Abstract

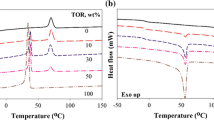

In this study, a thermoresponsive shape memory polymer based on various compositions of melt blended of polylactic acid (PLA) and styrene-butadiene-styrene (SBS) copolymer was prepared. Dynamic rheological behavior was measured using a parallel plate rheometer over a range of 0.1–100 rad− 1 and was correlated with the shape memory, thermal and tensile properties of the blends. The blend with 70%PLA (70PLA/30SBS) that possessed intermediate storage and loss moduli showed the best shape memory performance in terms of shape fixity ratio (Rf) and shape recovery ratio (Rr). The tensile strength and modulus increased while elongation at break reduced with increasing PLA with significant changes found at 50PLA/50SBS due to the formation of co-continuous morphology. The SBS content did not significantly affect the glass transition temperature of the PLA but the crystallinity slightly increased with increasing SBS. The sea-island morphology of 70PLA/30SBS where SBS formed droplets in the PLA continuous phase provides optimum tensile and shape memory properties.

Similar content being viewed by others

References

Huang WM, Ding Z, Wang CC, Wei J, Zhao Y, Purnawali H (2010) Shape memory materials. Mater Today 13(7–8):54–61

Hu J, Zhu Y, Huang H, Lu J (2012) Recent advances in shape-memory polymers: Structure, mechanism, functionality, modeling and applications. Prog Polym Sci 37(12):1720–1763

Hager MD, Bode S, Weber C, Schubert US (2015) Shape memory polymers: Past, present and future developments. Prog Polym Sci 49–50:3–33

Mather PT, Luo X, Rousseau IA (2009) Shape memory polymer research. Annu Rev Mater Res 39:445–471

Berg GJ, McBride MK, Wang C, Bowman CN (2014) New directions in the chemistry of shape memory polymers. Polym (Guildf) 55(23):5849–5872

Kolesov I, Dolynchuk O, Radusch HJ (2015) Shape-memory behavior of cross-linked semi-crystalline polymers and their blends. Express Polym Lett 9(3):255–276

Wu X, Huang WM, Zhao Y, Ding Z, Tang C, Zhang J (2013) Mechanisms of the shape memory effect in polymeric materials. Polym (Basel) 5:1169–1202

Huang WM, Zhao Y, Wang CC, Ding Z, Purnawali H, Tang C et al (2012) Thermo/chemo-responsive shape memory effect in polymers: A sketch of working mechanisms, fundamentals and optimization. J Polym Res 19

Zhou Y, Min W (2015) Shape memory effect in polymeric materials: mechanisms and optimization. Procedia IUTAM 12:83–92

Sabzi M, Babaahmadi M, Rahnama M (2017) Thermally and Electrically Triggered Triple-Shape Memory Behavior of Poly(vinyl acetate)/Poly(lactic acid) Due to Graphene-Induced Phase Separation. ACS Appl Mater Interfaces 9(28):24061–24070

Samuel C, Barrau S, Lefebvre JM, Raquez JM, Dubois P (2014) Designing multiple-shape memory polymers with miscible polymer blends: Evidence and origins of a triple-shape memory effect for miscible PLLA/PMMA blends. Macromolecules 47(19):6791–6803

Li MQ, Song F, Chen L, Wang XL, Wang YZ (2016) Flexible material based on poly(lactic acid) and liquid crystal with multishape memory effects. ACS Sustain Chem Eng 4(7):3820–3829

Chatterjee T, Dey P, Nando GB, Naskar K (2015) Thermo-responsive shape memory polymer blends based on alpha olefin and ethylene propylene diene rubber. Polym (Guildf) 78:180–192

Zhang Z-X, Liao F, He ZZ, Yang J-H, Huang T, Zhang N et al (2015) Tunable shape memory behaviours of poly(ethylene vinyl acetate) achieved by adding poly(L-lactide). Smart Mater Struct 24

Behl M, Lendlein A (2007) Shape-memory polymers. Mater Today 10(4):20–28

Zhang H, Wang H, Zhong W, Du Q (2009) A novel type of shape memory polymer blend and the shape memory mechanism. Polym (Guildf) 50:1596–1601

Hao X, Kaschta J, Liu X, Pan Y, Schubert DW (2015) Entanglement network formed in miscible PLA/PMMA blends and its role in rheological and thermo-mechanical properties of the blends. Polym (Guildf) 80:38–45

Wang Y, Zhu G, Tang Y (2014) Mechanical and shape memory behavior of chemically cross-linked SBS / LDPE blends. J Polym Res

Azizul Rahim FH, Saleh AA, Shuib RK, Ku Ishak KM, Abdul Hamid ZA, Abdullah MK et al (2021) Thermo-responsive shape memory properties based on polylactic acid and styrene-butadiene-styrene block copolymer. J Appl Polym Sci 138(39):51000

Zhang N, Lu X (2016) Morphology and properties of super-toughened bio-based poly(lactic acid)/poly(ethylene-co-vinyl acetate) blends by peroxide-induced dynamic vulcanization and interfacial compatibilization. Polym Test 56:354–363

Nehra R, Maiti SN, Jacob J (2018) Poly(lactic acid)/(styrene-ethylene-butylene-styrene)-g-maleic anhydride copolymer/sepiolite nanocomposites: Investigation of thermo-mechanical and morphological properties. Polym Adv Technol 29(1):234–243

