Abstract

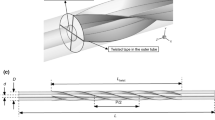

In this paper, the effect of different channel spacing in spiral heat exchanger filled with Cu–ZnO–water hybrid nanofluid was investigated to find the optimum thermal–hydraulic performance. The hot water flow enters into the test section from central aperture of heat exchanger, and the cold hybrid nanofluid flow enters into the test section from the outer aperture of the heat exchanger. The effects of different flow velocities, nanoparticles φ and channel spacing values have been analyzed. Results have been presented on Nusselt number, outlet temperature, pressure drop and PEC. According to the obtained results, channel spacing decrease in constant flow velocity values is more effective than volume fraction increase on outlet temperature improvement. Also, an increase in inlet flow velocity leads to lower heat transfer between cold and hot channels, but the growth of volume fraction can improve the thermal efficiency of the heat exchanger at high velocities. On the other hand, the reduction in channel spacing leads to more pressure drop penalty. Especially for the hot water flow, this behavior reduces the hydraulic performance of heat exchanger. The less the channel spacing, the more the pressure drop. The highest average Nusselt number occurs at a velocity of 0.45 (m s−1) and φ = 4% at a channel spacing of 35 mm. The maximum value of the pressure drop occurs at b = 2.5–5 mm. Besides considering the PEC value, 2% volume fraction is recommended for the spiral heat exchanger.

Similar content being viewed by others

Abbreviations

- A s :

-

Inside heat transfer surface (m2)

- b :

-

Channel spacing (mm)

- c r :

-

Curvature ratio

- c p :

-

Specific heat capacity (J kg−1 K−1)

- D h :

-

Hydraulic diameter (mm)

- h :

-

Convective heat transfer coefficient (W m−2 K−1)

- H :

-

Width of the plate (mm)

- k :

-

Thermal conductivity (W m−1 K−1)

- L m :

-

Mean plate length (mm)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- n :

-

Number of turns

- Nu:

-

Nusselt number

- P :

-

Pitch of the spiral plate (mm)

- P :

-

Pressure (Pa)

- \(\dot{q}\) :

-

Heat transfer rate (J s−1)

- R :

-

Spiral radius (mm)

- Re:

-

Reynolds number

- t :

-

Plate thickness (mm)

- T :

-

Temperature (K)

- V m :

-

Fluid mean velocity (m s−1)

- φ 1, φ 2, φ :

-

Hybrid nanofluid concentration (%)

- \(\mu\) :

-

Dynamic viscosity (Pa s)

- \(\rho\) :

-

Density (kg m−3)

- 1:

-

First internal spiral curve

- 2:

-

Second internal spiral curve

- c:

-

Cold

- f:

-

Fluid

- h:

-

Hot

- in:

-

Inlet

- LMTD:

-

Logarithmic mean temperature difference

- nf:

-

Hybrid nanofluid

- out:

-

Outlet

- p1, p2, p:

-

Nanoparticle

- w:

-

Water

References

Ji JD, Ge PQ, Bi WB. Numerical investigation of flow and heat transfer performances of horizontal spiral-coil pipes. J Hydrodyn. 2016;28(4):576–84.

Patil RH. Experimental studies on heat transfer to Newtonian fluids through spiral coils. Exp Therm Fluid Sci. 2017;84:144–55.

Barbosa JR Jr, Sigwalt RA. Air-side heat transfer and pressure drop in spiral wire-on-tube condensers. Int J Refrig. 2012;35(4):939–51.

Bhavsar JJ, Matawala VK, Dixit S. Design and experimental analysis of spiral tube heat exchanger. Int J Mech Prod Eng. 2013;1(1):37–42.

Jamal-Abad MT, Zamzamian A, Dehghan M. Experimental studies on the heat transfer and pressure drop characteristics of Cu–water and Al–water nanofluids in a spiral coil. Exp Therm Fluid Sci. 2013;47:206–12.

Naphon P, Wiriyasart S, Arisariyawong T, Nualboonrueng T. Magnetic field effect on the nanofluids convective heat transfer and pressure drop in the spirally coiled tubes. Int J Heat Mass Transf. 2017;110:739–45.

Khoshvaght-Aliabadi M, Khaligh SF, Tavassoli Z. An investigation of heat transfer in heat exchange devices with spirally-coiled twisted-ducts using nanofluid. Appl Therm Eng. 2018;143:358–75.

