Abstract

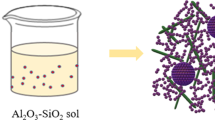

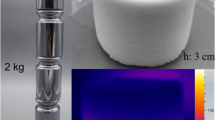

Al2O3-SiO2 aerogel (ASA) was prepared by convenient ambient pressure drying using inexpensive AlCl3·H2O as precursor, and silicon was deposited during the aging of aluminum gel. To explore the influence of Chloride ion on the property of ASA, ion exchange technology was used to remove the Chloride ion in the aluminum sol. ASA exhibits a low thermal conductivity of 0.029 W m−1 K−1 at room temperature, and the specific surface area of Cl-free ASA after heat-treated at 1200 °C is 95.2 m2/g, which is higher than that of the chlorine-containing aerogel (11.4 m2/g), showing enhanced thermal stability of ASA. Analysis of XRD and XPS indicate that the removal of chloride ions makes it more difficult for ASA to establish Al–O–Si groups during the aging process, so the γ-Al2O3 and cristobalite phase do not transform to mullite phase at 1200 °C. Due to the better thermal stability of ASA, it has great potential for high-temperature applications in the fields of insulation, thermal protection materials, and building external wall thermal insulation.

Similar content being viewed by others

References

G. Zu, J. Shen, L. Zou et al., Chem. Mater. 25(23), 4757–4764 (2013). https://doi.org/10.1021/cm402900y

G. Zu, J. Shen, X. Wei et al., J. Non-Cryst. Solids. 357(15), 2903–2906 (2011). https://doi.org/10.1016/j.jnoncrysol.2011.03.031

M. Shen, X. Jiang, M. Zhang et al., J. Sol-Gel Sci. Technol. 93(2), 281–290 (2019). https://doi.org/10.1007/s10971-019-05204-y

H. Jia, S. Liu, Z. Mao et al., Ceram. Int. 47(1), 1466–1471 (2021). https://doi.org/10.1016/j.ceramint.2020.08.206

J.J. Liao, P.Z. Gao, L. Xu et al., J. Adv. Ceram. 7(4), 307–316 (2018). https://doi.org/10.1007/s40145-018-0280-6

M.E. Ghica, C.M.R. Almeida, M. Fonseca et al., Polymers (Basel). (2020). https://doi.org/10.3390/polym12061278

X. Zhang, F. Wang, L. Dou et al., ACS Nano 14(11), 15616–15625 (2020). https://doi.org/10.1021/acsnano.0c06423

C. Li, Z. Gong, L. Ding et al., Micro Nano Lett. 13(9), 1240–1244 (2018). https://doi.org/10.1049/mnl.2018.5077

B. Gao, J. Cao, C. Yao et al., Appl. Surf. Sci. (2022). https://doi.org/10.1016/j.apsusc.2022.153044

L.F. Posada, M.K. Carroll, A.M. Anderson et al., J. Supercrit Fluids (2019). https://doi.org/10.1016/j.supflu.2019.05.004

L. Courthéoux, F. Popa, E. Gautron et al., J. Non-Cryst. Solids. 350, 113–119 (2004). https://doi.org/10.1016/j.jnoncrysol.2004.06.051

Y. Funahashi, Y. Xin, K. Kato et al., J. Adv. Ceram. 11(4), 523–531 (2022). https://doi.org/10.1007/s40145-021-0552-4

B.E. Yoldas, Am. Ceram. Soc. Bull. 54(3), 289–290 (1975)

J.F. Poco, J.H. Satcher, L.W. Hrubesh, J. Non-Cryst. Solids. 285(1–3), 57–63 (2001). https://doi.org/10.1016/s0022-3093(01)00432-x

T.F. Baumann, A.E. Gash, S.C. Chinn et al., Chem. Mater. 17(2), 395–401 (2004). https://doi.org/10.1021/cm048800m

