Abstract

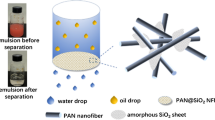

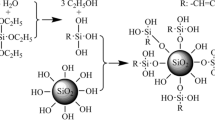

In this work, nanofibrous membranes for separating oil-in-water (O/W) emulsion were prepared by electrospinning. The membrane material was polymer blend of polyacrylonitrile (PAN)/polyvinyl alcohol (PVA), and by adjusting polymer composition and concentration, as well as applying crosslinking by glutaraldehyde (GD) and hydrolysis inside NaOH solution, membrane with desired properties, particularly hydrophilicity and underwater oil repellency were obtained. For PAN/PVA composite membrane modified by glutaraldehyde for 1.5 h and NaOH for 1.5 h, the water contact angle initially was around 5° and decreased to 0o with a transition time of only 0.3 s. The membrane also showed recommendable performance in O/W emulsion separation. Under a driving force of 0.8 kPa, the highest starting flux of 953 L/m2h and 532 L/m2h were registered with the treatment of surfactant-free emulsion (SFE) and surfactant-stabilized emulsion (SSE), respectively. The membrane recovered 96% of its initial flux in a 5-cycle reusability test using SFE, and the oil rejection coefficient maintained higher than 97%. FTIR and XPS characterizations confirmed the success in chemical modifications. It was also found that glutaraldehyde crosslinking helped to improve the macroscopic structure integrity of the membrane in aqueous environment.

Similar content being viewed by others

References

Zhang Y, Yu T, Bi YH, Zhang YJ (2008) Research progress on treatment methods of oily wastewater (in Chinese). Chem Ind & Eng Pro (China):1155–1161

Xu ZG, Zou Q, Tang QM, Li J, Wang CH (2014) Common problems in solvent extraction system (in Chinese). Hydrometall. China 133:1–3. https://doi.org/10.13355/j.cnki.sfyj.2014.01.001

Lu JZ, Li FL (2019) Cause analysis and solution of rare earth extraction emulsification (in Chinese). Tech Dev Chem Ind 48:61–63

Xiao LS (2017) Membrane based-separation in metallurgy: Principles and Applications. Elsevier. Reference to a chapter in an edited book: chapter 2. https://doi.org/10.1016/B978-0-12-803410-1.00002-5

Sun YL (2011) Discussion on Ultrafiltration Membrane Treatment Technologies for Emulsion Wastewater in the Cold Rolling Mill (in Chinese). Metallurg Gansu 33:77–80. https://doi.org/10.16042/j.cnki.cn62-1053/tf.2011.01.032

Fang ZB, Xiao GJ, Yin YG, Liu WR (2009) Application of inorganic membrane technology in oil emulsion treatment (in Chinese). The Third National (China) Symposium on Application of Membrane Separation Technologies in Metallurgical Industry 3:74–80

Wang ZG (2014) Application of membrane separation technology in hydrometallurgy (in Chinese). The Fourth National (China) Symposium on Application of Membrane Separation Technologies in Metallurgical Industry 54–61

Zhang YH, Gan FX, Li M, Wu SH, Gao YP, Zhang L, Wu LY (2009) Industrial test research on new combined process (principally based on MBR) for treatment of cold rolling emulsion wastewater (in Chinese). Third National (China) Symposium on Application of Membrane Separation Technologies in Metallurgical Industry 76–80

Li L, Ding L, Tu Z, Wan Y, Clausse D, Lanoisellé J (2009) Recovery of linseed oil dispersed within an oil-in-water emulsion using hydrophilic membrane by rotating disk filtration system. J Membr Sci 342:70–79. https://doi.org/10.1016/j.memsci.2009.06.023

Agi A, Junin R, Alqatta AYM, Gbadamosi A, Yahya A, Abbas A (2019) Ultrasonic assisted ultrafiltration process for emulsification of oil field produced water treatment. Ultrason Sonochem 51:214–222. https://doi.org/10.1016/j.ultsonch.2018.10.023

