Abstract

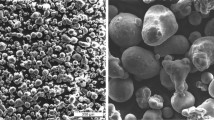

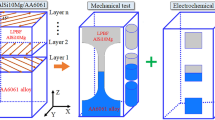

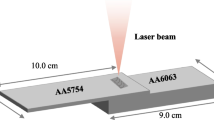

Additive manufacturing provides alternative solutions for complex geometry and design freedom for the customization of aluminum alloys, while the unique microstructure as well as the complex solidification behavior is of great concern due to the severe thermal stress in the layer-by-layer accumulated process. In this work, the effects of laser power, laser scanning speed, and hatch spacing on the microstructure and mechanical properties of a laser powder bed fusion (LPBF) fabricated thermal conductive aluminum alloy 6063 (AA6063) were studied. The relationship between processing parameters and metallurgical defects was investigated. The element distribution and misorientation between grains around the crack were characterized. The results revealed that the majority of cracks were parallel to the building direction. The crack density was suppressed by increasing the scanning speed. The orientated cracks lead to the anisotropy of mechanical properties. The strength and ductility of the vertical samples are both higher than those of the horizontal samples. After aging treatment, an ultimate tensile strength of 241 MPa, yield strength of 215 MPa, and elongation of 4.9% were obtained in the vertical specimen of the LPBF processed AA6063. It was demonstrated that cracks tend to stretch along the high-angle grain boundaries because of the concentration of local thermal stress at the final stage of solidification. This work provides guidance for defects suppression and mechanical properties optimization in additively manufactured AA6063 and other aluminum alloys.

Similar content being viewed by others

References

Martin JH, Yahata BD, Hundley JM, Mayer JA, Schaedler TA, Pollock TM (2017) 3D printing of high-strength aluminium alloys. Nature 549 (7672):365-+. https://doi.org/10.1038/nature23894

Li RD, Wang MB, Li ZM, Cao P, Yuan TC, Zhu HB (2020) Developing a high-strength Al-Mg-Si-Sc-Zr alloy for selective laser melting: crack-inhibiting and multiple strengthening mechanisms. Acta Mater 193:83–98. https://doi.org/10.1016/j.actamat.2020.03.060

Kumar P, Ramamurty U (2019) Microstructural optimization through heat treatment for enhancing the fracture toughness and fatigue crack growth resistance of selective laser melted Ti-6Al-4V alloy. Acta Mater 169:45–59. https://doi.org/10.1016/j.actamat.2019.03.003

Herzog D, Seyda V, Wycisk E, Emmelmann C (2016) Additive manufacturing of metals. Acta Mater 117:371–392. https://doi.org/10.1016/j.actamat.2016.07.019

Tomus D, Tian Y, Rometsch PA, Heilmaier M, Wu XH (2016) Influence of post heat treatments on anisotropy of mechanical behaviour and microstructure of Hastelloy-X parts produced by selective laser melting. Mater Sci Eng A 667:42–53. https://doi.org/10.1016/j.msea.2016.04.086

Zhang SS, Zhu HH, Hu ZH, Zeng XY, Zhong F (2019) Selective Laser melting of Cu-10Zn alloy powder using high laser power. Powder Technol 342:613–620. https://doi.org/10.1016/j.powtec.2018.10.002

Deng JW, Chen C, Liu XC, Li YP, Zhou KC, Guo SM (2021) A high-strength heat-resistant Al-5.7Ni eutectic alloy with spherical Al3Ni nano-particles by selective laser melting. Scr Mater. https://doi.org/10.1016/j.scriptamat.2021.114034

Wang M, Song B, Wei QS, Zhang YJ, Shi YS (2019) Effects of annealing on the microstructure and mechanical properties of selective laser melted AlSi7Mg alloy. Mater Sci Eng A 739:463–472. https://doi.org/10.1016/j.msea.2018.10.047

Zhang JL, Song B, Wei QS, Bourell D, Shi YS (2019) A review of selective laser melting of aluminum alloys: processing, microstructure, property and developing trends. J Mater Sci Technol 35(2):270–284. https://doi.org/10.1016/j.jmst.2018.09.004

Rashid R, Masood SH, Ruan D, Palanisamy S, Rashid RAR, Elambasseril J, Brandt M (2018) Effect of energy per layer on the anisotropy of selective laser melted AlSi12 aluminium alloy. Addit Manuf 22:426–439. https://doi.org/10.1016/j.addma.2018.05.040

Read N, Wang W, Essa K, Attallah MM (2015) Selective laser melting of AlSi10Mg alloy: process optimisation and mechanical properties development. Mater Des 65:417–424. https://doi.org/10.1016/j.matdes.2014.09.044

Kotadia H, Gibbons G, Das A, Howes P (2021) A review of laser powder bed fusion additive manufacturing of aluminium alloys: microstructure and properties. Addit Manuf 46:102155. https://doi.org/10.1016/j.addma.2021.102155

Sing SL, Yeong WY (2020) Laser powder bed fusion for metal additive manufacturing: perspectives on recent developments. Virtual Phys Prototyp 15(3):359–370. https://doi.org/10.1080/17452759.2020.1779999

