Abstract

The 3-triethylammonium propane sulfonic (TEA-PS+) cation associated with the anion tetrafluoroborate, hydrogen sulfate or trifluoromethanesulfonate leads to the formation of the new protic ionic liquids (ILs) 3-triethylammonium propane sulfonic acid tetrafluoroborate (TEA-PS·BF4), 3-triethylammonium propane sulfonic acid hydrogen sulfate (TEA-PS·HSO4) and 3-triethylammonium propane sulfonic acid trifluoromethanesulfonate (TEA-PS·CF3SO3), respectively. These ILs are used to produce Nafion/IL composite membranes with 2.5, 5 or 10 wt% of IL. The results show that the IL addition improves the thermal stability, hydrophilicity and conductivity. Experiments performed with the Nafion/IL membranes in a single proton exchange membrane fuel cell at 100 °C indicate that the membrane containing 5 wt% of TEA-PS·HSO4 is the most efficient one producing an increase of the maximum current density of approximately 230% when compared to the pristine membrane.

Similar content being viewed by others

Change history

29 May 2020

After the manuscript was revised following peer review, an error was introduced in the conductivity data reported in Table��3. Adding the standard values (SD) of the original values, which were correct, we made an error about the unit used for the membrane thickness.

References

Chen G-Y, Wang C, Leia YJ, Zhang J, Mao Z, Mao ZQ, Guo M-W, Li J, Ouyang M (2017) Gradient design of Pt/C ratio and Nafion content in cathode catalyst layer of PEMFCs. Int J Hydrog Energy 42:29960–29965. https://doi.org/10.1016/j.ijhydene.2017.06.229

Ogungbemi E, Ijaodola O, Khatib FN, Wilberforce T, El Hassan Z, Thompson J, Ramadan M, Olabi AG (2019) Fuel cell membranes e pros and cons. Energy 172:155–172. https://doi.org/10.1016/j.energy.2019.01.034

Wong CY, Wong WY, Ramya K, Khalid M, Loh KS, Daud WRW, Lim KL, Walvekar R, Kadhum AAH (2019) Additives in proton exchange membranes for low- and high-temperature fuel cell applications: a review. Int J Hydrog Energy 44:6116–6135. https://doi.org/10.1016/j.ijhydene.2019.01.084

Li P, Wu W, Liu J, Shi B, Du Y, Li Y, Wang J (2018) Investigating the nanostructures and proton transfer properties of Nafion-GO hybrid membranes. J Membr Sci 555:327–336. https://doi.org/10.1016/j.memsci.2018.03.066

Sun X, Simonsen SC, Norby T, Chatzitakis A (2019) Composite membranes for high temperature PEM fuel cells and electrolysers: a critical review. Membranes 9:1–46. https://doi.org/10.3390/membranes9070083

Karimi MB, Mohammadi F, Hooshyari K (2019) Recent approaches to improve Nafion performance for fuel cell applications: a review. Int J Hydrog Energy 44:28919–28938. https://doi.org/10.1016/j.ijhydene.2019.09.096

Steffya NJ, Parthibanc V, Sahua AK (2018) Uncovering Nafion-multiwalled carbon nanotube hybrid membrane for prospective polymer electrolyte membrane fuel cell under low humidity. J Membr Sci 563:65–74. https://doi.org/10.1016/j.memsci.2018.05.051

Parthiban V, Akula S, Sahu AK (2017) Surfactant templated nanoporous carbon-Nafion hybrid membranes for direct methanol fuel cells with reduced methanol crossover. J Membr Sci 541:127–136. https://doi.org/10.1016/j.memsci.2017.06.081

Zhang Y, Xue R, Zhong Y, Jiang F, Hu M, Yu Q (2018) Nafion/IL intermediate temperature proton exchange membranes improved by mesoporous hollow silica spheres. Fuel Cells 4:389–396. https://doi.org/10.1002/fuce.201700228

Moshnikov VA, Muratova EN, Spivak YM (2017) Alumina membranes as a mask for the structures used in hydrogen energy. Int J Hydrog Energy 42:21817–21821. https://doi.org/10.1016/j.ijhydene.2017.07.133

Saccà A, Carbone A, Gatto I, Pedicini R, Freni A, Patti A, Passalacqua E (2016) Composites Nafion-titania membranes for polymer electrolyte fuel cell (PEFC) applications at low relative humidity levels: chemical physical properties and electrochemical performance. Polym Test 56:10–18. https://doi.org/10.1016/j.polymertesting.2016.09.015

Díaz M, Ortiz A, Ortiz I (2014) Progress in the use of ionic liquids as electrolyte membranes in fuel cells. J Membr Sci 469:379–396. https://doi.org/10.1016/j.memsci.2014.06.033

Martins VL, Torresi RM (2018) Ionic liquids in electrochemical energy storage. Curr Opin Electrochem 9:26–32. https://doi.org/10.1016/j.coelec.2018.03.005

Sun J, Jordan MR, Forsyth M, MacFarlane DR (2001) Acid-Organic base swollen polymer membranes. Electrochem Acta 46:1703–1708. https://doi.org/10.1016/s0013-4686(00)00774-x