J. Zhu, S. Guo, X. Li, RSC Adv. 5(125), 103656–103661 (2015). https://doi.org/10.1039/c5ra20392a

X. Zhang, R. Zhang, S. Jin et al., J. Sol-Gel Sci. Technol. 87(2), 486–495 (2018). https://doi.org/10.1007/s10971-018-4679-x

X. Wu, G. Shao, S. Cui et al., Ceram. Int. 42(1), 874–882 (2016). https://doi.org/10.1016/j.ceramint.2015.09.012

X. Ji, Q. Zhou, G. Qiu et al., J. Non-Cryst. Solids. 471, 160–168 (2017). https://doi.org/10.1016/j.jnoncrysol.2017.05.038

Y. Zhong, Y. Kong, J. Zhang et al., J. Porous Mater. 21(5), 653–658 (2014). https://doi.org/10.1007/s10934-014-9811-x

X. Li, H. He, L. Ren, J. Porous Mater. 24(3), 679–683 (2016)

S.M. Jones, J. Sol-Gel Sci. Technol. 40(2–3), 351–357 (2006)

P.H. Dunlap, B.M. Steinetz, D.M. Curry et al., J. Spacecr. Rocket. 40(4), 570–583 (2003)

C. Zhao, F. Chen, S. Dong et al., J. Appl. Polym. Sci. (2022). https://doi.org/10.1002/app.52385

S. Dhomne, A.M. Mahalle, J. Mater. Res. Technol. 8(1), 1532–1537 (2019). https://doi.org/10.1016/j.jmrt.2018.08.002

N. Jeyakumar, A.C.A. Kayambu, R. Ramasubbu et al., Energ. Source. Part. A. 41(7), 854–865 (2019). https://doi.org/10.1080/15567036.2018.1520364

S. Wen, H. Ren, J. Zhu et al., J. Porous Mater. 26(4), 1027–1034 (2018). https://doi.org/10.1007/s10934-018-0700-6

J. Yang, Q. Wang, T. Wang et al., J. Porous Mater. 24(4), 889–897 (2016). https://doi.org/10.1007/s10934-016-0328-3

R. Zhang, C. Ye, B. Wang, J. Porous Mater. 25(1), 171–178 (2018). https://doi.org/10.1007/s10934-017-0430-1

H. Li, Y. Chen, P. Wang et al., Ceram. Int. 44(3), 3484–3487 (2018). https://doi.org/10.1016/j.ceramint.2017.11.064

Z. Shi, H. Gao, X. Wang et al., Microporous Mesoporous Mater. 259, 26–32 (2018). https://doi.org/10.1016/j.micromeso.2017.09.025

X. Wu, Y. Zhong, Y. Kong et al., J. Porous Mater. 22(5), 1235–1243 (2015). https://doi.org/10.1007/s10934-015-0001-2

Y. Zhong, G. Shao, X. Wu et al., Rsc Adv. 9(40), 22942–22949 (2019). https://doi.org/10.1039/c9ra03227d

F.I. Hurwitz, M. Gallagher, T.C. Olin et al., Int. J. Appl. Glas. Sci. 5(3), 276–286 (2014). https://doi.org/10.1111/ijag.12070

N.S. Nesterov, A.S. Shalygin, V.P. Pakharukova et al., J. Supercrit. Fluids. 149, 110–119 (2019). https://doi.org/10.1016/j.supflu.2019.03.014

F. Peng, Y. Jiang, J. Feng et al., Chem. Eng. J. 411, 10 (2021)

K. Sridhar, R. Rustum et al., J. Mater. Res. 8(12), 3163–3167 (1993)

X. Wu, G. Shao, X. Shen et al., Rsc Adv. 6(7), 5611–5620 (2016). https://doi.org/10.1039/c5ra19764c

R. Castellani, A. Poulesquen, F. Goettmann et al., Colloids Surf., A 430, 39–45 (2013). https://doi.org/10.1016/j.colsurfa.2013.03.056

