Abstract

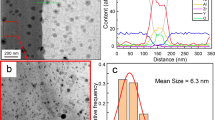

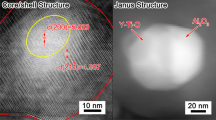

The effect of aging on a mechanical alloyed (MA) ferritic oxide dispersion strengthened (ODS) alloy was investigated focusing on the B2-NiAl nano-precipitates. The matrix of the alloy is decorated with a high volume fraction of B2-NiAl precipitates and dispersed nano-oxide particles. Due to the coarsening effect of Al on oxides and the changed Zener drag effect on grain growth, the bimodal grain structure was formed. With the extension of the aging time, the size of nano-precipitate increases and its morphology changed from near spherical to rodlike. The temporal evolution of nano-precipitates upon aging treatment is consistent with the modified Lifshitz–Slyozov–Wangner (LSW) theory. In addition, the quantitative calculation reveals the weakening effect caused by nano-precipitates coarsening during aging is the main reason for the decrease in alloy strength.

Similar content being viewed by others

References

Edahiro T, Kouzai K, Yasuda HY (2013) Mechanical properties and hardening mechanism of Fe–Al–Ni single crystals containing NiAl precipitates. Acta Mater 61:1716–1725. https://doi.org/10.1016/j.actamat.2012.11.046

Teng ZK, Miller MK, Ghosh G, Liu CT, Huang S, Russell KF, Fine ME, Liaw PK (2010) Characterization of nanoscale NiAl-type precipitates in a ferritic steel by electron microscopy and atom probe tomography. Scripta Mater 63:61–64. https://doi.org/10.1016/j.scriptamat.2010.03.013

Stallybrass C, Schneider A, Sauthoff G (2005) The strengthening effect of (Ni, Fe)Al precipitates on the mechanical properties at high temperatures of ferritic Fe–Al–Ni–Cr alloys. Intermetallics 13:1263–1268. https://doi.org/10.1016/j.intermet.2004.07.048

Sun Z, Song G, Ilavsky J, Ghosh G, Liaw PK (2015) Nano-sized precipitate stability and its controlling factors in a NiAl-strengthened ferritic alloy. Sci Rep-UK 5:16081. https://doi.org/10.1038/srep16081

Teng ZK, Zhang F, Miller MK, Liu CT, Huang S, Chou YT, Tien RH, Chang YA, Liaw PK (2012) New NiAl-strengthened ferritic steels with balanced creep resistance and ductility designed by coupling thermodynamic calculations with focused experiments. Intermetallics 29:110–115. https://doi.org/10.1016/j.intermet.2012.05.007

Huang S, Brown DW, Clausen B, Teng ZK, Gao YF, Liaw PK (2012) In situ neutron-diffraction studies on the creep behavior of a ferritic superalloy. Metall Mater Trans A 43:1497–1508. https://doi.org/10.1007/s11661-011-0979-2

Sun Z, Liebscher CH, Huang S, Teng ZK, Song G, Wang G, Asta M, Rawlings M, Fine ME, Liaw PK (2013) New design aspects of creep-resistant NiAl-strengthened ferritic alloys. Scripta Mater 68:384–388. https://doi.org/10.1016/j.scriptamat.2012.10.040

Song G, Sun Z, Poplawsky JD, Gao Y, Liaw PK (2017) Microstructural evolution of single Ni2TiAl or hierarchical NiAl/Ni2TiAl precipitates in Fe-Ni-Al-Cr-Ti ferritic alloys during thermal treatment for elevated-temperature applications. Acta Mater 127:1–16. https://doi.org/10.1016/j.actamat.2017.01.011

Chen T, Parish CM, Yang Y, Tan L (2018) High-temperature strengthening mechanisms of Laves and B2 precipitates in a novel ferritic alloy. Mater Sci Eng A 720:110–116. https://doi.org/10.1016/j.msea.2018.02.013

Yang M, Zhu J, Yang T, Luan J, Jiao Z, Fan X, Liu X (2019) A novel ferritic steel family hardened by intermetallic compound G-phase. Mater Sci Eng A 745:390–399. https://doi.org/10.1016/j.msea.2018.11.148

Zhang L, Qu X, Qin M, Wang Y (2014) Ferritic alloys strengthened by β′ phase and nanosized oxide. Mater Lett 117:286–289. https://doi.org/10.1016/j.matlet.2013.11.127