Doyle M, Choi S, Proulx G (2000) High-temperature proton conducting membranes based on perfluorinated ionomer membrane–ionic liquid composites. J Electrochem Soc 147:34–37. https://doi.org/10.1149/1.1393153

Schmidt C, Glück T, Schmidt-Naake G (2008) Modification of Nafion membranes by impregnation with ionic liquids. Chem Eng Technol 31:13–22. https://doi.org/10.1002/ceat.200700054

Danyliv O, Martinelli A (2019) Nafion/protic ionic liquid blends: nanoscale organization and transport properties. J Phys Chem C 123:14813–14824. https://doi.org/10.1021/acs.jpcc.9b02874

Hao J, Li X, Yu S, Jiang Y, Luo J, Shao Z, Yi B (2015) Development of proton-conducting membrane based on incorporating a proton conductor 1,2,4-triazolium methanesulfonate into the Nafion membrane. J Energy Chem 24:199–206. https://doi.org/10.1016/s2095-4956(15)60301-1

Di Noto V, Negro E, Sanchez J-Y, Iojoiu C (2010) Structure-relaxation interplay of a new nanostructured membrane based on tetraethylammonium trifluoromethanesulfonate ionic liquid and neutralized Nafion 117 for high-temperature fuel Cells. J Am Chem Soc 132:2183–2195. https://doi.org/10.1021/ja906975z

Sood R, Iojoiu C, Espuche E, Gouanvé F, Mendil-Jakani H, Lyonnard S (2015) Influence of different perfluorinated anion based Ionic liquids on the intrinsic properties of Nafion®. J Membr Sci 495:445–456. https://doi.org/10.1016/j.memsci.2015.07.006

Sood R, Iojoiu C, Espuche E, Gouanvé F, Gebel G, Mendil-Jakani H, Lyonnard S, Jestin J (2014) Comparative study of Proton conducting ionic liquid doped Nafion® membranes elaborated by swelling and casting methods: processing conditions, morphology and functional properties. J Phys Chem C 118:14157–14168. https://doi.org/10.1021/jp502454m

Cho E, Park J-S, Sekhon SS, Park G-G, Yang T-H, Lee W-Y, Kim C-S, Par S-B (2009) A study on proton conductivity of composite membranes with various ionic liquids for high-temperature anhydrous fuel cells. J Electrochem Soc 156:B197–B202. https://doi.org/10.1149/1.3031406

Li Y, Shi Y, Mehio N, Tan M, Wang Z, Hu X, Chen GZ, Dai S, Jin X (2016) More sustainable electricity generation in hot and dry fuel cells with a novel hybrid membrane of Nafion/nano-silica/hydroxyl ionic liquid. Appl Energy 175:451–458. https://doi.org/10.1016/j.apenergy.2016.03.075

Trindade LG, Zanchet L, Martinsa PC, Borba KMN, Santos RDM, Paiva RS, Vermeersch LAF, Ticianelli EA, Souza MO, Martini EMA (2019) The influence of ionic liquids cation on the properties of sulfonated poly (ether ether ketone)/polybenzimidazole blends applied in PEMFC. Polymer 179:121723. https://doi.org/10.1016/j.polymer.2019.121723

Fiegenbaum F, Martini EMA, de Souza MO, Becker MR, de Souza RF (2013) Hydrogen production by water electrolysis using tetra-alkyl-ammonium-sulfonic acid ionic liquid electrolytes. J Power Sources 243:822–825. https://doi.org/10.1016/j.jpowsour.2013.06.077

Trindade LG, Zanchet L, Borba KMN, Souza JC, Leite ER, Martini EMA (2018) Effect of the doping time of the 1-butyl-3- methylimidazolium ionic liquid cation on the Nafion membrane proprieties. Int J Energy Res 42:1–9. https://doi.org/10.1002/er.4096

Maiti J, Kakati N, Woo SP, Yoon YS (2018) Nafion® based hybrid composite membrane containing GO and dihydrogen phosphate functionalized ionic liquid for high temperature polymer electrolyte membrane fuel cell. Compos Sci Technol 155:189–196. https://doi.org/10.1016/j.compscitech.2017.11.030

Sen U, Çelik U, Ata A, Bozkurt A (2008) Anhydrous proton conducting membranes for PEM fuel cells based on Nafion/Azole composites. Int J Hydrog Energy 33:2808–2815. https://doi.org/10.1016/j.ijhydene.2008.03.007

Mistry MK, Subianto S, Choudhury NR, Dutta NK (2009) Interfacial interactions in aprotic ionic liquid based protonic membrane and its correlation with high temperature conductivity and thermal properties. Langmuir 25:9240–9251. https://doi.org/10.1021/la901330y

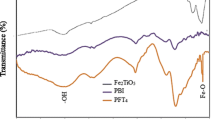

Buffeteau T, Grondin J, Lasse JC (2010) Infrared spectroscopy of ionic liquids: quantitative aspects and determination of optical constants. Appl Spectrosc 64:112–119. https://doi.org/10.1366/000370210790572089

