Abstract

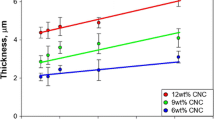

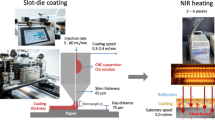

There is an increased interest in the use of cellulose nanocrystal (CNC) films and coatings for a range of functional applications in the fields of material science, biomedical engineering, and pharmaceutical sciences. Most of these applications have been demonstrated on films and coatings produced using laboratory-scale batch processes, such as solvent casting, dip coating, or spin coating. For successful coating application of CNC suspensions using a high throughput process, several challenges need to be addressed: relatively high viscosity at low solids content, coating brittleness, and potentially poor adhesion to the substrate. This work aims to address these problems. The impact of plasticizer on suspension rheology, coating adhesion, and barrier properties was quantified, and the effect of different pre-coatings on the wettability and adhesion of CNC coatings to paperboard substrates was explored. CNC suspensions were coated onto pre-coated paperboard in a roll-to-roll process using a custom-built slot die. The addition of sorbitol reduced the brittleness of the CNC coatings, and a thin cationic starch pre-coating improved their adhesion to the paperboard. The final coat weight, dry coating thickness, and coating line speed were varied between 1–11 g/m2, 900 nm–7 µm, and 2.5–10 m/min, respectively. The barrier properties, adhesive strength, coating coverage, and smoothness of the CNC coatings were characterized. SEM images show full coating coverage at coat weights as low as 1.5 g/m2. With sorbitol as plasticizer and at coat weights above 3.5 g/m2, heptane vapor and water vapor transmission rates were reduced by as much as 99% and 75% respectively. Compared to other film casting techniques, the process employed in this work deposits a relatively thick coating in significantly less time, and may therefore pave the way toward various functional applications based on CNCs.

Graphical abstract

Similar content being viewed by others

References

Abdollahi M, Alboofetileh M, Behrooz R, Rezaei M, Miraki R (2013) Reducing water sensitivity of alginate bio-nanocomposite film using cellulose nanoparticles. Int J Biol Macromol 54:166–173. https://doi.org/10.1016/j.ijbiomac.2012.12.016

Abitbol T, Rivkin A, Cao Y, Nevo Y, Abraham E, Ben-Shalom T, Lapidot S, Shoseyov O (2016) Nanocellulose, a tiny fiber with huge applications. Curr Opin Biotechnol 39:76–88. https://doi.org/10.1016/j.copbio.2016.01.002

Ambrosio-Martín J, Fabra MJ, Lopez-Rubio A, Lagaron JM (2015) Melt polycondensation to improve the dispersion of bacterial cellulose into polylactide via melt compounding: enhanced barrier and mechanical properties. Cellulose 22:1201–1226. https://doi.org/10.1007/s10570-014-0523-9

Bayati F, Boluk Y, Choi P (2014) Diffusion behavior of water at infinite dilution in hydroxypropyl xylan films with sorbitol and cellulose nanocrystals. ACS Sustain Chem Eng 2:1305–1311. https://doi.org/10.1021/sc500133p

Brodin FW, Gregersen OW, Syverud K (2014) Cellulose nanofibrils: challenges and possibilities as a paper additive or coating material–a review. Nord Pulp Pap Res J 29:156–166. https://doi.org/10.3183/NPPRJ-2014-29-01-p156-166

Carlsson DO, Hua K, Forsgren J, Mihranyan A (2013) Aspirin degradation in surface-charged TEMPO-oxidized mesoporous crystalline nanocellulose. Int J Pharm 461:74

Chowdhury RA, Clarkson C, Youngblood J (2018) Continuous roll-to-roll fabrication of transparent cellulose nanocrystal (CNC) coatings with controlled anisotropy. Cellulose 25:1769–1781. https://doi.org/10.1007/s10570-018-1688-4

Ding X, Liu J, Harris TAL (2016) A review of the operating limits in slot die coating processes. AIChE J 62:2508–2524. https://doi.org/10.1002/aic.15268

Dufresne A (2013) Nanocellulose: a new ageless bionanomaterial. Mater Today 16:220–227. https://doi.org/10.1016/j.mattod.2013.06.004

Eichhorn SJ, Dufresne A, Aranguren MM, Capadona JR, Rowan SJ, Weder C, Thielemans W, Roman M, Renneckar S, Gindl W (2010) Review: current international research into cellulose nanofibres and composites. J Mater Sci 45:1–33. https://doi.org/10.1007/s10853-009-3874-0

