Abstract

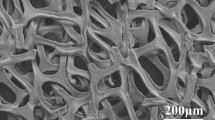

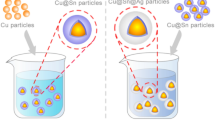

A simple and low-cost Cu foam/Sn composite preform was proposed for the low-temperature interconnection of high-power devices. The composite preform was prepared by pressing a Cu foam as the skeleton between two Sn foils as low-melting point metals with different pressures. The composite preform retains the high re-melting temperature superiority of transient liquid phase (TLP) bonding, as well as shortens the reflow time of intermetallic compounds (IMCs). The microstructures of the bondlines and the electrical and mechanical properties of the composite preform pressed at different pressures were studied. After sintering at 260 °C, the interconnection layer becomes denser with the increasing pressures of composite preform, and the bondline is composed of mainly Cu6Sn5, Cu3Sn and Ag3Sn phase. When the pressure of the composite preform increases from 200 to 400 MPa, the electrical resistivity decreases and the shear strength of bonded joints increases. At the pressure of 400 MPa, the electrical resistivity and the shear strength are 8.83 μΩ cm and 36.4 MPa, respectively, which are far better than the traditional Sn performs. Furthermore, two fracture failure models were obtained to analyze the breaking mechanism of the bonding joints under different sintering temperatures.

Similar content being viewed by others

References

X. Liu, S. He, H. Nishikawa, Thermally stable Cu3Sn/Cu composite joint for high-temperature power device. Scr. Mater. 110, 101–104 (2016)

Y. Peng, Q. Sun, J. Liu, H. Cheng, Y. Mou, Fabrication of stacked color converter for high-power WLEDs with ultra-high color rendering. J. Alloys Compd. 850, 156811 (2021)

J. Liu, K. Wang, F. Yu, C. Hang, X. Fu, H. Chen, M. Li, A paste based on Cu@Sn@Ag particles for die attachment under ambient atmosphere in power device packaging. J. Mater. Sci. 31, 1808–1816 (2020)

Y. Mou, J. Liu, H. Cheng, Y. Peng, M. Chen, Facile preparation of self-reducible Cu nanoparticle paste for low temperature Cu–Cu bonding. JOM 71, 3076–3083 (2019)

J. Li, Q. Liang, T. Shi, J. Fan, B. Gong, C. Feng, J. Fan, G. Liao, Z. Tang, Design of Cu nanoaggregates composed of ultra-small Cu nanoparticles for Cu–Cu thermocompression bonding. J. Alloys Compd. 772, 793–800 (2019)

C. Subramaniam, Y. Yasuda, S. Takeya et al., Carbon nanotube-copper exhibiting metal-like thermal conductivity and silicon-like thermal expansion for efficient cooling of electronics. Nanoscale 6, 2669–2674 (2014)

L. Coppola, D. Huff, F. Wang, R. Burgos, D. Boroyevich, Survey on high-temperature packaging materials for SiC-based power electronics modules. IEEE Power Electron. Spec. Conf. 38, 2234–2240 (2007)

Y. Kong, X. Li, Y. Mei, G. Lu, Effects of die-attach material and ambient temperature on properties of high-power COB blue LED module. IEEE Trans. Electron Devices 62, 2251–2256 (2015)

N. Narendran, Y. Gu, Life of LED-based white light sources. J. Disp. Technol. 1, 167–171 (2005)

F. Roccaforte, P. Fiorenza, G. Greco, R. Lo Nigro, F. Giannazzo, F. Iucolano, M. Saggio, Emerging trends in wide band gap semiconductors (SiC and GaN) technology for power devices. Microelectron. Eng. 187–188, 66–77 (2018)

Q. Sun, Z. Yang, H. Cheng, Y. Peng, Y. Huang, M. Chen, Creation of three-dimensional structures by direct ink writing with kaolin suspensions. J. Mater. Chem. C 6, 11392–11400 (2018)

Z. Shen, R.W. Johnson, M.C. Hamilton, SiC power device die attach for extreme. Environments 62, 346–353 (2015)

R.W. Johnson, J.L. Evans, P. Jacobsen, J.R. Thompson, M. Christopher, The changing automotive environment: high-temperature electronics. IEEE Trans. Electron. Packag. Manuf. 27, 164–176 (2004)

Y. Zhong, R. An, C. Wang, Z. Zheng, Z. Liu, C. Liu, C. Li, T. Kim, S. Jin, Low temperature sintering Cu6Sn5 nanoparticles for superplastic and super-uniform high temperature circuit interconnections. Small 11, 4097–4103 (2015)

Z.X. Zhu, C.C. Li, L.L. Liao, C.K. Liu, C.R. Kao, Au–Sn bonding material for the assembly of power integrated circuit module. J. Alloys Compd. 671, 340–345 (2016)

S.A. Paknejad, A. Mansourian, Y. Noh, K. Khtatba, S.H. Mannan, Thermally stable high temperature die attach solution. Mater. Des. 89, 1310–1314 (2016)