Cakl J, Bauer I, Doleček P, Mikulášek P (2000) Effects of backflushing conditions on permeate flux in membrane crossflow microfiltration of oil emulsion. Desalination 127:189–198. https://doi.org/10.1016/S0011-9164(99)00204-0

Pope JM, Yao S, Fane AG (1996) Quantitative measurements of the concentration polarisation layer thickness in membrane filtration of oil-water emulsions using NMR micro-imaging. J Membr Sci 118:247–257. https://doi.org/10.1016/0376-7388(96)00107-X

Belkacem M, Matamoros H, Cabassud C, Aurelle Y, Cotteret J (1995) New results in metal working wastewater treatment using membrane technology. J Membr Sci 106:195–205. https://doi.org/10.1016/0376-7388(95)00093-R

Xu ZL, Chung TS, Huang Y (1999) Effect of polyvinylpyrrolidone mol-ecular weights on morphology, oil/water separation, mechanical and therm-al properties of polyetherimide/polyvinylpyrrolidone hollow fiber membran-es. J Appl Polym Sci 74:2220–2233. https://doi.org/10.1002/(SICI)1097-4628(19991128)74:9%3c2220:AID-APP11%3e3.0.CO;2-1

Huang Y, Xiao CF, Huang QL, Liu HL, Guo Z, Sun KX (2018) Robust preparation of tubular PTFE/FEP ultrafine fibers-covered porous membrane by electrospinning for continuous highly effective oil/water separation. J Membr Sci 568:87–96. https://doi.org/10.1016/j.memsci.2018.09.062

Jin SY, Kim MH, Jeong YG, Yoon YI, Park WH (2017) Effect of alkaline hydrolysis on cyclization reaction of PAN nanofibers. Mater Design 124:69–77. https://doi.org/10.1016/j.matdes.2017.03.066

Kim J, Reneker DH (1999) Reneker, Polybenzimidazole nanofiber produced by electrospinning. Polym Eng Sci 39:849–854. https://doi.org/10.1002/pen.11473

Wang D, Lu QF, Wei MZ, Guo EY (2018) Electrospinning of flux-enhanced chitosan-poly (lactic acid) nanofiber mats as a versatile platform for oil-water separation. J Appl Polym Sci 135:45830. https://doi.org/10.1002/app.45830

Wang R, Liu Y, Li B, Hsiao BS, Chu B (2012) Electrospun nanofibrous membranes for high flux microfiltration. J Membr Sci 392–393:167–174. https://doi.org/10.1016/j.memsci.2011.12.019

Wang B, Liang WX, Guo ZG, Liu WM (2015) Biomimetic super-lyophobic and super-lyophilic materials applied for oil/water separation: a new strategy beyond nature. Chem Soc Rev 44:336–361. https://doi.org/10.1039/c4cs00220b

Liu CL, Mao HC, Zheng JF, Zhang SB (2017) In situ surface crosslinked tight ultrafiltration membrane prepared by one-step chemical reaction-involved phase inversion process between activated PAEK-COOH and PEI. J Membr Sci 538:58–67. https://doi.org/10.1016/j.memsci.2017.05.055

Hardman SJ, Muhamad-Sarih N, Riggs HJ, Thompson RL, Rigby J, Bergius WNA, Hutchings LR (2011) Electrospinning superhydrophobic fibers using surface segregating end-functionalized polymer additives. Macromolecules 44:6461–6470. https://doi.org/10.1021/ma200852z

Asmatulu R, Ceylan M, Nuraje N (2011) Study of sperhydrophobic electrospun nanocomposite fibers for energy systems. Langmuir 27:504–507. https://doi.org/10.1021/la103661c

Wang LF, Yang SY, Wang J, Wang CF, Chen L (2011) Fabrication of superhydrophobic TPU film for oil–water separation based on electrospinning route. Matter Lett 65:869–872. https://doi.org/10.1016/j.matlet.2010.12.024