Kurnia JC, Sasmito AP, Akhtar S, Shamim T, Mujumdar AS. Numerical investigation of heat transfer performance of various coiled square tubes for heat exchanger application. Energy Procedia. 2015;75:3168–73.

Chao D, Hai-tao H, Guoliang D. Heat transfer and pressure drop characteristics of two-phase propane flow in shell side of LNG spiral wound heat exchanger. Energy Procedia. 2017;142:3857–62.

Wang S, Jian G, Xiao J, Wen J, Zhang Z, Tu J. Fluid-thermal-structural analysis and structural optimization of spiral-wound heat exchanger. Int Commun Heat Mass Transf. 2018;95:42–52.

Miyara A. Thermal performance and pressure drop of spiral-tube ground heat exchangers for ground-source heat pump. Appl Therm Eng. 2015;90:630–7.

Yang W, Lu P, Chen Y. Laboratory investigations of the thermal performance of an energy pile with spiral coil ground heat exchanger. Energy Build. 2016;128:491–502.

Li H, Nagano K, Lai Y. A new model and solutions for a spiral heat exchanger and its experimental validation. Int J Heat Mass Transf. 2012;55(15–16):4404–14.

Guha P, Unde V. Mathematical modeling of spiral heat exchanger. Int J Eng Res. 2014;3(4):226–9.

Nguyen DK, San JY. Effect of solid heat conduction on heat transfer performance of a spiral heat exchanger. Appl Therm Eng. 2014;30(1):e10.

Nguyen DK, San JY. Decrement in heat transfer effectiveness due to solid heat conduction for a counter-current spiral heat exchanger. Appl Therm Eng. 2016;103:821–31.

Khorshidi J, Heidari S. Design and construction of a spiral heat exchanger. Adv Chem Eng Sci. 2016;6(02):201.

Bahiraei M, Ahmadi AA. Thermohydraulic performance analysis of a spiral heat exchanger operated with water–alumina nanofluid: effects of geometry and adding nanoparticles. Energy Convers Manag. 2018;170:62–72.

Manjo V, Gopal P, Senthilkumar T. Heat transfer enhancement by using nanofluid in spiral plate heat exchanger. Int J Eng Res Technol. 2016;5(06):2278-0181.

Bidabadi M, Sadaghiani AK, Azad AV. Spiral heat exchanger optimization using genetic algorithm. Sci Iran Trans B Mech Eng. 2013;20(5):1445.

Devois JF, Durastanti JF, Martin B. Numerical modelling of the spiral plate heat exchanger. J Therm Anal. 1995;44(2):305–12.

Akbari OA, Afrouzi HH, Marzban A, Toghraie D, Malekzade H, Arabpour A. Investigation of volume fraction of nanoparticles effect and aspect ratio of the twisted tape in the tube. J Therm Anal Calorim. 2017;129(3):1911–22.

Al-Rashed AA, Sheikhzadeh GA, Aghaei A, Monfared F, Shahsavar A, Afrand M. Effect of a porous medium on flow and mixed convection heat transfer of nanofluids with variable properties in a trapezoidal enclosure. J Therm Anal Calorim. 2020;139(1):741–54.

Zheng Y, Yang H, Mazaheri H, Aghaei A, Mokhtari N, Afrand M. An investigation on the influence of the shape of the vortex generator on fluid flow and turbulent heat transfer of hybrid nanofluid in a channel. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09415-2.

Khodabandeh E, Boushehri R, Akbari OA, Akbari S, Toghraie D. Numerical investigation of heat and mass transfer of water–silver nanofluid in a spiral heat exchanger using a two-phase mixture method. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09533-x.

Abbas N, Awan MB, Amer M, Ammar SM, Sajjad U, Ali HM, Zahra N, Hussain M, Badshah MA, Jafry AT. Applications of nanofluids in photovoltaic thermal systems: a review of recent advances. Phys A Stat Mech Appl. 2019;536:122513.

Ali HM. Applications of combined/hybrid use of heat pipe and phase change materials in energy storage and cooling systems: a recent review. J Energy Storage. 2019;26:100986.

Ambreen T, Saleem A, Ali HM, Shehzad SA, Park CW. Performance analysis of hybrid nanofluid in a heat sink equipped with sharp and streamlined micro pin-fins. Powder Technol. 2019;355:552–63.

