Abstract

The nanoreactors with yolk-shell configuration have been one of the most attractive objects because of their unique performance in specific reactions. However, complicated synthesis procedures have restricted the truth understanding and wide application of the yolk-shell architectures. This article presents a universal and facile sol-gel process for fabrication of mesoporous silica hollow structure and derived yolk-shell composites with extended Stöber resorcinol-formaldehyde resin as sacrificed template. The crucial influence factors for the morphology of products are investigated. A series of yolk-shell composites with multitudinous components have been successfully designed and are further catalytic tested by different reactions. This work has provided a universal avenue for the fabrication of yolk-shell nanoreactors to suit specific reaction needs.

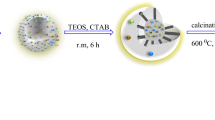

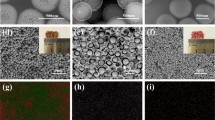

Graphical Abstract

Highlights

-

The resorcinol-formaldehyde resin is an effective template to construct hollow mesoporous silica.

-

Suitable surfactant ligand and solvent composition are crucial.

-

Universal yolk-shell architecture can be fabricated by this facile approach.

Similar content being viewed by others

References

Gawande MB, Goswami A, Asefa T et al. (2015) Core-shell nanoparticles: synthesis and applications in catalysis and electrocatalysis. Chem Soc Rev 44:7540–7590. https://doi.org/10.1039/c5cs00343a

Tubtimkuna S, Danilov, DL, Sawangphruk, M et al. (2023) Review of the Scalable Core-Shell Synthesis Methods: The Improvements of Li-Ion Battery Electrochemistry and Cycling Stability. Small Methods. https://doi.org/10.1002/smtd.202300345

Li ZW, Li M, Bian ZF et al. (2016) Design of highly stable and selective core/yolk-shell nanocatalysts-A review. Appl Catal B-Environ 188:324–341. https://doi.org/10.1016/j.apcatb.2016.01.067

Moon GD (2020) Yolk Shell Nanostructures: Syntheses and Applications for Lithium-Ion Battery Anodes. Nanomaterials-Basel 10. ARTN 67510.3390/nano10040675

Dai CY, Zhang AF, Liu M et al. (2015) Hollow ZSM-5 with Silicon-Rich Surface, Double Shells, and Functionalized Interior with Metallic Nanoparticles and Carbon Nanotubes. Adv Funct Mater 25:7479–7487. https://doi.org/10.1002/adfm.201502980

Das S, Perez-Ramirez J, Gong JL et al. (2020) Core-shell structured catalysts for thermocatalytic, photocatalytic, and electrocatalytic conversion of CO2. Chem Soc Rev 49:2937–3004. https://doi.org/10.1039/c9cs00713j

Jin CZ, Wang YJ, Tang HL et al. (2016) Versatile rattle-type magnetic mesoporous silica spheres, working as adsorbents and nanocatalyst containers. J Sol-Gel Sci Techn 77:279–287. https://doi.org/10.1007/s10971-015-3830-1

Zhu YF, Ikoma T, Hanagata N et al. (2010) Rattle-type Fe3O4@SiO2 hollow mesoporous spheres as carriers for drug delivery. Small 6:471–478. https://doi.org/10.1002/smll.200901403

Chen Y, Chen HR, Guo LM et al. (2010) Hollow/rattle-type mesoporous nanostructures by a structural difference-based selective etching strategy. Acs Nano 4:529–539. https://doi.org/10.1021/nn901398j

Dong C, Yu Q, Ye RP et al. (2020) Hollow carbon sphere nanoreactors loaded with pdcu nanoparticles: void-confinement effects in liquid-phase hydrogenations. Angew Chem Int Ed 59:18374–18379. https://doi.org/10.1002/anie.202007297

Du D, Shi W, Wang LZ et al. (2017) Yolk-shell structured Fe3O4@void@TiO2 as a photo-Fenton-like catalyst for the extremely efficient elimination of tetracycline. Appl Catal B-Environ 200:484–492. https://doi.org/10.1016/j.apcatb.2016.07.043

Kuo CH, Tang Y, Chou LY et al. (2012) Yolk-shell nanocrystal@ZIF-8 nanostructures for gas-phase heterogeneous catalysis with selectivity control. J Am Chem Soc 134:14345–14348. https://doi.org/10.1021/ja306869j

Lee I, Joo JB, Yin YD et al. (2011) A yolk@shell nanoarchitecture for Au/TiO2 catalysts. Angew Chem Int Ed 50:10208–10211. https://doi.org/10.1002/anie.201007660