I.A. Rahman, P. Vejayakumaran, C.S. Sipaut et al., Ceram. Int. 32(6), 691–699 (2006). https://doi.org/10.1016/j.ceramint.2005.05.004

S.S. Prakash, C.J. Brinker, A.J. Hurd et al., Nature 374(6521), 439–443 (1995)

K. Kanamori, M. Aizawa, K. Nakanishi et al., Adv. Mater. 19(12), 1589–1593 (2007)

V. Paunovic, S. Mitchell, R. Verel et al., Phys. Chem. C. 124(1), 722–773 (2020). https://doi.org/10.1021/acs.jpcc.9b09984

M. Sakhalkar, R.P. Choudhury, V. Bhakthavatsalam et al., J. Mol. Struct. (2020). https://doi.org/10.1016/j.molstruc.2020.128936

Y. Bi, H. Ren, L. He et al., Mater. Lett. 139, 205–207 (2015). https://doi.org/10.1016/j.matlet.2014.10.091

H. Chen, X. Sui, C. Zhou et al., J. Ceram. Soc. Jpn. 124(4), 442–447 (2016). https://doi.org/10.2109/jcersj2.15184

A.N. Mitropoulos, F.J. Burpo, C.K. Nguyen et al., Materials (Basel). (2019). https://doi.org/10.3390/ma12060894

F.D. Sun, Z.J. Hu, J.N. Li et al., Ceram. Int. 40(8), 11787–11793 (2014). https://doi.org/10.1016/j.ceramint.2014.04.008

Y. Wang, Z. Chen, S. Yu et al., Compos. Part. B-Eng. 129, 180–186 (2017). https://doi.org/10.1016/j.compositesb.2017.07.068

Z.C. Hu, S.H. Meng, J.P. Li et al., Compos Part A-Appl S. (2020). https://doi.org/10.1016/j.compositesa.2020.105799

J. Li, J. Rui, Y. Li et al., Int. J. Appl. Ceram. Tec. (2023). https://doi.org/10.1111/ijac.14356

X.L. Lan, H.R. Zhao, B.X. Zhang et al., Chem. Eng. J. (2021). https://doi.org/10.1016/j.cej.2021.130727

Q. Tian, N. Wu, B. Wang et al., Mater. Lett. 239, 109–112 (2019). https://doi.org/10.1016/j.matlet.2018.12.077

B. Tang, Y. Wang, L. Hu et al., J. Eng. Fiber. Fabr. (2019). https://doi.org/10.1177/1558925019884691

P. Pazhamalai, K. Krishnamoorthy, S. Sahoo et al., Chem. Eng. J. (2020). https://doi.org/10.1016/j.cej.2019.123886

L. Ding, J. Liao, Y. Zhang, Coll. Surfaces A Physicochem. Eng. Aspects. (2021). https://doi.org/10.1016/j.colsurfa.2020.125980

Y.L. Liu, T.T. Yang, L. Zhu et al., Fusion Eng. Des. (2022). https://doi.org/10.1016/j.fusengdes.2022.113134

H. Yu, Z. Tong, S. Yue et al., J. Eur. Ceram. Soc. 41(1), 580–589 (2021). https://doi.org/10.1016/j.jeurceramsoc.2020.0

Acknowledgements

We acknowledge the funding supports from National Natural Science Foundation of China (Grant. No.: 51972222).

Author information

Authors and Affiliations

Contributions

WZ: Conceptualization, Experimentalize, Data curation, Writing – original draft. YJ: Data curation. YP: Validation. XL: Supervision. HJ: Supervision Review & Editing.

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, W., Ji, Y., Pang, Y. et al. Preparation of Al2O3-SiO2 aerogel by ambient pressure drying for thermal insulation application. J Porous Mater 30, 1753–1761 (2023). https://doi.org/10.1007/s10934-023-01457-9

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10934-023-01457-9