Abstract

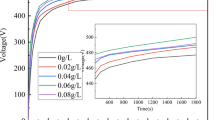

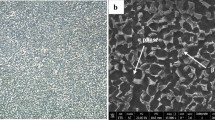

The corrosion behavior and transpassive dissolution properties of TC4 alloy produced by additive manufacturing technology via the laser cladding deposition method were investigated in static NaCl solutions with concentrations of 3.5, 10, and 15 wt%. The corrosion resistance exhibited nonlinear characteristics with respect to the various NaCl concentrations, but the passive film formed on the surface decreased with increasing NaCl concentrations. Simultaneously, transpassive dissolution properties and morphologies were evidently affected by the concentration of NaCl. The mechanism of the anodic dissolution behavior and film evolution under different Cl− concentrations were discussed based on the relevant electrochemical tests and point defects model.

Graphical abstract

Similar content being viewed by others

References

Boyer RR (1996) An overview on the use of titanium in the aerospace industry. Mater Sci Eng A 213:103–114

Niinomi M (1998) Mechanical properties of biomedical titanium alloys. Mater Sci Eng A 243:231–236

Froes FH, Suryanarayana C, Eliezer D (1992) Synthesis, properties and applications of titanium aluminides. J Mater Sci 27:5113–5140

Machado AR, Wallbank J (1990) Machining of titanium and its alloys—a review. Proc Inst Mech Eng B 204:53–60

Hayes BJ, Martin BW, Welk B et al (2017) Predicting tensile properties of Ti-6Al-4V produced via directed energy deposition. Acta Mater 133:120–133

Li HS, Gao CP, Wang GQ et al (2016) A study of electrochemical machining of Ti-6Al-4V in NaNO3 solution. Sci Rep 6:1–11

Bonaiti G, Parenti P, Annoni M et al (2017) Micro-milling machinability of DED additive titanium Ti-6Al-4V. Procedia Manuf 10:497–509

Klocke F, Zeis M, Klink A et al (2012) Technological and economical comparison of roughing strategies via milling, EDM and ECM for titanium- and nickel-based blisks. Procedia CIRP 2:98–101

Qin T, Lin X, Yu J et al (2021) Performance of different microstructure on electrochemical behaviors of laser solid formed Ti–6Al–4V alloy in NaCl solution. Corros Sci 185:109392

Guo P, Lin X, Liu J et al (2020) Passive behavior of nickel-based superalloys prepared by high-deposition-rate laser solid forming additive manufacturing. Corros Sci 177:109036

Li J, Lin X, Guo P et al (2018) Electrochemical behaviour of laser solid formed Ti–6Al–4V alloy in a highly concentrated NaCl solution. Corros Sci 142:161–174

Wang X, Qu N, Guo P et al (2017) Electrochemical machining properties of the laser rapid formed inconel 718 alloy in NaNO3 solution. J Electrochem Soc 164:E548–E559

Al-Bermani SS, Blackmore ML, Zhang W et al (2010) The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall and Mater Trans A 41:3422–3434

Yang J, Yang H, Yu H et al (2017) Corrosion behavior of additive manufactured Ti-6Al-4V alloy in NaCl solution. Metall Mater Trans A 48:3583–3593

Li J, Lin X, Yang Y et al (2021) Distinction in electrochemical behaviour of Ti6Al4V alloy produced by direct energy deposition and forging. J Alloys Compd 860:157912

Dai N, Zhang L, Zhang J et al (2016) Distinction in corrosion resistance of selective laser melted Ti-6Al-4V alloy on different planes. Corros Sci 111:703–710

Wu B, Pan Z, Li S et al (2018) The anisotropic corrosion behaviour of wire arc additive manufactured Ti-6Al-4V alloy in 3.5% NaCl solution. Corros Sci 137:176–183

Dai N, Zhang L, Zhang J et al (2016) Corrosion behavior of selective laser melted Ti-6Al-4 V alloy in NaCl solution. Corros Sci 102:484–489

