Abstract

Cotton fabrics have high hydrophilicity and low limiting oxygen index (LOI) value, so they are susceptible to fires and bacterial growth, which endanger people’s lives and property and limit their further application. To solve the issue, the prepared green flame retardant β-cyclodextrin phosphate ammonium salt (β-CPAS) was first used to prepare flame retardant cotton fabric, which was then treated with hydrophobic agent phosphorylated hexadecanol (HP) to obtain flame retardant and hydrophobic cotton fabrics (FR-H-cotton) by the traditional dip-dry-cure technique. Fourier transforms infrared spectroscopy showed that β-CPAS and HP were covalently bonded to the cotton sample by a P–O–C bond. The treated cotton was self-extinguished under a vertical flame and had an LOI value of up to 31%. Cone calorimeter analysis showed that both the total heat release rate and peak heat release rate of treated cotton were decreased by about 80% than the control sample. Furthermore, the treated samples have excellent hydrophobicity and self-cleaning capabilities because of the presence of long-chain hexadecanol. Interestingly, FR-H-cotton remained excellent flame retardant and hydrophobic properties after 50 laundering cycles. This green and multifunctional cotton fabric has excellent potential for future market applications.

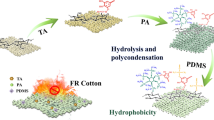

Graphical abstract

Similar content being viewed by others

Data availability

All data generated or analyzed in this study are included in this paper and its Supplementary Information document.

References

Bentis A, Boukhriss A, Zahouily M, Manoun B, Gmouh S (2023) Functionalization of cotton fabrics by sol-gel method using ionic liquids with high-hydrophobic, excellent water repellent, oil/water separation, and self-cleaning properties. Cellulose 30:6719–6740. https://doi.org/10.1007/s10570-023-05276-8

Chen XS, Yusuf A, del Rio JS, Wang DY (2021) A facile and robust route to polyvinyl alcohol-based triboelectric nanogenerator containing flame-retardant polyelectrolyte with improved output performance and fire safety. Nano Energy 81:105656. https://doi.org/10.1016/j.nanoen.2020.105656

Chen XY, Ding F, Zhang SM, Liu Y, Hou XL, Ren XH (2023) Flame-retardant, antibacterial and hydrophobic multifunctional coatings on cotton fabrics via layer-by-layer self-assembly. Cellulose 30:6679–6694. https://doi.org/10.1007/s10570-023-05287-5

Crini G (2014) Review: a history of cyclodextrins. Chem Rev 114:10940–10975. https://doi.org/10.1021/cr500081p

Ding F, Zhang SM, Chen XM, Li R, Ren XH (2022) PET fabric treated with environmental-friendly phosphorus-based compounds for enhanced flame retardancy, thermal stability and anti-dripping performance. Compos Part B-Eng 235:109791. https://doi.org/10.1016/j.compositesb.2022.109791

Fang F, Huo SQ, Shen HF, Ran SY, Wang H, Song PA, Fang ZP (2020) A bio-based ionic complex with different oxidation states of phosphorus for reducing flammability and smoke release of epoxy resins. Compos Commun 17:104–108. https://doi.org/10.1016/j.coco.2019.11.011

Feng JX, Su SP, Zhu J (2011) An intumescent flame retardant system using beta-cyclodextrin as a carbon source in polylactic acid (PLA). Polym Adv Technol 22:1115–1122. https://doi.org/10.1002/pat.1954

Gao M, Wu FC (2011) Thermal degradation of flame retardant cotton cellulose. J Therm Anal 168–170:380–383. https://doi.org/10.1023/A:1010132121811

Guo WW, Wang X, Huang JL, Zhou YF, Cai W, Wang JL, Song L, Hu Y (2020) Construction of durable flame-retardant and robust superhydrophobic coatings on cotton fabrics for water-oil separation application. Chem Eng J 398:125661. https://doi.org/10.1016/j.cej.2020.125661

