Abstract

Photo-crosslinkable poly (vinyl alcohol)-g-glycidyl methacrylate/cellulose nanocrystal-g-methacrylic anhydride (PVA-g-GMA/CNC-g-MA) composites were developed through solution casting. After UV crosslinking, a significant increase of 137% in tensile strength, a decrease of 65.45% in water absorption, and a decrease of 34.3% (in 98% relative humidity) in water vapor barrier property were obtained for the PVA-g-GMA/10% CNC-g-MA composite compared to those of pure PVA, exhibiting excellent mechanical, water resistance, and noticeable humidity stability. It is because UV photo-crosslinking significantly improves the interaction between PVA-g-GMA and CNC-g-MA in PVA-g-GMA/CNC-g-MA composites even under high humidity. In addition, CNC-g-MA was evenly distributed in the PVA-g-GMA matrix in PVA-g-GMA/10% CNC-g-MA composites, and the hydrophobicity of MA and GMA endows the PVA-g-GMA/10% CNC-g-MA composites with low surface hydrophobicity and excellent water resistance, water vapor barrier property and barrier stability in high humidity. Overall, a new, effective, and environment-friendly method for the preparation of PVA/CNC based composite is demonstrated, offering a great value in packaging applications.

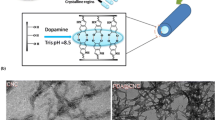

Graphical abstract

Photo-crosslinkable poly (vinyl alcohol)-g-glycidyl methacrylate/cellulose nanocrystal-g-methacrylic anhydride (PVA-g-GMA/CNC-g-MA) composites were developed through solution casting. After UV crosslinking, PVA-g-GMA/CNC-g-MA composites possessed excellent mechanical, water resistance, noticeable humidity stability, and low surface hydrophobicity.

Schematic diagram of photo-crosslinking of PVA-g-GMA and CNC-g-MA.

Similar content being viewed by others

References

Abdollahi M, Alboofetileh M, Behrooz R, Rezaei M, Miraki R (2013) Reducing water sensitivity of alginate bio-nanocomposite film using cellulose nanoparticles. Int J Biol Macromol 54:166–173

Aloui H, Khwaldia K, Hamdi M, Fortunati E, Kenny JM, Buonocore GG, Lavorgna M (2016) Synergistic effect of halloysite and cellulose nanocrystals on the functional properties, ACS Sustain. Chem Eng 4:794–800

Bader RA, Rochefort WE (2008) Rheological characterization of photopolymerized poly (vinyl alcohol) hydrogels for potential use in nucleus pulposus replacement. J Biomed Mater Res A 86:494–501

Bai H, Li Y, Wang W, Chen G, Rojas OJ, Dong W, Liu X (2015) Interpenetrated polymer networks in composites with poly (vinyl alcohol), micro- and nano- fibrillated cellulose (M/NFC) and polyHEMA to develop packaging materials. Cellulose 22:3877–3894

Bai H, Li Y, Zhang S, Wang W, Dong W (2018) Interpenetrating polymer networks in polyvinyl alcohol/cellulose nanocrystals hydrogels to develop absorbent materials. Carbohyd Polym 200:468–476

Cao X, Chen Y, Chang PR, Stumborg M, Huneault MA (2008) Green composites reinforced with hemp nanocrystals in plasticized starch. J Appl Polym Sci 109:3804–3810

Di Pierro P, Mariniello L, Giosafatto CVL, Masi P, Porta R (2005) Solubility and permeability properties of edible pectin-soy flour films obtained in the absence or presence of transglutaminase. Food Biotechnol 19:37–49

Dufresne A (2011) Preparation of cellulose nanocomposite. In: Zaferiropoulos NE (ed) Interface Engineering of Natural Fiber Composites for Maximum Performance. Woodhead Publishing in Materials, Philadelphia, pp 82–116

Eichhorn SJ, Dufresne A, Aranguren M et al (2010) Review: current international research into cellulose nanofibres and nanocomposites. J Mater Sci 45:1–33

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896

Hassan CM, Peppas NA (2000) Structure and applications of poly (vinyl alcohol) hydrogels produced by conventional crosslinking or by freezing/thawing methods. Biopolymers· PVA hydrogels, anionic polymerisation nanocomposites. Springer, Berlin Heidelberg, pp 37–65

