Abstract

Purposes

We previously reported an unexpected phenomenon that shaking stress could cause more protein degradation in freeze-dried monoclonal antibody (mAb) formulations than liquid ones (J Pharm Sci, 2022, 2134). The main purposes of the present study were to investigate the effects of shaking stress on protein degradation and sub-visible particle (SbVP) formation in freeze-dried mAb formulations, and to analyze the factors influencing protein degradation during production and transportation.

Methods

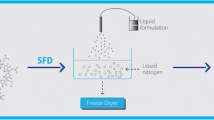

The aggregation behavior of mAb-X formulations during production and transportation was simulated by shaking at a rate of 300 rpm at 25°C for 24 h. The contents of particles and monomers were analyzed by micro-flow imaging, dynamic light scattering, size exclusion chromatography, and ultraviolet − visible (UV–Vis) spectroscopy to compare the protective effects of excipients on the aggregation of mAb-X.

Results

Shaking stress could cause protein degradation in freeze-dried mAb-X formulations, while surfactant, appropriate pH, polyol mannitol, and high protein concentration could impact SbVP generation. Water content had little effect on freeze-dried protein degradation during shaking, as far as the water content was controlled in the acceptable range as recommended by mainstream pharmacopoeias (i.e., less than 3%).

Conclusions

Shaking stress can reduce the physical stability of freeze-dried mAb formulations, and the addition of surfactants, polyol mannitol, and a high protein concentration have protective effects against the degradation of model mAb formulations induced by shaking stress. The experimental results provide new insight for the development of freeze-dried mAb formulations.

Similar content being viewed by others

Data Availability

The data will be available upon request.

Abbreviations

- DLS:

-

Dynamic light scattering

- HES:

-

Hydroxyethyl starch

- His-HCl:

-

Histidine-HCl

- kD :

-

Diffusion interaction parameter

- mAb:

-

Monoclonal antibody

- MFI:

-

Micro-flow imaging

- NMPA:

-

National Medicinal Products Administration of China

- PDI:

-

Distribution coefficient

- PES:

-

Polyethersulfone

- PS:

-

Polysorbate

- SbVP:

-

Sub-visible particle

- SE − HPLC:

-

Size exclusion high-performance liquid chromatography

- UV − Vis:

-

Ultraviolet − visible spectroscopy

References

Carter PJ, Lazar GA. Next generation antibody drugs: pursuit of the “high-hanging fruit.” Nat Rev Drug Discov. 2018;17(3):197–223.

Wang Z, Wang G, Lu H, Li H, Tang M, Tong A. Development of therapeutic antibodies for the treatment of diseases. Mol Biomed. 2022;3(1):35.

Kollár É, Balázs B, Tari T, Siró I. Development challenges of high concentration monoclonal antibody formulations. Drug Discov Today Technol. 2020;37:31–40.

Krämer I, Thiesen J, Astier A. Formulation and administration of biological medicinal products. Pharm Res. 2020;37(8):159.

Kozlowski S, Swann P. Current and future issues in the manufacturing and development of monoclonal antibodies. Adv Drug Deliv Rev. 2006;58(5–6):707–22.

Akbarian M, Chen SH. Instability challenges and stabilization strategies of pharmaceutical proteins. Pharmaceutics. 2022;14(11):2533.

Movafaghi S, Daniels AL, Kelly MD, Witeof AE, Calderon CP, Randolph TW, Goodwin AP. Hydrogel coatings on container surfaces reduce protein aggregation caused by mechanical stress and cavitation. ACS Appl Bio Mater. 2021;4(9):6946–53.

Movafaghi S, Wu H, Francino Urdániz IM, Bull DS, Kelly MD, Randolph TW, Goodwin AP. The effect of container surface passivation on aggregation of intravenous immunoglobulin induced by mechanical shock. Biotechnol J. 2020;15(9):e2000096.

van Beers MM, Sauerborn M, Gilli F, Brinks V, Schellekens H, Jiskoot W. Oxidized and aggregated recombinant human interferon beta is immunogenic in human interferon beta transgenic mice. Pharm Res. 2011;28(10):2393–402.

Rosenberg AS. Effects of protein aggregates: an immunologic perspective. AAPS J. 2006;8(3):E501–7.

De Groot AS, Scott DW. Immunogenicity of protein therapeutics. Trends Immunol. 2007;28(11):482–90.

Swanson MD, Rios S, Mittal S, Soder G, Jawa V. Immunogenicity risk assessment of spontaneously occurring therapeutic monoclonal antibody aggregates. Front Immunol. 2022;27(13):915412.

Butreddy A, Janga KY, Ajjarapu S, Sarabu S, Dudhipala N. Instability of therapeutic proteins - an overview of stresses, stabilization mechanisms and analytical techniques involved in lyophilized proteins. Int J Biol Macromol. 2021;15(167):309–25.

Izutsu KI. Applications of freezing and freeze-drying in pharmaceutical formulations. Adv Exp Med Biol. 2018;1081:371–83.

Nejadnik MR, Randolph TW, Volkin DB, Schöneich C, Carpenter JF, Crommelin DJA, Jiskoot W. Postproduction handling and administration of protein pharmaceuticals and potential instability issues. J Pharm Sci. 2018;107(8):2013–9.

Ueda T, Nakamura K, Abe Y, Carpenter JF. Effects of product handling parameters on particle levels in a commercial factor VIII product: impacts and mitigation. J Pharm Sci. 2019;108(1):775–86.

Rathore N, Rajan RS. Current perspectives on stability of protein drug products during formulation, fill and finish operations. Biotechnol Prog. 2008;24(3):504–14.

