ. 167, 282 (2021)

Z. Nasresfahani, M.Z. Kassaee, E. Eidi, J. Iran. Chem. Soc. 16, 1819 (2019)

B. Wang, L.M. Yang, J.S. Suo, Fuel 33, 3929 (2003)

B. Wang, L.M. Yang, J.S. Suo, Tetrahedron Lett. 44, 5037 (2003)

S. Rostamnia, E. Doustkhah, J. Mol. Catal. A Chem. 411, 317 (2016)

C. Zhang, Z. Fu, Y.C. Liu, B. Dai, Y. Zou, X. Gong, Y. Wang, X. Deng, H. Wu, Q. Xu, K.R. Steven, D. Yin, Green Chem. 14, 1928 (2012)

Y. Turhan, M. Doǧan, M. Alkan, Polym. Advan. Technol. 32, 65 (2013)

Y. Turhan, M. Doǧan, M. Alkan, Ind. Eng. Chem. Res. 49, 1503 (2010)

M. Parveen, S. Azaz, F. Ahmad, A.M. Malla, M. Alam, Catal. Lett. 146, 1687 (2016)

M. Sheykhan, L. Ma’mani, A. Ebrahimi, A. Heydari, J. Mol. Catal. A Chem. 335, 253 (2011)

K. Niknam, A. Jamali, M. Tajaddod, A. Deris, Chin. J. Catal. 33, 1312 (2012)

S. Tarannum, Z.N. Siddiqui, Mon. Chem. 148, 717 (2017)

Z. Ahmad, F. Al-Sagheer, N.A. Al-Awadi, J. Anal. Appl. Pyrol. 87, 99 (2010)

D.Q. Vu, W.J. Koros, S.J. Miller, J. Membr. Sci. 211, 311 (2003)

M. Mohagheghian, M. Sadeghi, M.P. Chenar, M. Naghsh, Korean J. Chem. Eng. 31, 2041 (2014)

Y. Zou, Y. Li, S. Bourbigot, J. Zhang, Y. Guo, K. Li, X. He, J. Baolati, Polym. Degrad. Stabil. 193, 109741 (2021)

A. Zhu, A. Cai, J. Zhang, H. Jia, J. Wang, J. Appl. Polym. Sci. 108, 2189 (2018)

O.S. Nayal, M.S. Thakur, R. Rana, R. Upadhyay, S.K. Maurya, Chem. Select. 4, 1371 (2019)

A.S. Abel, O.K. Grigorova, A.D. Averin, O.A. Maloshitskaya, G.M. Butov, E.N. Savelyev, B.S. Orlinson, I.A. Novakov, I.P. Beletskaya, Russ. Chem. 65, 1820 (2017)

S.I. Vdovenko, I.I. Gerus, V.P. Kukhar, J. Phys. Org. Chem. 20, 190 (2010)

A.D. Vylder, J. Lauwaert, M.K. Sabbe, M. Reyniers, J.D. Clercq, P.V.D. Voort, J.W. Thybaut, Catal. Today. 334, 96 (2019)

M. Kitamura, Y. Kitaoka, H. Fujita, M. Kunishima, Tetrahedron Lett. 93, 153692 (2022)

E. Walter, P. Schmid, H. Zollinger, Helv. Chim. Acta. 58, 257 (1975)

Acknowledgements

This work was supported by the Science and Technology Research Program of Chongqing Municipal Education Commission (KJQN202201348, KJQN201901307), Major Cultivation Project of Natural Science Foundation of Chongqing University of Arts and Sciences (P2022HH04), the High-level Talents Foundation of Chongqing University of Art and Sciences (R2021SHH03, 2017RCH04), Natural Science Foundation of Chongqing (cstc2019jcyj-msxmX0751), Natural Science Foundation of Chongqing Yongchuan District (2022yc-jckx20008).

Author information

Authors and Affiliations

Contributions

ZW and RZ made with main contribution to all the experiment work; DJ guided the work of the entire experiment and made main contribution to a complication of this paper; DL, TY, PN and LR assisted to accomplish a part of experiment work; KH, QC and LX participated in the guideless of a part of the work.

Corresponding authors

Ethics declarations

Conflict of interest

All authors are aware of the submission and agree to its publication, and have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Z., Zhang, R., Liu, D. et al. Sulfamic acid functionalized PVC: a remarkably efficient heterogeneous reusable catalyst for the acid-catalyzed reactions. Res Chem Intermed 49, 5407–5429 (2023). https://doi.org/10.1007/s11164-023-05121-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11164-023-05121-4