Abstract

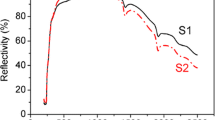

The application of carbon fiber epoxy resin composite (CFRP) in the aerospace industry is limited by the laser treatment, because of the poor oxidation resistance and anti-laser ablation performance of the composites. The application of a coating on components is an effective method to improve their laser ablation resistance. The nitride coatings, consisting of Si3N4, AlN, BN, and an epoxy resin, were applied onto the CFRP using brush painting. When irradiating at 100 W/cm2 for 5 s, the damage has occurred on the coating with Si3N4 and AlN, and the BN coating remains original morphology at 100 W/cm2 for 20 s. With the power density has increased to 200 W/cm2, the serious ablation damage occurs in the BN coating irradiated for 10 s. Due to the heat absorption of resin pyrolysis and the low thermal conductivity of CFRP, the highest back-surface temperature is only 75 °C. The laser protection performance of CFRP should mainly improved by increasing the reflectivity of the coating.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Li F, Liu Y, Qu CB et al (2015) Enhanced mechanical properties of short carbon fiber reinforced polyethersulfone composites by graphene oxide coating. Polymer (Guildf) 59:155–165. https://doi.org/10.1016/j.polymer.2014.12.067

Fu J, Zhang M, Jin L et al (2019) Enhancing interfacial properties of carbon fibers reinforced epoxy composites via Layer-by-Layer self assembly GO/SiO2 multilayers films on carbon fibers surface. Appl Surf Sci 470:543–554. https://doi.org/10.1016/j.apsusc.2018.11.168

Kim K, Jung YC, Kim SY et al (2018) Adhesion enhancement and damage protection for carbon fiber-reinforced polymer (CFRP) composites via silica particle coating. Compos Part A Appl Sci Manuf 109:105–114. https://doi.org/10.1016/j.compositesa.2018.02.042

Hopmann C, Karatzias C, Wagner R et al (2017) Production of CFRP components with clear surface layer in the PU spray impregnation process. AIP Conf Proc 1914. https://doi.org/10.1063/1.5016754

Malinowski PH, Ostachowicz WM, Brune K, Schlag M (2017) Study of electromechanical impedance changes caused by modifications of CFRP adhesive bonds. Fatigue Fract Eng Mater Struct 40:1592–1600. https://doi.org/10.1111/ffe.12661

Ganesan A, Takuma O, Yamada M, Fukumoto M (2016) Microstructure and mechanical properties of warm-sprayed titanium coating on carbon fiber-reinforced plastic. J Therm Spray Technol 25:788–796. https://doi.org/10.1007/s11666-016-0392-x

Khalil YF (2017) Eco-efficient lightweight carbon-fiber reinforced polymer for environmentally greener commercial aviation industry. Sustain Prod Consum 12:16–26. https://doi.org/10.1016/j.spc.2017.05.004

Liu YC, Wu CW, Huang YH et al (2017) Interlaminar damage of carbon fiber reinforced polymer composite laminate under continuous wave laser irradiation. Opt Lasers Eng 88:91–101. https://doi.org/10.1016/j.optlaseng.2016.08.001

Nan P, Li X, Pan Y et al (2020) Characteristics and influences of plume during CW laser-CFRP interaction under tangential gas flow. Laser Phys 30. https://doi.org/10.1088/1555-6611/ab92a8

Yang Y, Tian X, Ma Z et al (2022) Laser irradiation behavior of carbon fiber epoxy resin composites with laminar structure. Crystals 12. https://doi.org/10.3390/cryst12121767

Liu T, Niu Y, Pan X et al (2019) Laser ablation behaviors of vacuum plasma sprayed ZrC-based coatings. J Am Ceram Soc 102:4247–4258. https://doi.org/10.1111/jace.16278

Cheng S, Geng L, Liu X, Wang Y (2020) Laser ablation behavior and mechanism of C/SiC coated with ZrB2–MoSi2–SiC/Mo prepared by HVOF. Ceram Int 46:17752–17762. https://doi.org/10.1016/j.ceramint.2020.04.080

Ma C, Ma Z, Gao L et al (2019) Zirconium carbide-modified polymer-matrix composites with improved reflectivity under high-energy laser ablation. Ceram Int 45:17681–17687. https://doi.org/10.1016/j.ceramint.2019.05.335

Li W, Gao L, Ma Z, Wang F (2017) Ablation behavior of graphite/SiO2 composite irradiated by high-intensity continuous laser. J Eur Ceram Soc 37:1331–1338. https://doi.org/10.1016/j.jeurceramsoc.2016.11.052

Chen G, Zhu S, Jiang Z et al (2017) Laser ablation protection of polymer matrix composites by adhesive inorganic coatings. J Mater Sci 52:12734–12741. https://doi.org/10.1007/s10853-017-1400-3