Guo P, Lin X, Li J et al (2018) Electrochemical behavior of Inconel 718 fabricated by laser solid forming on different sections. Corros Sci 132:79–89

Li J, Lin X, Zheng M et al (2018) Distinction in anodic dissolution behavior on different planes of laser solid formed Ti-6Al-4V alloy. Electrochim Acta 283:1482–1489

Gong X, Cui Y, Wei D et al (2017) Building direction dependence of corrosion resistance property of Ti–6Al–4V alloy fabricated by electron beam melting. Corros Sci 127:101–109

Bai Y, Gai X, Li S et al (2017) Improved corrosion behaviour of electron beam melted Ti-6Al–4V alloy in phosphate buffered saline. Corros Sci 123:289–296

Qin P, Chen LY, Liu YJ et al (2021) Corrosion and passivation behavior of laser powder bed fusion produced Ti-6Al-4V in static/dynamic NaCl solutions with different concentrations. Corros Sci 191:109728

Chelariu R, Bolat G, Izquierdo J et al (2014) Metastable beta Ti-Nb-Mo alloys with improved corrosion resistance in saline solution. Electrochim Acta 137:280–289

Handzlik P, Fitzner K (2013) Corrosion resistance of Ti and Ti–Pd alloy in phosphate buffered saline solutions with and without H2O2 addition. Trans Nonferr Metals Soc China 23:866–875

Osório WR, Cremasco A, Andrade PN et al (2010) Electrochemical behavior of centrifuged cast and heat treated Ti–Cu alloys for medical applications. Electrochim Acta 55:759–770

Vida TA (2017) Electrochemical corrosion behavior of as-cast Zn-rich Zn-Mg alloys in a 0.06M NaCl solution. Int J Electrochem Sci 12:5264–5283

Verissimo NC, Freitas ES, Cheung N et al (2017) The effects of Zn segregation and microstructure length scale on the corrosion behavior of a directionally solidified Mg-25wt%Zn alloy. J Alloy Compd 723:649–660

Li B, Wang X, Min Y et al (2016) Corrosion resistance and mechanical properties of titanium with hierarchical micro-nanostructure. Mater Lett 182:43–46

Baehre D, Ernst A, Weißhaar K et al (2016) Electrochemical dissolution behavior of titanium and titanium-based alloys in different electrolytes. Procedia CIRP 42:137–142

Li J, Lin X, Wang J et al (2019) Effect of stress-relief annealing on anodic dissolution behaviour of additive manufactured Ti-6Al-4V via laser solid forming. Corros Sci 153:314–326

Dinda GP, Song L, Mazumder J (2008) Fabrication of Ti-6Al-4V scaffolds by direct metal deposition. Metall Mater Trans A 39:2914–2922

Wang T, Zhu YY, Zhang SQ et al (2015) Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. J Alloys Compd 632:505–513

Macdonald DD (2011) The history of the point defect model for the passive state: a brief review of film growth aspects. Electrochim Acta 56:1761–1772

Lavos-Valereto IC, Wolynec S, Ramires I et al (2004) Electrochemical impedance spectroscopy characterization of passive film formed on implant Ti-6Al-7Nb alloy in Hank’s solution. J Mater Sci Mater Med 15:55–59

Acknowledgements

The research was supported under the National Natural Science Foundation of China (Nos. 52105387, 52105197), the China Postdoctoral Science Foundation (No. 2021M692349), the Natural Science Research Projects of General Universities in Jiangsu Province (Nos. 21KJB460019, 21KJB460025), and the Hong Kong Scholars Program (No. XJ2021032). This work was also supported by the 23rd batch of extracurricular academic research fund projects for college students of Soochow University.

Funding

Funding was provided by the National Natural Science Foundation of China (52105387).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, J., Han, Q., Zou, Y. et al. Electrochemical behavior of additive manufactured TC4 alloy in different concentrated NaCl solutions. J Appl Electrochem 52, 1419–1431 (2022). https://doi.org/10.1007/s10800-022-01714-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10800-022-01714-w