Aversa A, Marchese G, Saboori A, Bassini E, Manfredi D, Biamino S, Ugues D, Fino P, Lombardi M (2019) New aluminum alloys specifically designed for laser powder bed fusion: a review. Materials 12(7):1007. https://doi.org/10.3390/ma12071007

Uddin SZ, Murr LE, Terrazas CA, Morton P, Roberson DA, Wicker RB (2018) Processing and characterization of crack-free aluminum 6061 using high-temperature heating in laser powder bed fusion additive manufacturing. Addit Manuf 22:405–415. https://doi.org/10.1016/j.addma.2018.05.047

Louvis E, Fox P, Sutcliffe CJ (2011) Selective laser melting of aluminium components. J Mater Process Technol 211(2):275–284. https://doi.org/10.1016/j.jmatprotec.2010.09.019

Loh LE, Chua CK, Yeong WY, Song J, Mapar M, Sing SL, Liu ZH, Zhang DQ (2015) Numerical investigation and an effective modelling on the selective laser melting (SLM) process with aluminium alloy 6061. Int J Heat Mass Transf 80:288–300. https://doi.org/10.1016/j.ijheatmasstransfer.2014.09.014

Huang YY, Hu ZL, Wang JJ (2014) Research progress on the aluminum alloy with high thermal conductivity. In: Applied Mechanics and Materials, Trans Tech Publication, 396–400. https://doi.org/10.4028/www.scientific.net/AMM.574.396

Chauhan KPS (2017) Influence of heat treatment on the mechanical properties of aluminium alloys (6xxx series): a literature review. Int J Eng Res 6(03):386–389. https://doi.org/10.17577/IJERTV6IS030301

Dong C, Wu A, Hao S, Zou J, Liu Z, Zhong P, Zhang A, Xu T, Chen J, Xu J, Liu Q, Zhou Z (2003) Surface treatment by high current pulsed electron beam. Surf Coat Technol 163:620–624. https://doi.org/10.1016/s0257-8972(02)00657-6

Liu JW, Kou S (2017) Susceptibility of ternary aluminum alloys to cracking during solidification. Acta Mater 125:513–523. https://doi.org/10.1016/j.actamat.2016.12.028

Zhang H, Zhu HH, Qi T, Hu ZH, Zeng XY (2016) Selective laser melting of high strength Al-Cu-Mg alloys: processing, microstructure and mechanical properties. Mater Sci Eng A 656:47–54. https://doi.org/10.1016/j.msea.2015.12.101

J-pZhang WUB, WANG R-l (2005) The application of XRD analysis on the measuring of the solubility of solid solution. J Shaanxi Uni Sci Technol 1:238. https://doi.org/10.3969/j.issn.1000-5811.2005.01.009

Xu R, Li RD, Yuan TC, Niu PD, Wang MB, Lin ZH (2020) Microstructure, metallurgical defects and hardness of Al-Cu-Mg-Li-Zr alloy additively manufactured by selective laser melting. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2020.155372

Elton L, Jackson DF (1966) X-ray diffraction and the Bragg law. Am J Phys 34(11):1036–1038. https://doi.org/10.1119/1.1972439

Qian GA, Hong YS, Zhou CG (2010) Investigation of high cycle and very-high-cycle fatigue behaviors for a structural steel with smooth and notched specimens. Eng Fail Anal 17(7–8):1517–1525. https://doi.org/10.1016/j.engfailanal.2010.06.002

Delahaye J, Tchuindjang JT, Lecomte-Beckers J, Rigo O, Habraken AM, Mertens A (2019) Influence of Si precipitates on fracture mechanisms of AlSi10Mg parts processed by selective laser melting. Acta Mater 175:160–170. https://doi.org/10.1016/j.actamat.2019.06.013

Li JG, Zhang Q, Huang RR, Li XY, Gao HJ (2020) Towards understanding the structure-property relationships of heterogeneous-structured materials. Scr Mater 186:304–311. https://doi.org/10.1016/j.scriptamat.2020.05.013

Li Y, Chen K, Tamura N (2018) Mechanism of heat affected zone cracking in Ni-based superalloy DZ125L fabricated by laser 3D printing technique. Mater Des 150:171–181. https://doi.org/10.1016/j.matdes.2018.04.032

Zhou ZP, Huang L, Shang YJ, Li YP, Jiang L, Lei Q (2018) Causes analysis on cracks in nickel-based single crystal superalloy fabricated by laser powder deposition additive manufacturing. Mater Des 160:1238–1249. https://doi.org/10.1016/j.matdes.2018.10.042

Kontis P, Chauvet E, Peng ZR, He JY, da Silva AK, Raabe D, Tassin C, Blandin JJ, Abed S, Dendievel R, Gault B, Martin G (2019) Atomic-scale grain boundary engineering to overcome hot-cracking in additively-manufactured superalloys. Acta Mater 177:209–221. https://doi.org/10.1016/j.actamat.2019.07.041