Elazzouzi-Hafraoui S, Nishiyama Y, Putaux J, Heux L, Dubreuil F, Rochas C (2007) The shape and size distribution of crystalline nanoparticles prepared by acid hydrolysis of native cellulose. Biomacromol 9:57–65. https://doi.org/10.1021/bm700769p

Feng X, Meng X, Zhao J, Miao M, Shi L, Zhang S, Fang J (2015) Extraction and preparation of cellulose nanocrystals from dealginate kelp residue: structures and morphological characterization. Cellulose 22:1763–1772. https://doi.org/10.1007/s10570-015-0617-z

Fortunati E, Peltzer M, Armentano I, Torre L, Jiménez A, Kenny JM (2012) Effects of modified cellulose nanocrystals on the barrier and migration properties of PLA nano-biocomposites. Carbohydr Polym 90:948–956. https://doi.org/10.1016/j.carbpol.2012.06.025

Fortunati E, Luzi F, Puglia D, Dominici F, Santulli C, Kenny JM, Torre L (2014) Investigation of thermo-mechanical, chemical and degradative properties of PLA-limonene films reinforced with cellulose nanocrystals extracted from Phormium tenax leaves. Eur Polym J 56:77–91. https://doi.org/10.1016/j.eurpolymj.2014.03.030

Gicquel E, Martin C, Garrido Yanez J, Bras J (2017) Cellulose nanocrystals as new bio-based coating layer for improving fiber-based mechanical and barrier properties. J Mater Sci 52:3048–3061. https://doi.org/10.1007/s10853-016-0589-x

Habibi Y, Lucia LA, Rojas OJ (2010) Cellulose nanocrystals: chemistry, self-assembly, and applications. Chem Rev 110:3479

Hamad WY (2017) Cellulose nanocrystals and nanofibrils in advanced applications. In: Kargarzadeh H, Ahmad I, Thomas S, Dufresne A (eds) Handbook of nanocellulose and cellulose nanocomposites. Wiley, Hoboken, pp 799–832

Herrera MA, Mathew AP, Oksman K (2017) Barrier and mechanical properties of plasticized and cross-linked nanocellulose coatings for paper packaging applications. Cellulose 24:3969–3980. https://doi.org/10.1007/s10570-017-1405-8

Hubbe MA, Ferrer A, Tyagi P, Yin Y, Salas C, Pal L, Rojas OJ (2017) Nanocellulose in thin films, coatings, and plies for packaging applications: a review. BioResources 12:2143–2233. https://doi.org/10.15376/biores.12.1.2143-2233

Isogai A (2013) Wood nanocelluloses: fundamentals and applications as new bio-based nanomaterials. J Wood Sci 59:449–459. https://doi.org/10.1007/s10086-013-1365-z

Jackson JK, Letchford K, Wasserman BZ, Ye L, Hamad WY, Burt HM (2011) The use of nanocrystalline cellulose for the binding and controlled release of drugs. Int J Nanomed 6:321–330. https://doi.org/10.2147/IJN.S16749

Kinnunen-Raudaskoski K, Hjelt T, Kenttä E, Forsström U (2014) Thin coatings for paper by foam coating. Tappi J 13:9–19

Klemm D, Kramer F, Moritz S, Lindström T, Ankerfors M, Gray D, Dorris A (2011) Nanocelluloses: a new family of nature-based materials. Angew Chem Int Ed 50:5438–5466. https://doi.org/10.1002/anie.201001273

Kumar V (2018) Roll-to-roll processing of nanocellulose into coatings, Åbo Akademi University

Kumar V, Elfving A, Koivula H, Bousfield D, Toivakka M (2016a) Roll-to-roll processed cellulose nanofiber coatings. Ind Eng Chem Res 55:3603–3613. https://doi.org/10.1021/acs.iecr.6b00417

Kumar V, Nazari B, Bousfield D, Toivakka M (2016b) Rheology of microfibrillated cellulose suspensions in pressure-driven flow. Appl Rheol 26:43534. https://doi.org/10.3933/APPLRHEOL-26-43534

Kumar V, Koppolu VR, Bousfield D, Toivakka M (2017a) Substrate role in coating of microfibrillated cellulose suspensions. Cellulose 24:1247–1260. https://doi.org/10.1007/s10570-017-1201-5

Kumar V, Ottesen V, Syverud K, Gregersen ØW, Toivakka M (2017b) Coatability of cellulose nanofibril suspensions: role of rheology and water retention. BioResources 12:7656–7679. https://doi.org/10.15376/biores.12.4.7656-7679

Lavoine N, Desloges I, Dufresne A, Bras J (2012) Microfibrillated cellulose–its barrier properties and applications in cellulosic materials: a review. Carbohydr Polym 90:735–764. https://doi.org/10.1016/j.carbpol.2012.05.026