Li J, Krause ME, Chen X, Cheng Y, Dai W, Hill JJ, Huang M, Jordan S, LaCasse D, Narhi L, Shalaev E, Shieh IC, Thomas JC, Tu R, Zheng S, Zhu L. Interfacial stress in the development of biologics: fundamental understanding, current practice, and future perspective. AAPS J. 2019;21(3):44.

Telikepalli S, Kumru OS, Kim JH, Joshi SB, O’Berry KB, Blake-Haskins AW, Perkins MD, Middaugh CR, Volkin DB. Characterization of the physical stability of a lyophilized IgG1 mAb after accelerated shipping-like stress. J Pharm Sci. 2015;104(2):495–507.

Fang WJ, Ingle RG, Liu JW, Ge XZ, Wang H. Freeze-dried monoclonal antibody formulations are unexpectedly more prone to degradation than liquid formulations under shaking stress. J Pharm Sci. 2022;111(7):2134–8.

Le Basle Y, Chennell P, Tokhadze N, Astier A, Sautou V. Physicochemical stability of monoclonal antibodies: a review. J Pharm Sci. 2020;109(1):169–90.

Zbacnik TJ, Holcomb RE, Katayama DS, Murphy BM, Payne RW, Coccaro RC, Evans GJ, Matsuura JE, Henry CS, Manning MC. Role of buffers in protein formulations. J Pharm Sci. 2017;106(3):713–33.

Pandey LM. Physicochemical factors of bioprocessing impact the stability of therapeutic proteins. Biotechnol Adv. 2022;55:107909.

Rao VA, Kim JJ, Patel DS, Rains K, Estoll CR. A comprehensive scientific survey of excipients used in currently marketed, therapeutic biological drug products. Pharm Res. 2020;37(10):200.

Holm TP, Meng-Lund H, Rantanen J, Jorgensen L, Grohganz H. Screening of novel excipients for freeze-dried protein formulations. Eur J Pharm Biopharm. 2021;160:55–64.

Koepf E, Eisele S, Schroeder R, Brezesinski G, Friess W. Notorious but not understood: how liquid-air interfacial stress triggers protein aggregation. Int J Pharm. 2018;537(1–2):202–12.

Vaclaw C, Merritt K, Pringle V, Whitaker N, Gokhale M, Carvalho T, Pan D, Liu Z, Bindra D, Khossravi M, Bolgar M, Volkin DB, Ogunyankin MO, Dhar P. Impact of polysorbate 80 grade on the interfacial properties and interfacial stress induced subvisible particle formation in monoclonal antibodies. J Pharm Sci. 2021;110(2):746–59.

Kiese S, Papppenberger A, Friess W, Mahler HC. Shaken, not stirred: mechanical stress testing of an IgG1 antibody. J Pharm Sci. 2008;97(10):4347–66.

Usami A, Ohtsu A, Takahama S, Fujii T. The effect of pH, hydrogen peroxide and temperature on the stability of human monoclonal antibody. J Pharm Biomed Anal. 1996;14(8–10):1133–40.

Zheng S, Qiu D, Adams M, Li J, Mantri RV, Gandhi R. Investigating the degradation behaviors of a therapeutic monoclonal antibody associated with pH and buffer species. AAPS PharmSciTech. 2017;18(1):42–8.

Mahler HC, Friess W, Grauschopf U, Kiese S. Protein aggregation: pathways, induction factors and analysis. J Pharm Sci. 2009;98(9):2909–34.

Sudrik CM, Cloutier T, Mody N, Sathish HA, Trout BL. Understanding the role of preferential exclusion of sugars and polyols from native state IgG1 monoclonal antibodies and its effect on aggregation and reversible self-association. Pharm Res. 2019;36(8):109.

Kamerzell TJ, Esfandiary R, Joshi SB, Middaugh CR, Volkin DB. Protein-excipient interactions: mechanisms and biophysical characterization applied to protein formulation development. Adv Drug Deliv Rev. 2011;63(13):1118–59.

Wang W. Protein aggregation and its inhibition in biopharmaceutics. Int J Pharm. 2005;289(1–2):1–30.

Wang W, Nema S, Teagarden D. Protein aggregation–pathways and influencing factors. Int J Pharm. 2010;390(2):89–99.

Hauptmann A, Podgoršek K, Kuzman D, Srčič S, Hoelzl G, Loerting T. Impact of buffer, protein concentration and sucrose addition on the aggregation and particle formation during freezing and thawing. Pharm Res. 2018;35(5):101.

Zhang C, Bye JW, Lui LH, Zhang H, Hales J, Brocchini S, Curtis RA, Dalby PA. Enhanced thermal stability and reduced aggregation in an antibody Fab fragment at elevated concentrations. Mol Pharm. 2023;20(5):2650–61.

Schersch K, Betz O, Garidel P, Muehlau S, Bassarab S, Winter G. Systematic investigation of the effect of lyophilizate collapse on pharmaceutically relevant proteins, part 2: stability during storage at elevated temperatures. J Pharm Sci. 2012;101(7):2288–306.

Acknowledgements

This study was supported by the National Nature Science Foundation of China (Grant No. 81741144) and the Huadong Medicine Joint Funds of the Zhejiang Provincial Natural Science Foundation of China (Grant No. LHDMZ24H300003). We thank Ms. Haihong Hu for laboratory management.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare no conflict of interest, financial or otherwise.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jin, MJ., Ge, XZ., Huang, Q. et al. The Effects of Excipients on Freeze-dried Monoclonal Antibody Formulation Degradation and Sub-Visible Particle Formation during Shaking. Pharm Res 41, 321–334 (2024). https://doi.org/10.1007/s11095-024-03657-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11095-024-03657-7