Abstract

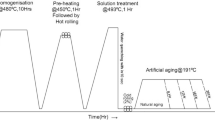

Enhancing the high temperature mechanical properties and the thermal stability of aluminum alloys are in urgent demand for the lightweight application scenarios (such as pistons, fan blades, crankshafts) working at elevated temperatures. The fabrication of aluminum matrix composites is a promising solution. In this work, TiB2 nanoparticles were in-situ introduced to a typical heat resistant Al–Cu–Mg–Fe–Ni (Al2618) alloy matrix and subjected to hot extrusion. Microscopically, the extruded TiB2/Al composite exhibited refined and bimodal sized grain structure, which was stable after long-time thermal exposure associated with TiB2 particle banding along the extrusion direction. The TiB2/Al composite showed an evident improvement in high temperature strength as well as the strength retention after long-time thermal exposure up to 300 °C, compared to the unreinforced alloy. The strengthening effect was remarkable especially at 200 °C with an increase of ~ 20% (60–70 MPa) in tensile strength and strength retention after thermal exposure but without the trade-off of ductility. The effects of TiB2 particles on the temperature-dependent strengthening mechanisms and microstructure evolutions were investigated. This work inspires the design, processing and evaluation of novel high strength and heat resistant particle-reinforced aluminum matrix composites for the potential applications under elevated temperature service conditions.

Graphical Abstract

Similar content being viewed by others

Data and code availability

Data supporting the findings of the current study are available from the corresponding authors upon request.

References

Michi RA, Plotkowski A, Shyam A et al (2022) Towards high-temperature applications of aluminium alloys enabled by additive manufacturing. Int Mater Rev 67:298–345. https://doi.org/10.1080/09506608.2021.1951580

Gao YY, Qiu F, Zhao QL, Jiang QC (2019) A new approach for improving the elevated-temperature strength and ductility of Al–Cu–Mg–Si alloys with minor amounts of dual-phased submicron/nanosized TiB2–TiC particles. Mater Sci Eng A 764:138266. https://doi.org/10.1016/j.msea.2019.138266

Sims ZC, Rios OR, Weiss D et al (2017) High performance aluminum-cerium alloys for high-temperature applications. Mater Horizons 4:1070–1078. https://doi.org/10.1039/c7mh00391a

Williams JC, Starke EA (2003) Progress in structural materials for aerospace systems. Acta Mater 51:5775–5799. https://doi.org/10.1016/j.actamat.2003.08.023

Moreau ED, Donaldson IW, Hexemer RL, Paul Bishop DP (2013) Effects of Fe and Ni additions on emerging Al-4·5Cu-1·5Mg powder metallurgy alloy: Part 2—Influence of elevated temperature exposure. Can Metall Q 52:380–390. https://doi.org/10.1179/1879139513Y.0000000072

Bian Z, Dai S, Wu L et al (2019) Thermal stability of Al-Fe-Ni alloy at high temperatures. J Mater Res Technol 8:2538–2548. https://doi.org/10.1016/j.jmrt.2019.01.028

Hu K, Xu Q, Ma X et al (2019) A novel heat-resistant Al–Si–Cu–Ni–Mg base material synergistically strengthened by Ni-rich intermetallics and nano-AlNp microskeletons. J Mater Sci Technol 35:306–312. https://doi.org/10.1016/j.jmst.2018.09.051

Balducci E, Ceschini L, Morri A et al (2015) High temperature behavior of the EN AW-2618A Piston alloy containing 0.12wt% Zr: influence of heat treatment. Elsevier Ltd, Amsterdam

Elgallad EM, Shen P, Zhang Z, Chen X (2014) Effects of heat treatment on the microstructure and mechanical properties of AA2618 DC cast alloy. Mater Des 61:133–140. https://doi.org/10.1016/j.matdes.2014.04.045

Ceschini L, Morri A, Morri A, Di Sabatino M (2015) Effect of thermal exposure on the residual hardness and tensile properties of the EN AW-2618A piston alloy. Mater Sci Eng A 639:288–297. https://doi.org/10.1016/j.msea.2015.04.080

Chao ZL, Zhang LC, Jiang LT et al (2019) Design, microstructure and high temperature properties of in-situ Al3Ti and nano-Al2O3 reinforced 2024Al matrix composites from Al-TiO2 system. J Alloys Compd 775:290–297. https://doi.org/10.1016/j.jallcom.2018.09.376

Tian WS, Zhao QL, Zhang QQ et al (2018) Simultaneously increasing the high-temperature tensile strength and ductility of nano-sized TiCp reinforced Al-Cu matrix composites. Mater Sci Eng A 717:105–112. https://doi.org/10.1016/j.msea.2018.01.069