Shang YW, Si Y, Raza A, Yang LP, Mao X, Ding B, Yu JY (2012) An insitu polymerization approach for the synthesis of superhydrophobic and superoleophilic nanofibrous membranes for oil–water separation. Nanoscale 4:7847. https://doi.org/10.1039/c2nr33063f

Qing WH, Shi XA, Deng YJ, Zhang WD, Wang JQ, Tang CY (2017) Robust superhydrophobic-superoleophilic polytetrafluoroethylene nanofibrous membrane for oil/water separation. J Membr Sci 540:354–361. https://doi.org/10.1016/j.memsci.2017.06.060

Ryšánek P, Benada O, Tokarský J, Syrový M, Čapková P, Pavlík J (2019) Specific structure, morphology, and properties of polyacrylonitrile (PAN) membranes prepared by needleless electrospinning, Forming hollow fibers. Mat Sci Eng C 105:110151. https://doi.org/10.1016/j.msec.2019.110151

Xing C, Meng F, Quan M, Ding K, Dang Y, Gong Y (2017) Quantit-ative fabrication, performance optimization and comparison of PEG and zw-itterionic polymer antifouling coatings. Acta Biomater 59:129–138. https://doi.org/10.1016/j.actbio.2017.06.034

Shahkaramipour N, Ramanan SN, Fister D, Park E, Venna SR, Sun H, Cheng C, Lin HQ (2017) Facile grafting of zwitterions onto the membrane surface to enhance antifouling properties for wastewater reuse. Ind Eng Chem Res 56:9202–9212. https://doi.org/10.1021/acs.iecr.7b02378

Alsohaimi IH, Kumar M, Algamdi MS, Khan MA, Nolan K, Lawler J (2017) Antifouling hybrid ultrafiltration membranes with high selectivity fabricated from polysulfone and sulfonic acid functionalized TiO2 nanotubes. Chem Eng J 316:573–583. https://doi.org/10.1016/j.cej.2017.02.001

Shakiba M, Nabavi SR, Emadi H, Faraji M (2020) Development of a superhydrophilic nanofiber membrane for oil/water emulsion separation via modification of polyacrylonitrile/polyaniline composite. Polym Advan Technol. https://doi.org/10.1002/pat.5178

Zhang P, Tian R, Lv R, Na B, Liu Q (2015) Water-permeable polylactide blend membranes for hydrophilicity-based separation. Chem Eng J 269:180–185. https://doi.org/10.1016/j.cej.2015.01.111

Ahmadi A, Qanati O, Seyed Dorraji MS, Rasoulifard MH, Vatanpour V (2017) Investigation of antifouling performance a novel nanofibrous S-PVDF/PVDF and S-PVDF/PVDF/GO membranes against negatively charged oily foulants. J Membr Sci 536:86–97. https://doi.org/10.1016/j.memsci.2017.04.056

Yang MC, Lin WC (2002) Surface modification and blood compatibility of polyacrylonitrile membrane with immobilized chitosan-heparin conjugate. J Polym Res 9:201–206. https://doi.org/10.1023/A:1021347810130

Liang W, Chenyang Y, Bin Z, Xiaona W, Zijun Y, Lixiang Z, Hongwei Z, Nanwen L (2019) Hydrophobic polyacrylonitrile membrane preparation and its use in membrane contactor for CO2 absorption. J Membr Sci 569:157–165. https://doi.org/10.1016/j.memsci.2018.09.066

Zhang J, Liu Y, Guo J, Yu Y, Li Y, Zhang X (2020) A CO2-responsive PAN/PAN-co-PDEAEMA membrane capable of cleaning protein foulant without the aid of chemical agents. React Funct Polym 149:104503. https://doi.org/10.1016/j.reactfunctpolym.2020.104503