Guo X, Wang Y, Ren YL, Liu XH (2021a) Fabrication of flame retardant lyocell fibers based on carboxymethylation and aluminum ion chelation. Cellulose 28:6679–6698. https://doi.org/10.1007/s10570-021-03931-6

Guo YB, Xiao MY, Ren YL, Liu YS, Wang Y, Guo X, Liu XH (2021b) Synthesis of an effective halogen-free flame retardant rich in phosphorus and nitrogen for lyocell fabric. Cellulose 28:7355–7372. https://doi.org/10.1007/s10570-021-03975-8

Guo YB, Zuo CL, Liu YS, Chen XZ, Ren YL, Liu XH (2023a) Construction of a fully bio-based intumescent flame retardant for improving the flame retardancy of polyacrylonitrile. Polym Degrad Stab 214:110385. https://doi.org/10.1016/j.polymdegradstab.2023.110385

Guo CS, Qian Y, Liu PB, Zhang QL, Zeng XH, Xu ZW, Zhang SN, Li N, Qian XM, Yu FY (2023b) One-step construction of the positively/negatively charged ultrathin janus nanofiltration membrane for the separation of Li+ and Mg2+. ACS Appl Mater Interfaces 15:4814–4825. https://doi.org/10.1021/acsami.2c19956

Hamdani S, Longuet C, Perrin D, Lopez-cuesta JM, Ganachaud F (2009) Flame retardancy of silicone-based materials. Polym Degrad Stab 94:465–495. https://doi.org/10.1016/j.polymdegradstab.2008.11.019

Ingtipi K, Choudhury BJ, Moholkar VS (2023) Kaolin-embedded cellulose hydrogel with tunable properties as a green fire retardant. Carbohydr Polym 313:120871. https://doi.org/10.1016/j.carbpol.2023.120871

Jiang Q, Li P, Liu Y, Zhu P (2022) Phytic acid-iron/laponite coatings for enhanced flame retardancy, antidripping and mechanical properties of flexible polyurethane foam. Int J Mol Sci 23:9145. https://doi.org/10.3390/ijms23169145

Lai XJ, Tang S, Li HQ, Zeng XR (2015) Flame-retardant mechanism of a novel polymeric intumescent flame retardant containing caged bicyclic phosphate for polypropylene. Polym Degrad Stab 113:22–31. https://doi.org/10.1016/j.polymdegradstab.2015.01.009

Li SN, Huang S, Xu F, Zhao TF, Zhang FX, Zhang GX (2020a) Imparting superhydrophobicity and flame retardancy simultaneously on cotton fabrics. Cellulose 27:3989–4005. https://doi.org/10.1007/s10570-020-03041-9

Li WX, Zhang HJ, Hu XP, Yang WX, Cheng Z, Xie CQ (2020b) Highly efficient replacement of traditional intumescent flame retardants in polypropylene by manganese ions doped melamine phytate nanosheets. J Hazard Mater 398:123001. https://doi.org/10.1016/j.jhazmat.2020.123001

Li M, Prabhakar MN, Song JL (2022a) Synthesis of novel Si–P–N complex coating for the fabrication of flame-retardant and hydrophobic cotton textile potentially suitable for rail seat cover. Prog Org Coat 172:107144. https://doi.org/10.1016/j.porgcoat.2022.107144

Li P, Liu C, Jiang Q, Tao Y, Xu YJ, Liu Y, Zhu P (2022b) Halogen-free coatings combined with the synergistic effect of phytic acid and montmorillonite for fire safety flexible polyurethane foam. Macromol Mater Eng 307:2100930. https://doi.org/10.1002/mame.202100930

Lin DM, Zeng XR, Li HQ, Lai XJ, Wu TY (2019) One-pot fabrication of superhydrophobic and flame-retardant coatings on cotton fabrics via sol-gel reaction. J Colloid Interface Sci 533:198–206. https://doi.org/10.1016/10.1016/j.jcis.2018.08.060