Li J, Nie J, Xu Q et al (2020) Enhanced mechanical properties of a novel heat resistant Al-based composite reinforced by the combination of nano-aluminides and submicron TiN particles. Mater Sci Eng A 770:138488. https://doi.org/10.1016/j.msea.2019.138488

Rofman OV, Mikhaylovskaya AV, Kotov AD et al (2020) AA2024/SiC metal matrix composites simultaneously improve ductility and cracking resistance during elevated temperature deformation. Mater Sci Eng A 790:139697. https://doi.org/10.1016/j.msea.2020.139697

Wang M, Chen D, Chen Z et al (2014) Mechanical properties of in-situ TiB2/A356 composites. Mater Sci Eng A 590:246–254. https://doi.org/10.1016/j.msea.2013.10.021

Sanaty-Zadeh A (2012) Comparison between current models for the strength of particulate-reinforced metal matrix nanocomposites with emphasis on consideration of Hall-Petch effect. Mater Sci Eng A Struct Mater 531:112–118. https://doi.org/10.1016/j.msea.2011.10.043

Gao M, Chen Z, Li L et al (2021) Microstructure and enhanced mechanical properties of hybrid-sized B4C particle-reinforced 6061Al matrix composites. Mater Sci Eng A 802:140453. https://doi.org/10.1016/j.msea.2020.140453

Ma L, Zhang X, Duan Y et al (2023) Achieving exceptional high-temperature resistant Al matrix composites via two-dimensional BN pinning grain rotation. Compos Part B Eng 253:110570. https://doi.org/10.1016/j.compositesb.2023.110570

Ma SM, Zhang P, Ji G et al (2014) Microstructure and mechanical properties of friction stir processed Al–Mg–Si alloys dispersion-strengthened by nanosized TiB2 particles. J Alloys Compd 616:128–136. https://doi.org/10.1016/j.jallcom.2014.07.092

Greer AL, Bunn AM, Tronche A et al (2000) Modelling of inoculation of metallic melts: application to grain refinement of aluminium by Al–Ti–B. Acta Mater 48:2823–2835. https://doi.org/10.1016/S1359-6454(00)00094-X

Chen Z, Sun GA, Wu Y et al (2017) Multi-scale study of microstructure evolution in hot extruded nano-sized TiB2 particle reinforced aluminum composites. Mater Des 116:577–590. https://doi.org/10.1016/j.matdes.2016.12.070

Ma S, Wang Y, Wang X (2020) Microstructures and mechanical properties of an Al-Cu-Mg-Sc alloy reinforced with in-situ TiB2 particulates. Mater Sci Eng A Struct Mater 788:139603. https://doi.org/10.1016/j.msea.2020.139603

Ma Y, Addad A, Ji G et al (2020) Atomic-scale investigation of the interface precipitation in a TiB2 nanoparticles reinforced Al–Zn–Mg–Cu matrix composite. Acta Mater 185:287–299. https://doi.org/10.1016/j.actamat.2019.11.068

Liu J, Chen Z, Zhang F et al (2019) Microstructural evolution and mechanical property of nanoparticles reinforced Al matrix composites during accumulative orthogonal extrusion process. Mater Charact 155:. https://doi.org/10.1016/j.matchar.2019.109790

Ma Y, Chen H, Zhang MX et al (2023) Break through the strength-ductility trade-off dilemma in aluminum matrix composites via precipitation-assisted interface tailoring. Acta Mater 242. https://doi.org/10.1016/j.actamat.2022.118470

Geng J, Hong T, Shen Y et al (2017) Microstructural stability of in-situ TiB2/Al composite during solution treatment. Mater Charact 124:50–57. https://doi.org/10.1016/j.matchar.2016.11.032

Zhu Y, Wu X (2019) Perspective on hetero-deformation induced (HDI) hardening and back stress. Mater Res Lett 7:393–398. https://doi.org/10.1080/21663831.2019.1616331

Ma S, Li Y, Kan W et al (2022) Enhancement of grain refinement and heat resistance in TiB.sub.2-reinforced Al-Cu-Mg-Fe-Ni matrix composite additive manufactured by electron beam melting. J Alloys Compd 924. https://doi.org/10.1016/j.jallcom.2022.166395

Ceschini L, Minak G, Morri A (2009) Forging of the AA2618/20 vol.% Al2O3p composite: Effects on microstructure and tensile properties. Compos Sci Technol 69:1783–1789. https://doi.org/10.1016/j.compscitech.2008.08.027

Sakthivel A, Palaninathan R, Velmurugan R, Raghothama Rao P (2008) Production and mechanical properties of SiCp particle-reinforced 2618 aluminum alloy composites. J Mater Sci 43:7047–7056. https://doi.org/10.1007/s10853-008-3033-z

