Abstract

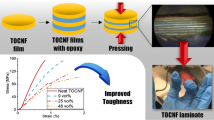

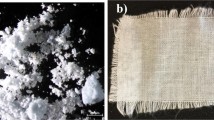

Lyocell-fabric based all-cellulose composite (ACC) laminates were produced using a compression molding technique by four different routes using ionic liquid (1-butyl-3-methylimidazolium chloride) as solvent. Process I to Process III were used to produce cross-plied ACC laminates while unidirectional ACC laminates were produced by Process IV. The microstructures of the laminates were analyzed on the basis of SEM images and percentage void content. The relations between microstructure and mechanical properties of ACCs were studied on the basis of effect of dissolution time and different process techniques. The tensile and flexural properties of lyocell-ACCs manufactured through the present routes were also compared with conventional biocomposites. In all processes, longer dissolution times resulted in more reduction of internal void content as well as improved microstructure and properties. Compared to Process I, slightly better mechanical properties were achieved by Process II and Process III. An important improvement was observed in tensile and flexural properties for the unidirectional ACC produced using Process IV. The ACC-laminate prepared by Process III with 2 h dissolution time showed the highest inter-laminar adhesion strength (2.15 N/mm). The best tensile strength obtained was 102.6 MPa for the sample produced by Process IV with 1 h dissolution time. ACC-laminate prepared by Process IV with 2 h dissolution time showed the highest flexural strength, flexural modulus and Young’s modulus which were 178.3 MPa, 11 and 4.2 GPa, respectively. These mechanical properties are better than those of most conventional biocomposites.

Similar content being viewed by others

References

Adak B, Mukhopadhyay S (2016a) Effect of the dissolution time on the structure and properties of lyocell-fabric-based all-cellulose composite laminates. J Appl Polym Sci. doi:10.1002/app.43398

Adak B, Mukhopadhyay S (2016b) Effect of pressure on structure and properties of lyocell fabric based all-cellulose composite laminates. J Text Inst. doi:10.1080/00405000.2016.1209827

Bao L, Chen Y, Zhou W, Wu Y, Huang Y (2011) Bamboo fibers@ poly (ethylene glycol)-reinforced poly (butylene succinate) biocomposites. J Appl Polym Sci 122:2456–2466. doi:10.1002/app.34365

Bondeson D, Syre P, Niska KO (2007) All cellulose nanocomposites produced by extrusion. J Biobased Mater Bioenergy 1:367–371. doi:10.1166/jbmb.2007.011

Bourban C, Karamuk E, De Fondaumiere MJ, Ruffieux K, Mayer J, Wintermantel E (1997) Processing and characterization of a new biodegradable composite made of a PHB/V matrix and regenerated cellulosic fibers. J Environ Polym Degrad 5:159–166. doi:10.1007/BF02763659

Duchemin BJ, Mathew AP, Oksman K (2009a) All-cellulose composites by partial dissolution in the ionic liquid 1-butyl-3-methylimidazolium chloride. Compos A Appl Sci Manuf 40:2031–2037. doi:10.1016/j.compositesa.2009.09.013

Duchemin BJ, Newman RH, Staiger MP (2009b) Structure-property relationship of all-cellulose composites. Compos Sci Technol 69:1225–1230. doi:10.1016/j.compscitech.2009.02.027

Ferreira JAM, Capela C, Costa JD (2010) A study of the mechanical properties of natural fibre reinforced composites. Fiber Polym 11:1181–1186. doi:10.1007/s12221-010-1181-7

Ghaderi M, Mousavi M, Yousefi H, Labbafi M (2014) All-cellulose nanocomposite film made from bagasse cellulose nanofibers for food packaging application. Carbohydr Polym 104:59–65. doi:10.1016/j.carbpol.2014.01.013

Gindl W, Keckes J (2005) All-cellulose nanocomposite. Polymer 46:10221–10225. doi:10.1016/j.polymer.2005.08.040

Gindl-Altmutter W, Keckes J, Plackner J, Liebner F, Englund K, Laborie MP (2012) All-cellulose composites prepared from flax and lyocell fibres compared to epoxy–matrix composites. Compos Sci Technol 72:1304–1309. doi:10.1016/j.compscitech.2012.05.011