Dai Z, Aboukeilaa H, Ansalonia L, Denga J, Baschettib MG, Deng L (2019) Engineerin, Nafion/PEG hybrid membrane for CO2 separation: effect of PEG on membrane micro-structure and performance. Sep Purif Technol 214:67–77. https://doi.org/10.1016/j.seppur.2018.03.062

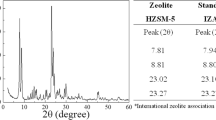

Blanton TN, Koestner R (2015) Characterization of Nafion proton exchange membranefilmsusing wide-angle X-ray diffraction. Int Center Diffr Data 1097:128–136

Jian-hua T, Peng-fei G, Zhi-yuan Z, Wen-hui L, Zhong-qiang S (2008) Preparation and performance evaluation of a Nafion-TiO2 composite membrane for PEMFCs. Int J Hydrogen Energy 33:5686–5690. https://doi.org/10.1016/j.idene.2008.07.036

Anis A, Al-Zahrani SM, Banthia AK, Bandyopadhyay S (2011) Fabrication and characterization of novel crosslinked composite membranes for direct methanol fuel cell application—part I. Poly (Vinyl alcohol-co-vinyl acetate-coitaconic acid)/phosphotungstic. Int J Electrochem Sci 6:2461–2487

Hyder MN, Huang RYM, Chen P (2006) Correlation of physicochemical characteristics with pervaporation performance of poly(vinyl alcohol) membranes. J Membr Sci 283:281–290. https://doi.org/10.1016/j.memsci.2006.06.045

Hyder MN, Huang RYM, Chen P (2009) Composite poly(vinyl alcohol) poly(sulfone) membranes crosslinked by trimesoyl chloride: characterization and dehydration of ethylene glycol–water mixtures. J Membr Sci 326:363–371. https://doi.org/10.1016/j.memsci.2008.10.017

Meenakshi S, Manokaran A, Bhat SD, Sahu AK, Sridhar P, Pitchumani S (2014) Impact of mesoporous and microporous materials on performance of nafion and SPEEK polymer electrolytes: a comparative study in DEFCs. Fuel Cells 6:842–852. https://doi.org/10.1002/fuce.201300298

Sun L, Thrasher JS (2005) Studies of the thermal behavior of Nafion® membranes treated with aluminum (III). Polym Degrad Stab 89:43–49. https://doi.org/10.1016/j.polymdegradstab.2005.01.001

Devrim Y, Erkan S, Bac N, Eroglu I (2012) Improvement of PEMFC performance with Nafion/inorganic nanocomposite membrane electrode assembly prepared by ultrasonic coating technique. Int J Hydrog Energy 37:16748–16758. https://doi.org/10.1016/j.ijhydene.2012.02.148

Ren Y, Liu S, Duan B, Xu Y, Li Z, Huang Y, Hu L, Zhu J, Dai S (2017) Controllable intermediates by molecular self-assembly for optimizing the fabrication of large-grain perovskite films via one-step spin-coating. J Alloys Compd 705:205–210. https://doi.org/10.1016/j.jallcom.2017.01.035

Lu F, Gao X, Xie S, Sun N, Zheng L (2014) Chemical modification of Nafion membranes by protic ionic liquids: the key role of ionomer–cation interactions. Soft Matter 10:7819–7825. https://doi.org/10.1039/c4sm01473a

Lu F, Gao X, Yan X, Gao H, Shi L, Jia H, Zheng L (2013) Preparation and characterization of nonaqueous proton-conducting membranes with protic ionic liquids. ACS Appl Mater Interfaces 5:7626–7632. https://doi.org/10.1021/am401940y

Mukaddam M, Litwiller E, Pinnau I (2016) Gas sorption, diffusion, and permeation in nafion. Macromolecules 49:280–286. https://doi.org/10.1021/acs.macromol.5b02578

Dai Z, Ansaloni L, Ryan JJ, Spontak Deng L (2018) Nafion/IL hybrid membranes with tuned nanostructure for enhanced CO2 separation: effects of ionic liquid and water vapor. Green Chem 20:1391–1404. https://doi.org/10.1039/c7gc03727a

Sood R, Iojoiu C, Espuche E, Gouanve F, Gebel G, Mendil-Jakani H, Lyonnard S, Jestin J (2012) Proton conducting ionic liquid doped nafion membranes: nano structuration, transport properties and water sorption. J Phys Chem C 116:24413–24423. https://doi.org/10.1021/jp306626y

Lide RD (2005) Dissociation constants of inorganic acids and bases in CRC Handbook of Chemistry and Physics. CRC Press, Boca Raton

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001 and CNPq. Edson Antonio Ticianelli thanks the financial support from FAPESP (Proc. 2013/16930-7).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zanchet, L., da Trindade, L.G., Bariviera, W. et al. 3-Triethylammonium propane sulfonate ionic liquids for Nafion-based composite membranes for PEM fuel cells. J Mater Sci 55, 6928–6941 (2020). https://doi.org/10.1007/s10853-020-04454-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04454-4