Iwamoto S, Kai W, Isogai A, Iwata T (2009) Elastic modulus of single cellulose microfibrils from tunicate measured by atomic force microscopy. Biomacromol 10:2571–2576

Le TY, Roper TM, Jonsson ES et al (2003) The kinetics of vinyl acrylate photopolymerization. Polymer 44:2859–2865

Li Z, Bai H, Zhang S, Wang W, Ma P, Dong W (2018) DN strategy constructed photo-crosslinked PVA/CNC/P(NIPPAm-co-AA) hydrogels with temperature-sensitive and pH-sensitive properties. New J Chem 42:13453–13460

Lin N, Huang J, Dufresne A (2012) Preparation, properties and applications of polysaccharide nanocrystals in advanced functional nanomaterials: a review. Nanoscale 4:3274–3294

Paradossi G, Cavalieri F, Chiessi E, Spagnoli C, Cowman MK (2003) Poly (vinyl alcohol) as versatile biomaterial for potential biomedical applications. J Mater Sci-Mater m 14:687–691

Paralikar SA, Simonsen J, Lombardi J (2008) Poly (vinyl alcohol)/cellulose nanocrystal barrier membranes. J Mater Sci 320:248–258

Peresin MS, Habibi Y, Vesterinen AH, Rojas OJ, Pawlak JJ, Seppälä JA (2010) Effect of moisture on electrospun nanofiber composites of poly (vinyl alcohol) and cellulose nanocrystals. Biomacromol 11:2471–2477

Peresin MS, Vesterinen AH, Habibi Y, Johansson LS, Pawlak JJ, Nevzorov AA, Rojas OJ (2014) Crosslinked PVA nanofibers reinforced with cellulose nanocrystals: water interactions and thermomechanical properties. J Appl Polym Sci. https://doi.org/10.1002/APP.40334

Rhim JW (2007) Mechanical and water barrier properties of biopolyester films prepared by thermo-compression. Food Sci Biotechnol 16:62–66

Santos C, Seabra P, Veleirinho B, Delgadillo I, Lopes da Silva JA (2006) Acetylation and molecular mass effects on barrier and mechanical properties of shortfin squid chitosan membranes. Eur Polym J 42:3277–3285

Sau S, Pandit S, Kundu S (2021) Crosslinked poly (vinyl alcohol): structural, optical and mechanical properties. Surf Interfaces 25:101198

Scherzer T, Decker U (2000) The effect of temperature on the kinetics of diacrylate photopolymerizations studied by real-time FTIR spectroscopy. Polymer 41:7681–7690

Siracusa V, Rocculi P, Romani S, Rosa MD (2008) Biodegradable polymers for food packaging: a review. Trend Food Sci Tech 19:634–643

Wang JW, Gardner DJ, Stark NM, Bousfield DW, Tajvidi M, Cai ZY (2018) Moisture and oxygen barrier properties of cellulose nanomaterial-based films. ACS Sustainable Chem Eng 6:49–70

Yihun FA, Ifuku S, Hiroyuki S, Hironori I, Minoru M (2020) Highly transparent and flexible surface modified chitin nanofibers reinforced poly (methyl methacrylate) nanocomposites: Mechanical, thermal and optical studies. Polymer 197:122497

Yihun FA, Ifuku S, Hiroyuki S, Yihun DA (2021) Thermo-mechanically improved polyvinyl alcohol composite films using maleated chitin nanofibers as nanoreinforcement. Cellulose 28:2965–2980

Zhou L, He H, Li MC, Huang SW, Mei CT, Wu QL (2018) Enhancing mechanical properties of poly (lactic acid) through its in-situ crosslinking with maleic anhydride-modified cellulose nanocrystals from cottonseed hulls. Ind Crops Prod 112:449–459

Acknowledgments

This work is supported by the MOE & SAFEA for the 111 Project (B13025). The authors also thank Dr. Wei Wang for his valuable suggestions in the process of revising the manuscript.

Funding

The MOE & SAFEA for the 111 Project No. B13025, Huiyu Bai.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have not disclosed any competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Bai, H., Li, Y., Zhang, S. et al. Photo-crosslinkable poly (vinyl alcohol)/nanocrystalline cellulose composites with controllable performance and exceptional water vapor barrier property for packaging application. Cellulose 29, 7721–7734 (2022). https://doi.org/10.1007/s10570-022-04760-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-022-04760-x