Li A, Zhu WJ, Li CC et al. (2019) Rational design of yolk-shell nanostructures for photocatalysis. Chem Soc Rev 48:1874–1907. https://doi.org/10.1039/c8cs00711j

Lin LS, Song, JB, Yang, HH et al. (2018) Yolk-shell nanostructures: design, synthesis, and biomedical applications. Adv Mater 30. ARTN 170463910.1002/adma.201704639

Yang Y, Liu X, Li XB et al. (2012) A yolk-shell nanoreactor with a basic core and an acidic shell for cascade reactions. Angew Chem Int Ed 51:9164–9168. https://doi.org/10.1002/anie.201204829

Zhao LZ, Peng JJ, Huang Q et al. (2014) Near- infrared photoregulated drug release in living tumor tissue via yolk- shell upconversion nanocages. Adv Funct Mater 24:363–371. https://doi.org/10.1002/adfm.201302133

Qiao MT, Lei XF, Ma Y et al. (2018) Application of yolk-shell Fe3O4@N-doped carbon nanochains as highly effective microwave-absorption material. Nano Res 11:1500–1519. https://doi.org/10.1007/s12274-017-1767-0

Liu J, Qiao SZ, Chen JS et al. (2011) Yolk/shell nanoparticles: new platforms for nanoreactors, drug delivery and lithium-ion batteries. Chem Commun 47:12578–12591. https://doi.org/10.1039/c1cc13658e

Zhu T, Zhu LL, Wang J et al. (2016) Rational integration of inbuilt aperture with mesoporous framework in unusual asymmetrical yolk-shell structures for energy storage and conversion. Acs Appl Mater Inter 8:32901–32909. https://doi.org/10.1021/acsami.6b12284

Chen JC, Xue ZT, Feng SS et al. (2014) Synthesis of mesoporous silica hollow nanospheres with multiple gold cores and catalytic activity. J Colloid Inter Sci 429:62–67. https://doi.org/10.1016/j.jcis.2014.05.005

Chen Z, Cui ZM, Niu F et al. (2010) Pd nanoparticles in silica hollow spheres with mesoporous walls: a nanoreactor with extremely high activity. Chem Commun 46:6524–6526. https://doi.org/10.1039/c0cc01786h

Cui ZM, Chen Z, Cao CY et al. (2013) A yolk-shell structured Fe2O3@mesoporous SiO2 nanoreactor for enhanced activity as a Fenton catalyst in total oxidation of dyes. Chem Commun 49:2332–2334. https://doi.org/10.1039/c3cc38649j

Park JC, Bang JU, Lee J et al. (2010) Ni@SiO2 yolk-shell nanoreactor catalysts: High temperature stability and recyclability. J Mater Chem 20:1239–1246. https://doi.org/10.1039/b918446e

Park JC, Song H (2011) Metal@silica yolk-shell nanostructures as versatile bifunctional nanocatalysts. Nano Res 4:33–49. https://doi.org/10.1007/s12274-010-0039-z

Yao TJ, Cui TY, Fang X et al. (2013) Preparation of yolk-shell FexOy/Pd@mesoporous SiO2 composites with high stability and their application in catalytic reduction of 4-nitrophenol. Nanoscale 5:5896–5904. https://doi.org/10.1039/c3nr01470c

Zhang T, Ge J, Hu Y et al. (2008) Formation of hollow silica colloids through a spontaneous dissolution-regrowth process. Angew Chem Int Ed 47:5806–5811. https://doi.org/10.1002/anie.200800927

Zhao XY, Li HR, Zhang JP et al. (2016) Design and synthesis of NiCe@m-SiO2 yolk-shell framework catalysts with improved coke- and sintering-resistance in dry reforming of methane. Int J Hydrog Energ 41:2447–2456. https://doi.org/10.1016/j.ijhydene.2015.10.111

Yue Q, Li JL, Zhang Y et al. (2017) Plasmolysis-inspired nanoengineering of functional yolk-shell microspheres with magnetic core and mesoporous silica shell. J Am Chem Soc 139:15486–15493. https://doi.org/10.1021/jacs.7b09055

Wang SN, Zhang MC, Zhang WQ (2011) Yolk-shell catalyst of single au nanoparticle encapsulated within hollow mesoporous silica microspheres. Acs Catal 1:207–211. https://doi.org/10.1021/cs1000762

Wu X-J, Xu D (2009) Formation of yolk/SiO2 shell structures using surfactant mixtures as template. J Am Chem Soc 131:2774–2775. https://doi.org/10.1021/ja808452r

Wong YJ, Zhu L, Teo WS et al. (2011) Revisiting the Stöber method: in homogeneity in silica shells. J Am Chem Soc 133:11422–11425. https://doi.org/10.1021/ja203316q