Babar H, Ali HM. Towards hybrid nanofluids: preparation, thermophysical properties, applications, and challenges. J Mol Liquids. 2019;281:598–633.

Babar H, Ali HM. Airfoil shaped pin-fin heat sink: potential evaluation of ferric oxide and titania nanofluids. Energy Convers Manag. 2019;202:112194.

Hassan A, Wahab A, Qasim MA, Janjua MM, Ali MA, Ali HM, Jadoon TR, Ali E, Raza A, Javaid N. Thermal management and uniform temperature regulation of photovoltaic modules using hybrid phase change materials-nanofluids system. Renew Energy. 2020;145:282–93.

Javed S, Ali HM, Babar H, Khan MS, Janjua MM, Bashir MA. Internal convective heat transfer of nanofluids in different flow regimes: a comprehensive review. Phys A Stat Mech Appl. 2020;538:122783.

Sajid MU, Ali HM. Thermal conductivity of hybrid nanofluids: a critical review. Int J Heat Mass Transf. 2018;126:211–34.

Sajid MU, Ali HM. Recent advances in application of nanofluids in heat transfer devices: a critical review. Renew Sustain Energy Rev. 2019;103:556–92.

Shah TR, Ali HM. Applications of hybrid nanofluids in solar energy, practical limitations and challenges: a critical review. Solar Energy. 2019;183:173–203.

Tian Z, Shahsavar A, Al-Rashed AAAA, Rostami S. Numerical simulation of nanofluid convective heat transfer in an oblique cavity with conductive edges equipped with a constant temperature heat source: Entropy production analysis. Comput Math Appl. 2019. https://doi.org/10.1016/j.camwa.2019.12.007.

Niknejadi MR, Afrand M, Karimipour A, Shahsavar A, Isfahani AHM. Experimental investigation of the hydrothermal aspects of water–Fe3O4 nanofluid inside a twisted tube. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09271-0.

Ma Y, Shahsavar A, Talebizadehsardari P. Two-phase mixture simulation of the effect of fin arrangement on first and second law performance of a bifurcation microchannels heatsink operated with biologically prepared water–Ag nanofluid. Int Commun Heat Mass Transf. 2020;114:104554.

Alsarraf J, Shahsavar A, Khaki M, Ranjbarzadeh R, Karimipour A, Afrand M. Numerical investigation on the effect of four constant temperature pipes on natural cooling of electronic heat sink by nanofluids: a multifunctional optimization. Adv Powder Technol. 2020;31:416–32.

Al-Rashed AAAA, Sheikhzadeh GA, Aghaei A, Monfared F, Shahsavar A, Afrand M. Effect of a porous medium on flow and mixed convection heat transfer of nanofluids with variable properties in a trapezoidal enclosure. J Therm Anal Calorim. 2020;139:741–54.

Chen Z, Shahsavar A, Alrashed AAAA, Afrand M. The impact of sonication and stirring durations on the thermal conductivity of alumina-liquid paraffin nanofluid: an experimental assessment. Powder Technol. 2020;360:1134–42.

Liu W, Shahsavar A, Barzinjy A, Al-Rashed AAAA, Afrand M. Natural convection and entropy generation of a nanofluid in two connected inclined triangular enclosures under magnetic field effects. Int Commun Heat Mass Transf. 2019;108:104309.

Shahsavar A, Baseri MH, Al-Rashed AAAA, Afrand M. Numerical investigation of forced convection heat transfer and flow irreversibility in a novel heatsink with helical microchannels working with biologically synthesized water-silver nano-fluid. Int Commun Heat Mass Transf. 2019;108:104324.

Alsarraf J, Rahmani R, Shahsavar A, Afrand M, Wongwises S. Effect of magnetic field on laminar forced convective heat transfer of MWCNT–Fe3O4/water hybrid nanofluid in a heated tube. J Therm Anal Calorim. 2019;137:1809–25.

Liu WI, Al-Rashed AAAA, Alsagri AS, Mahmoudi B, Shahsavar A, Afrand M. Laminar forced convection performance of non-Newtonian water-CNT/Fe3O4 nano-fluid inside a minichannel hairpin heat exchanger: effect of inlet temperature. Powder Technol. 2019;354:247–58.