Ye W, Zhang S, Lopez Mendez L et al (2021) Numerical simulation of the melting and alloying processes of elemental titanium and boron powders using selective laser alloying. J Manuf Process 64:1235–1247. https://doi.org/10.1016/j.jmapro.2021.02.044

Rockenhäuser C, Rowolt C, Milkereit B et al (2021) On the long-term aging of S-phase in aluminum alloy 2618A. J Mater Sci 56:8704–8716. https://doi.org/10.1007/s10853-020-05740-x

Li Z, Li Z, Tan Z et al (2020) Stress relaxation and the cellular structure-dependence of plastic deformation in additively manufactured AlSi10Mg alloys. Int J Plast 127:102640. https://doi.org/10.1016/j.ijplas.2019.12.003

Liu J, Chen Z, Zhang F et al (2018) Simultaneously increasing strength and ductility of nanoparticles reinforced al composites via accumulative orthogonal extrusion process. Mater Res Lett 6:406–412. https://doi.org/10.1080/21663831.2018.1471421

Kevin A, John W, Gilbert KJ (2019) ASM Handbook®, Volume 2B—Properties and selection of aluminum alloys. ASM International, Materials Park

Xue Y, Hao Q, Li B et al (2021) Elevated temperature mechanical properties of in-situ synthesized TiB2/Al-4.5Cu matrix composites. J Phys Conf Ser 1885. https://doi.org/10.1088/1742-6596/1885/3/032041

Yu K, Li W, Li S, Zhao J (2004) Mechanical properties and microstructure of aluminum alloy 2618 with Al3(Sc. Zr) phases. Mater Sci Eng A 368:88–93. https://doi.org/10.1016/j.msea.2003.09.092

Zhang LJ, Qiu F, Wang JG, Jiang QC (2015) High strength and good ductility at elevated temperature of nano-SiCp/Al2014 composites fabricated by semi-solid stir casting combined with hot extrusion. Mater Sci Eng A 626:338–341. https://doi.org/10.1016/j.msea.2014.12.089

Lin B, Zhang W, Zheng X et al (2019) Developing high performance mechanical properties at elevated temperature in squeeze cast Al-Cu-Mn-Fe-Ni alloys. Mater Charact 150:128–137. https://doi.org/10.1016/j.matchar.2019.01.022

Chen X, Liu C, Chen H, et al (2022) Enhanced strength and ductility of TiB2/AA7034 composite by accumulative orthogonal extrusion process. Mater Sci Eng A 848. https://doi.org/10.1016/j.msea.2022.143413

Dan CY, Chen Z, Ji G et al (2017) Microstructure study of cold rolling nanosized in-situ TiB2 particle reinforced Al composites. Mater Des 130:357–365. https://doi.org/10.1016/j.matdes.2017.05.076

Gladman T (1966) On the Theory of the effect of precipitate particles on grain growth in metals. Proc R Soc Lond A 294:298–309. https://doi.org/10.1098/rspa.1966.0208

Lifshitz IM, Slyozov VV (1961) The kinetics of precipitation from supersaturated solid solutions. J Phys Chem Solids 19:35–50. https://doi.org/10.1016/0022-3697(61)90054-3

Wagner C (1961) Theorie der Alterung von Niederschlägen durch Umlösen (Ostwald-Reifung). Zeitschrift für Elektrochemie, Berichte der Bunsengesellschaft für Phys Chemie 65:581–591. https://doi.org/10.1002/bbpc.19610650704

Styles MJ, Hutchinson CR, Chen Y et al (2012) The coexistence of two S (Al 2CuMg) phases in Al-Cu-Mg alloys. Acta Mater 60:6940–6951. https://doi.org/10.1016/j.actamat.2012.08.044

Oguocha INA, Yannacopoulos S (1999) A calorimetric study of S′ and θ′ precipitation in Al2O3 particle-reinforced AA2618. J Mater Sci 4:3335–3340. https://doi.org/10.1023/A:1004620829443

Du R, Gao Q, Wu S et al (2018) Influence of TiB2 particles on aging behavior of in-situ TiB2/Al-4.5Cu composites. Mater Sci Eng A 721:244–250. https://doi.org/10.1016/j.msea.2018.02.099

Dai S, Zhang H, Bian Z et al (2021) Insight into the recrystallization behavior and precipitation reaction of in-situ nano TiB2/Al[sbnd]Cu[sbnd]Mg composite during heat treatment. Mater Charact 181:. https://doi.org/10.1016/j.matchar.2021.111458

Zhang X, Li W, Ma J et al (2020) Temperature dependent strengthening mechanisms and yield strength for CNT/metal composites. Compos Struct 244:112246. https://doi.org/10.1016/j.compstruct.2020.112246

