Abstract

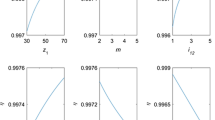

Transmission error (TE) as an important indicator in high performance gear pairs and accurate prediction of the TE is an important scientific issue. On this research, the relationship and connections between TE and tooth pitch error (TPE) for face-hobbed hypoid gears (FH-HG) are researched. Firstly, the kinematics of FH-HG based on the cutter-plate, machine and gear blanks are elucidated and the mathematical tooth surface of considering PE and the finite element model (FEM) are established. After, the effect of PE on the TE is explored and the relationship between PE and TE is analyzed by comparison the curves of the TPE, TPE and coincidence (TPE-C) with the calculating TE. Then, the curve segment idea of TE of pinion and gear is adopted to calculate the TPE of gear pair, respectively. The analytical prediction formulas of TE and TPE is proposed. Finally, an experiment example verifies the efficient of this method.

Similar content being viewed by others

References

Liang C, Song C, Zhu C et al (2023) Modelling method, simulation and experimental verification of hypoid gear involved tooth surface deviation under manufacturing process. Mech Mach Theory 182:105248

Wildhaber E (1945) Basic relationship of hypoid gears. Am Mach 90(20):24–30

Wildhaber E (1946) Basic relationship of hypoid gears-II. Am Mach 90(3):108–111

Wildhaber E (1946) Basic relationship of hypoid gears-III. Am Mach 90(5):131–134

Stadtfeld H (1991) Duplex method of manufacturing a generated spiral-toothed bevel gear of a bevel-gear or hypoid-gear drive. U.S. Patent 5000632

Vijayakar S (1991) A combined surface integral and finite contact problem element solution for a three-dimensional. Int J Numer Meth Eng 31:525–545

Fan Q (2006) Computerized model and simulation of spiral bevel and hypoid gears manufactured gleason face hobbing process. J Mech Des 128(6):1315–1327

Fan Q (2007) Enhanced algorithms of contact simulation for hypoid gear drives produced by face-milling and face-hobbed process. J Mech Des 129(1):31–37

Fong ZH (2000) Mathematical model of universal hypoid generator with supplemental kinematic flank correction motions. J Mech Des 122(1):136–142

Shih YP, Fong ZH, Lin CY (2007) Mathematical model for a universal face hobbing hypoid gear generator. J Mech Des 129(1):38–47

Gonzalez-Perez I, Fuentes A, Ruiz-Orzaez R (2015) An approach for determination of basic machine-tool settings from blank data in face-hobbed and face-milled hypoid gears. J Mech Des 137(9):093303

Gonzalez-Perez I, Fuentes A (2017) Analytical determination of basic machine-tool settings for generation of spiral bevel gears and compensation of errors of alignment in the cyclo-palloid system. Int J Mech Sci 120:91–104

Han D, Tang J (2018) Six sigma robust multi-objective optimization modification of machine-tool settings for hypoid gears by considering both geometric and physical performances. Appl Soft Comput 70:550–561

Han D et al (2017) Nonlinearity analysis based algorithm for identifying machine settings in the tooth flank topography correction for hypoid gears. Mech Mach Theory 113:1–21

Chen Z, Zhou Z, Zhai W, Wang K (2020) Improved analytical calculation model of spur gear mesh excitations with tooth profile deviations. Mech Mach Theory 149:103838

Xiong C, Chen S (2020) Experimental study of the effect of assembly error on the lightly loaded TE of spur gear with crown modification. J Low Freq Noise Vib Active Control 39(4):1039–1051

Huang D, Wang Z, Kubo A (2020) Hypoid gear integrated wear model and experimental verification design and test. Int J Mech Sci 166:105228

Hu Q, Chen X, Xu Z, Mai Q, Zhu C (2020) Study on kinematic characteristics of planetary multistage face gears transmission. Proc Inst Mech Eng Part D J Automob Eng 234(2–3):572–585

Liang C, Song C, Zhu C et al (2020) Investigation of the effects with linear, circular and polynomial blades on contact characteristics for face-hobbed hypoid gears. Mech Mach Theory 146:1–14

Liu S, Song C, Zhu C et al (2019) Investigation on the influence of work holding equipment errors on contact characteristics of face-hobbed hypoid gear. Mech Mach Theory 138:95–111

Liang C, Song C, Zhu C et al (2020) Investigation of tool errors and their influences on tooth surface topography for face-hobbed hypoid gears. J Mech Des 142:1–11

Liang C, Song C, Zhu C et al (2020) Effects of machine-tool parameters on geometry and contact pattern for face hobbed hypoid gears. Meccanica 57:1429–1442

Funding

This study was funded the National Natural Science Foundation of China (52175040, 52205051) and Project No. 2022CDJKYJH050 supported by the Fundamental Research Funds for the Central Universities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Xue, C., Liang, C., Song, C. et al. An analytical prediction methodology of the correlation between transmission error and tooth pitch error for face-hobbed hypoid gears. Meccanica 59, 217–233 (2024). https://doi.org/10.1007/s11012-023-01749-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11012-023-01749-z