Y. Du, C. Li, B. Huang, M. Tang, C. Du, Research and prospect of binary high-temperature Pb-free solders. Solder. Surf. Mt. Technol. 27, 7–12 (2015)

T. Yang, J. Wu, C. Li, S. Yang, C.R. Kao, Low temperature bonding for high temperature applications by using SnBi solders. J. Alloys Compd. 647, 681–685 (2015)

C. Chen, D. Kim, Z. Wang, Z. Zhang, Y. Gao, C. Choe, K. Suganuma, Low temperature low pressure solid-state porous Ag bonding for large area and its high-reliability design in die-attached power modules. Ceram. Int. 45, 9573–9579 (2019)

Y. Mou, H. Wang, Y. Peng, J. Liu, H. Cheng, Q. Sun, M. Chen, Low temperature enhanced flexible conductive film by Ag flake/ion composite ink. Mater. Des. 186, 108339 (2020)

E. Ide, S. Angata, A. Hirose, K. Kobayashi, Metal–metal bonding process using Ag metallo-organic nanoparticles. Acta Mater. 53, 2385–2393 (2005)

Z. Liu, J. Cai, Q. Wang, Z. Wang, L. Liu, G. Zou, Thermal-stable void-free interface morphology and bonding mechanism of low-temperature Cu–Cu bonding using Ag nanostructure as intermediate. J. Alloys Compd. 767, 575–582 (2018)

J. Li, X. Zhang, X. Liu, Q. Liang, G. Liao, Z. Tang, T. Shi, Conductivity and foldability enhancement of Ag patterns formed by PVAc modified Ag complex inks with low-temperature and rapid sintering. Mater. Des. 185, 108255 (2020)

J. Liu, Y. Mou, Y. Peng, Q. Sun, M. Chen, Novel Cu–Ag composite nanoparticle paste for low temperature bonding. Mater. Lett. 248, 78–81 (2019)

T. Hu, H. Chen, M. Li, C. Wang, Microstructure evolution and thermostability of bondline based on Cu@Sn core-shell structured microparticles under high-temperature conditions. Mater. Des. 131, 196–203 (2017)

B.S. Lee, S.K. Hyun, J.W. Yoon, Cu–Sn and Ni–Sn transient liquid phase bonding for die-attach technology applications in high-temperature power electronics packaging. J. Mater. Sci. Mater. Electron. 28, 7827–7833 (2017)

H. Shao, A. Wu, Y. Bao, Y. Zhao, G. Zou, L. Liu, Novel transient liquid phase bonding through capillary action for high-temperature power devices packaging. Mater. Sci. Eng. 724, 231–238 (2018)

X. Liu, S. He, H. Nishikawa, Low temperature solid-state bonding using Sn-coated Cu particles for high temperature die attach. J. Alloys Compd. 695, 2165–2172 (2017)

F. Yu, B. Wang, Q. Guo, X. Ma, M. Li, H. Chen, Ag@Sn core-shell powder preform with a high re-melting temperature for high-temperature power devices packaging. Adv. Eng. Mater. 20, 1700524 (2018)

F. Yu, C. Hang, M. Zhao, H. Chen, An interconnection method based on Sn-coated Ni core-shell powder preforms for high-temperature applications. J. Alloys Compd. 776, 791–797 (2019)

T. Hu, H. Chen, M. Li, Die attach materials with high remelting temperatures created by bonding Cu@Sn microparticles at lower temperatures. Mater. Des. 108, 383–390 (2016)

Y. Xiao, Q. Wang, L. Wang, X. Zeng, M. Li, Z. Wang, X. Zhang, X. Zhu, Ultrasonic soldering of Cu alloy using Ni-foam/Sn composite interlayer. Ultrason. Sonochem. 45, 223–230 (2018)

H. He, S. Huang, Y. Ye, Y. Xiao, Z. Zhang, M. Li, R. Goodall, Microstructure and mechanical properties of Cu joints soldered with a Sn-based composite solder, reinforced by metal foam. J. Alloys Compd. 845, 156240 (2020)

F. Yu, H. Chen, C. Hang, M. Li, Fabrication of high-temperature-resistant bondline based on multilayer core–shell hybrid microspheres for power devices. J. Mater. Sci. Mater. Electron. 30, 3595–3603 (2019)

Acknowledgements

The authors sincerely thank the facility support of Analytical and Testing Center of Huazhong University of Science and Technology for SEM, TG-DSC and EDS measurements. This work was financially supported by the National Natural Science Foundation of China (51775219, 51805196) and the Fundamental Research Funds for Central Universities (2017JYCXJJ006).

Author information

Authors and Affiliations

Contributions

JL: experimental design, write the manuscript. QW and JL: participate in the experimental process, data curation. YM: give some advices to this work. YP and MC: supervision, review and edit, be related to the funding projects. All authors have read and approved the manuscript.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Wang, Q., Liu, J. et al. Facile preparation of Cu foam/Sn composite preforms for low-temperature interconnection of high-power devices. J Mater Sci: Mater Electron 32, 12547–12556 (2021). https://doi.org/10.1007/s10854-021-05890-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10854-021-05890-x