Liu J, Dong CH, Zhang Z, Kong DZ, Sun H, Lu Z (2020a) Multifunctional flame-retarded and hydrophobic cotton fabrics modified with a cyclic phosphorus/polysiloxane copolymer. Cellulose 27:3531–3549. https://doi.org/10.1007/s10570-020-03016-w

Liu YS, Guo YB, Ren YL, Wang Y, Guo X, Liu XH (2020b) Phosphorylation of sodium copper chlorophyll enables color-fasten and durable flame retardant wool fibers. Polym Degrad Stab 179:109286. https://doi.org/10.1016/j.polymdegradstab.2020.109286

Liu YS, Zhang JY, Ren YL, Zhang GL, Liu XH (2022) Synthesis of a phosphorus- and nitrogen-containing flame retardant and the fabrication of flame retardant cotton. Text Res J 92:3426–3442. https://doi.org/10.1177/00405175221074069

Liu YS, Yu X, Guo YB, Ren YL, Liu XH (2023) Preparation of flame retardant, smoke suppression and reinforced polyacrylonitrile composite fiber by using fully biomass intumescent flame retardant system and its sustainable recycle application. Compos Part A-Appl Sci Manuf 173:107705. https://doi.org/10.1016/j.compositesa.2023.107705

Luda MP, Zanetti M (2019) Cyclodextrins and cyclodextrin derivatives as green char promoters in flame retardants formulations for polymeric materials: a review. Polymers 11:664. https://doi.org/10.3390/polym11040664

Ma ZY, Zhang ZH, Zhao F, Wang YH (2022) A multifunctional coating for cotton fabrics integrating the superior performance of flame-retardant and self-cleaning. Adv Compos Hybrid Mater 5:2817–2833. https://doi.org/10.1007/s42114-022-00464-9

Mohamed AL, El-sheikh MA, Waly AI (2014) Enhancement of flame retardancy and water repellency properties of cotton fabrics using silanol based nano composites. Carbohydr Polym 102:727–737. https://doi.org/10.1016/j.carbpol.2013.10.097

Nabipour H, Wang X, Rahman MZ, Song L, Hu Y (2020) An environmentally friendly approach to fabricating flame retardant, antibacterial and antifungal cotton fabrics via self-assembly of guanazole-metal complex. J Clean Prod 273:122823. https://doi.org/10.1016/j.jclepro.2020.122832

Pan Y, Liu LX, Wang X, Song L, Hu Y (2018) Hypophosphorous acid cross-linked layer-by-layer assembly of green polyelectrolytes on polyester-cotton blend fabrics for durable flame-retardant treatment. Carbohydr Polym 201:1–8. https://doi.org/10.1016/j.carbpol.2018.08.044

Przybylak M, Dutkiewicz M, Szubert K, Maciejewski H, Rojewski S (2021) Multifunctional cotton fabrics obtained by modification with silanes containing esters of phosphoric acid as substituents. Materials 14:1542. https://doi.org/10.3390/ma14061542

Qi LY, Qiu SL, Xi JC, Yu B, Hu Y, Xing WY (2022a) Construction of super-hydrophobic, highly effective flame retardant coating for cotton fabric with superior washability and abrasion resistance. J Colloid Interface Sci 607:2019–2028. https://doi.org/10.1016/j.jcis.2021.10.021

Qi P, Li YC, Wang XG, Wang KH, Meng D, Gu XY, Li HF, Zhang S (2022b) Flame retardant and anti-dripping surface treatment through a co-deposition of polydopamine/polyphosphonamide for fabric and foam materials. Compos Part B-Eng 247:110262. https://doi.org/10.1016/j.compositesb.2022.110262

Qi P, Li YC, Yao Y, Sun J, Li L, Liu J, Gu XY, Li HF, Zhang S (2022c) Ultra washing durable flame retardant coating for cotton fabric by the covalent bonding and interface polymerization. Chem Eng J 452:139453. https://doi.org/10.1016/j.cej.2022.139453