Li F, Biagioni P, Bollani M, Maccagnan A, Piergiovanni L (2013) Multi-functional coating of cellulose nanocrystals for flexible packaging applications. Cellulose 20:2491–2504. https://doi.org/10.1007/s10570-013-0015-3

Lindström T, Naderi A, Wiberg A (2015) Large Scale applications of nanocellulosic materials. Palpu Chongi Gisul J Korea Tech Assoc Pulp Pap Ind 47:5–21. https://doi.org/10.7584/ktappi.2015.47.6.005

Mariano M, El Kissi N, Dufresne A (2014) Cellulose nanocrystals and related nanocomposites: review of some properties and challenges. J Polym Sci, Part B: Polym Phys 52:791–806. https://doi.org/10.1002/polb.23490

Meng Q, Manas-Zloczower I (2015) Carbon nanotubes enhanced cellulose nanocrystals films with tailorable electrical conductivity. Compos Sci Technol 120:1–8. https://doi.org/10.1016/j.compscitech.2015.10.008

Miettinen P, Auvinen S, Kuusipalo J, Haakana S (2015) Validity of traditional barrier-testing methods to predict the achievable benefits of the new generation water based barrier coatings for packaging materials. In: D3 Professional conference proceedings. PTS coating symposium, Munich, Germany, pp 328–342

Moon RJ, Schueneman GT, Simonsen J (2016) Overview of cellulose nanomaterials, their capabilities and applications. JOM 68:2383–2394. https://doi.org/10.1007/s11837-016-2018-7

Nazari B, Kumar V, Bousfield DW, Toivakka M (2016) Rheology of cellulose nanofibers suspensions: boundary driven flow. J Rheol 60:1151–1159. https://doi.org/10.1122/1.4960336

Nelson K, Retsina T, Iakovlev M, van Heiningen A, Deng Y, Shatkin JA, Mulyadi A (2016) American process: production of low cost nanocellulose for renewable, advanced materials applications. In: Madsen LD, Svedberg EB (eds) Materials research for manufacturing. Springer, Berlin, pp 267–302

Osong SH, Norgren S, Engstrand P (2016) Processing of wood-based microfibrillated cellulose and nanofibrillated cellulose, and applications relating to papermaking: a review. Cellulose 23:93–123. https://doi.org/10.1007/s10570-015-0798-5

Pan M, Zhou X, Chen M (2013) Cellulose nanowhiskers isolation and properties from acid hydrolysis combined with high pressure homogenization. BioResources 8:933–943. https://doi.org/10.15376/biores.8.1.933-943

Pereira ALS, do Nascimento DM, Filho Souza, Men de Sá M, Morais JPS, Vasconcelos NF, Feitosa JPA, Brígida AIS, Rosa MDF (2014) Improvement of polyvinyl alcohol properties by adding nanocrystalline cellulose isolated from banana pseudostems. Carbohyd Polym 112:165–172. https://doi.org/10.1016/j.carbpol.2014.05.090

Plackett DV, Letchford K, Jackson JK, Burt HM (2014) A review of nanocellulose as a novel vehicle for drug delivery. Nord Pulp Pap Res J 29:105–118. https://doi.org/10.3183/NPPRJ-2014-29-01-p105-118

Samyn P, Barhoum A, Öhlund T, Dufresne A (2018) Review: nanoparticles and nanostructured materials in papermaking. J Mater Sci 53:146–184. https://doi.org/10.1007/s10853-017-1525-4

Shafiei-Sabet S, Hamad WY, Hatzikiriakos SG (2012) Rheology of nanocrystalline cellulose aqueous suspensions. Langmuir 28:17124–17133. https://doi.org/10.1021/la303380v

Valentini L, Cardinali M, Fortunati E, Torre L, Kenny JM (2013) A novel method to prepare conductive nanocrystalline cellulose/graphene oxide composite films. Mater Lett 105:4–7. https://doi.org/10.1016/j.matlet.2013.04.034

Acknowledgments

We thank Stora Enso, Omya International, CP Kelco and; Chemigate for kindly providing us with pigment-coated paperboard, CaCO3 pigment, CMC and cationic starch respectively. The project was partly funded by VINNOVA testbed project called TinyBTalented. TA acknowledges Marie Skłodowska-Curie actions as research fellow and AS the Nils and Dorthi Troëdsson Foundation for Scientific Research.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Koppolu, R., Abitbol, T., Kumar, V. et al. Continuous roll-to-roll coating of cellulose nanocrystals onto paperboard. Cellulose 25, 6055–6069 (2018). https://doi.org/10.1007/s10570-018-1958-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-018-1958-1