Abstract

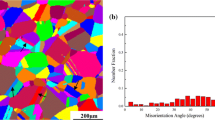

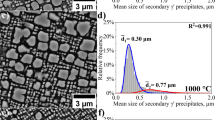

Welding thermal cycles with different peak temperatures were reproduced by a Gleeble testing machine to simulate the heat-affected zone of a Ni-17Mo-7Cr superalloy-welded joint. The effects of the thermal cycle times and peak temperatures on the microstructure and tensile properties of the thermal simulation specimens were systematically studied. The results show that no eutectic carbides are observed below 1300 °C, even when the number of thermal cycles is increased to 5. However, the eutectic reaction occurs above 1300 °C and causes a significant change in the carbide morphology because it transforms from a granular to lamellar structure. Moreover, the carbide composition transforms from (Ni, Cr)3Mo3C for the primary carbides to Ni3(Mo, Cr)3C for the lamellar carbides after the eutectic reaction. Tensile tests show that the thermal cycle has a minor effect on the tensile properties, except when the specimen underwent 5 thermal cycles with a peak temperature of 1340 °C. This is mainly due to the severe liquation reaction caused by elevated temperatures from the welding heat source, which induces cracking along the grain boundaries and results in a degradation of the tensile properties.

Similar content being viewed by others

References

Dymek S, Wróbel M, Stępniowska E, Dollár M (2010) Microstructure stability and mechanical properties of an age-hardenable Ni–Mo–Cr alloy subjected to long-term exposure to elevated temperature. Mater Charact 61(8):769–777

He W, Hu R, Wu Y, Gao X, Yang J (2018) Mechanical properties of an aged Ni-Cr-Mo alloy and effect of long-range order phase on deformation behavior. Mater Sci Eng A 731:29–35

Zhao S, Xie X, Smith GD, Patel SJ (2003) Microstructural stability and mechanical properties of a new nickel-based superalloy. Mater Sci Eng A 355(1):96–105

Park NK, Kim IS, Na YS, Yeom JT (2001) Hot forging of a nickel-base superalloy. J Mater Process Technol 111(1):98–102

Gao Z, Wei G, Zhang C, Tan J (2017) Development of fine-grained structure in Ni-Cr-W based superalloy and its effect on the mechanical properties. Mater Sci Eng A 682:156–163

Ul-Hamid A, Mohammed A, Al-Jaroudi S, Tawancy H, Abbas N (2007) Evolution of oxide scale on a Ni–Mo–Cr alloy at 900 C. Mater Charact 58(1):13–23

Leitnaker JM, Potter GA, Bradley DJ, Franklin JC, Laing WR (1978) The composition of eta carbide in hastelloy N after aging 10,000 h at 815°C. Metall Trans A 9(3):397–400

Braski DN, Leitnaker JM (1979) Homogenization of Ti-Hastelloy-N. Metall Trans A 10(4):427–432

McCoy HE, Gehlbach RE (1971) Influence of irradiation temperature on the creep-rupture properties of Hastelloy-N. Nucl Technol 11(1):45–60

Liu T, Dong JS, Wang L, Li ZJ, Zhou XT, Lou LH, Zhang J (2015) Effect of long-term thermal exposure on microstructure and stress rupture properties of GH3535 superalloy. J Mater Sci Technol 31(3):269–279

Han F, Zhou B, Huang H, Leng B, Lu Y, Dong J, Li Z, Zhou X (2016) The tensile behavior of GH3535 superalloy at elevated temperature. Mater Chem Phys 182:22–31

Wang Y, Liu H, Yu G, Hou J, Zeng C (2015) Electrochemical study of the corrosion of a Ni-based alloy GH3535 in molten (Li, Na, K)F at 700 degrees C. J Fluor Chem 178:14–22

Huang H, Zhou X, Li C, Jie G, Tao W, Lei G, Li J, Ye L, Huang Q, Zhu Z (2017) Temperature dependence of nickel ion irradiation damage in GH3535 alloy weld metal. J Nucl Mater 497:108–116

Dong XM, Wang WY, Xie JP, Xu J, Wang AQ (2011) Microstructure and fractrue behaviors of welded joint of particle reinforced SiCp/ZC71 magnesium matrix composites. Mater Sci Forum 704–705:706–709

Silva CC, Farias JP, Miranda HC, Guimarães RF, Menezes JWA, Neto MAM (2008) Microstructural characterization of the HAZ in AISI 444 ferritic stainless steel welds. Mater Charact 59(5):528–533

Yue CX, Chen HD, Bai XH, Liu DS (2012) Microstructure and impact fracture behavior of simulated HAZ of F500 steel. Trans Mater Heat Treat 33:105–112

Li J, Li H, Peng W, Xiang T, Yang J (2019) Effect of simulated welding thermal cycles on microstructure and mechanical properties of coarse-grain heat-affected zone of high nitrogen austenitic stainless steel. Mater Charact 149:206–217

