Abstract

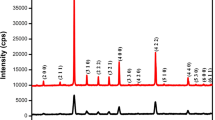

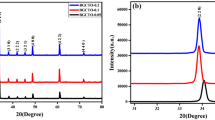

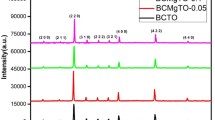

Bi0.617Y0.05Cu3Ti4O12(BYCTO) was successfully synthesized through an economically semi-wet route using metals nitrates, acetate, and TiO2 precursor and sintered at 1173 K for 8 h. The single phase of ceramic was authorized by XRD analysis. The crystallite size of BYCTO ceramic was calculated to be 62.3 nm through XRD measurement. The particle size obtained by TEM analysis was to be in the range of 55 ± 7 nm. The average grain size observed through the SEM technique was 0.783 μm. The route means square roughness, as well as average roughness, were determined to be 0.224 μm and 0.179 μm by atomic force microscope. The dielectric constant (ɛ′) of BYCTO was measured to be 1481 at 307 K and 100 Hz. The tangent loss (tan δ) was observed to be in the range of 0.13–0.29 at all selected temperatures (307–487 K) and 10 kHz which is lower than that of Bi2/3Cu3Ti4O12. The oxidation state of all metal present in the ceramic material was verified by XPS analysis.

Similar content being viewed by others

References

K. Sun, L.F. Xu, C. Mao, X. Feng, J.Y. Liang, H.B. Xiao, R.L. Wang, D.W. Shi, C.P. Yang, J. Alloys Compd. 704, 676 (2017)

P. Mao, J. Wang, S. Liu, L. Zhang, Y. Zhao, L. He, J. Alloys Compd. 778, 625 (2019)

L.C. Kretly, A.F.L. Almeida, P.B.A. Fechine, R.S. De Oliveira, A.S.B. Sombra, J. Mater. Sci. 15, 657 (2004)

R. K. Pandey, W. A. Stapleton, J. Tate, A. K. Bandyopadhyay, I. Sutanto, S. Sprissler, and S. Lin, AIP Adv. 3, 0 (2013).

S. Rani, N. Ahlawat, K.M. Sangwan, S. Rani, R. Punia, J. Malik, J. Mater. Sci. Mater. 29, 10825 (2018)

L. Singh, B.C. Sin, I.W. Kim, K.D. Mandal, H. Chung, Y. Lee, J. Am. Ceram. Soc. 99, 27 (2016)

M.A. Subramanian, D. Li, N. Duan, B.A. Reisner, A.W. Sleight, J. Solid State Chem. 151, 323 (2000)

C. Kai, L. Wei, L. Yun-Fei, B. Peng, L. Xiao-Mei, Z. Jin-Song, Chin. Phys. Lett. 21, 1815 (2004)

M. Li, A. Feteira, D.C. Sinclair, A.R. West, Appl. Phys. Lett. 88, 1 (2006)

M. H. Cohen, J. B. Neaton, L. He, D. Vanderbilt, M. H. Cohen, J. B. Neaton, L. He, and D. Vanderbilt, 3299, (2012).

M. Li, Z. Shen, M. Nygren, A. Feteira, D. C. Sinclair, and A. R. West, J. Appl. Phys. 106, (2009).

P.R. Bueno, R. Tararan, R. Parra, E. Joanni, M.A. Ramírez, W.C. Ribeiro, E. Longo, J.A. Varela, J. Phys. D 42, 055404 (2009)

D.C. Sinclair, T.B. Adams, F.D. Morrison, A.R. West, Appl. Phys. Lett. 80, 2153 (2002)

W. Li, R.W. Schwartz, Appl. Phys. Lett. 89, 87 (2006)

Y.Q. Tan, J.L. Zhang, W.T. Hao, G. Chen, W.B. Su, C.L. Wang, Mater. Chem. Phys. 124, 1100 (2010)

Z. Yang, P. Liang, L. Yang, P. Shi, X. Chao, Z. Yang, J. Mater. Sci. Mater. 26, 1959 (2015)

L. Yang, X. Chao, Z. Yang, N. Zhao, L. Wei, Z. Yang, Ceram. Int. 42, 2526 (2016)

L. Yang, G. Huang, T. Wang, H. Hao, Y. Tian, Ceram. Int. 42, 9935 (2016)

L. Sun, Z. Wang, W. Hao, E. Cao, Y. Zhang, H. Peng, J. Alloys Compd. 651, 283 (2015)

V.S. Saji, H.C. Choe, Thin Solid Films 517, 3896 (2009)