Qi LY, Cai W, Zhang WJ, Wang BY, Li WS, Jin XH, Chen L, Yu B, Xing WY (2023) Application of silver-loaded halloysite nanotubes in flame retardant and smoke-suppressive coating for polyester-cotton fabric. ACS Appl Mater Interfaces 15:23725–23735. https://doi.org/10.1021/acsami.3c02139

Ren YL, Liu YS, Wang Y, Guo X, Liu XH (2020) Preparation of durable and flame retardant lyocell fabrics by using a biomass-based modifier derived from vitamin C. Cellulose 27:6677–6689. https://doi.org/10.1007/s10570-020-03218-2

Singh N, Yadav M, Khanna S, Sahu O (2017) Sustainable fragrance cum antimicrobial finishing on cotton: indigenous essential oil. Sustain Chem Pharm 5:22–29. https://doi.org/10.1016/j.scp.2017.01.003

Song WM, Zhang LY, Li P, Liu Y (2023) High-efficient flame-retardant finishing of cotton fabrics based on phytic acid. Int J Mol Sci 24:1093. https://doi.org/10.3390/ijms24021093

Tan W, Ren YL, Guo YB, Liu YS, Liu XH, Qu HQ (2022) A novel multi-claw reactive flame retardant derived from DOPO for endowing lyocell fabric with high effective flame retardancy. Cellulose 29:6941–6962. https://doi.org/10.1007/s10570-022-04690-8

Wang D, Zhou KQ, Yang W, Xing WY, Hu Y, Gong XL (2013) Surface modification of graphene with layered molybdenum disulfide and their synergistic reinforcement on reducing fire hazards of epoxy resins. Ind Eng Chem Res 52:17882–17890. https://doi.org/10.1021/ie402441g

Wang BB, Qian XD, Shi YQ, Yu B, Hong NM, Song L, Hu Y (2015) Cyclodextrin microencapsulated ammonium polyphosphate: preparation and its performance on the thermal, flame retardancy and mechanical properties of ethylene vinyl acetate copolymer. Compos Part B-Eng 69:22–30. https://doi.org/10.1016/j.compositesb.2014.09.015

Wang D, Peng HY, Yu B, Zhou KQ, Pan HF, Zhang LP, Li M, Liu MM, Tian AL, Fu SH (2020) Biomimetic structural cellulose nanofiber aerogels with exceptional mechanical, flame-retardant and thermal-insulating properties. Chem Eng J 389:124449. https://doi.org/10.1016/j.cej.2020.124449

Wang S, Kong DZ, Chen HF, Wang Z, Lu Z (2022) Construction of a novel B/N/Si synergistic flame retardant system and its application on cotton fabric. Ind Crop Prod 178:114574. https://doi.org/10.1016/j.indcrop.2022.114574

Wei DD, Dong CH, Chen ZH, Liu J, Li Q, Lu Z (2019) A novel cyclic copolymer containing Si/P/N used as flame retardant and water repellent agent on cotton fabrics. J Appl Polym Sci 136:47280. https://doi.org/10.1002/app.47280

Xia L, Lv Y, Miao ZX, Luo LL, Luo WA, Xu YT, Yuan CH, Zeng BR, Dai LZ (2022) A flame retardant fabric nanocoating based on nanocarbon black particles@polymer composite and its fire-alarm application. Chem Eng J 433:133501. https://doi.org/10.1016/j.cej.2021.133501

Xu DH, Wang SJ, Hu JW, Liu Y, Jiang ZM, Zhu P (2021) Enhancing antibacterial and flame-retardant performance of cotton fabric with an iminodiacetic acid-containing N-halamine. Cellulose 28:3265–3277. https://doi.org/10.1007/s10570-021-03716-x

Xu J, Niu YJ, Liang F, Guo FH, Wu JJ (2023) Synergistic flame retardant effect of carbon nanohorns and ammonium polyphosphate as a novel flame retardant system for cotton fabrics. Chem Eng J 451:138566. https://doi.org/10.1016/j.cej.2022.138566