Liu W, Lu F, Yang R, Tang X, Cui H (2015) Gleeble simulation of the HAZ in Inconel 617 welding. J Mater Process Technol 225:221–228

Mohammadi F, Eliyan FF, Alfantazi A (2012) Corrosion of simulated weld HAZ of API X-80 pipeline steel. Corros Sci 63:323–333

Gehlbach R, McCoy H (1968) Phase instability in Hastelloy N. International Symposium on Structural Stability in Superalloys, Seven Springs Pennsylvania, pp 346–366

Jiang L, Zhang W-Z, Xu Z-F, Huang H-F, Ye X-X, Leng B, Yan L, Li Z-J, Zhou X-T (2016) M2C and M6C carbide precipitation in Ni-Mo-Cr based superalloys containing silicon. Mater Design 112:300–308

Wang W, Li C, Jiang L, Ye X-X, Yu K, Chen S, Li Z, Zhou X (2018) Evolution of carbide precipitates in Hastelloy N joints during welding and post weld heat treatment. Mater Charact 135:311–316

Yu K, Jiang Z, Leng B, Li C, Chen S, Tao W, Zhou X, Li Z (2016) Effects of post-weld heat treatment on microstructure and mechanical properties of laser welds in GH3535 superalloy. Opt Laser Technol 81:18–25

Chen S, Ye X-X, Yu K, Li C, Li Z, Li Z, Zhou X (2017) Microstructure and mechanical properties of UNS N10003 alloy welded joints. Mater Sci Eng A 682:168–177

Han F, Jiang L, Ye X, Lu Y, Li Z, Zhou X (2017) Carbides evolution in a Ni-16Mo-7Cr base Superalloy during long-term thermal exposure. Mater 10(5):521

Shuangjian C, Chaowen L, Kun Y, Zhijun L, Zhou X, Zhong L (2015) The effects of thermal aging on microstructural and mechanical properties of GH3535 alloy welded joint, ASME PVP Conference.

Yang J, He Y, Qin C, Zhao W, Chen S, Gao Z (2015) Microstructure evolution in a Ni–Mo–Cr superalloy subjected to simulated heat-affected zone thermal cycle with high peak temperature. Mater Design 86:230–236

Mccoy HE, Beatty RL, Cook WH, Gehlbach RE, Kennedy CR, Koger JW, Litman AP, Sessions CE, Weir JR (1970) New developments in materials for molten-salt reactors. Nucl Appl Technol 8(2):156–169

He Y, Yang J, Qin C, Chen S, Gao Z (2015) Characterization of the Ni–Mo–Cr superalloy subjected to simulated heat-affected zone thermal cycle treatment. J Alloys Compd 643:7–16

Lippold JC (2015) Welding Metallurgy and Weldability. Wiley, Hoboken, New Jersey, pp 28–45

Bhattacharyya D, Davis J, Drew M, Harrison R, Edwards L (2015) Characterization of complex carbide–silicide precipitates in a Ni–Cr–Mo–Fe–Si alloy modified by welding. Mater Charact 105:118–128

Xu Z, Li J, Dong J, Li Z, Zhou X, Xu Z, Li J, Dong J, Li Z, Zhou X (2015) The effect of silicon on precipitation and decomposition behaviors of M6C carbide in a Ni–Mo–Cr superalloy. J Alloys Compd 620(620):197–203

Li J, Shrestha SL, Long Y, Li Z, Zhou X (2016) The formation of eutectic phases and hot cracks in one Ni–Mo–Cr superalloy. Mater Design 93:324–333

Marvel CJ, Hornbuckle BC, Darling KA, Harmer MP (2019) Intentional and unintentional elemental segregation to grain boundaries in a Ni-rich nanocrystalline alloy. J Mater Sci 54(4):3496–3508. https://doi.org/10.1007/s10853-018-3056-z

Dong J, Zhang M, Xie X, Thompson RG (2002) Interfacial segregation and cosegregation behaviour in a nickel-base alloy 718. Mater Sci Eng A 328(1):8–13

Furuta S, Kobayashi M, Uesugi K, Takeuchi A, Miura H, Aoba T (2017) Investigation of three-dimensional morphology changes of the eutectic Si particles affected by trace P and Sr in Al-7%Si cast alloys by means of synchrotron nano-tomography. Mater Charact 130:237–242

Acknowledgements

This work was supported by Shanghai Sailing Program (Grant No. 19YF1458300), National Key Research and Development Program of China (2016YFB0700404), the Natural Science Foundation of Shanghai (19ZR1468200 and 18ZR1448000), National Natural Science Foundation (Grant No. 51971238) and Youth Innovation Promotion Association, Chinese Academy of Science (Grant No. 2019264).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No conflict of interest exists in the submission of this manuscript, and it was approved by all authors for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, S., Zhao, L.b., Wang, J. et al. Microstructure evolution and mechanical properties of simulated HAZ in a Ni-17Mo-7Cr superalloy: effects of the welding thermal cycles. J Mater Sci 55, 13372–13388 (2020). https://doi.org/10.1007/s10853-020-04927-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04927-6