Sriyanti I, Marlina L, Jauhari J (2020) Optimization of the electrospinning process for preparation of nanofibers from poly (vinyl alcohol) (PVA) and chromolaena odorata l. extrac (COE). J Pendidik Fis Indon 16:47–56. https://doi.org/10.15294/jpfi.v16i1.12629

Hirsch E, Vass P, Demuth B, Petho Z, Bitay E, Andersen SK, Vigh T, Verreck G, Molnar K, Nagy ZK, Marosi G (2019) Electrospinning scale-up and formulation development of PVA nanofibers aiming oral deliv-ery of biopharmaceuticals. Express Polym Lett 13:590–603. https://doi.org/10.3144/expresspolymlett.2019.50

Niazi MBK, Jahan Z, Berg SS, Gregersen ØW (2017) Mechanical, thermal and swelling properties of phosphorylated nanocellulose fibrils/PVA nanocomposite membranes. Carbohyd Polym 177:258–268

Niazi MBK, Jahan Z, Ahmed A, Uzair B, Mukhtar A, Gregersen ØW (2020) Mechanical and thermal properties of carboxymethyl fibers (CMF)/PVA based nanocomposite membranes. J Ind Eng Chem 90:122–131. https://doi.org/10.1016/j.jiec.2020.07.004

Zhan F, Yan X, Li J, Sheng F, Li B (2021) Encapsulation of tangeretin in PVA/PAA crosslinking electrospun fibers by emulsion-electrospinning: Morphology characterization, slow-release, and antioxidant activity assessment. Food Chem 337:127763. https://doi.org/10.1016/j.foodchem.2020.127763

Liu HQ, Hsieh Y (2006) Preparation of Water-Absorbing Polyacrylonitrile Nanofibrous Membrane. Macromol Rapid Comm 27:142–145. https://doi.org/10.1002/marc.200500691

Bajaj P, Kumari MS (1988) Structural investigations on hydrolyzed acryl-onitrile terpolymers. Eur Polym 24:275–279. https://doi.org/10.1016/0014-3057(88)90222-4

Zhang H, Zhao K, Chen FY, Jiang Q (2014) Development and application prospect of battery grade high purity manganese sulfate monohydrate (in Chinese). China Manganese Ind 32:6–8. https://doi.org/10.14101/j.cnki.issn.1002-4336.2014.02.005

Shen YF, Xue WY, Niu WY (2008) Recovery of Co (II) and Ni (II) from hydrochloric acid solution of alloy scrap. T. Nonferr. Metal. Soc. 18:1262–1268. https://doi.org/10.1016/S1003-6326(08)60214-9

Nan JM, Han DM, Yang MJ, Cui M, Hou XL (2006) Recovery of metal values from a mixture of spent lithium-ion batteries and nickel-metal hydride batteries. Hydrometallurgy 84:75–80. https://doi.org/10.1016/j.hydromet.2006.03.059

Espinosa DCR, Bernardes AM, Tenório JAS (2004) An overview on the current processes for the recycling of batteries. J Power Sources 135:311–319. https://doi.org/10.1016/j.jpowsour.2004.03.083

Liu XR, Qiu GZ, Hu YH, Xu K (2002) Mechanism of limit coalescence of emulsion in copper solvent extraction interface (in Chinese). Chin J Nonferrous Met 582–586. https://doi.org/10.3321/j.issn:1004-0609.2002.03.036

Yang JF, Zhi MF, Shi LY, Su JJ (2014) Study on extraction emulsification reason and treatment method of a uranium-molybdenum mine (in C-hinese). Uranium Min. Metall. 33:89–93. https://doi.org/10.13426/j.cnki.yky.2014.02.008

Xie YB, Fan YJ, Zhang JF, Xie JN (2016) Emulsification and treatment in the process of extracting scandium from titanium dioxide waste acid (in Chinese). Nonferrous Met 48–50. https://doi.org/10.3969/J.ISSN.1007-7545.2016.12.031