Kou H, Li W, Ma J et al (2018) Theoretical prediction of the temperature-dependent yield strength of solid solution strengthening Nickel-based alloys. Int J Mech Sci 140:83–92. https://doi.org/10.1016/j.ijmecsci.2018.02.042

Gutierrez-Urrutia I, Muñoz-Morris MA, Morris DG (2007) Contribution of microstructural parameters to strengthening in an ultrafine-grained Al–7% Si alloy processed by severe deformation. Acta Mater 55:1319–1330. https://doi.org/10.1016/j.actamat.2006.09.037

Nardone VC, Prewo KM (1986) On the strength of discontinuous silicon carbide reinforced aluminum composites. Scr Metall 20:43–48. https://doi.org/10.1016/0036-9748(86)90210-3

Han G, Zhang W, Zhang G et al (2015) High-temperature mechanical properties and fracture mechanisms of Al-Si piston alloy reinforced with in situ TiB2 particles. Mater Sci Eng A 633:161–168. https://doi.org/10.1016/j.msea.2015.03.021

Song S, He X, Zhou Q et al (2021) Analytical models of the strength and ductility of CNT reinforced metal matrix nano composites under elevated temperatures. Mater Sci Eng A 813:. https://doi.org/10.1016/j.msea.2021.141078

Kapoor R, Kumar N, Mishra RS et al (2010) Influence of fraction of high angle boundaries on the mechanical behavior of an ultrafine grained Al–Mg alloy. Mater Sci Eng A Struct Mater 527:5246–5254. https://doi.org/10.1016/j.msea.2010.04.086

Yang C, Liu Z, Zheng Q et al (2018) Ultrasound assisted in-situ casting technique for synthesizing small-sized blocky Al3Ti particles reinforced A356 matrix composites with improved mechanical properties. J Alloys Compd 747:580–590. https://doi.org/10.1016/j.jallcom.2018.02.010

Liu ZY, Xiao BL, Wang WG, Ma ZY (2017) Modelling of carbon nanotube dispersion and strengthening mechanisms in Al matrix composites prepared by high energy ball milling-powder metallurgy method. Compos Part A Appl Sci Manuf 94:189–198. https://doi.org/10.1016/j.compositesa.2016.11.029

Pharr GM, Nix WD (1976) A comparison of the orowan stress with the threshold stress for creep for Ni20Cr2ThO2 single crystals. Scr Metall 10:1007–1010. https://doi.org/10.1016/0036-9748(76)90117-4

Martin KJ, Madan A, Hoffman D et al (2005) Mechanical properties and thermal stability of TiN∕TiB2 nanolayered thin films. J Vac Sci Technol A Vacuum Surfaces Film 23:90–98. https://doi.org/10.1116/1.1827628

Kearney AL, Kearney A, Company (1990) Properties of cast aluminum alloys. In: Metals handbook, Vol. 2-properties and selection: nonferrous alloys and special-purpose materials, 10th edn. p 569

Zhu AW, Starke EA (1999) Strengthening effect of unshearable particles of finite size: a computer experimental study. Acta Mater 47:3263–3269. https://doi.org/10.1016/S1359-6454(99)00179-2

Wu X, Zhu Y (2017) Heterogeneous materials: a new class of materials with unprecedented mechanical properties. Mater Res Lett 5:527–532. https://doi.org/10.1080/21663831.2017.1343208

Ma E, Zhu T (2017) Towards strength–ductility synergy through the design of heterogeneous nanostructures in metals. Mater Today 20:323–331. https://doi.org/10.1016/j.mattod.2017.02.003

Huang M, Li Z, Tong J (2014) The influence of dislocation climb on the mechanical behavior of polycrystals and grain size effect at elevated temperature. Int J Plast 61:112–127. https://doi.org/10.1016/j.ijplas.2014.06.002

Acknowledgements

This work is financially supported by the National Natural Science Foundation of China [Nos. 51971137, 52071207] and Natural Science Foundation of Shanghai (China, Grant No. 22ZR1432800). Siming would like to acknowledge the funding by the International Postdoctoral Exchange Fellowship Program (Talent-Introduction Program) of China.

Author information

Authors and Affiliations

Contributions

SM: Investigation, Formal analysis, Data Curation, Writing-Original draft preparation; JD: Data Curation; CZ: Conceptualization, Methodology; MW: Validation; JL: Investigation, Data Curation; LW: Validation; HW: Supervision; ZC: Conceptualization, Supervision, Writing—Review & Editing.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Ethical approval

Not Applicable.

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, S., Dai, J., Zhang, C. et al. Enhanced high temperature mechanical properties and heat resistance of an Al–Cu–Mg–Fe–Ni matrix composite reinforced with in-situ TiB2 particles. J Mater Sci 58, 13019–13039 (2023). https://doi.org/10.1007/s10853-023-08845-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-023-08845-1