F. Luo, J. He, J. Hu, Y.H. Lin, J. Am. Ceram. Soc. 93, 3043 (2010)

S. Sharma, S.S. Yadav, M.M. Singh, K.D. Mandal, J. Adv. Dielectr. 04, 1450030 (2014)

J. Liu, C.G. Duan, W.G. Yin, W.N. Mei, R.W. Smith, J.R. Hardy, Phys. Rev. B 70, 1 (2004)

P. Gautam, A. Khare, S. Sharma, N.B. Singh, K.D. Mandal, Prog. Nat. Sci. Mater. Int. 26, 567 (2016)

M. M. Ahmad and K. Yamada, J. Appl. Phys. 115 (2014).

M.M. Ahmad, E. Al-Libidi, A. Al-Jaafari, S. Ghazanfar, K. Yamada, Appl. Phys. A 116, 1299 (2014)

V. Kumar, S. Pandey, A. Kumar, M.K. Verma, S. Singh, V.S. Rai, D. Prajapati, T. Das, A. Sharma, C.L. Prajapat, A. Gangwar, K.D. Mandal, J. Mater. Res. Technol. 9, 12936 (2020)

V. S. Rai, S. Pandey, V. Kumar, M. K. Verma, A. Kumar, S. Singh, D. Prajapati, and K. D. Mandal, J. Mater. Sci. Mater. Electron. 12, (2020).

T. T. Carol T, J. Mohammed, R. Bhargava, S. Khan, S. Mishra, S. K. Godara, and A. K. Srivastava, Mater. Chem. Phys. 248, 122933 (2020).

R.K. Nimat, R.S. Joshi, S.H. Pawar, J. Alloys Compd. 466, 341 (2008)

Y. Zhao, B. Yang, Q. Wu, Y. Zhou, F. Guo, and S. Zhao, Nanoscale (2021).

L. Singh, M. Sheeraz, M.N. Chowdhury, U.S. Rai, S.S. Yadava, Y.S. Park, S.V. Singh, Y. Lee, J. Mater. Sci. Mater. 29, 10082 (2018)

S. Pandey, V. Kumar, V.K. Sharma, K.D. Mandal, Mater. Chem. Phys. 253, 123384 (2020)

M. Claros, M. Setka, Y.P. Jimenez, S. Vallejos, Nanomaterials 10, 1 (2020)

V. Kumar, A. Kumar, M. K. Verma, S. Singh, S. Pandey, V. S. Rai, D. Prajapati, T. Das, N. B. Singh, and K. D. Mandal, Mater. Chem. Phys. 245 (2020).

S. Jaiswar, K.D. Mandal, J. Phys. Chem. C 121, 19586 (2017)

S. Thakur, R. Rai, I. Bdikin, M.A. Valente, Mater. Res. 19, 1 (2016)

S.B.R.S. Adnan, N.S. Mohamed, Ceram. Int. 40, 11441 (2014)

M. Veith, S. Ren, M. Wittmar, H. Bolz, J. Solid State Chem. 182, 2930 (2009)

M. M. Costa, G. F. M. Pires, A. J. Terezo, M. P. F. Graa, and A. S. B. Sombra, J. Appl. Phys. 110 (2011).

A. Kumar, S.S. Yadava, P. Gautam, A. Khare, K.D. Mandal, J. Electroceram. 42, 47 (2019)

R. Jana, J. Datta, S. Sil, A. Dey, B. Pal, A. Biswas, and P. P. Ray, Mater. Res. Express 6 (2019).

Acknowledgements

The author is grateful to the Central Instrument Facility Centre (CIFC) IIT (BHU) Varanasi for providing SEM, TEM, AFM, EDX, and XPS facilities.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors state that there is no brawl among them concerning the publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Prajapati, D., Rai, V.S., Pandey, S. et al. Studies of microstructural, dielectric, and impedance spectroscopic properties of Bi0.617Y0.05Cu3Ti4O12 ceramic synthesized through semi-wet route. J Mater Sci: Mater Electron 32, 26371–26383 (2021). https://doi.org/10.1007/s10854-021-07005-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-07005-y