Wang Y, Zhang YM, Huang J, Li W, Zhang GB (2013) Study on the Cause of Emulsification of Acid Leachate for Extracting Vanadium from Stone Coal by P204 (in Chinese). Chin J Nonferrous Met 25–28. https://doi.org/10.3969/j.issn.1007-7545.2013.11.09

Wan CY, Chen CX (2000) Glutaraldehyde crosslinked PVA/ PAN composite membrane Experimental study on pervaporation performance (in Chinese). J B Univ Chem Technol: 6–9. https://doi.org/10.3969/j.issn.1671-4628.2000.01.002

Wang YH, Hsieh YL (2010) Crosslinking of polyvinyl alcohol (PVA) fibrous membranes with glutaraldehyde and PEG diacylchloride. J Appl Polym Sci 116:3249–3255. https://doi.org/10.1002/app.31750

Dhara D, Nisha CK, Chatterji PR (1999) Super absorbent hydrogels: Interpenetrating networks of poly (acrylamide-co-acrylic acid) and poly (vinyl alcohol): Swelling behavior and structural parameters. J Macromol Sci A 197–210. https://doi.org/10.1081/MA-100101525

Ma YH, Hu YN, Yang H, Zhu LJ, Wang LH (2021) In situ mussel-inspired Janus membranes using catechol and polyethylenei mine as the additives for highly efficient oil/water emulsions separation. Sep Purif Technol. https://doi.org/10.1016/j.seppur.2021.118310

Zhan YQ, He SJ, Wan XY, Zhao SM, Bai YL (2018) Thermally and chemically stable poly (arylene ether nitrile)/halloysite nanotubes intercalated graphene oxide nanofibrous composite membranes for highly efficient oil/water emulsion separation in harsh environment. J Membr Sci 567:76–88. https://doi.org/10.1016/j.memsci.2018.09.037

Li H, Yang J, Xu Z (2020) Hollow fiber membranes with Janus surfaces for continuous deemulsification and separation of oil-in-water emulsions. J Membr Sci 602:117964. https://doi.org/10.1016/j.memsci.2020.117964

Chen Y, Xiong J, Chang HY (2010) Adsorption properties of hydrolyzed PAN nanofiber membrane for Cu (II) ions (in Chinese). J Zhejiang Sci-Tech 27:529–533. https://doi.org/10.3969/j.issn.1673-3851.2010.04.004

Mou CL, Hu JX, Zhan YQ, He SJ, Chiao YH, Zhao SM (2020) Fabrication of stable super-hydrophilic/underwater super-oleophobic poly (arylene ether nitrile) nanofibrous composite membranes via the one-step co-deposition of dopamine and 3-aminopropyltriethoxysilane for efficient oil-in-water emulsion separation. J Chem Technol Biot 95:3149–3160. https://doi.org/10.1002/jctb.6492

Tao TX (1997) Study on acid hydrolysis of polyacrylonitrile to acid (in Chinese). Synth Fibre: 17–27. CNKI: SUN: HCXW.0.1997–05–003

Cheraghali R, Maghsoud Z (2019) Enhanced modification technique for polyacrylonitrile UF membranes by direct hydrolysis in the immersion bath. J Appl Polym Sci 137:48583. https://doi.org/10.1002/app.48583

Luo CP, Ke LF (1979) Pressure hydrolysis of polyacrylonitrile (in Chinese). Polym Commun 31–35

Diao CH, Xiao CF, Hu XY (2010) Study on hydrophilic porous polyacrylonitrile fiber (in Chinese). China Synth Fiber Ind 33:28–31. https://doi.org/10.3969/j.issn.1001-0041.2010.04.009

Miyagawa Y, Katsuki K, Matsuno R (2015) S. Adachi, Effect of oil droplet size on activation energy for coalescence of oil droplets in an O/W emulsion. Biosci Biotechnol Biochem 79:1695–1697. https://doi.org/10.1080/09168451.2015.1039482