Zhang L, Liu Y, Wang S, Chen X, Shan H, Qu X (2019) ODS alloy with ferritic-austenitic duplex matrix and NiAl precipitation prepared by master alloy approach. J Alloys Compd 811:152066. https://doi.org/10.1016/j.jallcom.2019.152066

Miller MK, Hoelzer DT, Kenik EA, Russell KF (2005) Stability of ferritic MA/ODS alloys at high temperatures. Intermetallics 13:387–392. https://doi.org/10.1016/j.intermet.2004.07.036

Ukai S, Fujiwara M (2002) Perspective of ODS alloys application in nuclear environments. J Nucl Mater 307:749–757. https://doi.org/10.1016/S0022-3115(02)01043-7

Alamo A, Lambard V, Averty X, Mathon MH (2004) Assessment of ODS-14% Cr ferritic alloy for high temperature applications. J Nucl Mater 329:333–337. https://doi.org/10.1016/j.jnucmat.2004.05.004

Zhang SH, Ukai S, Nishikawa T, Aghamiri SMS, Oono N, Hayashi S (2019) Development and characterization of γ/α transformable FeCrAl-ODS alloys by cobalt addition. J Alloys Compd 797:390–398. https://doi.org/10.1016/j.jallcom.2019.05.024

Nishikawa T, Zhang S, Ukai S, Oono N, Hayashi S (2019) Development of α/γ Transformable FeCrAl-ODS Alloys by Nickel Addition. Mater Trans 60:355–363. https://doi.org/10.2320/matertrans.m2018271

Maruyama K, Sawada K, KoiKe J-I (2001) Strengthening mechanisms of creep resistant tempered martensitic steel. ISIJ Int 41:641–653. https://doi.org/10.2355/isijinternational.41.641

Li X, Saunders N, Miodownik AP (2002) The coarsening kinetic of γ′ particles in nickel-based alloys. Metall Trans A 33:3367–3373. https://doi.org/10.1007/s11661-002-0325-9

Casas C, Tejedor R, Rodriguez-Baracaldo R, Benito JA (2015) The effect of oxide particles on the strength and ductility of bulk iron with a bimodal grain size distribution. Mat Sci Eng A 627:205–206. https://doi.org/10.1016/j.msea.2014.12.076

Xu S, Zhou ZJ, Long F, Jia HD, Guo N, Yao ZW, Daymond MR (2019) Combination of back stress strengthening and Orowan strengthening in bimodal structured Fe–9Cr–Al ODS steel with high Al addition. Mater Sci Eng A 739:45–52. https://doi.org/10.1016/j.msea.2018.09.111

Song GA, Sun ZQ, Poplawsky JD, Gao YF, Liaw PK (2017) Microstructural evolution of single Ni2TiAl or hierarchical NiAl/Ni2TiAl precipitates in Fe–Ni–Al–Cr–Ti ferritic alloys during thermal treatment for elevated-temperature applications. Acta Mater 127:1–16. https://doi.org/10.1016/j.actamat.2017.01.011

Mao Z, Booth-Morrison C, Sudbrack CK, Martin G, Seidman DN (2012) Kinetic pathways for phase separation: an atomic-scale study in Ni–Al–Cr alloys. Acta Mater 60(4):1871–1888. https://doi.org/10.1016/j.actamat.2011.10.046

Philippe T, Voorhees PW (2013) Ostwald ripening in multicomponent alloys. Acta Mater 61(11):4237–4244. https://doi.org/10.1016/j.actamat.2013.03.049

Dong YH, Yang HB, Zhang L, Li XY, Ding D, Wang XH, Li J, Li JG, Chen IW (2021) Ultra-uniform nanocrystalline materials via two-step sintering. Adv Funct Mater 31:2007750. https://doi.org/10.1002/adfm.202007750

Wagner C (1961) Theorie der alterung von Niederschlägen durch Umlösen (Ostwald-reifung). Zeitschrift für Elektrochemie Ber Bunsen Ges Phys Chem 65(7–8):581–591. https://doi.org/10.1002/bbpc.19610650704

Ardell AJ, Ozolins V (2005) Trans-interface diffusion-controlled coarsening. Nat Mater 4:309–316. https://doi.org/10.1038/nmat1340