Al-Rashed AAAA, Shahsavar A, Akbari M, Toghraie D, Akbari M, Afrand M. Finite volume simulation of mixed convection in an inclined lid-driven cavity filled with nanofluids: effects of a hot elliptical centric cylinder, cavity angle and volume fraction of nanoparticles. Phys A. 2019;527:121122.

Shahsavar A, Bagherzadeh SA, Mahmoudi B, Hajizadeh A, Afrand M, Nguyen TK. Robust weighted least squares support vector regression algorithm to estimate the nanofluid thermal properties of water/graphene oxide-silicon carbide mixture. Physica A. 2019;525:1418–28.

Karimi A, Al-Rashed AAAA, Afrand M, Mahian O, Wongwises S, Shahsavar A. The effects of tape insert material on the flow and heat transfer in a nanofluid-based double tube heat exchanger: Two-phase mixture model. Int J Mech Sci. 2019;156:397–409.

Liu WI, Alsarraf J, Shahsavar A, Rostamzadeh M, Afrand M, Nguyen TK. Impact of oscillating magnetic field on the thermal-conductivity of water–Fe3O4 and water–Fe3O4/CNT ferro-fluids: experimental study. J Magn Magn Mater. 2019;484:258–65.

Alsarraf J, Moradikazerouni A, Shahsavar A, Afrand M, Salehipour H, Tran MD. Hydrothermal analysis of turbulent boehmite alumina nanofluid flow with different nanoparticle shapes in a minichannel heat exchanger using two-phase mixture model. Physica A. 2019;520:275–88.

Ma J, Shahsavar A, Al-Rashed AAAA, Karimipour A, Yarmand H, Rostami S. Viscosity, cloud point, freezing point and flash point of zinc oxide/SAE50 nanolubricant. J Mol Liq. 2020;298:112045.

Liu X, Mohammed HI, Ashkezari AZ, Shahsavar A, Hussein AK, Rostami S. An experimental investigation on the rheological behavior of nanofluids made by suspending multi-walled carbon nanotubes in liquid paraffin. J Mol Liq. 2020;300:112269.

Ma Y, Shahsavar A, Moradi I, Rostami S, Moradikazerouni A, Yarmand H, Zulkifli NWBM. Using finite volume method for simulating the natural convective heat transfer of nano-fluid flow inside an inclined enclosure with conductive walls in the presence of a constant temperature heat source. Physica A. 2019. https://doi.org/10.1016/j.physa.2019.123035.

Monfared M, Shahsavar A, Bahrebar MR. Second law analysis of turbulent convection flow of boehmite alumina nanofluid inside a double-pipe heat exchanger considering various shapes for nanoparticle. J Therm Anal Calorim. 2019;135:1521–32.

Shahsavar A, Rahimi Z, Salehipour H. Nanoparticle shape effects on thermal-hydraulic performance of boehmite alumina nanofluid in a horizontal double-pipe minichannel heat exchanger. Heat Mass Transf. 2019;55:1741–51.

Pak BC, Cho YI. Hydrodynamic and heat transfer study of dispersed fluids with submicron metallic oxide particles. Exp Heat Transf Int J. 1998;11(2):151–70.

Xuan Y, Roetzel W. Conceptions for heat transfer correlation of nanofluids. Int J Heat Mass Transf. 2000;43(19):3701–7.

Maxwell JC. A treatise on electricity and magnetism, vol. 1. Oxford: Clarendon press; 1881.

Brinkman HC. The viscosity of concentrated suspensions and solution. J Chem Phys. 1952;20(4):571–81.

Parsaiemehr M, Pourfattah F, Akbari OA, Toghraie D, Sheikhzadeh G. Turbulent flow and heat transfer of water/Al2O3 nanofluid inside a rectangular ribbed channel. Physica E. 2018;96:73–84.

Naphon P. Experimental investigation the nanofluids heat transfer characteristics in horizontal spirally coiled tubes. Int J Heat Mass Transf. 2016;93:293–300.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rostami, S., Aghaei, A., Hassani Joshaghani, A. et al. Thermal–hydraulic efficiency management of spiral heat exchanger filled with Cu–ZnO/water hybrid nanofluid. J Therm Anal Calorim 143, 1569–1582 (2021). https://doi.org/10.1007/s10973-020-09721-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09721-9