Wang J, Li C, Hu W et al (2018) Hexagonal boron nitride nanosheets incorporated antireflective silica coating with enhanced laser-induced damage threshold. High Power Laser Sci Eng 6:1–6. https://doi.org/10.1017/hpl.2018.16

Zhuang Y, Wang S, Jia D et al (2015) Fabrication of gel cast BN/Si3N4 composite ceramics from surface-coated BN powder. Mater Sci Eng A 626:27–33. https://doi.org/10.1016/j.msea.2014.12.050

Yin X, Kong L, Zhang L et al (2014) Electromagnetic properties of Si-C-N based ceramics and composites. Int Mater Rev 59:326–355. https://doi.org/10.1179/1743280414Y.0000000037

Liu Z, Zhao S, Yang T, Zhou J (2021) Improvement in mechanical properties in AlN-h-BN composites with high thermal conductivity. J Adv Ceram 10:1317–1325. https://doi.org/10.1007/s40145-021-0506-0

Chen F, Li F, Shen Q, Zhang L (2013) Cold spray and presureless sintering of zirconium phosphate bonded silicon nitride ceramics with porous gradient structure. J Phys Conf Ser 419. https://doi.org/10.1088/1742-6596/419/1/012006

Chen S, Wang L, He G et al (2022) Microstructure and properties of porous Si3N4 ceramics by gelcasting-self-propagating high-temperature synthesis (SHS). J Adv Ceram 11:172–183. https://doi.org/10.1007/s40145-021-0525-7

Sun Y, Zhao Z, Li X et al (2018) A novel aerogels/porous Si3N4 ceramics composite with high strength and improved thermal insulation property. Ceram Int 44:5233–5237. https://doi.org/10.1016/j.ceramint.2017.12.132

Aasi A, Aghaei SM, Panchapakesan B (2023) Noble metal (Pt or Pd)-decorated atomically thin MoS2 as a promising material for sensing colorectal cancer biomarkers through exhaled breath. Int J Comput Mater Sci Eng 13:2350014. https://doi.org/10.1142/S2047684123500148

Aasi A, Ebrahimi Bajgani S, Panchapakesan B (2023) A first-principles investigation on the adsorption of octanal and nonanal molecules with decorated monolayer WS2 as promising gas sensing platform. AIP Adv 13:25157. https://doi.org/10.1063/5.0139950

Darut G, Dieu S, Schnuriger B et al (2021) State of the art of particle emissions in thermal spraying and other high energy processes based on metal powders. J Clean Prod 303:126952. https://doi.org/10.1016/j.jclepro.2021.126952

Li Y, Huang B, Liu Y, Lan L (2023) Sb2Se3/CdS/ZnO photodetectors based on physical vapor deposition for color imaging applications. Opt Lett 48:2583–2586

Li M, Wang D, Xue J, Jia R (2019) Direct preparation of Y3Al5O12 hollow microspheres using cathode plasma electrolytic deposition. Ceram Int 45:24919–24922. https://doi.org/10.1016/j.ceramint.2019.08.168

Miśkiewicz P, Frydrych I, Cichocka A (2022) Application of physical vapor deposition in textile industry. Autex Res J 22:42–54. https://doi.org/10.2478/aut-2020-0004

Zheng X, Park CW (2019) Thermal and mechanical properties of carbon fiber-reinforced resin composites with copper/boron nitride coating. Compos Struct 220:494–501. https://doi.org/10.1016/j.compstruct.2019.03.089

Kim G-W, Kim YJ (2021) Review of brush painting for cost-efficient paintable electronics. Appl Sci Converg Technol 30:1–5

Zeng X, Shen Y, Liu Y et al (2020) A cross-linked coating decorated mesh prepared by brush-painting method for oil-in-water emulsions separation. Mater Chem Phys 242:122541. https://doi.org/10.1016/j.matchemphys.2019.122541

Heo SW, Lee JY, Song HJ et al (2011) Patternable brush painting process for fabrication of flexible polymer solar cells. Sol Energy Mater Sol Cells 95:3041–3046. https://doi.org/10.1016/j.solmat.2011.06.029

Acknowledgements

This work was supported by National Key Research and Development Program (2022YFE0121200), National Natural Science Foundation of China (No. 52073029) and the special fund for Science and Technology Innovation Teams of Shanxi Province (202204051001001).

Author information

Authors and Affiliations

Contributions

Formal analysis, visualization, original draft preparation and writing, YY; supervision and project administration, ZM; conceptualization, AAR; data curation, WT, XG and BX; writing—review and editing, LG and XT.

Corresponding authors

Ethics declarations

Conflict of interest

The authors confirm that there is no conflict of interest.

Ethical approval

Not applicable.

Additional information

Handling Editor: Mohammad Naraghi.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, Y., Ma, Z., Rogachev, A. et al. Study on the laser ablation behavior of nitride coatings on carbon fiber epoxy resin composite. J Mater Sci 59, 95–104 (2024). https://doi.org/10.1007/s10853-023-09166-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-09166-z