Zhang Q, Zhang T, Ge J et al. (2008) Permeable silica shell through surface-protected etching. Nano Lett 8:2867–2871. https://doi.org/10.1021/nl8016187

Liu J, Qiao SZ, Liu H et al. (2011) Extension of the Stöber method to the preparation of monodisperse resorcinol-formaldehyde resin polymer and carbon spheres. Angew Chem Int Ed 50:5947–5951. https://doi.org/10.1002/anie.201102011

Liu R, Qu FL, Guo YL et al. (2014) Au@carbon yolk-shell nanostructures via one-step core-shell-shell template. Chem Commun 50:478–480. https://doi.org/10.1039/c3cc47050d

Fang XL, Liu SJ, Zang J et al. (2013) Precisely controlled resorcinol-formaldehyde resin coating for fabricating core-shell, hollow, and yolk-shell carbon nanostructures. Nanoscale 5:6908–6916. https://doi.org/10.1039/c3nr01723k

Li N, Zhang Q, Liu J et al. (2013) Sol-gel coating of inorganic nanostructures with resorcinol-formaldehyde resin. Chem Commun 49:5135–5137. https://doi.org/10.1039/c3cc41456f

Jin CZ, Wang YJ, Tang HL et al. (2014) Synthesis, characterization, and catalytic applications of core-shell magnetic carbonaceous nanocomposites. J Phys Chem C 118:25110–25117. https://doi.org/10.1021/jp508853a

Wang X, Li SY, Yang GS et al. (2020) Insights into the resorcinol-formaldehyde resin coating process focusing on surface modification of colloidal SiO2 particles. Langmuir 36:2654–2662. https://doi.org/10.1021/acs.langmuir.9b03595

Thangaraj A, Sivasanker, S (1992) An improved method for TS-1 synthesis - Si-29 NMR-studies. J Chem Soc-Chem Commun 123-124. https://doi.org/10.1039/c39920000123

Fuertes AB, Valle-Vigon P, Sevilla M (2012) One-step synthesis of silica@resorcinol-formaldehyde spheres and their application for the fabrication of polymer and carbon capsules. Chem Commun 48:6124–6126. https://doi.org/10.1039/c2cc32552g

Wang JX, Zhang KM, Kavak S et al. (2023) Modifying the Stöber process: is the organic solvent indispensable? Chem-Eur J 29. https://doi.org/10.1002/chem.202202670

Peyrovi MH, Parsafard N, Anajafi HR (2018) Catalytic performance of micro-mesoporous materials as the supports for Pt catalysts in n-heptane isomerization. Chem Phys Lett 713:32–38. https://doi.org/10.1016/j.cplett.2018.10.005

Jia LX, Sun XY, Ye XQ et al. (2013) Core-shell composites of USY@Mesosilica: Synthesis and application in cracking heavy molecules with high liquid yield. Micropor Mesopor Mat 176:16–24. https://doi.org/10.1016/j.micromeso.2013.03.029

Peng HG, Xu L, Zhang LY et al. (2012) Synthesis of core-shell structured TS-1@mesocarbon materials and their applications as a tandem catalyst. J Mater Chem 22:14219–14227. https://doi.org/10.1039/c2jm31788e

Srivastava VC (2012) An evaluation of desulfurization technologies for sulfur removal from liquid fuels. RSC Adv 2:759–783. https://doi.org/10.1039/c1ra00309g

Li C, Li D, Zou S et al. (2013) Extraction desulfurization process of fuels with ammonium-based deep eutectic solvents. Green Chem 15:2793–2799. https://doi.org/10.1039/c3gc41067f

Zhang H, Li XP, Zhao RX (2021) Preparation of V2O5/g⁃C3N4 catalyst and desulfurization ability in model oil. J Petrochem Univ 34:7–14. https://doi.org/10.3969/j.issn.1006-396X.2021.01.002

Acknowledgements

The authors gratefully acknowledge the financial supports from the Talent Scientific Research Fund of LNPU (2020XJJL-016), the Liaoning Provincial Natural Science Foundation of China (2019-MS-323).

Author contributions

This manuscript was written through contributions from all authors. HL and CJ wrote the main manuscript text. HL and WX finished the preparation experiment. MZ and JX finished characterization and catalytic tests. RW and HJ paticipated in the discussion and analysis of experiment results. All authors reviewed the manuscript and approved the final version.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, H., Xu, W., Xu, J. et al. Universal and facile sol-gel approach for fabrication of multitudinous yolk-shell architectures. J Sol-Gel Sci Technol 109, 421–432 (2024). https://doi.org/10.1007/s10971-023-06289-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10971-023-06289-2