Chen P, Xu Z (2013) Mineral-Coated Polymer Membranes with Superhydrophilicity and Underwater Superoleophobicity for Effective Oil/Water Separation. Sci Rep 3:2776. https://doi.org/10.1038/srep02776

Tummons EN, Chew JW, Fane AG, Tarabara VV (2017) Ultrafiltration of saline oil-in-water emulsions stabilized by an anionic surfactant: Effect of surfactant concentration and divalent counterions. J Membr Sci 537:384–395. https://doi.org/10.1016/j.memsci.2017.05.012

Meng H, Liang H, Xu T, Bai J, Li C (2021) Crosslinked electrospinning membranes with contamination resistant properties for highly efficient oil–water separation. J Polym Res 28:347. https://doi.org/10.1007/s10965-021-02700-0

Cai Y, Chen D, Li N, Xu Q, Li H, He J, Lu J (2017) Nanofibrous metal–organic framework composite membrane for selective efficient oil/wa-ter emulsion separation. J Membr Sci 543:10–17. https://doi.org/10.1016/j.memsci.2017.08.047

Longa Y, Shenb Y, Tiana H, Yanga Y, Fenga H, Lia J (2018) Super-wettable Coprinus comatus coated membranes used toward the controllableseparation of emulsified oil/water mixtures. J Membr Sci 565:85–94. https://doi.org/10.1016/j.memsci.2018.08.013

Zhu X, Yu Z, Liu Y, Li X, Long R, Wang P, Wang J (2021) NH2-MIL-125@PAA composite membrane for separation of oil/water emulsions and dyes. Colloid Surface A 630:127542. https://doi.org/10.1016/j.colsurfa.2021.127542

Denga Y, Zhanga G, Baia R, Shena S, Zhoua X, Wymanb I (2019) F-abrication of superhydrophilic and underwater superoleophobic membranesvia an in-situ crosslinking blend strategy for highly efficient oil/water emu-lsion separation. J Membr Sci 569:60–70. https://doi.org/10.1016/j.memsci.2018.09.069

Guan C, Li Z, Zhu L, Xia D (2021) A superhydrophilic and high dem-ulsification aramid nanofibers membrane with novel poly-pseudorotaxane st-ructure for oil-in-water separation. Sep Purif Technol 269:118715. https://doi.org/10.1016/j.seppur.2021.118715

Yanga J, Cuib J, Xieb A, Daia J, Lia C, Yan Y (2021) Facile prepar-ation of superhydrophilic/underwater superoleophobic cellulose membrane w-ith CaCO3 particles for oil/water separation. Colloids Surf A 608:125583. https://doi.org/10.1016/j.colsurfa.2020.125583

Zhang N, Yang N, Zhang L, Jiang B, Sun Y, Ma J, Cheng K, Peng F (2020) Facile hydrophilic modification of PVDF membrane with Ag/EGCG decorated micro/nanostructural surface for efficient oil-in-water emulsion separation. Chem Eng J 402:126200. https://doi.org/10.1016/j.cej.2020.126200

Acknowledgements

The authors would like to thank Dr. Guiqing Zhang for the suggestions in formulating and preparing the oil-in-water emulsions. This work was supported Hunan Provincial Science and Technology Project (2018TP1003).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

We confirm that there are no conflicts of interest associated with this publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• A new strategy for preparing superhydrophilic composite membranes was proposed.

• Synergy of PVA and PAN in terms of the easy crosslinking and hydrolysis was the key to the membrane property.

• In O/W emulsion separation, the highest lacks flux units was 937 and the rejection was 98%.

• The membrane also exhibited good performance in mechanical strength and reusability.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Guo, H., Zhang, D. & Jiang, L. PAN/PVA composite nanofibrous membranes for separating oil-in-water emulsion. J Polym Res 29, 108 (2022). https://doi.org/10.1007/s10965-022-02954-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-022-02954-2