Calderon H, Fine ME (1984) Coarsening kinetics of coherent NiAl-type precipitates in Fe-Ni-Al and Fe–Ni–Al–Mo alloys. Mater Sci Eng 63:197–208. https://doi.org/10.1016/0025-5416(84)90121-6

Orowan E (1968) Precipitation Hardening. Pergamon Press, Oxford

Nembach E (1998) Particle Strengthening of Metals and Alloys. Wiley-VCH, New York

Li SF, Zhou ZJ, Wang PH, Sun HY, Wang M, Zhang GM (2016) Long-term thermal-aging stability of a 16Cr-oxide dispersion strengthened ferritic steel at 973K. Mater Des 90:318–329. https://doi.org/10.1016/j.matdes.2015.10.138

Ashby MF (1958) Oxide dispersion strengthening. Godon And Breach, New York

Gladman T (1999) Precipitation hardening in metals. Mater Sci Technol 15:30–36. https://doi.org/10.1179/026708399773002782

Schaffer GB, Loretto MH, Smallman RE, Brooks JW (1989) The stability of the oxide dispersion in INCONEL alloy MA6000. Acta Metall 37:2551–2558. https://doi.org/10.1016/0001-6160(89)90053-9

Zilnyk KD, Sandim HRZ, Bolmaro RE, Lindau R, Möslang A, Kostka A, Raabe D (2014) Longterm microstructural stability of oxide-dispersion strengthened Eurofer steel annealed at 800 °C. J Nucl Mater 448:33–42. https://doi.org/10.1016/j.jnucmat.2014.01.032

Ramar A, Schäublin R (2013) Analysis of hardening limits of oxide dispersion strengthened steel. J Nucl Mater 432:323–333. https://doi.org/10.1016/j.jnucmat.2012.07.024

Li YF, Abe H, Li F, Satoh Y, Matsukawa Y, Matsunaga T, Muroga T (2014) Grain structural characterization of 9Cr-ODS steel aged at 973 K up to 10,000 h by electron backscatter diffraction. J Nucl Mater 455:568–572. https://doi.org/10.1016/j.jnucmat.2014.08.047

Toda-Caraballo I, Rivera-Díaz-del-Castillo PEJ (2015) Modelling solid solution hardening in high entropy alloys. Acta Mater 85:14–23. https://doi.org/10.1016/j.actamat.2014.11.014

Takeuchi S (1969) Solid-solution strengthening in single crystals of iron alloys. J Phys Soc Jpn 27:929–940. https://doi.org/10.1143/JPSJ.27.929

Leslie WC (1972) Iron and its dilute substitutional solid solutions. Metall Mater Trans B 3:5–26. https://doi.org/10.1007/BF02680580

Baik S, Rawlings MJS, Dunand DC (2018) Atom probe tomography study of Fe–Ni–Al–Cr–Ti ferritic steels with hierarchically-structured precipitates. Acta Mater 144:707–715. https://doi.org/10.1016/j.actamat.2017.11.013

Povoden-Karadeniz E, Kozeschnik E (2012) Simulation of precipitation kinetics and precipitation strengthening of B2-precipitates in martensitic PH 13–8 Mo steel. ISIJ Int 52:610–615. https://doi.org/10.2355/isijinternational.52.610

Song G, Sun ZQ, Li L, Clausen B, Zhang SY, Gao YF, Liaw PK (2017) High temperature deformation mechanism in hierarchical and single precipitate strengthened ferritic alloys by in situ neutron diffraction studies. Sci Rep 7:46965. https://doi.org/10.1038/srep45965

Pavlina EJ, Tyne CJV (2008) Correlation of yield strength and tensile strength with hardness for steels. J Mater Eng Perform 17:888–893. https://doi.org/10.1007/s11665-008-9225-5

Acknowledgements

This work is financially supported by National Natural Science Foundation of China (51974029, 52074032, 51604240), Natural Science Foundation of Hunan Province (2019JJ50585), Natural Science and Technology Major Project (2017-VI-0014-0086), Fundamental Research Funds for the Central Universities (FRF-AT-19-013) and 111 project (B170003).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Handling Editor: Naiqin Zhao.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, S., Zhang, L., Liu, Y. et al. Nano-precipitate and its aging behavior in a B2-NiAl strengthened ferritic ODS alloy. J Mater Sci 56, 19663–19673 (2021). https://doi.org/10.1007/s10853-021-06538-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-021-06538-1