Gu DD, Hagedorn YC, Meiners W, Meng GB, Batista RJS, Wissenbach K, Poprawe R (2012) Densification behavior, microstructure evolution, and wear performance of selective laser melting processed commercially pure titanium. Acta Mater 60(9):3849–3860. https://doi.org/10.1016/j.actamat.2012.04.006

Schwarz M, Arnold CB, Aziz MJ, Herlach DM (1997) Dendritic growth velocity and diffusive speed in solidification of undercooled dilute Ni-Zr melts. Mater Sci Eng A 226:420–424. https://doi.org/10.1016/s0921-5093(96)10656-0

Geng YX, Wang YM, Xu JH, Mi SB, Fan SM, Xiao YK, Wu Y, Luan JH (2021) A high-strength AlSiMg1.4 alloy fabricated by selective laser melting. J Alloys Compd. https://doi.org/10.1016/j.jallcom.2021.159103

Wang ZH, Lin X, Kang N, Hu YL, Chen J, Huang WD (2020) Strength-ductility synergy of selective laser melted Al-Mg-Sc-Zr alloy with a heterogeneous grain structure. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101260

Paul MJ, Liu Q, Best JP, Li XP, Kruzic JJ, Ramamurty U, Gludovatz B (2021) Fracture resistance of AlSi10Mg fabricate d by laser powder b e d fusion. Acta Mater. https://doi.org/10.1016/j.actamat.2021.116869

Shi YJ, Yang K, Kairy SK, Palm F, Wu XH, Rometsch PA (2018) Effect of platform temperature on the porosity, microstructure and mechanical properties of an Al-Mg-Sc-Zr alloy fabricated by selective laser melting. Mater Sci Eng A 732:41–52. https://doi.org/10.1016/j.msea.2018.06.049

Chrominski W, Lewandowska M (2016) Precipitation phenomena in ultrafine grained Al-Mg-Si alloy with heterogeneous microstructure. Acta Mater 103:547–557. https://doi.org/10.1016/j.actamat.2015.10.030

Turbalioğlu K, Yavuz S (2011) The improvement of the mechanical properties of AA 6063 aluminum alloys produced by changing the continuous casting parameters. Sci Res Essays 6(13):2832–2840. https://doi.org/10.5897/SRE11.471

Balogun SA, Esezobor DE, Adeosun SO (2007) Effects of deformation processing on the mechanical properties of aluminum alloy 6063. Metall Mater Trans A 38A(7):1570–1574. https://doi.org/10.1007/s11661-007-9228-0

Alloys H-SAPM (1998) Properties and selection: nonferrous alloys and special-purpose materials. ASM International, the United States of America

Ozturk F, Sisman A, Toros S, Kilic S, Picu RC (2010) Influence of aging treatment on mechanical properties of 6061 aluminum alloy. Mater Des 31(2):972–975. https://doi.org/10.1016/j.matdes.2009.08.017

Kurz W, Fisher DJ (1984) Fundamentals of solidification, 3rd edn. Trans Tech Publications, Aedermannsdorf, Switzerland

Rappaz M, Drezet J-M, Gremaud M (1999) A new hot-tearing criterion. MMTA 30(2):449–455. https://doi.org/10.1007/s11661-999-0334-z

Tang YBT, Panwisawas C, Ghoussoub JN, Gong YL, Clark JWG, Nemeth AAN, McCartney DG, Reed RC (2021) Alloys-by-design: Application to new superalloys for additive manufacturing. Acta Mater 202:417–436. https://doi.org/10.1016/j.actamat.2020.09.023

Sabzi HE, Rivera-Diaz-del-Castillo PEJ (2019) Defect prevention in selective laser melting components: compositional and process effects. Materials. https://doi.org/10.3390/ma12223791

Hu ZH, Nie XJ, Qi Y, Zhang H, Zhu HH (2021) Cracking criterion for high strength Al-Cu alloys fabricated by selective laser melting. Addit Manuf. https://doi.org/10.1016/j.addma.2020.101709

Lahaie D, Bouchard M (2001) Physical modeling of the deformation mechanisms of semisolid bodies and a mechanical criterion for hot tearing. Metall Mater Trans B 32(4):697–705. https://doi.org/10.1007/s11663-001-0124-5

Tan Q, Fan Z, Tang X, Yin Y, Li G, Huang D, Zhang J, Liu Y, Wang F, Wu T (2021) A novel strategy to additively manufacture 7075 aluminium alloy with selective laser melting. Mater Sci Eng A 821:141638. https://doi.org/10.1016/j.msea.2021.141638

Acknowledgements

The authors would like to acknowledge the financial support from the National Key R&D Program of China (No. 2017YFB0306305), Key R&D Program of Guangdong Province, China (No. 2019B010943001), and the fund of State Key Laboratory of Powder Metallurgy, Central South University.

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: M. Grant Norton.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, F., Zhang, T., Wu, Y. et al. Microstructure, mechanical properties, and crack formation of aluminum alloy 6063 produced via laser powder bed fusion. J Mater Sci 57, 9631–9645 (2022). https://doi.org/10.1007/s10853-022-06993-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-022-06993-4