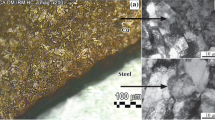

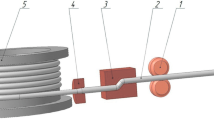

The change of the microstructure of a bimetallic wire during one pass of ECAP-drawing at room temperature is considered. It is shown that both layers of the bimetallic wire deform nonuniformly. The copper shell with an initial grain size of 50 μm is deformed to 30 μm on average. The steel core is characterized by different grain sizes in cross-section, the initial grain size being 18. The grain size is 14 μm in the surface layers of the core and about 17 μm in the axial zone. After drawing, the grains are elongated due to tensile stresses.

Similar content being viewed by others

References

M. A. Polyakova and A. E. Gulin, “Developing a method for continuous deformation nanostructurization of a wire combining several operations,” Zh. Sibir. Federal. Univ. Tekhn. Tekhnol., 5, No. 6, 624–630 (2012).

H. Dyja, L. Lesik, A. Milenin, and S. Mroz, “Theoretical and experimental analysis of stress and temperature distributions during the process of rolling bimetallic rods,” J. Mater. Process. Technol., 125–126, 731–735 (2002).

A. V. Zinov’ev, A. N. Koshmin, and A. Ya. Chasnikov, “Effect of continuous extrusion parameters on alloy M1 round section bar microstructure and mechanical property formation,” Metallurgist, 63, No. 3-4, 422–428 (2019).

M. Polyakova, A. Gulin, and D. Constantinov, “Investigation of microstructure and mechanical properties of carbon steel wire after continuous method of deformational nanostructuring,” Appl. Mech. Mater., 436, 114–120 (2013).

M. V. Chukin and D. G. Emaleeva, “Influence of heat treatment on the evolution of the structure and properties of a steel wire during ECAP–drawing,” Vestn. MGTU im. G. I. Nosova, No. 2, 70–71 (2008).

P. Eslami and A. Karimi Taheri, “An investigation on diffusion bonding of aluminum to copper using equal channel angular extrusion process,” Materials Letters, 65, 1862–1864 (2011).

M. V. Chukin, A. G. Korchunov, E. M. Golubchik, M. A. Polyakova, and A. E. Gulin, “Analyzing the method of continuous deformation nanostructurization of a wire using the concept of technology inheritance,” Vestn. MGTU im. G. I. Nosova, No. 4, 61–65 (2012).

K. Y. Rhee, W. Y. Han, H. J. Park, and S. S. Kim, “Fabrication of aluminum/copper clad composite using hot hydro static extrusion process and its material characteristics,” Mater. Sci. Eng., A, 384, 70–76 (2004).

G. Raab, R. Valiev, Т. Lowe, and Y. Zhu, “Continuous processing of ultrafine grained A1 by ECAP-Conform,” Mater. Sci. Eng., 382, 30–34 (2004).

I. Volokitina, A. Volokitin, A. Naizabekov, S. Lezhnev, and Y. Panin, “Deformation of bimetallic wire during combined ECAP-drawing,” in: Proc. 29th Int. Conf. on Metallurgy and Materials — METAL 2020, Brno, Czech Republic, May 20–22 (2020), pp. 183–189.

A. Naizabekov, S. Lezhnev, A. Volokitin, E. Panin, and M. Knapinski, “Development and research of combined process of equal channel angular pressing–drawing,” J. Chem. Technol. Metallurg., 52, 172–179 (2017).

A. Naizabekov, I. Volokitina, E. Panin, A. Volokitin, S. Lezhnev, T. Garstka, M. Knapinski, M. Latypova, and D. Zhumagaliev, “Computer simulation of combined deformation method ‘ECA-pressing–drawing’,” J. Chem. Technol. Metallurg., 55, 499–506 (2020).

A. Naizabekov, I. Volokitina, A. Volokitin, and E. Panin, “Structure and mechanical properties of steel in the process ‘pressing–drawing’,” J. Mater. Eng. Perform., 28, 1762–1771 (2019).

I. E. Volokitina, A. V. Volokitin, A. B. Naizabekov, and S. N. Lezhnev, “Change in structure and mechanical properties of grade А0 aluminum during implementation of a combined method of ECAE–drawing deformation,” Metallurgist, 63, 9–10, 978–983 (2020).

I. E. Volokitina and A. V. Volokitin, “Evolution of the microstructure and mechanical properties of copper during the pressing–drawing process,” Physics of Metals and Metallography, 119, 917–921 (2018).

S. N. Lezhnev, I. E. Volokitina, and A. V. Volokitin, “Evolution of microstructure and mechanical properties of steel during pressing–drawing,” Physics of Metals and Metallography, 118, 1167–1170 (2017).

Acknowledgements

The study was carried out in line with the AP08052852 Project “Improving the Strength and Service Properties of Bimetallic Wires and Bars by Applying Severe Plastic Deformation to Produce Ultrafine-grained Structure” within the framework of the Program “Grant Financing of Research or Development Projects for Young Scientists in 2020–2022.”

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Metallurg, Vol. 65, No. 7, pp. 69–74, July, 2021. Russian DOI: 10.52351/00260827_2021_07_69.

Rights and permissions

About this article

Cite this article

Volokitina, I.E., Naizabekov, A.B., Panin, E.A. et al. Effect of Ecap-Drawing on the Microstructure of a Bimetallic Wire. Metallurgist 65, 769–774 (2021). https://doi.org/10.1007/s11015-021-01214-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11015-021-01214-w