Han D, Yan L (2010) Preparation of all-cellulose composite by selective dissolving of cellulose surface in PEG/NaOH aqueous solution. Carbohydr Polym 79:614–619. doi:10.1016/j.carbpol.2009.09.008

Huber T, Bickerton S, Müssig J, Pang S, Staiger MP (2012a) Solvent infusion processing of all-cellulose composite materials. Carbohydr Polym 90:730–733. doi:10.1016/j.carbpol.2012.05.047

Huber T, Müssig J, Curnow O, Pang S, Bickerton S, Staiger MP (2012b) A critical review of all-cellulose composites. J Mater Sci 47:1171–1186. doi:10.1007/s10853-011-5774-3

Huber T, Pang S, Staiger MP (2012c) All-cellulose composite laminates. Compos A Appl Sci Manuf 43:1738–1745. doi:10.1016/j.compositesa.2012.04.017

Huber T, Bickerton S, Müssig J, Pang S, Staiger MP (2013) Flexural and impact properties of all-cellulose composite laminates. Compos Sci Technol 88:92–98. doi:10.1016/j.compscitech.2013.08.040

Johnson RK, Zink-Sharp A, Renneckar SH, Glasser WG (2008) Mechanical properties of wetlaid lyocell and hybrid fiber-reinforced composites with polypropylene. Compos A Appl Sci Manuf 39:470–477. doi:10.1016/j.compositesa.2007.12.007

Kalka S, Huber T, Steinberg J, Baronian K, Müssig J, Staiger MP (2014) Biodegradability of all-cellulose composite laminates. Compos A Appl Sci Manuf 59:37–44. doi:10.1016/j.compositesa.2013.12.012

Kreze T, Malej S (2003) Structural characteristics of new and conventional regenerated cellulosic fibers. Text Res J 73:675–684. doi:10.1177/004051750307300804

Li D, Liu Z, Al-Haik M, Tehrani M, Murray F, Tannenbaum R, Garmestani H (2010) Magnetic alignment of cellulose nanowhiskers in an all-cellulose composite. Polym Bull 65:635–642. doi:10.1007/s00289-010-0276-z

Li D, Sun X, Khaleel MA (2012) Materials design of all-cellulose composite using microstructure based finite element analysis. J Eng Mater Technol 134:010911. doi:10.1115/1.4005417

Liu L, Yu J, Cheng L, Qu W (2009) Mechanical properties of poly (butylene succinate)(PBS) biocomposites reinforced with surface modified jute fibre. Compos A Appl Sci Manuf 40:669–674. doi:10.1016/j.compositesa.2009.03.002

Mirza FA, Rasel SM, Kim MS, Afsar AM, Kim BS, Song JI (2010) Lyocell fiber reinforced polypropylene composites: effect of matrix modification. Adv Mater Res 123:1159–1162. doi:10.4028/www.scientific.net/AMR.123-125.1159

Nilsson H, Galland S, Larsson PT, Gamstedt EK, Nishino T, Berglund LA, Iversen T (2010) A non-solvent approach for high-stiffness all-cellulose biocomposites based on pure wood cellulose. Compos Sci Technol 70:1704–1712. doi:10.1016/j.compscitech.2010.06.016

Nishino T, Arimoto N (2007) All-cellulose composite prepared by selective dissolving of fiber surface. Biomacromolecules 8:2712–2716. doi:10.1021/bm0703416

Nishino T, Matsuda I, Hirao K (2004) All-cellulose composite. Macromolecules 37:7683–7687. doi:10.1021/ma049300h

Ouajai S, Shanks RA (2009) Preparation, structure and mechanical properties of all-hemp cellulose biocomposites. Compos Sci Technol 69:2119–2126. doi:10.1016/j.compscitech.2009.05.005

Pang JH, Liu X, Wu M, Wu YY, Zhang XM, Sun RC (2014) Fabrication and characterization of regenerated cellulose films using different ionic liquids. J Spectrosc 2014:1–8. doi:10.1155/2014/214057

Persico P, Acierno D, Carfagna C, Cimino F (2011) Mechanical and thermal behaviour of ecofriendly composites reinforced by Kenaf and Caroà fibers. Int J Polym Sci 2011:1–7. doi:10.1155/2011/841812