Yang YT, Huang JL, Wang X, Grunlan J, Song L, Hu Y (2022) Flame retardant and hydrophobic cotton using a unique phosphorus–nitrogen–silicon-containing coating. Cellulose 29:8473–8488. https://doi.org/10.1007/s10570-022-04772-7

Yang MN, Yang YW, Shi JJ, Rao WH (2023) Fabrication of eco-friendly flame-retardant and hydrophobic coating for cotton fabric. Cellulose 30:3267–3280. https://doi.org/10.1007/s10570-023-05051-9

Zeng SL, Xing CY, Chen L, Xu L, Li BJ, Zhang S (2020) Green flame-retardant flexible polyurethane foam based on cyclodextrin. Polym Degrad Stab 178:109171. https://doi.org/10.1016/j.polymdegradstab.2020.109171

Zhang M, Wang CY (2013) Fabrication of cotton fabric with superhydrophobicity and flame retardancy. Carbohydr Polym 96:396–402. https://doi.org/10.1016/j.carbpol.2013.04.025

Zhang DQ, Williams BL, Becher EM, Becher EM, Shrestha SB, Nasir Z, Lofink BJ, Santos VH, Patel H, Peng XH, Sun LY (2018a) Flame retardant and hydrophobic cotton fabrics from intumescent coatings. Adv Compos Hybrid Mater 1:177–184. https://doi.org/10.1007/s42114-017-0006-1

Zhang Y, Han PY, Fang ZP (2018b) Synthesis of phospholipidated-cyclodextrin and its application for flame-retardant poly (lactic acid) with ammonium polyphosphate. J Appl Polym Sci 135:46054. https://doi.org/10.1002/app.46054

Zheng XT, Dong YQ, Liu XD, Xu YL, Jian RK (2022) Fully bio-based flame-retardant cotton fabrics via layer-by-layer self assembly of laccase and phytic acid. J Clean Prod 350:131525. https://doi.org/10.1016/j.jclepro.2022.131525

Zhou XK, Liu YS, Ren YL, Liu XH (2022) A sustainable strategy for preparation of flame-retardant cotton fabric by phosphorylation of recycled cotton. Text Res J 92:3766–3781. https://doi.org/10.1177/00405175211068783

Zhu B, Shao RQ, Li N, Min CY, Liu SK, Xu ZW, Qian XM, Wang LJ (2022) Progress of cyclodextrin based membranes in water treatment: special 3D bowl-like structure to achieve excellent separation. Chem Eng J 409:137013. https://doi.org/10.1016/j.cej.2022.137013

Acknowledgments

The authors are very grateful for the financial support of the Open Research Fund of the State Key Laboratory of Biobased Fiber Manufacturing Technology. (No. SKL202202).

Funding

This study was supported by the Open Research Fund of the State Key Laboratory of Biobased Fiber Manufacturing Technology. (No. SKL202202).

Author information

Authors and Affiliations

Contributions

Xinke Zhou: Investigation, Experiments, Writing-original draft. Xiaowei Su: Formal analysis, Experiments, Writing-revision. Jieyun Zhao: Investigation, Methodology, Formal Analysis. Yansong Liu: Visualization, Formal analysis. Zhiwei Xu: Verification, Editing, Review. Yuanlin Ren: Validation, Supervision, Writing-Review. Xiaohui Liu: Supervision, Conceptualization, Editing. Xinke Zhou and Xiaowei Su contribute equally to the work.

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare there are no competitive financial interests, and all authors listed allow the publication of this manuscript.

Ethical approval and consent to participate

All authors declare their adherence to the Ethical Responsibilities of Authors. In addition, the work is ethical.

Consent for publication

All authors agree to the final manuscript and its submission to this journal.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, X., Su, X., Zhao, J. et al. Preparation of biomass-based green cotton fabrics with flame retardant, hydrophobic and self-cleaning properties. Cellulose 31, 3871–3892 (2024). https://doi.org/10.1007/s10570-024-05814-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-024-05814-y