Abreu FOMSMS, Forte MMCC, Liberman SA (2005) SBS and SEBS block copolymers as impact modifiers for polypropylene compounds. J Appl Polym Sci 95(2):254–263

Zhang H, Chen Z, Zheng Z, Zhu X, Wang H (2013) Shape memory polymer hybrids of SBS/dl-PLA and their shape memory effects. Mater Chem Phys 137:750–755

Wu CP, Wang CC, Chen CY (2015) Enhancing the PLA Crystallization Rate and Mechanical Properties by Melt Blending with Poly(styrene-butadiene-styrene) Copolymer. Polym - Plast Technol Eng 54(10):1043–1050

Li Y, Liu L, Shi Y, Xiang F, Huang T, Wang Y, Morphology ZZ (2010) Rheological, Crystallization Behavior, and Mechanical Properties of Poly(L-lactide)/Ethylene-co-Vinyl Acetate Blends with Different VA Contents. J Appl Polym Sci 121

Ji F, Li J, Weng Y, Ren J (2020) Synthesis of PLA-based thermoplastic elastomer and study on preparation and properties of PLA- based shape memory polymers. Mater Res Express

Lai SM, Lan YC (2013) Shape memory properties of melt-blended polylactic acid (PLA)/thermoplastic polyurethane (TPU) bio-based blends. J Polym Res 20(5):2–9

Zhang ZX, He ZZ, Yang JH, Huang T, Zhang N, Wang Y (2016) Crystallization controlled shape memory behaviors of dynamically vulcanized poly(l-lactide)/poly(ethylene vinyl acetate) blends. Polym Test 51:82–92

Naddeo M, Sorrentino A, Pappalardo D (2021) Thermo-rheological and shape memory properties of block and random copolymers of lactide and ε-caprolactone. Polymers (Basel) 13(4):1–19

Bocheng Wang, Zheng Tu, Chonggang Wu, Tao Hu, Xiaotao Wang SL and XG* (2019) Effect of Poly(styrene-ran-methyl acrylate) Inclusion on the Compatibility of Polylactide/Polystyrene-b-Polybutadiene-b-Polystyrene Blends Characterized by Morphological, Thermal, Rheological, and Mechanical Measurements. Polymers (Basel). 11:846

Agrawal P, Araújo APM, Lima JCC, Cavalcanti SN, Freitas DMG, Farias GMG et al (2019) Rheology, Mechanical Properties and Morphology of Poly(lactic acid)/Ethylene Vinyl Acetate Blends. J Polym Environ 27(7):1439–48

Wang X, Feng W, Li H, Ruckenstein E (2001) Optimum toughening via a bicontinuous blending: Toughening of PPO with SEBS and SEBS-g-maleic anhydride. Polymer (Guildf) 43(1):37–43

Lima JCC, Araujo EAG, Agrawal P, Melo TJA (2019) PLA/SEBS Bioblends : Influence of SEBS Content and Thermal Treatment on the Impact Strength and Morphology. Macromol Symp 1700072:1–6

Brown SB (2003) Reactive compatibilization of polymer blends. Vol. 10, Polymer Blends Handbook. 339–415 p

Kim DY, Lee J Bin, Lee DY, Seo KH (2020) Plasticization effect of poly(lactic acid) in the poly(butylene adipate-co-terephthalate) blown film for tear resistance improvement. Polymers (Basel) 12(9)

Akrami M, Ghasemi I, Azizi H, Karrabi M, Seyedabadi M (2016) A new approach in compatibilization of the poly(lactic acid)/thermoplastic starch (PLA/TPS) blends. Carbohydr Polym 144:254–262

Wang Y, Wei Z, Li Y (2016) Highly toughened polylactide/epoxidized poly(styrene-b-butadiene-b-styrene) blends with excellent tensile performance. Eur Polym J 85:92–104

Nehra R, Maiti SN, Jacob J (2018) Effect of Thermoplastic Elastomer on Melt Rheological and Fracture Behaviour of Poly(Lactic Acid). Polym - Plast Technol Eng 57(12):1254–64

Singla RK, Zafar MT, Maiti SN, Ghosh AK (2017) Physical blends of PLA with high vinyl acetate containing EVA and their rheological, thermo-mechanical and morphological responses. Polym Test 63:398–406

Johar M, Zarkasi KZ, Hashim F, Rusli A (2022) Thermal, mechanical, rheological and morphological properties of compatible poly(lactic acid)/ethylene vinyl acetate blends. Prog Rubber Plast Recycl Technol 38(2):172–187

Rezgui F, Swistek M, Hiver JM, G’Sell C, Sadoun T (2005) Deformation and damage upon stretching of degradable polymers (PLA and PCL). Polymer (Guildf). 46(18):7370–85

Acknowledgements

The authors would like to thank Universiti Sains Malaysia for the Research University Individual (RUI) grant (1001.PBAHAN.8014142) and the Emerging Polymer Research Group, School of Materials and Mineral Resources Engineering, Universiti Sains Malaysia, for their support.

Funding

This work was funded by Universiti Sains Malaysia under the Research University Individual (RUI) grant with grant number of 1001.PBAHAN.8014142.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and publication of this article.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Azizul Rahim, F.H., Rusli, A. Rheological and thermoresponsive shape memory properties of polylactic acid (PLA) and styrene-butadiene-styrene (SBS) copolymer blends. J Polym Res 29, 452 (2022). https://doi.org/10.1007/s10965-022-03296-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-03296-9