Pullawan T, Wilkinson AN, Eichhorn SJ (2010) Discrimination of matrix-fibre interactions in all-cellulose nanocomposites. Compos Sci Technol 70:2325–2330. doi:10.1016/j.compscitech.2010.09.013

Pullawan T, Wilkinson AN, Zhang LN, Eichhorn SJ (2014) Deformation micromechanics of all-cellulose nanocomposites: comparing matrix and reinforcing components. Carbohydr Polym 100:31–39. doi:10.1016/j.carbpol.2012.12.066

Qi H, Cai J, Zhang L, Kuga S (2009) Properties of films composed of cellulose nanowhiskers and a cellulose matrix regenerated from alkali/urea solution. Biomacromolecules 10:1597–1602. doi:10.1021/bm9001975

Qin C, Soykeabkaew N, Xiuyuan N, Peijs T (2008) The effect of fibre volume fraction and mercerization on the properties of all-cellulose composites. Carbohydr Polym 71:458–467. doi:10.1016/j.carbpol.2007.06.019

Sawpan MA, Pickering KL, Fernyhough A (2012) Flexural properties of hemp fibre reinforced polylactide and unsaturated polyester composites. Compos A Appl Sci Manuf 43:519–526. doi:10.1016/j.compositesa.2011.11.021

Schuermann H, Huber T, Staiger MP (2013) Prepreg style fabrication of all cellulose composites. In: Proceedings of 19th international conference on composite materials, Canada, pp 5626–5634

Shibata M, Oyamada S, Kobayashi SI, Yaginuma D (2004) Mechanical properties and biodegradability of green composites based on biodegradable polyesters and lyocell fabric. J Appl Polym Sci 92:3857–3863. doi:10.1002/app.20405

Soykeabkaew N, Arimoto N, Nishino T, Peijs T (2008) All-cellulose composites by surface selective dissolution of aligned ligno-cellulosic fibres. Compos Sci Technol 68:2201–2207. doi:10.1016/j.compscitech.2008.03.023

Soykeabkaew N, Nishino T, Peijs T (2009a) All-cellulose composites of regenerated cellulose fibres by surface selective dissolution. Compos A Appl Sci Manuf 40:321–328. doi:10.1016/j.compositesa.2008.10.021

Soykeabkaew N, Sian C, Gea S, Nishino T, Peijs T (2009b) All-cellulose nanocomposites by surface selective dissolution of bacterial cellulose. Cellulose 16:435–444. doi:10.1007/s10570-009-9285-1

Wang Y, Chen L (2011) Impacts of nanowhisker on formation kinetics and properties of all-cellulose composite gels. Carbohydr Polym 83:1937–1946. doi:10.1016/j.carbpol.2010.10.071

Yano H, Sugiyama J, Nakagaito AN, Nogi M, Matsuura T, Hikita M, Handa K (2005) Optically transparent composites reinforced with networks of bacterial nanofibers. Adv Mater 17:153–155. doi:10.1002/adma.200400597

Yousefi H, Nishino T, Faezipour M, Ebrahimi G, Shakeri A (2011) Direct fabrication of all-cellulose nanocomposite from cellulose microfibers using ionic liquid-based nanowelding. Biomacromolecules 12:4080–4085. doi:10.1021/bm201147a

Zhao J, He X, Wang Y, Zhang W, Zhang X, Zhang X et al (2014) Reinforcement of all-cellulose nanocomposite films using native cellulose nanofibrils. Carbohydr Polym 104:143–150. doi:10.1016/j.carbpol.2014.01.007

Zhou M, Yan J, Li Y, Geng C, He C, Wang K, Fu Q (2013) Interfacial strength and mechanical properties of biocomposites based on ramie fibers and poly (butylene succinate). RSC Adv 3:26418–26426. doi:10.1039/C3RA43713B

Acknowledgments

The Authors are very much thankful to Birla Cellulose (Gujrat, India) for supplying Lyocell fabric free of cost. The authors of this article are also grateful to Prof. B.L. Deopura, Department of Textile Technology, IIT Delhi for his valuable suggestions and technical assistance.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Adak, B., Mukhopadhyay, S. A comparative study on lyocell-fabric based all-cellulose composite laminates produced by different processes. Cellulose 24, 835–849 (2017). https://doi.org/10.1007/s10570-016-1149-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10570-016-1149-x